Leaderboard

Popular Content

Showing content with the highest reputation on 04/24/24 in all areas

-

To identify movements the standard practice is the actual diameter of the movement, and a front on image of both the movement side and the dial side- minus the dial. The setting mechanism (under the dial) is considered the "fingerprint" of the movement and 9/10 leads to full identification.3 points

-

2 points

-

Yes, it looks like GT Revue 30. Doctor, You can not replace escape wheel by the dimensions You listed. One needs to know much more things like number of leaves of the pinion and it's diameter, the position in high of the table and the pinion, the hight between the pivots, the exact pivots diameter... And then, even if suitable wheel is found, one will need to know how to adjust the pallets position correctly. Restoring antique movements is something different than replacing parts. In older movements parts are not interchangeable, this means spare parts do not exist. Here the case is different, but still escapement adjustment will be needed if a wheel from a donor is found. So may be it will be easier to restore the donor for You...Restoring antique movements usually means making of the parts needed and this requires knowlage and working on lathes skill. In this case repivoting of the wheel is the natural solution, but there is a long way that one must walk untill getting ready for such work.2 points

-

Well, when you first posted some time back, I downloaded and ran it through my slicer to get a print time. A bit long for me. Your new idea would solve this. I am anxious to see your progress!!1 point

-

Hi. Breaks like this can br fixed with conductive paint like the paint used to repair a car rear screen heater. I have used it successfully, you don’t need much and unlike solder there is no heat 6020A-1.pdf1 point

-

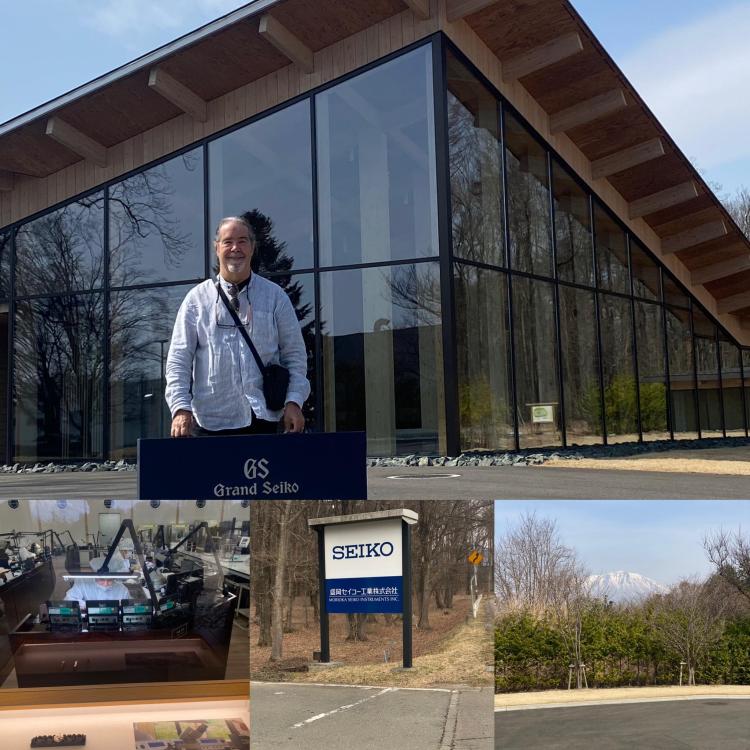

I am an Australian American living in the beautiful Gold Coast, Queensland Australia. I love Grand Seiko and Seiko watches, and recently came back from the Grand Seiko Shizukuishi Studio in northern Japan where I was blown away by the design artistry and technical excellence. More later on that (including photos, if interested!)1 point

-

Maybe a little off-topic, but it still amazes me that most people (and myself before I got into this hobby) don't realise that the movement of their watch was (in most cases) not made by the name on the dial of the watch. This is especially true of many 'fashion' watches which use the cheapest of cheap movements ($4 each) which are completely out of proportion to the overall cost of the watch ($++100s). Usually the actual manufacturer is stamped somewhere inconspicuous on the movement, usually around the balance, and this is what you need to find so you can locate spare parts or servicing manuals etc. This is like buying a top of the line Rolls Royce Phantom and learning it has a BMW engine..... oh wait a minute, it does! (6.75-liter, 460-horsepower BMW V12 engine - reference)1 point

-

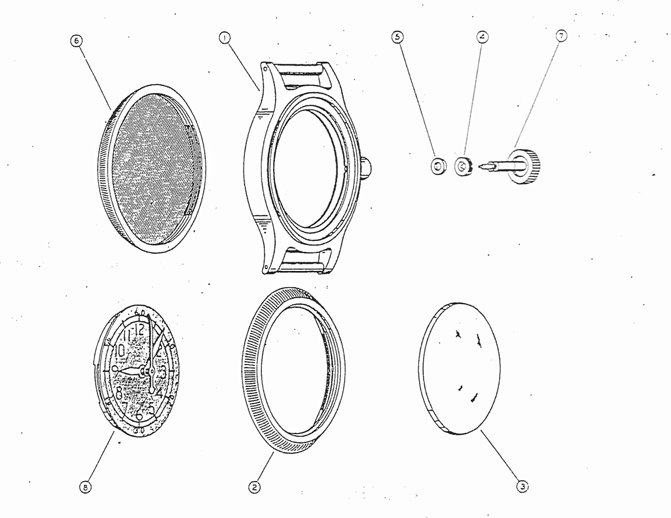

I have an image of what the case is supposed to look like disassembled. then an interesting website https://www.mybulova.com/vintage-bulova-catalogs there's all sorts of interesting things here for anyone in watch repair. but for the particular subject these are the two I recommend. You can see page 7 is where I got the image of the case. Then the word apartment technical manual is really a training manual of watch repair covers wristwatches and pocket watches everybody should have a copy of this.1 point

-

I agree, the bezel needs removing. If there isn't a gap between the case and bezel for removal, it's probably screw on. If so you need to grip the bezel itself.1 point

-

Looking at the picture, the case screws appear to stop the movement moving forward (towards the crystal) indicating that this is the way the watch needs to travel to remove it from the case, hence it appears to be a front loader, this is just a 'rule of thumb' and as ever there are many exceptions. Hence, I would be fairly confident that the front bezel needs to be removed and the movement taken out the front of the watch. Look on the bezel for a small slit, similar to what you would see on a snap-on case back to remove it then the watch movement should fall out the front of the watch.1 point

-

This is a very valid point and a subtlety that I was unaware of until fairly recently, learning all the time, the video below explains this point well:1 point

-

1 point

-

Nickelsilver is right, movement diameter and keyless works ‘fingerprint’ are important for identifying movements. That said, this appears to be a 7 jewel version of the a Revue 30 movement. A quick search with google turns up parts movements, and individual parts should be quite easy to come by. Hope that helps, Mark1 point

-

Sometimes surface damage like this can be repaired with solder. Run pre-tinned soldering iron tip with a tiny blob of solder over the damaged area and pray that the Gods of watchmaking are on your side.1 point

-

Thanks for the screenshots. That's very helpful even the drawing which resembles a Bergeon 6160 so I know what you're saying. Most probably I'll get the horotec clone from Ali-x. Yes, looks like time to go shopping for the tool. Alix for the removing took and Cousins for the pushers. They do come with the gasket in-built yeah? I guess I'll find out. Thanks guys for your input. Keep up the horology work!1 point

-

1 point

-

I appreciate all of your responses and plan to take your advice. Especially, the advice to practice on inexpensive models that don’t matter before attempting something special. Over the years I have worked on cars, motorcycles and bicycles and I believe I have a feel for turning metal things lubricated with oil. But, as for really small things, this could quite a new adventure!1 point

-

1 point

-

Thanks for the help guys! VWatchie I already found your thread but I'll check it again. Nice to know about acetone, I still have to get the shellac off since I made a little mess. I adjusted the jewel, put new shellac (the so called soldering technique, pallet tool too hot this time so the shellac "wire" melted in air before getting in contact with jewels or fork) rinsed the pallet fork and put it back dry. Amplitude is now in the 240-250 range that I expected in the first place. I guess there's enough oil in the escape wheel teeth already but I'll check that later. The mainspring was pretty beaten so a new one would probably boost the amplitude even further. Nice to learn new things. Now I have another thing to look for while disassembling. I wonder if the watch left the factory that way.1 point

-

These are all American movements (with the exception of the "Rubis"), and are all almost certainly "negative set" which means the stem is part of the case. So it's normal that they are all missing- they are with their cases. You will need male square bench keys to wind/disarm them. Vintagewatchstraps has a great writeup on the different systems. But basically, any American "x" size movement will fit any case for that size, possibly with some adjusting of the stem position. With Swiss movements, there is some interchangeability between calibers, usually within the same maker's range, but not really overall- there are thousands of different stems out there.1 point

-

Double Oooooo Removal tool? Dreamed of one of these. However, Kalle on Chronoglide showed everyone my system with the pegwood. Worked a treat. Felt so chuffed to be mentioned. https://www.youtube.com/watch?v=tTFrXjiyGKc 46:40 for the wheel removal. Mentions me at 50:00 and does the removal with the pegwood. Felt like my 15 minutes of fame.1 point

-

I'm sure you will get help on here soon. Kkramme we like new members to make an introduction before posting. A little about your self such as where you life and what got you interested in Horology1 point

-

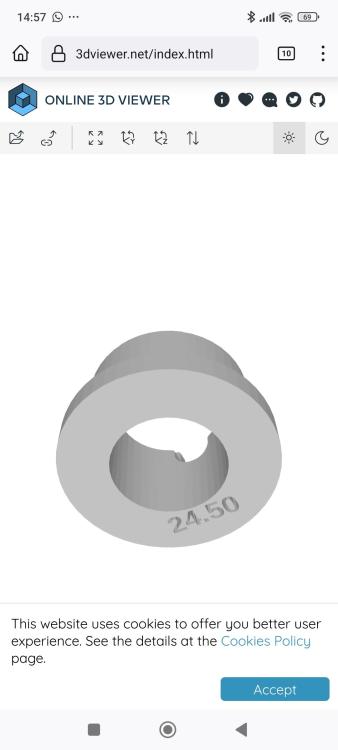

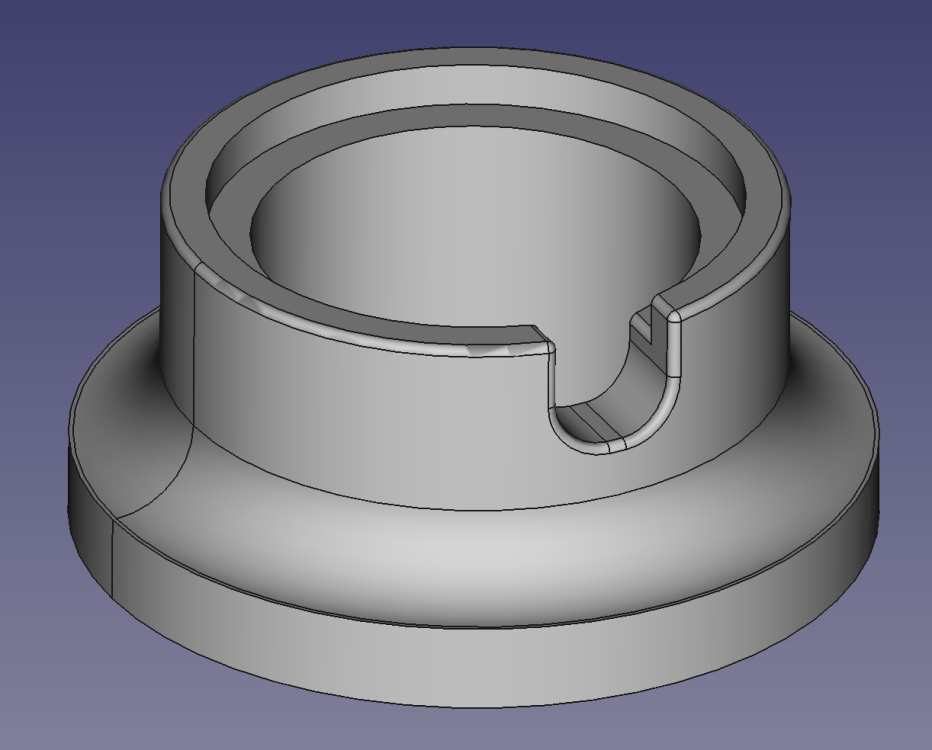

I use the exact OD and it fits in with a little force and a pleasing 'click' so it's snug and wont rotate within the holder, but that depends on how you have set up and calibrated your printer so you may need to play with the settings/dimensions a little to allow for any discrepancies in your printer calibration. PS I just finished (2 days ago) a new revision which automatically prints the movement OD on the bottom of the holder, I'll see if I can upload it here Here is rev 4 remember to change the .pdf to .FCStd so it will open in FreeCAD - also you may need to install the LiberationSansBold font and tell FreeCAD where it lives on your PC, or change the font to something you already have on your system. Para Movement Holder V4.pdf Examples below:1 point

-

1 point

-

1 point

-

One of the things that I've been bothered with lately is timekeeping? For instance a 90-year-old pocket watch what so to timekeeping was it supposed to keep? They publish railroad timekeeping but I don't know how well normal non-railroad watches were supposed to keep time. The reason why the question comes up for me is I spend a lot of time at work adjusting watches to keep really really good time because I have to please my boss where as when the watch was made I have to wonder what kind timekeeping would've been acceptable. After all they typically didn't have timing machines 100 years ago and they were timing and six positions certainly not for the non-railroad grade watch. On the other hand I do get paid by the hour so maybe I shouldn't be concerned of how much time I Spend trying to make everything keep chronometer timekeeping almost. Citing a Delta of 40 seconds for a 90-year-old watch is quite outstanding.1 point

-

1 point

-

Thanks for the replies. I did the job today and found that the oversized stem fitted just perfectly into the worn mainplate without any adjustment. Original stem diameter was 1.24mm and the oversized was 1.40mm. I did have to make an adjustment to the setting lever though. The small pip that engages with the groove in the stem hub was slightly to wide. I made that a bit smaller with a fine file. Don't ask me why that was too big, it just was. All working very well now. No wobble and not pulling out. New crown fitted as good measure.1 point

-

Perhaps not where you live, but here in DK, you get by the taxman financially quartered if you buy from outside the EUSR. These center wheel weren't that expensive 5 - 7 years ago, around $45-$50. I guess the stock is drying up and these days we have to pay with getting worth less & less confetti money.1 point

-

New version of parametric movement holder, link HERE, updated based on feedback from other WRT members and removed a few bugs. I have printed in PLA+ and PETG and prints well, rendering below: I uploaded FreeCAD, step and .stl versions to printables web site as this seems to have replaced thingiverse as the go-to place for 3D models - opinions? Note, parametric functionality only works in the FreeCAD file version All you need to do is measure your movement outer diameter (OD) and then put this value into the model spreadsheet and it will generate a bespoke model of the holder to fit your movement that will look something like the one above. Depending on your settings the print time will be around 1 hour. How do you upload the FCStd and stl files here? Whenever I try I get a warning box saying that the file format is not allowed.1 point

-

That would be slugs and snails and puppy dog tails as they nicely counteract the carcinogenic effects of tetrachloroethylene. Or does that only work for the dextro isomer of hexane?!1 point