Leaderboard

Popular Content

Showing content with the highest reputation on 04/19/24 in all areas

-

I've seen some really nice early 20th century pieces where all the jewels, including center wheel, were convex. Definitely to reduce friction. It can be quite hard to tell if a jewel has olive holes, especially on small sizes, but that again reduces friction- as well as accommodates small misalignments better. Why they aren't used more often? I imagine it was found that at a certain point in the train the actual advantage became negligible, and the added cost on high production movements is why it's not seen on those, just higher-end pieces. I did an experiment on a little 5x7"' AS 1012 a few years back. These things run OK sometimes, but often are absolute dogs. And AS made gajillions of them. I had a NOS novelty watch in for a service, ran OK flat, massive drop in amplitude vertical. Made like 3 staffs for it trying different pivot sizes, no change. Tried high quality (not Seitz) convex/olive jewels, no change- the original were flat, but could have been olive hole. Same for the pallet fork, then escape wheel, no change. Probably had 20 hours in the watch, new staff and new hole jewels through the escape wheel, no difference in running. Just a dog of a movement. But if I were making a watch I would use them, just because.3 points

-

That's very interesting information. I haven't tried to see if my bombé jewel holes have olive holes but I think I should be able to tell on the larger jewels at least. See if I get a chance to have a look later today. This little story was very comforting to read for a "bungler" like myself. That success isn't a given even for a pro. Thanks for sharing!2 points

-

2 points

-

2 points

-

2 points

-

I picked up a similar amount of these jewels some years ago in a watch and clock fair. Every now and then they come in handy. This week I've got a rubbed in bombe jewel in the balance cock that is cracked and needs replacing. Very handy to have a vintage assortment of these type of jewels!2 points

-

2 points

-

So I just wanted to say "thank you" again. The angle is the key bit it seems and yes, it did basically just fall, or float, back into position when I got it lined up just right. I had meant to add that now that I see how it goes in, I totally see how it came out in the first place, and that whomever cloned the original movement didn't pay much attention to the fine details around the setting or how it interfaces with the balance cock or the "rings" on the regulator and/or stud carrier arms.2 points

-

You can use bombé jewels with regular pivots if you put the convex surface facing the shoulder. You see it on (primarily older) high end pieces, particularly nearer to and including the escapement.2 points

-

Well, the vintage-watch bug has been nibbling at me for a good while now, and I have finally given in and got me some tools, and I am working on improving my skills and knowledge on an inexpensive ebay find. I have some older watches (Hamilton, Gruen, Aero Watch) I don't dare touch yet and hope to gain more insight from this forum that I have found invaluable already on many occasions. Looking forward to interact and learn! Have a great day everybody!1 point

-

This little story was very comforting to read for a "bungler" like myself. That success isn't a given even for a pro. Thanks for sharing! Plus the added foresight not to buy a watch with an AS 1012 inside it.1 point

-

I forgot that I said I would do that. Will take some tomorrow and post them up post haste.1 point

-

When Nicklesilver mentioned the use of them on non coned pivots on older high end watches closer to the escapement. That suggested to me probably fourth wheels and possibly third wheels. The square shoulder rotatating on the much smaller surface area of a dome as opposed to a flat jewel surface. I'm curious as to why they are not used predominantly?1 point

-

1 point

-

1 point

-

If frank says these bombè jewels are for balances and similar pivots then they are used cupped side facing the pivot and then capped i assume. In Nicklesilver's reply i guess that cup can also be reversed and used as an oil reservoir leaving the shoulder riding on a less frictioned domed surface. Hence the use of them on wheels closer to the escapement that have less torque requiring efforts to reduce friction and are also uncapped.1 point

-

Looks that way, if it had any amount of significant jewel count it would say so on the dial. Looks that way, if it had any amount of significant jewel count it would say so on the dial. Same answer as Mike regarding the dial, its often just a slapped on name of a retailer but i thought you were way above this understanding Pete ? You could just wear it as a warning to others when you have run out of underpants. I can still manage to find the odd little joke ( pun one joke is enough for today ).1 point

-

I don’t know anything about this product, however assuming you have it if you put a drop on a mirror or piece of glass lying flat on a table and leave it to evaporate if it leaves any sort of residue it is not really suitable for watch part cleaning. Tom1 point

-

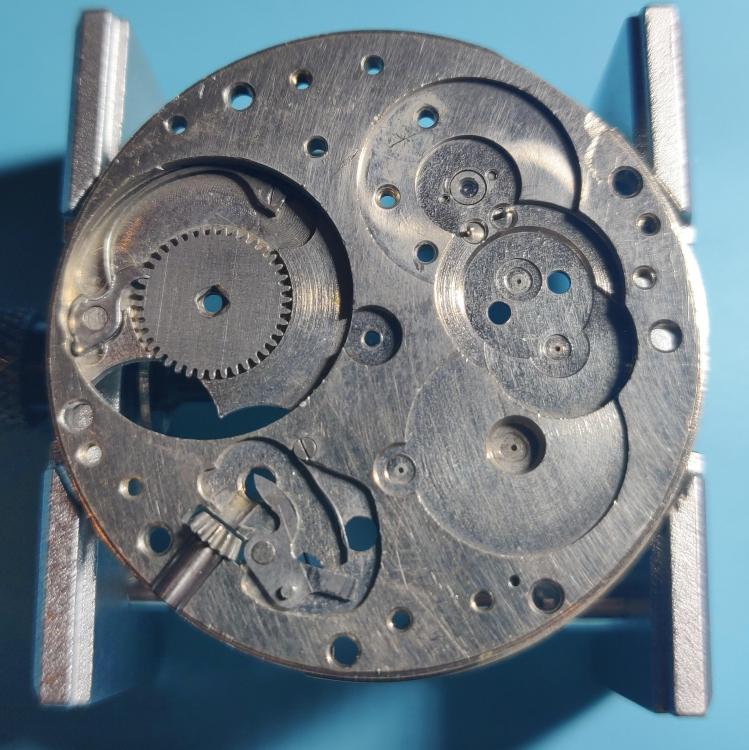

I would like to see the movement. The watch is the movement. Anyone can print a name on a dial and sell it as "the maker".1 point

-

@Randy55 welcome, here are some screwdrivers I can highly recommend, not the cheapest out there, but I prefer them to my Bergeon ones.: And for tweezers I can't recommend highly enough the CousinsUK own brand titanium (link here), I even prefer them to the Dumont tweezers I have, here is my write up: Other piece of advice would be to 'cut to the chase' and get a trinocular microscope on a boom arm, I tried all kinds of loupes and visors etc, but now do 90% of my work on the scope.1 point

-

1 point

-

1 point

-

Not sure, but just looking at it, it seems like the screw on the right may be a fake? The one on the left may not be a screw in the regular sense at all, rather a 2 position device, I think you need to point the slot towards either of the 2 dots and one will secure and one will open. Like I said this is just my best guess looking at the pictures.1 point

-

Welcome to the group Stirky. You can search for just about every subject in the craft here. Don't be afraid to ask if you can't find the answer that may have already been covered ( some ad nauseum LOL ). You don't have to buy Bergeon to get good quality. There are many decent mid-range tools available that will last you a lifetime. Cousins would be a good place to start . Cheers from across the pond ! Randy1 point

-

1 point

-

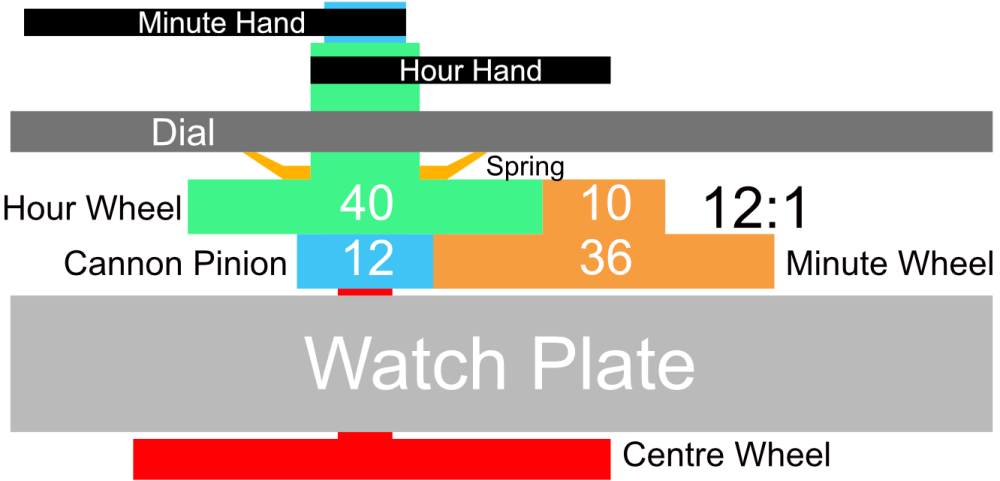

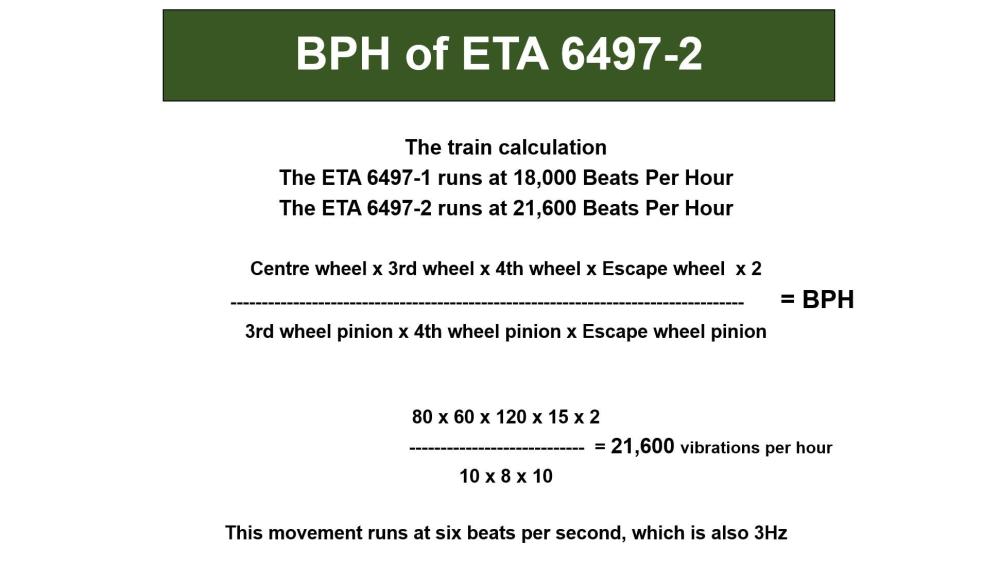

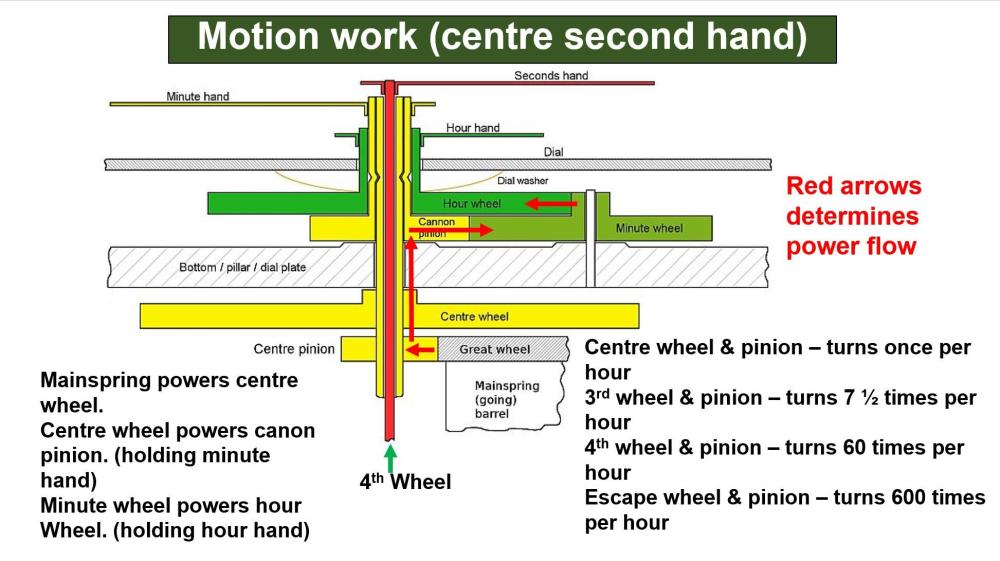

Great diagram with the teeth and pinion count. Simple way to reduce the speed of the hour wheel by the 12:1 minute wheel. Genius and yet so simple. Always good to reinforce the principal by what you have done in your drawing. Keep doing that. I had a drawing on my wall for years showing me this which is very similar to the drawing you have done. Here's a formula to work out the beats per hour of a watch movement. The movement's BPH is dictated by the wheel teeth and pinion count and the hairspring being vibrated to the correct BPH by finding the pinning up point on the hairspring using a vibrating tool. The reason in the formula there is X2 on the top line is because there are two pallet stones.1 point

-

It's pronounced "bombay" like the city. French for bomb is, , bombe, pronounced the same as in English. Bombé, bombe.1 point

-

I looked up bombè, domed in French. It's pronunciation is bomb, does a bomb (explosive device) get It's name from bombè? I know we're going off subject but it's interesting.1 point

-

They are for balance wheels only and wheels with similar pivots (B = bombé). You can use flat jewels for balance wheels (not recommended) but no bombé jewels for ordinary wheels.1 point

-

I finished my polisher yesterday, and just tried it out. I'm surprised how easy it is to get a good result - just a couple of minutes. I thought it was going to be more difficult - a nice surprise as most things in watchmaking are harder than you expect. I bought self adhesive 3M lapping film https://www.cousinsuk.com/product/film-lapping-3m-261x266x , 9, 3 and 1 micron, and stuck it to sheets of glass. The 9 micron is course enough to remove large scratches. I'm glad I used the M6 thumb screws as the large heads allow for small adjustments.1 point

-

Oh really, like my Seiko 6139? When I pulled out the crown it had 3 positions, so I assumed one position set the day/date. I'll check more closely when I put it back together. Thanks again!1 point

-

There’s no doubt that the traditional method works, and works well. It has stood the test of time. It does have a steeper learning curve, but as you say if you do it often enough and gain experience, the method is definitely sound. I feel that the cost of a lab hotplate is money well spent because of the other uses it also has. The following is off topic in terms of bluing but : If you add a Pyrex measuring cup and thermometer you can anneal metals with reliable results. As mentioned above it is handy for working on pallet stone adjustments, either with an escapement meter or a home made brass block with holes to accommodate fork pivots and guard pins, plus a means of holding the fork still. If using the brass block, precision adjustments to the pallet jewels are accomplished by the use of a reticule eyepiece in a microscope. This setup is easily the equal of a Bergeon escapement meter + bergeon heater for the meter, but for the same money you can buy a decent stereomicroscope, a reticule eyepiece and the hotplate, which are capable of doing much more than the escapement meter+heater are. Best Regards, Mark1 point

-

Never any harm in exploring new ideas, even if they’re at odds with established best practice. The two issues I see with using glue are that the next watchmaker to replace the staff won’t expect to encounter glue securing it, or know what kind of glue it is and therefore how it might be removed without damaging the parts, and given concentricity is of utmost importance when restaffing, ensuring the staff is glued in an oversized hole such that it’s centred isn’t trivial. Uneven mass distribution can have a dramatic effect upon the poise of the balance wheel, but the effect is much greater at the balance wheel rim than it is near the staff. This is why the safety cutout on the roller table, the roller jewel and the shellac securing the roller jewel don’t upset poise much, they’re very close to the centre. A blob of shellac or glue on the rim of the balance will upset poise significantly, though. Best Regards, Mark1 point

-

Well I have just received the following Timelab tools all the way from the USA. The 9 set of screwdrivers with spare baleds in each size. A 4 way movement holder. A set of 1mm hand lifting tools. Some hand setting tools. Some springbar tools. A squeezy ball for removing screw on casebacks. A 70mm silicon cushion. First impressions? The screwdrivers are really nice compared to anything I have seen. Makes me realise how much rubbish is peddled as being quality. However, I got rather scared by the smallest one. The 0.8mm. I can't imagine a screw that small. I just can't. Movement holder. This impressed me. Can handle four different sizes on each of the faces. Isn't sloppy as it could easily have been. The hand lifting tools look really nice. Very fine. Again, another tool that makes me admire watchmakers more by the moment. Three different size springbar removal tools. Another tool that you don't think you may ever need until you have seen one. I recall as a teenager, you know the one, know all and know nothing, using a 'precision' screwdriver to remove springbars. Each of them has what looks like a punch on the other end. I suppose it would be more for pushing a spring bar out of a bracelet or strap? Squeezy ball. Is a squeezy ball. Truth will be in the use of. The cushion is really nice. Has a nice weighty feel to it. The working surface is really smooth. No wrinkles. The base is a really nice non-slip material. I'll take some photos tomorrow. I know these aren't Chinese tools, so they don't belong on that other topic, but based on what I know from tools during my apprenticeship etc, I would have no hesitation in recommending any of these. If Bergeon etc are another step up, they must be some seriously good tools. I am worried about how deep and mazey (is that even a word?) this rabbit hole goes.1 point

-

Haha looking all forlorn in your little man cave, the old sympathy tactic eh, good luck with that one . Nah Lizzys ain't so bad , mine is ok, i know when I've overstepped the mark and have to start reeling it in. Its when you find she's locked the door to keep in there that the problems start. Why waggy why, now i have to buy a 3D printer. You guys have me spending all my hard earned dosh .1 point

-

It's around 10 seconds I guess? Very fast. Maybe less than 10 seconds. But depends on how you use it, pressure, twirl speed, etc. I would try it on a scrap balance first for sure. If you have a really fine Arkansas stone you can make it flat, dome it, make it flat, dome it, until you're comfortable.1 point

-

Yes, I just oil it and twirl it around while nutating a bit (not simply holding it vertically over the pivot). Mine is ancient, no idea if the new ones are as good/better or what, but I imagine the new ones are fine. I rarely use it though- if I need to retouch a pivot I do it in the lathe. But it does work.1 point

-

Here I just got a couple pics that might help. One is without the pin and one I put the pin where I thought it "might" go. Still not sure what is missing from setting parts Actually I didn't think it looks crappy very well decorated movement that looks quite nice We can try to do it by your instruction maybe I'll be able to get it that way, I don't want to put you out.1 point

-

1 point

-

1 point

-

So I have far too many pictures to go through but I haven't given up but in the meantime I'll try to explain taking something out of the video above. So the very beginning it shows how things go together. At around 11 seconds to get a silhouette. If you look at the image I have attached notice I drew a red line and then look at the video you'll notice that the tail end of the Gold spring hinges In that convenient slot. Because there's a slot spring almost never comes out. But in the Chinese version cutting that extra groove was complicated so that's missing. This means when you hinge it up there is nothing to hold it in place it typically falls out. So found some of the pictures. I labeled one bad clone this is where should be the same setting that you have I do not recommend taking it out I only did it to get a picture. So you notice there is no cutaway slot like in the video there's nothing holding the spring once it's released its free to go where it feels like. Then there is a Omega setting and you'll see the cut part and the spring is also in there so you can see that does not come out. Now comes the problem attempting to describe something that I don't have a picture of. So in the picture labeled putting back in notice the pinkish colored line going at the angle? Whatever you do do not force the spring if you get it right it almost just floats in to place. So you need to put the spring in at a angle in other words basically Corner to corner of the open area underneath I can't remember if You have to stick one of the tabs in first I vaguely think you can just literally drop it in the corner to corner. Then basically rotated so it's in the correct position and then it hinge right down. Then I'm sorry if my description sucks hopefully it makes sense.1 point