Leaderboard

Popular Content

Showing content with the highest reputation since 03/17/24 in all areas

-

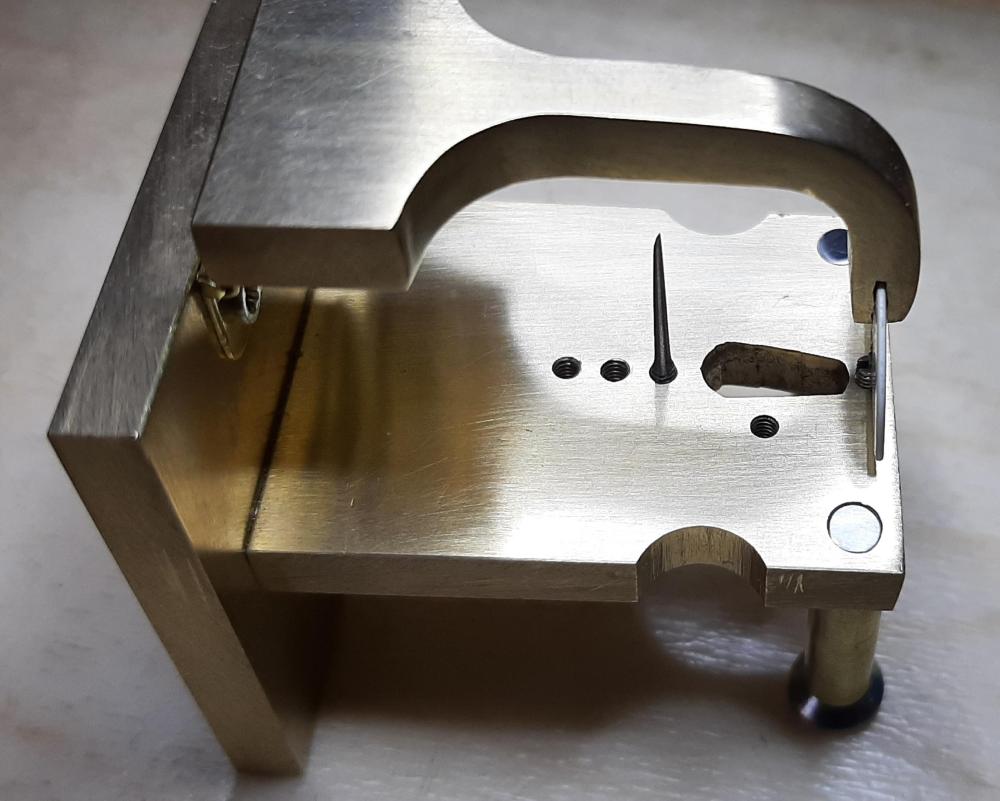

DIY Screw polisher. Inspired by Alex Hamilton, I have made my own screw head polisher. Less than £4 in parts. I hour to make. Chuffed. Additional photograph information Bottom nuts are tightened to make a solid base. Nuts below and above wood are to make the level set when using the polishing base. I will get a small picture frame with glass to insert the polishing paper. The screws can be altered to accommodate. I can now polish to 1 micron. I piece of wood 2" x 2 1/4". 2 x M4-30mm bolts. 6 nuts. 1 pin vice from set of 4.12 points

-

11 points

-

Hi everyone, I've been here two years now almost to the day and have loved every minute of it. During this time I've connected with folk that have suddenly disappeared leaving me sad and wondering why they left and what happened to them, its now my time to leave for a while. But first i want to thank everyone for all the help, advice and banter over the last two years I've met some incredibly kind and amazing guys. My time has become limited and precious, so watchrepair and visiting the forum is taking a backseat for the moment, although i may pop in occasionally when i have time. This is due to a personal life change regarding my 87 yr old mum who had a stroke on Sunday. My learning here is on hold while i do some teaching of my own, helping my mum to talk and communicate again . Thanks again for making my time here so enjoyable and i hope to join you all again soon. Take care and look after yourselves, make every minute of the day count, time is so precious x.10 points

-

10 points

-

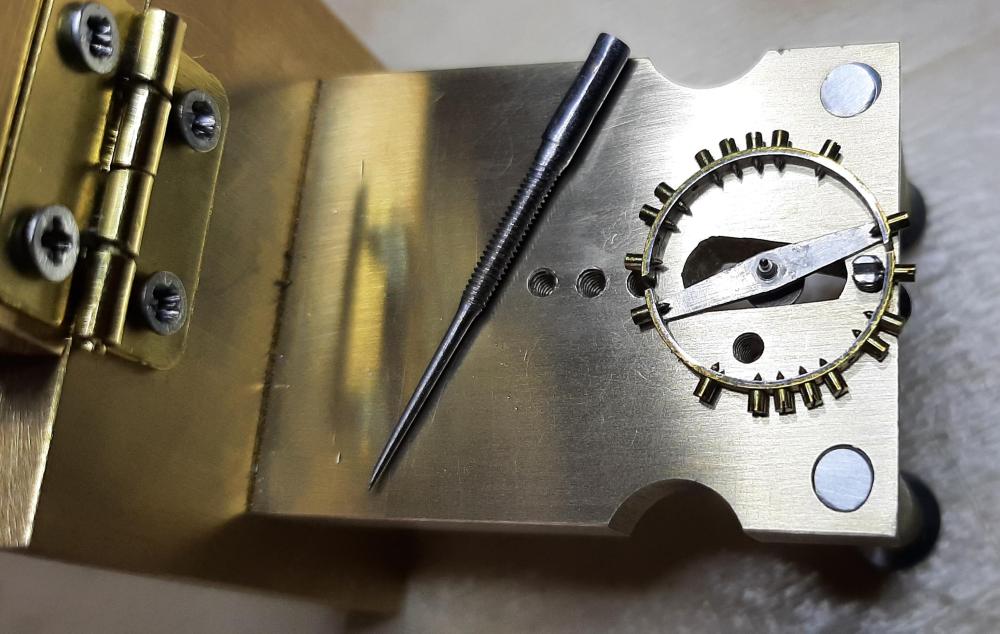

I've come to the same conclusion. After breaking ANOTHER pivot whilst trying to hold a balance+cock to adjust a timing screw, I decided all watch fettling was on hold until I made one of these thingies. I've wanted one since this post started years ago, but wasn't sure I had the tools to make one. I still don't have a workshop or any workshop power tools, but the good news is I managed to lash this one together with just the following : Vice, hacksaw, files, cordless drill (), M2 tap and die, M4 tap. Oh, and a blowtorch for bending the brass. So I bought some 5mm brass bar and started hacking. Without workshop power tools I had to improvise the hinge (I just bought a small brass hinge) and the front legs (just M4 screws). I couldn't have done it without @nickelsilver's plan and pictures. Thanks It's not perfect, but I just tried it on a balance to change a timing screw, and it works. It's great. I recommend everyone should have one. So buy some brass and start hacking. I can provide guidance if anyone needs it (but my metal working skills are pretty limited).10 points

-

8 points

-

7 points

-

7 points

-

Certainly all the big high end makers haven't supplied parts in many years. Swatch will provide parts if you meet certain requirements, and for a professional those actually aren't that hard to meet (certain equipment, training etc.). Richemont forget it. For a long time Rolex would supply parts to professionals who met their requirements for training and equipment. Then those requirements became harder and harder to meet, and finally they just stopped supplying to any other than Rolex dealers (who still had to meet the requirements). But they actually put in place a service network of their own during this time that works (pretty) well. Other makers tried to cut off abrubtly and suddenly "factory" service took 2-3x or more than before. I do kind of get that they want to control the quality of service. But ultimately even they often mess up- I have seen and repaired the results (from upset customers who absolutely didn't want to send it back again, even under warranty). Geez 25 years ago Patek would sell you parts! Not long ago I made a ratchet wheel for a fairly recent JLC perpetual calendar; customer had dealt with JLC before and waited like a year or more just for the watch to go back again, wait again. They were happy to find someone who would/could do it. But it's nerve racking work: if any part is lost or damaged, which can happen any time to anyone, woo-boy. Mechanical parts I can make, haha, but a scratch on the dial or something is another story. It actually makes more sense for car makers to restrict at least some of the parts- I was a mechanic as a very young man before watchmaking, and I've seen stuff on brakes, suspension, etc. that were definitely from a shade-tree mechanic and a definite safety issue. But you can get whatever you want and do the work however you want on your _____ car.7 points

-

Heres my watch of today, a Smith 13'" RY . My missus bought me this for this Valentines day a bargain 14.99 with a reduction, the seller has occasional 20% off offers now and then so it was about 15ish with delivery. I love Smiths and i love bulleye dials, this is my first one. The watch arrived non working as stated and i knew what was inside and what would be against me, but i enjoy a challenge, we dont expect a lot if anything from pin pallet movements. A balance pivot was broken and i didnt have another staff but i did have another RY with a battered dial so i robbed the balance and tweaked it around to make it work apart from that mostly just a good clean and relubrication. Keyless works are pretty rough by design and the crown is a bugger to get in and out with the dial on, the setting lever hits the dial before it releases it, so a little mod is needed to help that along. Major problem was the pins on the lever were quite worn which make the old tg have a snow storm fit. Its a similar read for most pin pallets, these were brass as was the escape wheel. But perseverance is me, i didn't change the pins but i did spend some time dressing and polishing the worn areas which improved the trace a lot with some straightish lines and a beat error of .5 . Not sure what the lift angle should be on these and i Wasn't in the mood to work it out and who believes timegraphers anyway, but at the default 52° it runs with 260ish full 210 after 24 hours dial down , the verticals rates were pretty much all over place. So lets just put it in it's superlight aluminium case and see what happens. Been wearing it now for 3 weeks and it's consistently losing around 1.5 minutes a week winding each morning i think pretty good for an old pin pallet watch. I just love this dial, thanks wifey heres my Valentine's gift for yer sweetie x7 points

-

This video demonstrates how to hold a burnisher comfortably, safely, and efficiently for burnishing a wheel pivot in a Jacot tool—a huge thank you to @nickelsilver, who generously shared this information. I can’t thank you enough! https://www.watchrepairtalk.com/topic/28602-longines-balance-staff-pivots-are-they-too-flat/page/2/#comment-2418877 points

-

7 points

-

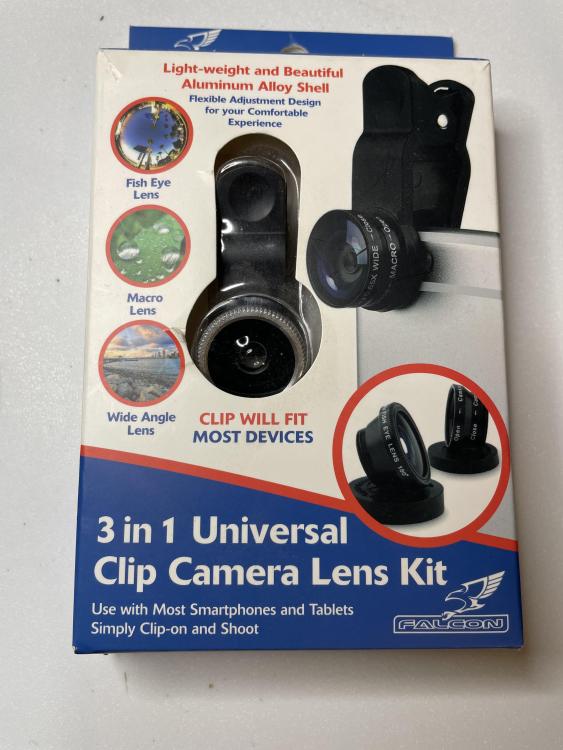

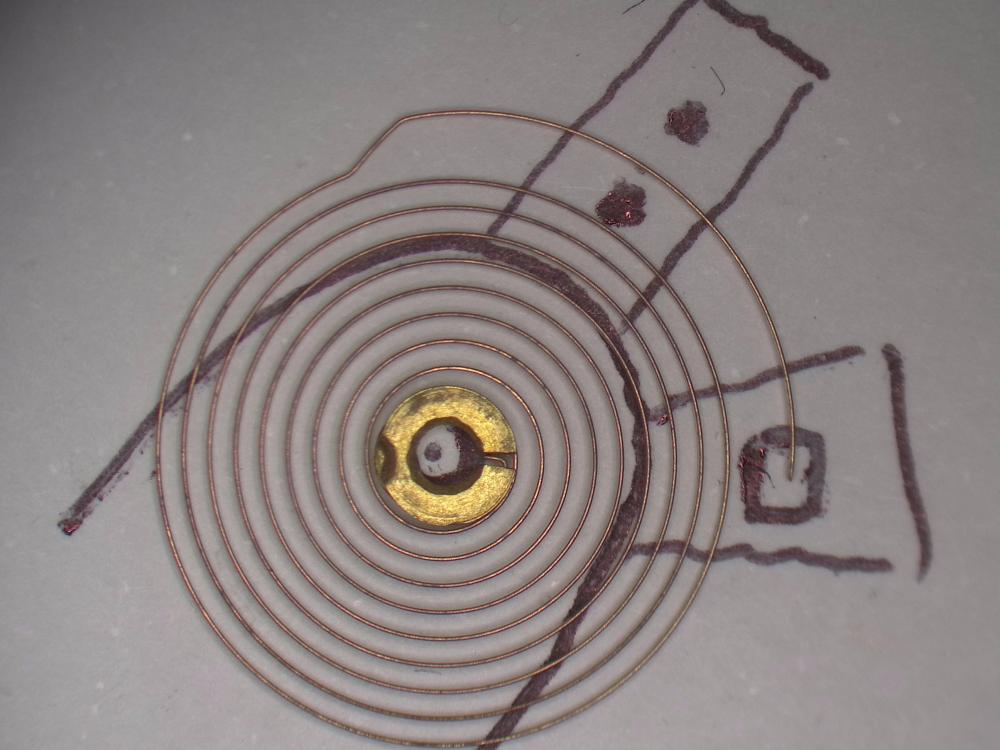

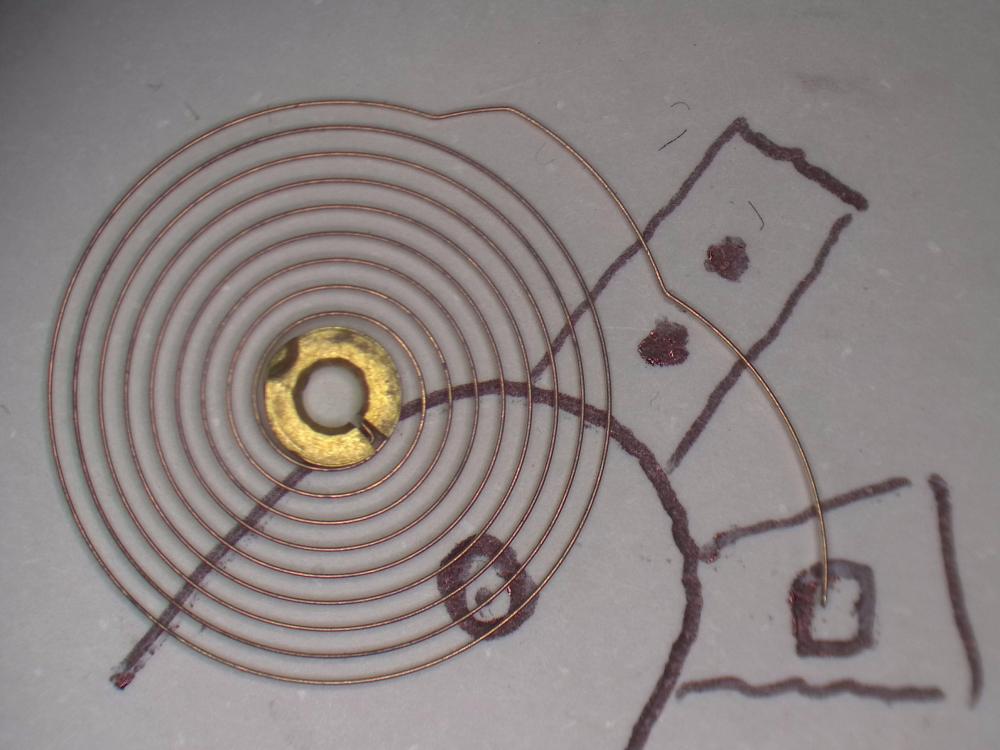

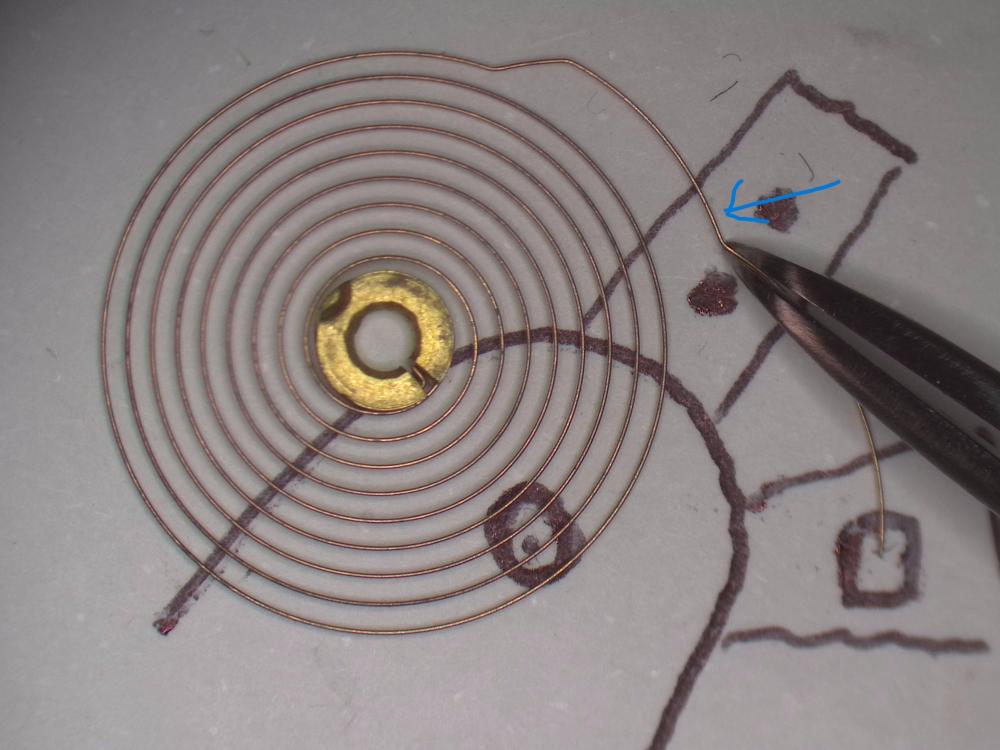

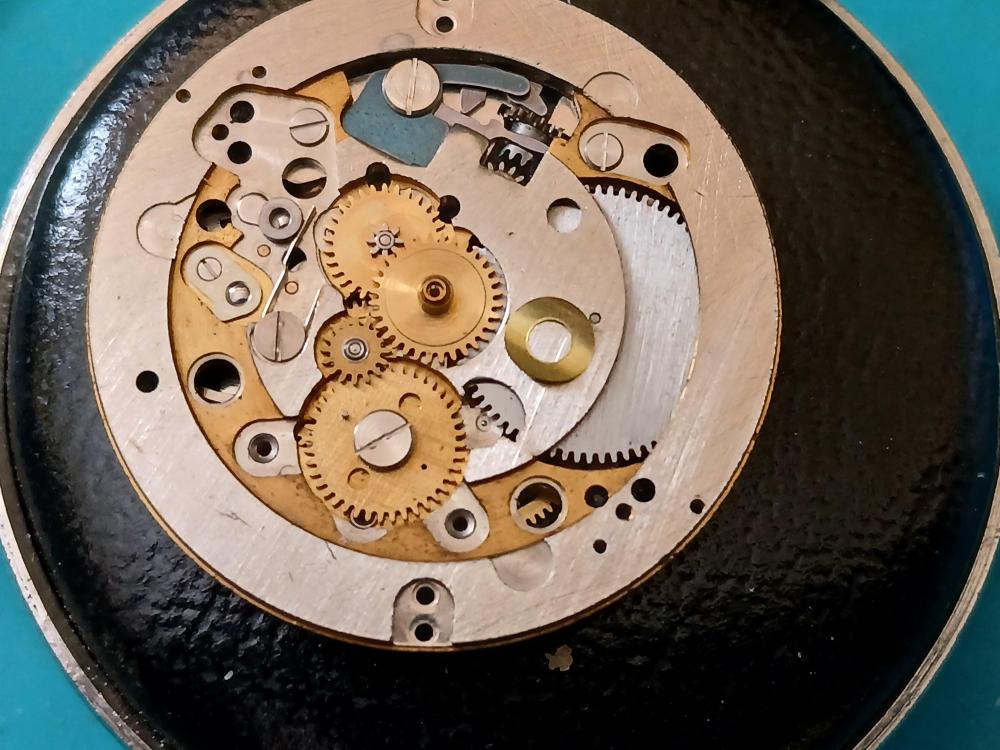

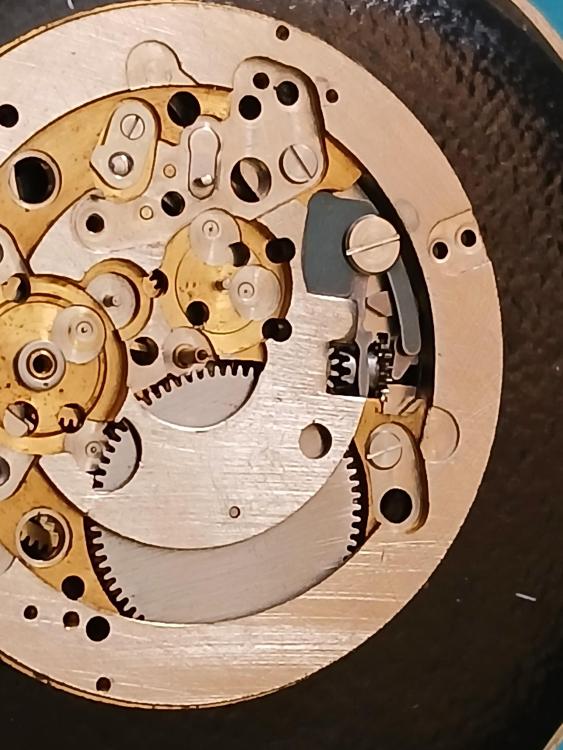

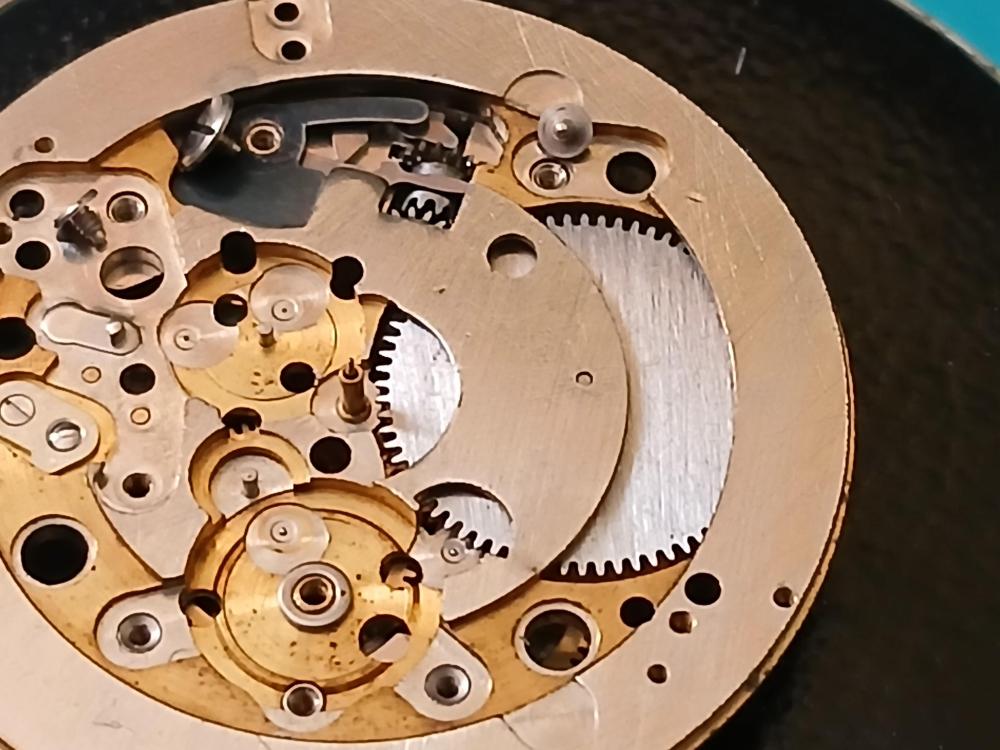

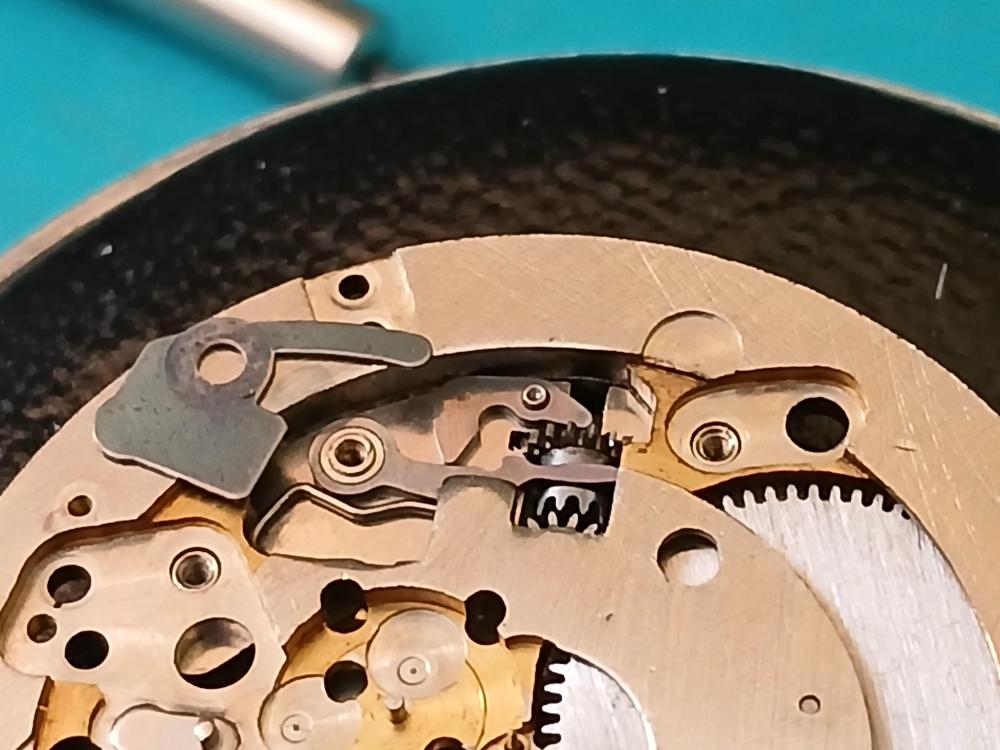

I saw a mention in one thread with the OP saying they could not take good photos of a watch movement they were asking about, so I thought I'd post my ultra-cheapo method: A local second hand shop had a stack of the nasty looking "clip on" lens kits for smartphones; they were priced at 50p so I got one out of curiosity. I didn't even try they for weeks, until I was struggling to take a high enough magnification of a damaged piece of jewellery, for a friend. The "macro" lens in these kits is actually amazing, it's very effective - and the full kits around only around £3 to £4 on ebay. The first photos are the particular 50p lens kit I got, and the lens I'm using from that, then examples photos, using my iphone with the macro lens in the clip and approximately centred over the camera lens. It does need a good light, and finding the exact height for best focus can be tricky sometimes, but the results are worth it. The movement is a Junghans calibre 73 from ebay:7 points

-

Casio MDV106G-1AV Gold DURO200 I'm going on a long family vacation to Southeast Asia this summer and wanted a cheap but reliable beater in case I lose it, break it, or get robbed. Quartz movements aren't my thing, but I'm not dogmatic and this was a cheap option. A few years ago you could buy it for under $50, but since this particular model with the Marlin fish has been discontinued, you have to pay about double that, but I still thought it was acceptable. Sure, I could wear one of my cheap and very reliable Vostok Amphibian divers watches, but I have a personal relationship with them (having put a lot of work into them) and don't want to risk losing them. Strangely, I feel very excited. Maybe because I haven't bought a brand-new watch in over 10 years! The only downside is that this is the watch Bill Gates has been seen wearing, and I'm not exactly a fanboy of Bill Gates. Anyway, who cares!?6 points

-

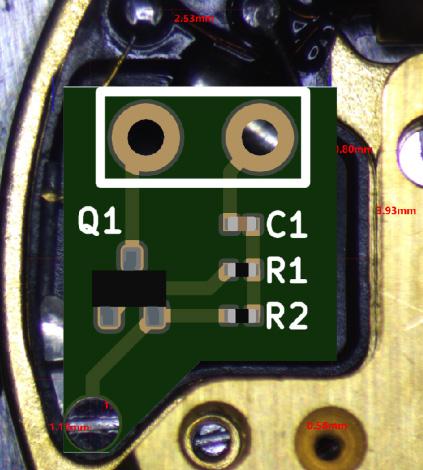

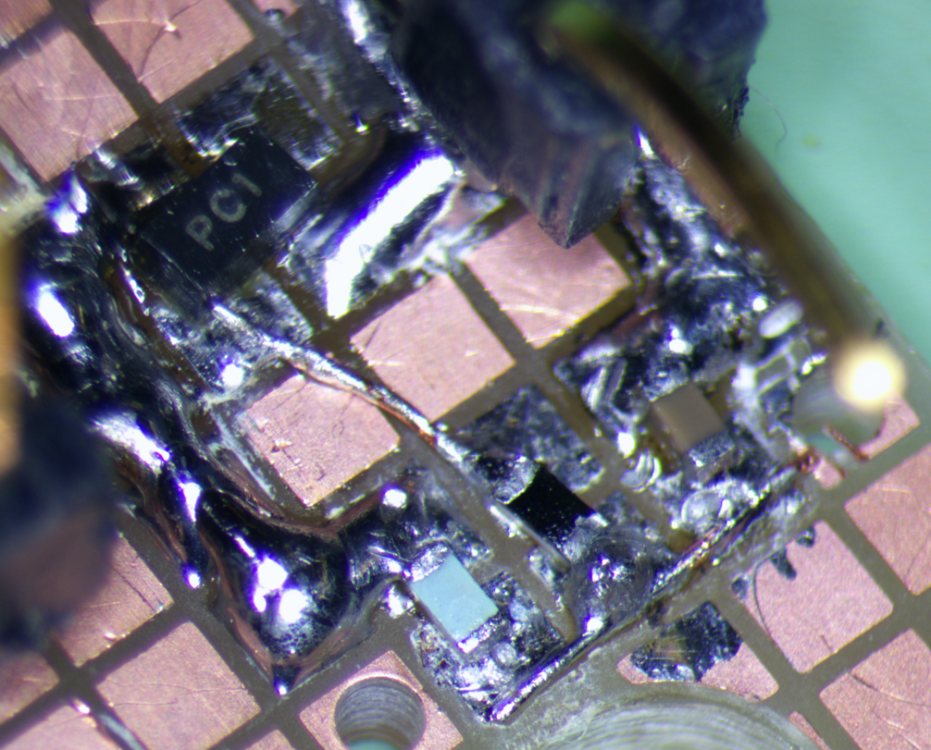

Well, the first attempt was a wash because I bought 22nF capacitors instead of 220nF. So after a second order, I soldered everything onto my SMD breadbaord. I de-soldered the electronics from a 218 movement that I had previous tested and hooked my little circuit up in its place, and hooked the whole thing up to 1.4v from my power supply. ...and realized I'd gotten the pinout of the transistor wrong. After I removed and re-soldered it in the correct orientation, I realized I had the connections to the coils backwards. Once I fixed that, THE FORK STARTED VIBRATING! I could not have been more excited!!! If you haven't guessed, my somewhat evil plan is to make a surface-mount PCB replacement for the resistor, capacitor, and transistor in the 218s. Why? Because why not? The transistor is in a SOT-523 package, the resistors and capacitor are 0402 (1005 metric) packages. I have to redo the circuit to get the transistor pinout correct, but here's what I have in mind:6 points

-

6 points

-

It would be nice if Sellita stood up to the block and advertised their products as hard as swatch. We all know what brands use the swatch movements but it’s not that commonly known which watches use SELLITA movements, that way the public could avoid the SWATCH brands, The parts availability and service data being good points to put forward. I have when asked for advice on a watch purchase told the customer to avoid the Swatch brands because of the high cost off parts and servicing in-house. I think they ,SWATCH are trading on the known names which in the past were quality pieces and people were used to them and therefore bought them on that basis only to find out later when requiring a service it was out of their reach and the watch was deposited in a drawer lo languish un loved and un used for many a year6 points

-

people be honest.... Swatch is evil for the watchmakers and repairers, BUT not everything in watches from Switzerland is from the Swatch-Group. As far as i know, Selitta got sacked by Swatch as a Movement-Assembler for them and they started to produce Movements in their own Name with slight Modifications. As far as i know, they sell Parts to the Market for their Movements. In most cases, if a ETA-Movement fails, it is a valid Option to replace it with a Selitta Movement, which i consider the Solution for this Mess with the Swatch-Group...... I have no Connection to anybody at Selitta, but being a Swiss-Guy, i still like to have Swiss-Made Watches, but not from the Swatch-Group. ok ? regards, Ernst6 points

-

6 points

-

Getting back to the issue which is us guys repairing or just enjoying horological exploits. The big worry now is how sound is Cousins as company going forward. The of cost if this 8 year legal battle will be astronomical. Cut backs will happen noticed already how the Cousins catalogue is half its size this year. The main supplier going out of business will hit the UK horological community in a big way. On the Brexit issue it was about a sovereign country being able to make its own laws and trade with any country in the world. I cannot see what was wrong with this. For those who wish to re join the cost would be very high indeed.6 points

-

6 points

-

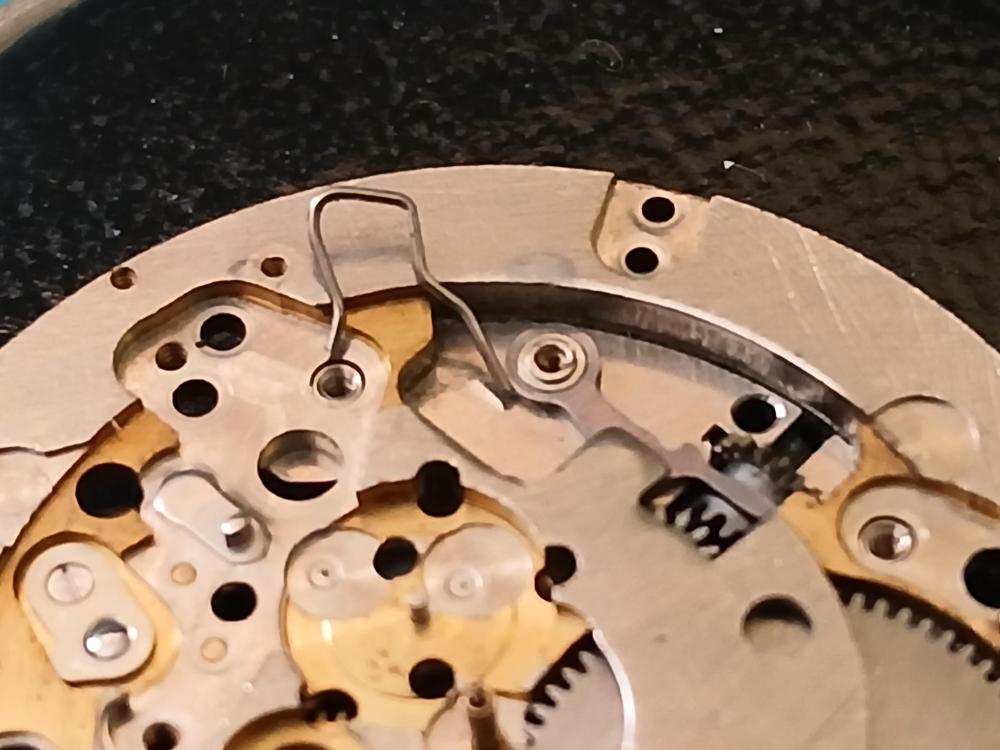

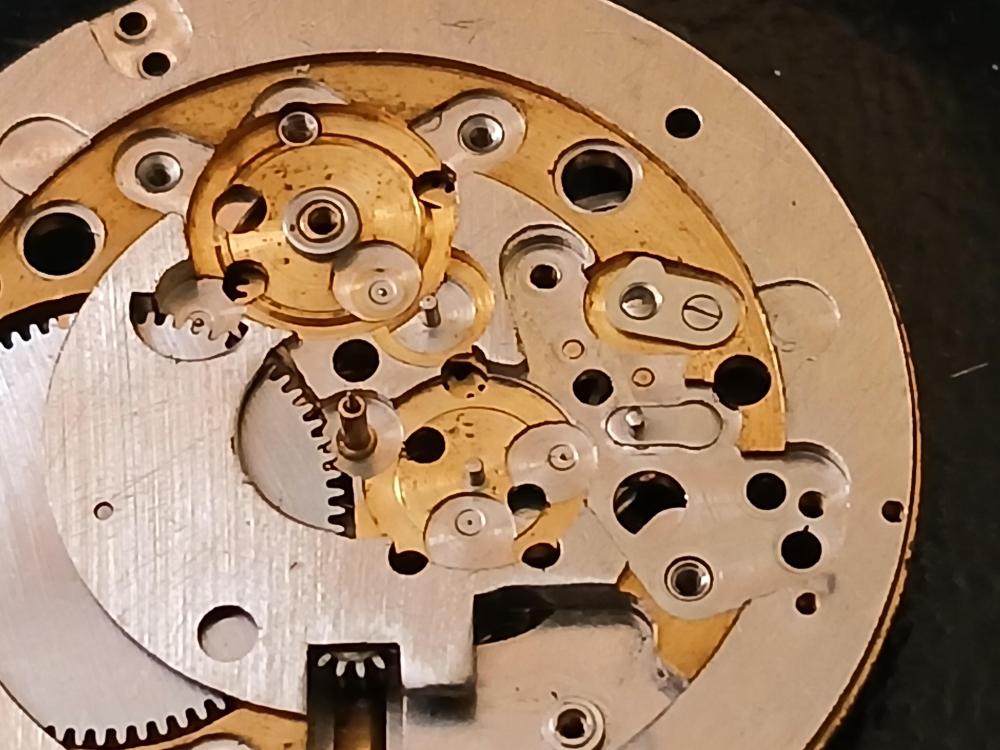

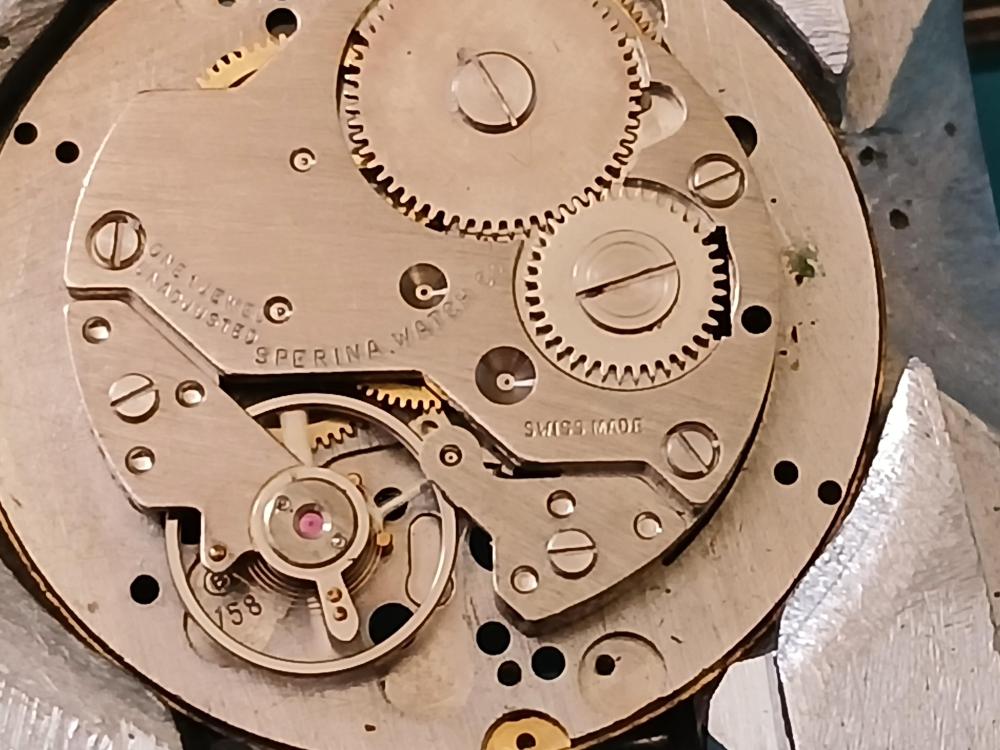

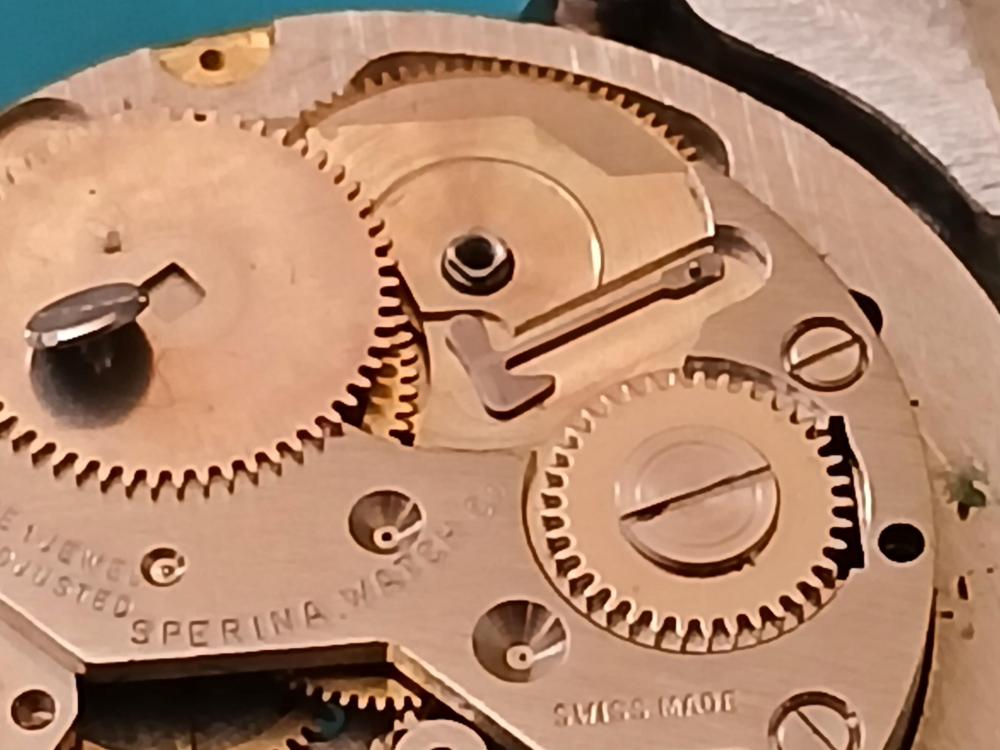

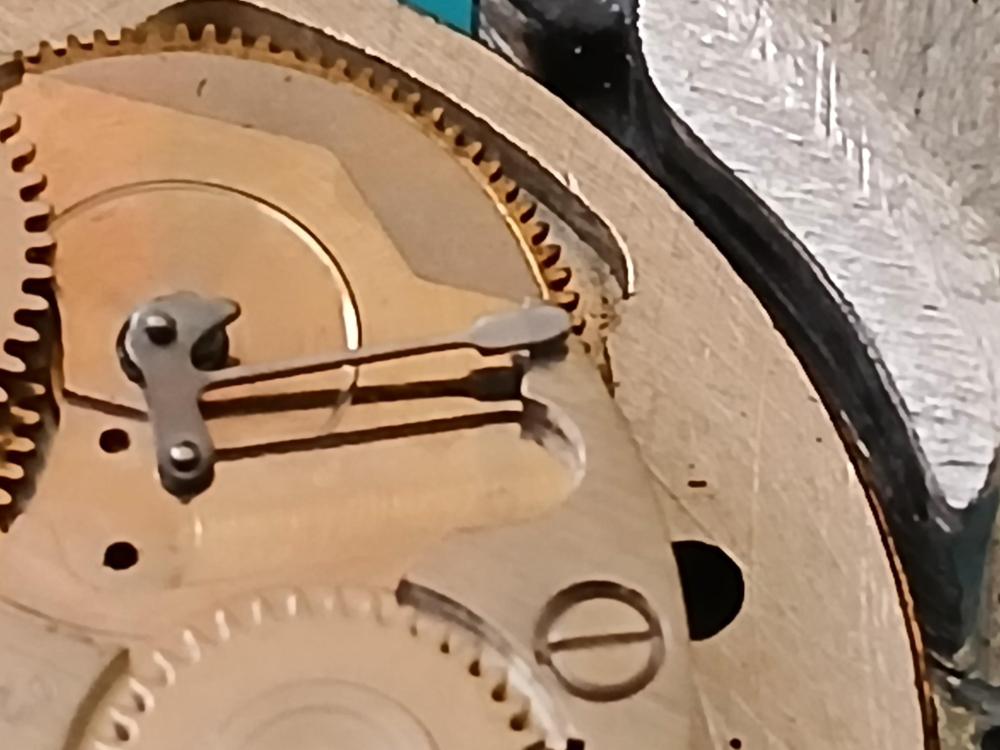

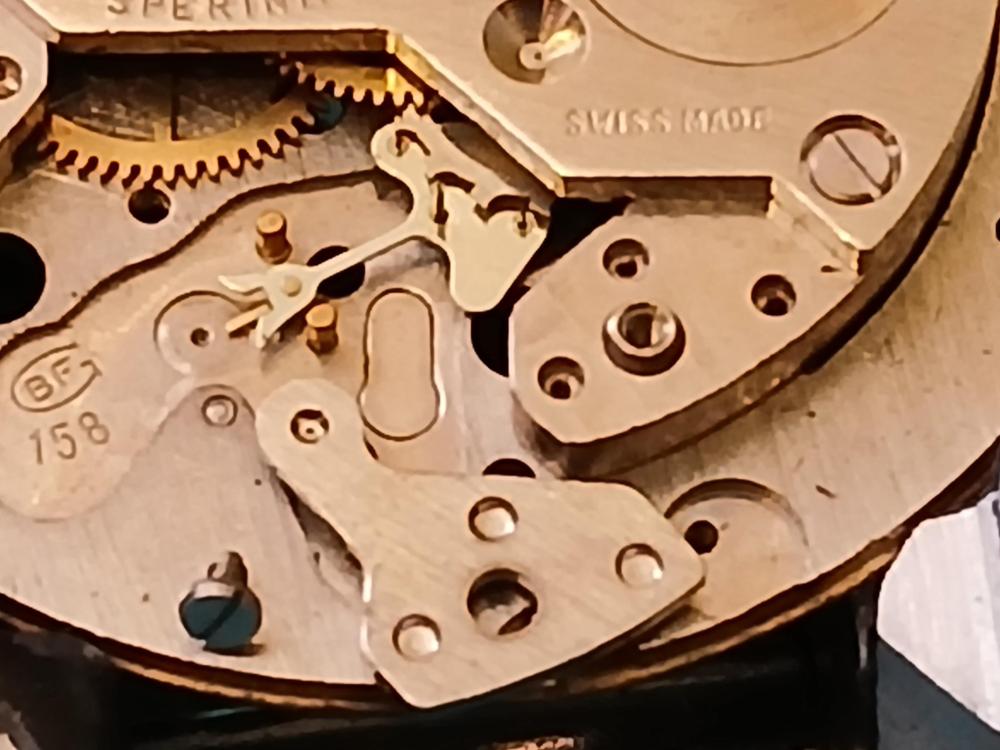

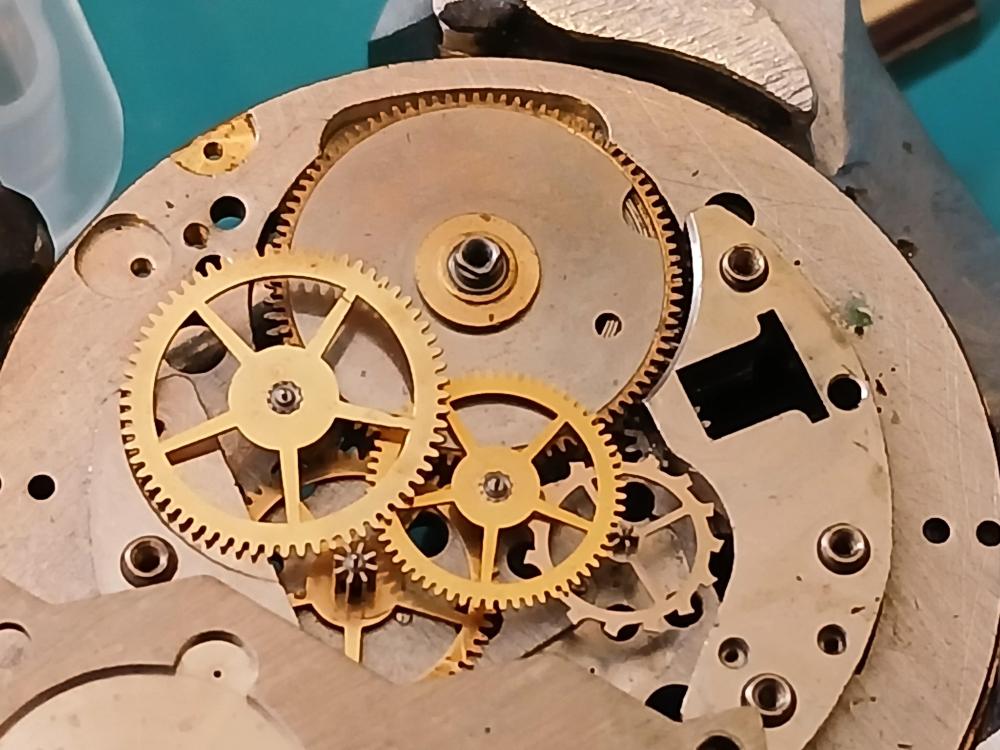

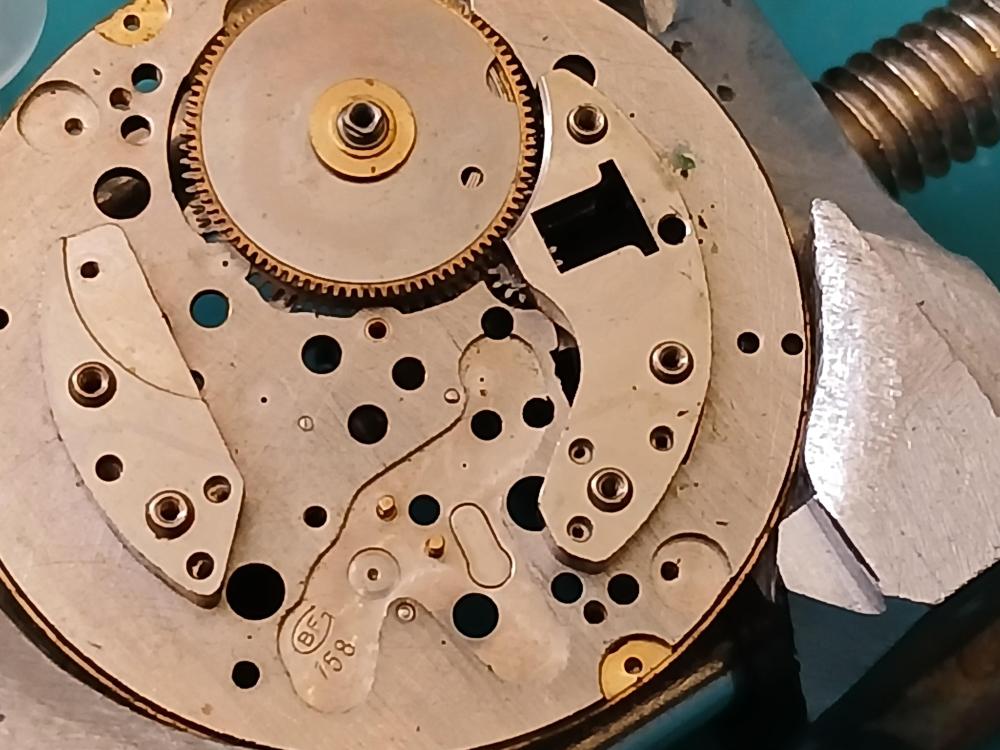

Haven't posted for a while as I've had family visiting and then sick with a cold . but did manage to work on this Gruen (AS 5203) watch which has really grown on me. It also has a cool escapement setup, and an even stranger keyless works (no sliding pinion!). Picture of pallet fork (stock image): Here is the before shot: Movement with and without automatic works: Here is the dial side showing the complicated keyless works without a sliding pinion Here is a closeup on that pallet fork in the movement: showing only 1 banking pin The image below shows the mechanism where the hands setting wheel is not horizontally brought into position, instead it engages and disengages vertically, rather than use a sliding pinion (stock image): And here is the finished watch with its new strap and crystal (original was cracked):6 points

-

I've had a quick bite to eat and would like to crack on with this if thats ok, i know its not watchstuff but its important, if even just one of you can avoid this happening to either yourself or a family member then it's 100 % worth my time and getting it out of my system really helps me as well and hopefully spurs some of you to make sure you and your family are ok. And please anyone that can add some input from knowledge or experience then just jump on. The stroke mum had is known as an Ischemic stroke of which there are more than one kind , mum's was an embolic stroke , these are caused by blood clots ( wandering clots or embolisms ) another type is a thrombotic clot that can block main arteries that may supply blood flow to the brain . From what i gather thrombotic clots are stationary, these are the type that cause pain and restrict blood flow in the particular area where they form ie. leg , chest. Mum's embolism travelled to her brain , so she had no experience of pain and no warning until it was too late. Many things play a part of clot formation, we can't change our genetics but we can edge our bets by leading a healthy lifestyle. My mum is 87 5' 1" and weighs around 55 kg, has always been extremely fit, goes out nearly every day into her village or the next town sometimes a town 40 miles away on the bus if she's buying presents. She eats healthy as far as mainstream guidance tells folk, fish chicken no red meat, fruit veg nuts etc, all the usual stuff thats considered healthy and no real crap like pastries sweets . Has never smoked and has never really drunk alcohol, but she is a stress head and worries about everybody and things she really does not need to. This is me to a tee, i worry about everyone and rarely myself. Being in hospital we've discovered she has an irregular heartbeat ( caused by the stroke ? the doctors seem to think not ) . Atrial Fibrillation, doctors have attributed the stroke cause to her irregular heartbeat, apparently clots can form in the upper chambers of the heart were irregularity occurs, brake up and become mobile to cause damage. Those are just one type of stroke, hemorrhagic stroke (less common than an ischemic stroke ) caused by a bleed in the brain generally thought of as more serious as not only is the brain being starved the bleed itself can exert pressure on the brain. Its important to know the difference which cannot be ascertained until a scan is carried out, and the treatment is different. Common thinking was to give someone experiencing a heartattack an aspirin to improve blood flow, this can actually worsen the effects of a bleed on the brain. There are lots of causes for a stroke, genetics for sure like i said, but getting the most from your genetics and nursing the weak areas by living healthily will not only extend our time but give us more quality time that we have left ( change just one thing if thats all you can manage for now ). Regular visits to see the quack will pick up warning signs early , just one visit for an mot might save not only your life but wont destroy the lives of your loved ones. Anyone here in their 50s not had an mot medical check up yet ? Er cough er maybe its time to make sure everything is working as it should, and not just your heart ( dont clench when the doc stretches on those latex gloves, and definitely dont have a smile on your face when you stand up straight again ) . A stroke can strike anyone of any age and of any lifestyle if there is something underlying going unnoticed, make that call and find out how you really are with your health. Love you people x Absolutely Richard, i cant help my mum if I'm not well myself. I have a habit of keeping going and draining my batteries too low ( maybe i need a wind up key in my back ). The Mrs cant figure out i get by with hardly any sleep or rest, calls me a robot with emotions. Thank you , very kind of you Del. Thank you rehajm Thanks OH, i know i can be a pain in the bum and have you watch over my antics but that means a lot. Thanks MSB , she'll keep kicking as long as I'm around , thank you. Thanks WW, i will make sure to do that, my time here is not done by a long chalk. Thanks Hector i take note of everything you say and completely agree, i cant do it all myself and my mum wouldn't want me to. Bit difficult to let go of the reigns though. Thanks Guy, i appreciate those comments . Thanks Nev, my mum makes it easy she is very resilient and very independent, she will get all the care she needs and wants thank you. Thanks so much , my mum and me aren't going anywhere, the forum will have to manage with a diluted version of me for a while. Thanks Steven really kind of you to say that, thank you for the times you have kept me straight, i dont forget that. Thanks Tom yep i know where you are at , very much appreciated. Thanks matey, at the rate my mum goes i won't be gone for very long. Thanks Steve i appreciate that. Thanks Ross i really appreciate that. If i helped you in any way then that makes me happy. I know we are not supposed to have favourites among family friends etc. But i think you are one of mine so just dont tell anyone Thanks Jon , there are others in my family, but i have always been the doggedly determined one that likes to get things done. Thanks Mike, thats really nice of you to say so.5 points

-

Hello forum, i have some things i would like to say today if thats ok. Being here is something of a sanctuary for me, talking about something that i love doing with folk that i have become fond of ( yes quite surprisingly under all that craziness and verbal brawn lays a soft heart of gold ). I imagine that the same can be said by many of you , a certain number of us are here daily both learning and offering any advice that we are able to. Quoting our experiences both successful and failures for others to learn from. For me at the moment just making this post is a distraction from my current bubble but also from the world around me for various reasons. Its a place not just for teaching and learning but to make others laugh and smile and be part of a community. I would even go so far as to say we are a team, supporting and encouraging each other when needed and when we are down, my own situation with my mum being a perfect example of everyone's kindness. Thats the soppy bit out of the way . So my mum has been moved to a brand new facility after making amazing progress with her speech and word recognition in hospital ( poor mum has had to suffer my company and my teaching to the full extent of her visiting hours barring one day off for me that my sister insisted upon ) her consultant calls my mum his medical miracle , and will be starting her intensive speech rehab today after her initial assessment. Things I've learned about having a stroke, and I'd really like everyone to take note of the causes and outcomes of having one. Please do your own research I am a joiner and not a doctor , i just want to make everyone aware and just get checked out if you notice anything in yourself that you are unsure about, any risk of having one can be reduced with either medical intervention or/and a change of lifestyle ( which would be my own preference in an attempt to limit my risk, something i have now noticed in myself ). I do know a few of you here have experience but this is what i have become aware of and how it has affected my mum and me. First i want to touch on the effects of a stroke, not only to the sufferer but to the whole family, we all know how dementia affects lives. A stroke effecting language is almost instant non aggressive dementia. Like being in a foreign country where you can no longer read, write or speak to someone without some form of very basic sign language gesturing ( when annoyed i think everyone understands the middle finger ). But a stroke can affect movement ( fortunately my mum is virtually unaffected with her mobility, the nurses can't believe she is 87 and just had a stroke, she's like bloody Supergran, in fact she is a great great grandmother to 2 toddlers ) . Improvement after a stroke carries on for years afterwards, but from what i understand and now believe after being with my mum almost every day since it happened for 7 hours a day, language rehab should be started as soon as possible when the patient is out of danger and physically able. The brain is ready and set to go and rewire itself soon after injury, in a similar ready state to young children ( when we say kids brains absorb information like a sponge, thats pretty much true in early stroke patients) After the first few weeks maybe a couple of months things start to slow down and lesser progression carries on for the years following . After a day she could manage only one word, which was my cue to get on her back and start pushing her progress. Day two i wanted to see how capable she was so i had her writing on a whiteboard ( it wasn't great tbh ) . Day 3 and until she left the hospital most time with her was spent on picture/word recognition on my laptop, picture books, some writing and teaching her to play cards again ( i refrained from gambling for real money, though i was tempted, as I'm pretty good at poker , she has a few bob and i have space for another watchmakers lathe in my watchroom ) Now i suppose i have to back off as the rehab place is fairly intense focused and visiting times are crap as they interfere with all the physio and rehab going on . So i only have 2 hours max a day with her sometimes only 1 if her grandkids want to visit, but she is in good hands and i know she will get as much help as she needs , and as difficult as it is to admit i probably need a bit of a break and distract myself. I'll end this post for now but i want to come back and talk about what caused this and hopefully remind some of you to think about how we live , what to do in the event of a stroke and how we can lower our risk. I'm not a pussy by any means and very little frightens me, but seeing this first hand has put the fear of god into me if i ever had to suffer the outcome of a stroke. My mum is a tough old cookie and i imagine i will be just as tough, but watching the frustration on her face when trying to communicate completely tore my heart into pieces. Please dont let this happen to you, do everything you can to avoid it, I'll come back soon to talk more about as long as everyone is ok with it, take care for now x5 points

-

Hi @Neverenoughwatches, I will keep you and your Mum in my prayers. A caregiver's job is a tough one. I have known nice little old ladies to undergo drastic changes in their demeanor after suffering a stroke. Patience and understanding is essential in all circumstances. Never lose your cool or be condescending. Try and enroll in a caregivers training course. It really helps. You cannot take on the role of a caregiver 24/7. You need to get a relief caregiver. You need to take care of yourself before you can take care of others. Do not be afraid to ask for help. Hope to hear from you soon.5 points

-

What I consider ebay "Paydirt" - taking the back off a watch and finding years worth of accumulation of crud around the edges, so it is as previously worn rather than someone else's failure or Frankenstein attempt they are getting shut of. And even better when you also find an immaculate movement with no sign of rust or chewed up screws! Another couple I think are fantastic old ones, from an ebay job lot (under £2 each). They both look like they have been worn to death, with little plating left. The "Claridge" one (upper) has the date 1922 (or 23) scratched in the back, and the Ingersoll has 2/48/FW in the back. (Is that when it was sold, or serviced)? The movement in the Claridge looks like it was a reasonably high end one at the time, from the finish? It's also got quite a fancy dial. That one tries to run, but is very sticky. The Ingersoll is only a pin escapement type, but it's still going strong with good amplitude!5 points

-

I have a different view to the DD module world. I began watchmaking for one main reason: To understand and enjoy complicated mechanisms. So when I already had some years of experience with several ETAs, PUWs, Rolex I entered the chronograph business step by step. Landeron 248, Valjoux 7734, Valjoux 72, Buren 12. And while working on the last one I came across a picture of the DD2020 without cover plate and had only one thought: Wow! Freaky! How the hell does this thing work? So I bought a Omega Speedmaster Reduced just for the sake of disassembling, reassembling and understand that thing. I wrote a little article on the r-l-x-forum about this (not a service-walkthrough as this is not a watchmaker-forum, but just a description how it works): https://www.r-l-x.de/forum/showthread.php/197912-Konstrukteure-auf-Speed-–-das-Omega-1140-mit-Dubois-Depraz-Chrono-Modul There is a lot of information on the internet which guided me, especially Marks videos about his Breitling for Bentley service and the Omega 1140 tech sheet availiable on watchguy UK: https://watchguy.co.uk/cgi-bin/files?showfile=Omega/Omega 1140.pdf&filename=Omega 1140.pdf&dir=Technical Manuals&action=documents I am not familiar with the DD4500 but after a look at this article https://www.thenakedwatchmaker.com/decon-dubois-depraz-chrono-big-date I am quite sure that in the area of the chronograph there are a lot of levers and wheels which are identical to the DD2020. Of course this doesn't change anything on the situation that parts are not availiable (when I worked on the DD2020 I was lucky that no module parts where worn). I like the DDs as they are freaky mechanical stuff, interesting challenge for advanced amateurs with lots of time. If I was a pro and had to do a service in a short time at reasonable costs maybe I would get to a less positive judgement.5 points

-

DD modules... I have 'adopted' some watchmakers who i have to save from time to time. For example, now I have an AP movement on my bench that needs to make new winding pinion and one of winding gears for it, this is for a young watchmaker that I am trying to teach and will not want to dissappoint him... I have newer worked on a DD module, but I have repivoted two times for different watchmakers the small pivot on the back side of center seconds (4th) wheel of 2892 that has break while pressing the gear on top of the wheel. I know from them that the modules are real pain and they need a special holder that holds all the buttons pressed, othervice almost not possible to assemble them.5 points

-

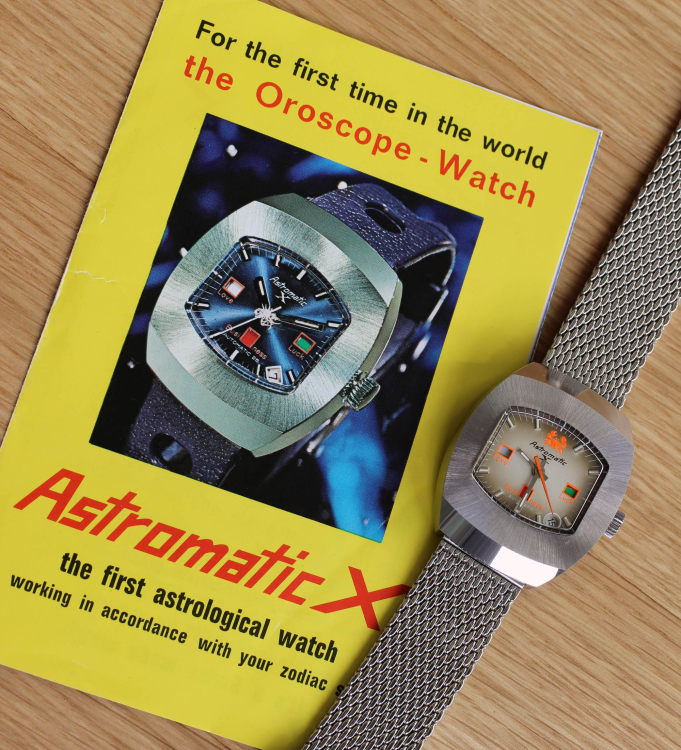

Judging by this, you could get them with whichever sign of the Zodiac seemed appropriate. History does not relate whether the "water signs" were waterproof, but I suspect not. I'm intrigued to see how the "love, luck and business" mechanism works. We have to assume it uses some very advanced gravity sensors to detect the positions of all of the planets and a very intricate arrangement of cams and levers to align those coloured flags (or alternatively it is driven by the hour wheel).5 points

-

An interesting question. I refuse to wear designer clothes for two reasons, firstly I don't care less about clothes but more importantly I refuse to pay a premium to advertise someone's clothing. Want me to wear a t shirt with someone's name on it, pay me.5 points

-

LOL, good luck with that. It's really just an example of the golden rule -- whoever has the gold, makes the rules. Is it any surprise that huge swaths of people can be convinced of a deep state shadow government conspiracy or whatever terminology you want to use to identify a corporate consumer rule under the guise of the "free" market. If you truly want absolute freedom, then you must accept that people (and corporations) have the freedom to do the absolute worst without regard to others. Oh, but try to force companies to behave fairly then it's an attack against rights, liberty and quite possible your mother. For the most part your average voter gets more upset about a controversial call during a sporting event that has exactly ZERO impact on their daily life than they do a foreign trade policy that has the potential to price them out of the market for certain goods or impose restrictions on their profession. It's no wonder that the western countries tend to vilify Chinese manufacturing. They are scared of a country with capacity and capability being able to serve the world market and not play by their rules. Now, I am not saying I approve of the "rules" that China or other countries play under, but play they do and have been winning in many respects. And that winning comes from the defensive western posture of attacking the competition rather than improving your product, service, price or process. Let's not forget that Rolex, Swatch and Richemont are essentially a marketing companies that absorbed well-known brands of obsolete technology and turned them into fashion and status items. And they did it exceedingly well. The general watch-buying public holds the belief that if you have a Swiss made watch from an iconic brand you are somehow better than the person with the drug store Timex regardless of the fact that a $20 Casio is more accurate than a $100,000 Patek. Omega, Rolex, Longines, et. al. of the mass produced luxury watches bring some of that elitism to the masses. The harder you have to work to get that luxury, the more elite it makes you feel, which is ironic since it is the "elites" that get blames for what's wrong with everything. Swatch is protecting the Brand and not the quality, craftsmanship or value, hence the disposable Omega moon swatch or the 50 fathoms monstrosity. The more elite and restricted it seems the more people will stand in line to throw money at them.5 points

-

@VWatchieis correct, once bought the product is yours, whatever the product is and therefore you should be able to do as you feel fit.5 points

-

In my opinion, manufacturers should be obliged to sell parts for a "reasonable price" to anyone. If I own a product I should be eligible to handle it in any way I see fit. As the owner of a product, you should have complete control over it. When it comes to safety issues, like with cars, there must be an independent inspection authority. Simple as that!5 points

-

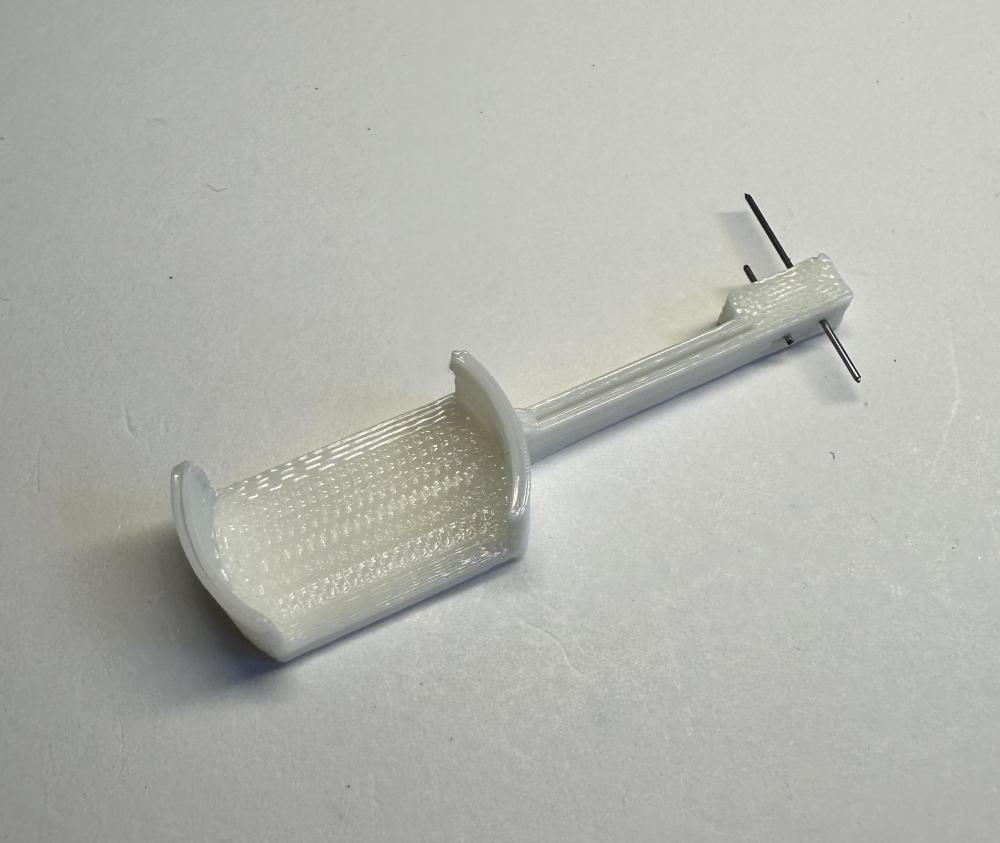

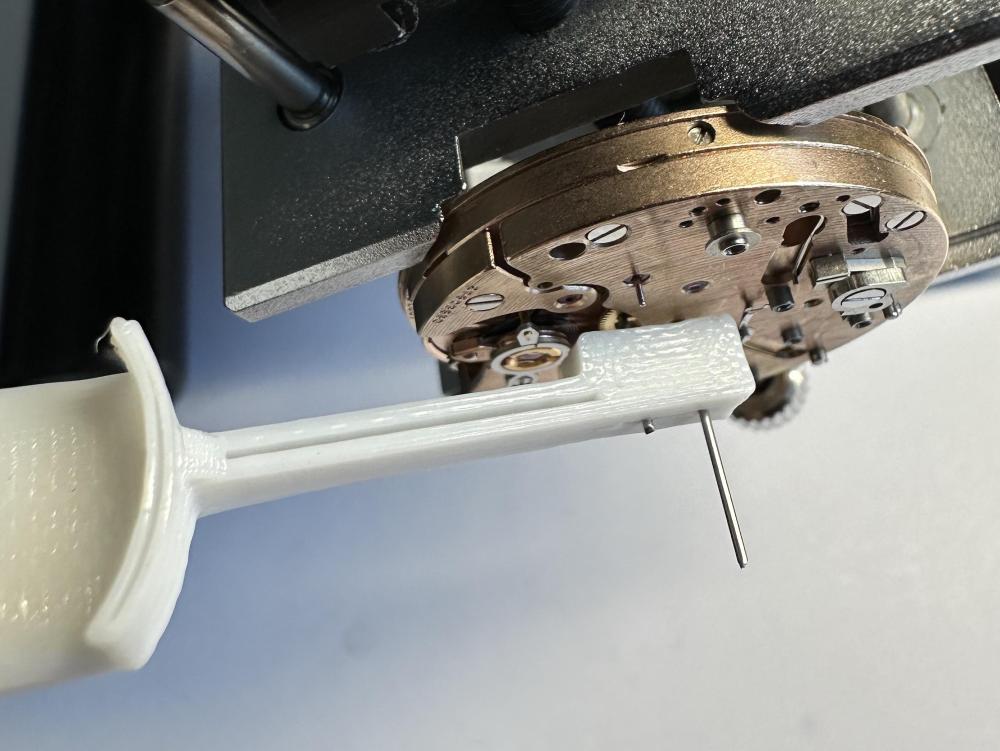

Over the last weeks I followed VWatchies thread about his ETA 2763 showing erratic amplitude: https://www.watchrepairtalk.com/topic/28929-serviced-eta-2763-having-erratic-rate-and-amplitude/page/4/#comment-245378 I have a similar problem on an Omega 861. The base movement shows alternating amplitude in both horizontal and vertical positions. The range is more than 25 degrees, no periodical behavior, pure random. In the above quoted thread there was a lot of talk about the regulator pins, hairspring, collet, geartrain, etc. and I do not doubt that all these may be sources for the problem. However, I couldn‘t get one question out of my head: Can the problem be on the other side - mainspring, barrel, ratchet wheel? Some kind of error which prevents the barrel from delivering constant torque to the center wheel? To find out where to look I built the following setup: I assembled the movement without barrel and ratchet wheel. Then after some research and calculation about torque in the geartrain I 3D-printed this part and completed it with an axle and a pin. The movement in a well chosen vertical position. Please notice the spoke of the center wheel. Now the „torque generator“ is fitted to the center wheel. The axle is pushed into the pinion and the pin is lying on the spoke. Finally I have to choose the correct weight to get a torque which results in an amplitude in the area of 280 degrees ( yes, watchmaking is an expensive hobby - my 2 cents). And that‘s all. When the lever is in nearly horizontal position this setup provides a nearly constant torque on the center wheel for several minutes (I assume you live in an area with constant gravity). For me this one answered my question. The alternating amplitude was gone, less than 4 degrees fluctuation now, which is always the case with my Weishi. So the source of my problem is somewhere in the area of the barrel - will work on that the following days.5 points

-

My first attempt at silvering of watch hands. First I rubbed the hands back to the brass with 7000 grit paper. Then I polished a bit with pegwood and 1 micron diamond paste. Cleaned in solvent (Essence of Renata is what I have handy). Then used silvering powder as directed from Priory polishes (eBay). Finished of with a brush stroke of lacquer to avoid tarnishing. I think they look quite good, a nice satin effect.5 points

-

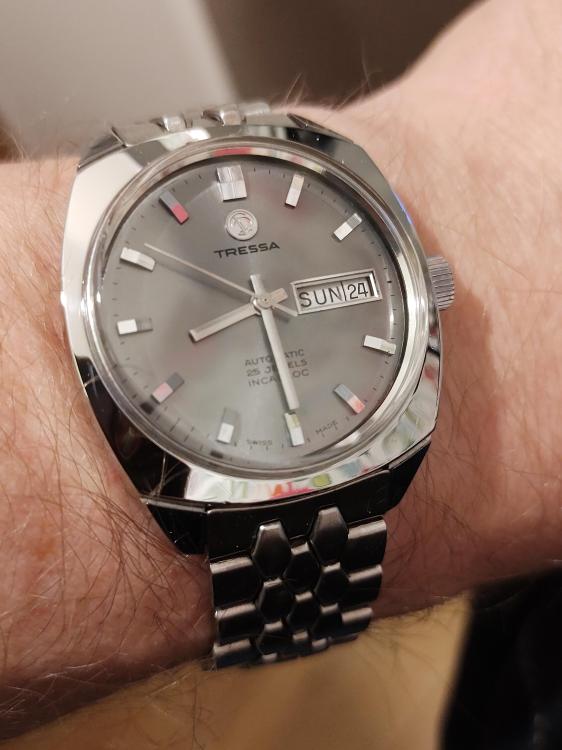

Ricoh has a similar pallet fork Tressa 1970s ETA 2788 Unusual Grey Sunburst Dial all original except for the crystal Running really well for its age, + 0.5 SPD, 300 degrees amplitude horizontal after 12 hours. I have another crystal arriving next week with a wider tension ring that I hope can hide the gap between the dial and case (XAC 321.577). Wide tension ring crystals appear to be few and far between so if anyone has any tips for a good source then that's most appreciated. I did look at ATCB range from Sternkreuz but they seem a bit higher than I would like based on the dimensions.5 points

-

After a long delay, I finally got a larger o-ring to seal the crystal. Somehow it's not thick enough to really grab the crystal, despite being the same size as the old one. Either way, the design of the case very firmly seals the crystal against the inside of the case, so I'm just going to wear it and keep it out of the sink. I think Pop-pop would be proud. And just to round out the whole story, mom texted me this after I sent pictures:5 points

-

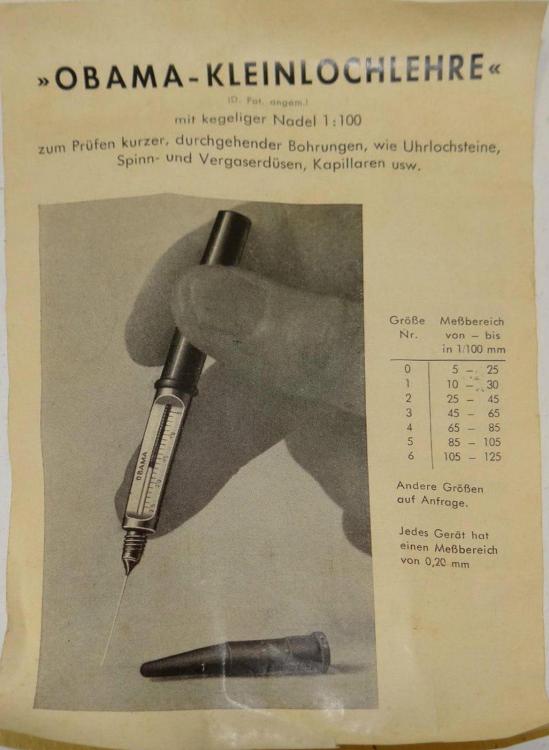

There is a tool for this, if you can find one. It's called an Obama Jewel Hole Gauge. It consists of a finely tapered pin which you push into the hole as far as it will go. The pin then pushes back into the body of the instrument until the jewel is against the tip. The hole diameter can then be read off the scale in 0.01mm increments down to 0.05mm. If you could find a suitably fine tapered pin there's no reason why you couldn't improvise by marking where the jewel sits on the taper and then measuring it with a micrometer. In practice though if you are replacing a jewel you could always just measure the pivot that is going to run in it.5 points

-

All the best, family always comes first, and I believe you have made the right call that you mother deserves your full attention. However, when you need a little outside distraction the guys here will always be available for some banter or a heated discussion on lubrication .4 points

-

I'm pretty sure the impulse pin is held in place by friction on this caliber, not shellac, so luckily that shouldn't be a problem. Of course, it doesn't hurt to take a look. BTW, I've been using Horosolv degreaser for my balance springs for several years now and I'm super happy with it. Yes, likely costs a fortune compared to KleanStrip but as an enthusiast, I use very small volumes.4 points

-

Ok, it gets even weirder. I did a Google Lens image search on one of his photos and found that it was from an earlier eBay listing. And it's from Pakistan. https://www.ebay.com/itm/4044625307894 points

-

Well, 02 in 3602 means 'no shock protection, small seconds hand'. For sure there is only one balance staff for 3602, so no way to order wrong one, but spare parts from the last years of the production are wid bad quality. I would advice to true the balance and check how it behaves in the movement without the roller first. To see if the endshake is normal and the balance position against the lever bridge, because in Molnia the distance between the balance and the lever bridge is verry small and if not trued, the balance may rubb.4 points

-

How did you clean the balance assembly, by hand? If you clean the balance and mainplate together, so the balance is mounted on the mainplate, this wouldn't happen, unless you're prodding with a brush if it is hand cleaned. Funnily enough, my students have just spent the last three weeks learning how to manipulate hairsprings and shaping end-curves, first by working on clock hairsprings, then scaling it down to ETA 6497 hairsprings. It isn't a bad bend, but I would remove the hairspring from the balance and then lay the hairspring on the underside of the cock then bring the end-curve back to where it should be. It's very important to place the stud in the stud support and tighten with the screw to get it to position properly to give you an idea where the collet will end up once assembled. There is a small groove in the stud that the screw will locate with. I've taken some photos of a clock mainspring and drawn the underside of the balance for it to position on. The first pic is the underside of the balance cock (I know the curb pin and boot is quite a gap, but I wanted the pic to be understood well). The second pic is how the hairspring and end-curve should ideally be with the collet bang on the jewel hole. When the index is moved the hairspring shouldn't be pushed or pulled by the curb pin and boot, or in modern watches the regulator pins. If that happens you'll see a difference in beat error when you move the index arm from fast to slow. You have to make sure there is a gap between the curb pin and boot before you move the index, otherwise it will bend the hairspring, which might have happened in this instance. The last pic is the hairspring being manipulated to form the end-curve again. This is done away from the cock and then try for shape on the cock remembering to ensure you tighten the stud screw to get the proper position of the spring. I have gripped the spring with No. 7 tweezers and where the arrow is, push the spring until the kink is out and the collet is on the jewel. If you've never done this type of work before, it's best to try with a scrapper first. It is a lot safer to remove the hairspring from the balance first. I use scalpels to lever the hairspring off, or very fine hand removing tools, but I still prefer scalpels4 points

-

Working on a ladies Seiko that is testing my patience, full service and had it running sweetly - and put it on my winder rig for a 24 hour test, but found it stopped after an hour. I took it apart and found the ubiquitous red fibre wrapped around the pivot of the escape wheel, removed and the watch is up and running again, victory! ......Then it stops again after about an hour, complete strip and notice some movement on the arbor of the barrel... hammer time.... and the watch is up and running again, victory! ......Then it stops again after about an hour. Another complete strip and clean after checking all the jewels on my new LED light box i notice a slight chip (but probably just an inclusion?), re-jewel anyway .... and the watch is up and running again, victory! ......Then it stops again after about an hour.... Top up swear jar, have an argument with Mrs W. and then watch crap TV for the rest of the day. But I got to wondering, where do those red fibres come from??? I do not wear red or have any red rags or cleaning cloths etc... conclusion is that watch gremlins wear red sewaters ->4 points

-

I avoid these at all cost! They really aren't pleasant to work on, and the absolute unavailability of parts or tech info just makes it a gut wrenching nightmare. You can have friends in the biz with parts accounts all over the map, there are no parts available from DD. A friend of mine even lives about a block from their main building, and is their local fireman, and a trained watchmaker, and I'm 1000% sure he could show up with brownies and croissants for the whole workshop and no parts.4 points

-

hello everyone! im new to this forum. i never really used forums before so its a bit new and exciting at the same time. i will be posting my questions and topics later on but in the mean time ill tell a bit about myself. i am a 18 year old guy with a OBSESSION of watch collecting. ive grown up around watches and always had a love and passion for them. ive collected many over the years and will show my collection some time soon. i dont have any "high end luxury" brands like rolex, omega, etc but to me its not always about the brand but simply how the watch looks and some of their features. i have around 20 or 30 so watches all including brands like citizen, seiko, fossil, bulova, and a few others. not the most luxurious but they get the job done and still look incredible. thanks for stopping by to read all that haha hope you all can help me through my journey of the watch world and hope i can share and receive much knowledge from this community.4 points

-

As @rossjackson01says, "good this hobby, isn't it " or words to that effect. I'm not sure that I do learn daily but no matter how much I do learn, there's always something new and I'm constantly learning. So yes, since I love learning, this is a brilliant hobby or profession.4 points

-

4 points

-

Re. rust removal: I'm using a formula created by one of the science channels on youtube (Elementalmaker). It's cheap, not acidic and works in a similar way to evaporust, but seems milder. It has worked well on everything I've tried it with so far, with no detrimental effects. The formula is: Per 100ml deionised water; 5g Tetrasodium EDTA [from amazon or ebay etc] then enough citric acid to bring it to ~6.5ph, testing with ph paper, plus a few drops of washing up liquid / dish soap. I've only made one, 100ml batch so far and it shows no signs of stopping working, though it is starting to look a bit murky! These spring winding arbours were the worst rusted items I've put in it - they had quite heavy scaled rust patches; you can see the darker grey areas where the rust ate in to the metal, compared to the untouched areas. The small clock parts are unaffected by the solution, other than the rust having gone. (I've also used it on such as setting levers & other keyless components, that had quite significant rust from water ingress).4 points

-

Well, I've done it. completed my first service on a pin movement. It was a non runner when I purchased it. When doing the service I found the reason. Two items on the crown wheel stopping rotation. Removed and cleaned. Only a cheap watch, but I wanted to try my skill. Pin are more difficult than jewelled watches, in my opinion. Running well. Disassembly 1 hr. Cleaning 1/2 hr. Assembly 1 1/2 hrs. Followed members instructions. Photograph each removal and watch in reverse for assembly. Happy bunny. thank you to all. Ross4 points