Leaderboard

Popular Content

Showing content with the highest reputation on 05/24/23 in all areas

-

Yes I can read it thank you. If you mean does anyone know the meaning of the numbers then my answer is no.3 points

-

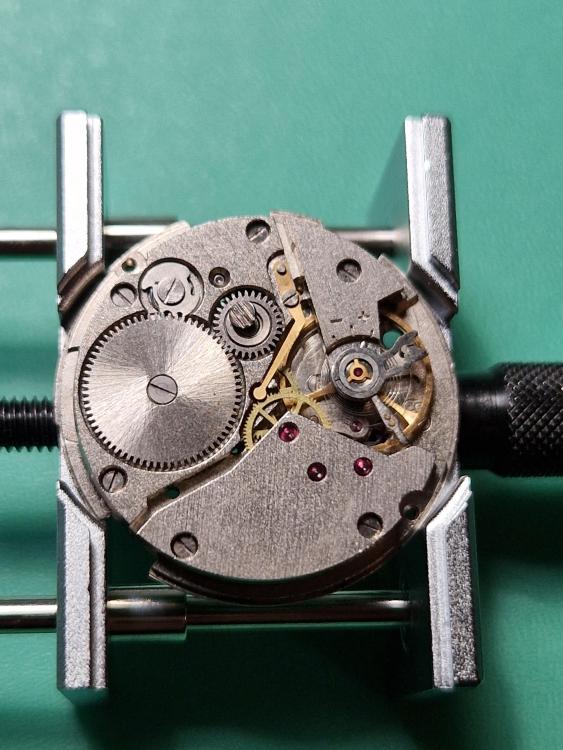

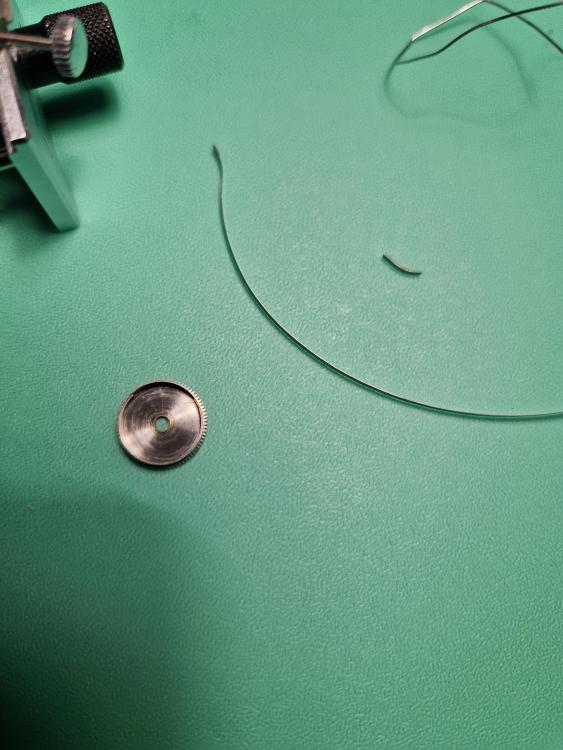

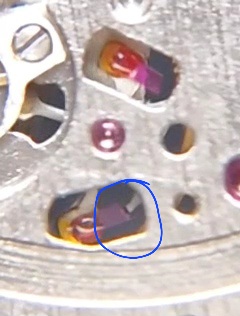

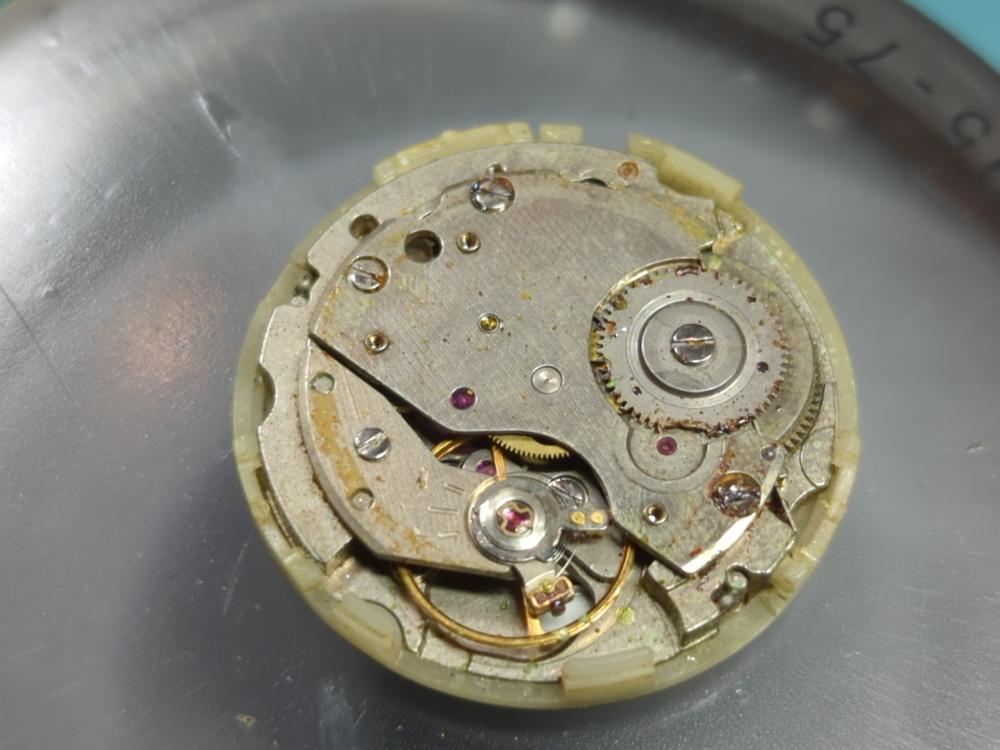

This is my Vostok 2414 from the late 1980s. It was my first ever full (and successful) service. Photos in reverse chronological order. The final product. I like how the dial colour has cracked in different levels of intensity as the shade of the paint changes. Full wind. Couldn't be happier. I'm a bit of an OCD person... note: lift angle is correctly set to 42°. Not sure if this is visible at all . But maybe you can see the small black area between the pallet (exit) stone and escape wheel tooth. That's lubricant (9415). Took me a while to get close to the recommended 60-70% of contact area (maybe I went slightly above..). And it took me the same amount of time to film it with my basic phone+loupe+slowmo technique. Oh boy, it took quite a number of attempts to get that drop of oil done well (being a first-timer). But I probably spent even more time with that bloody shock spring!!! Including 2-3 hours of searching on the floor... When I received it, the watch wouldn't wind. Upon opening the barrel and removing the mainspring, I found that the bridle had broken off... I followed a cool trick I saw somewhere (can't find the source anymore) and used a lighter to heat the spring and then bend it backwards to create a bridle. To my astonishment, it works perfectly and I get the full power reserve. Just some pics of the movement.3 points

-

Hahaha, oh dear, I'm getting myself involved in these kinds of debates --- as a new member and beginner watchmaker . I should also start posting my opinions on lubricants For me, to stick to the analogy of cars, the equivalent of engine rev's (supercar vs Volkswagen) is beat rate. Take a Zenith El Primero with 36'000 bph ("high rev") that will wear faster and need more frequent servicing. Also, the fuel tank (mainspring) will run out faster (unless you size that up as well). The Volkswagen are those "low-rev" 18'000 bph movements (or 19'800 for my Vostok). Servicing will be less frequent and fuel/mainspring will last longer. Amplitude, to me, is how "smooth"/effective/clean the engine is running. If you press down the accelerator pedal in your car (you wind the mainspring), and only half of the manufacturer-specified horse-power/torque arrives in the wheels (balance wheel), you would assume a problem. Probably friction somewhere. I see it the same for watches: if the amplitude is lower than expected (with a fresh mainspring), there is more friction than there should/need be. And friction entails wear. That all being said, I agree that we shouldn't OBSESS about amplitude. For sure not. The car can still drive fine; timekeeping can still be fine. But we should not be dismissive of it, either. Where I'm 100% with you is that we should not looks so much at the fully-wound and dial up (DU) amplitude. But rather at amplitude after 24h and in a vertical position. John always posts the Omega specs and that's all they care about. They want to know if amplitude is sufficient in the least favourable moment. There's no point in having 300+ amplitude at 0h/DU if it drops to 100 at 24h+vertical -- maybe less likely, but just to make a point. When I worked on my tiny tiny Omega ladies movements from the 50s and 70s, I'd go from 290° at 0h/DU to 190° at 24h/vertical (a loss of 100° !). And Omega spec asks for 170 at 24h/vertical. Do the math and you'd hope for at least 170+100=270 at full wind/DU. Conversely, now imagine you "only" get 240° at full wind/DU -- you'd end up with 140° after 24h/vertical. I'm sure timekeeping will be affected. In fact, even when going from 290° 0h/DU to 190° 24h/vertical, my delta between positions doubles -- that is timekeeping. NOTE: above, I refer to tiny movements that only have a total power reserve of 30h, so at 24h they are running quite low on power. You won't have that issue much less with higher power reserves. OK, now that I've put myself out there, I'll go into hiding2 points

-

2 points

-

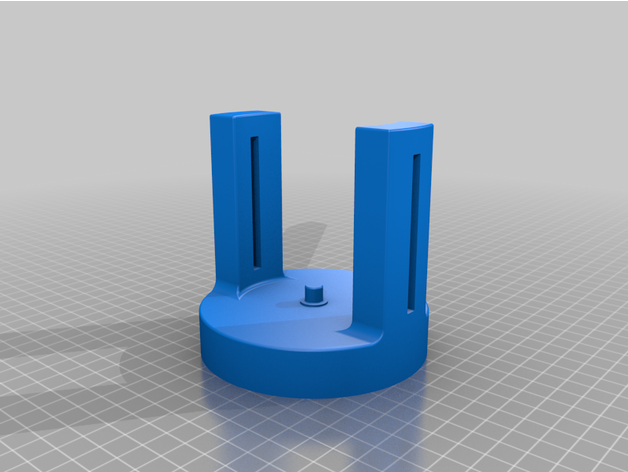

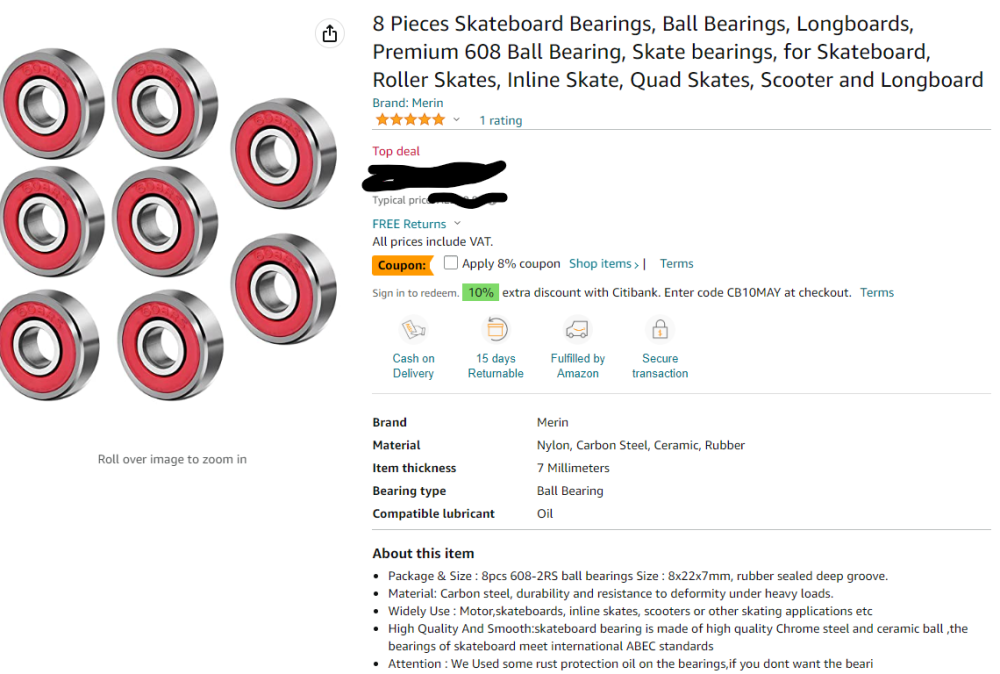

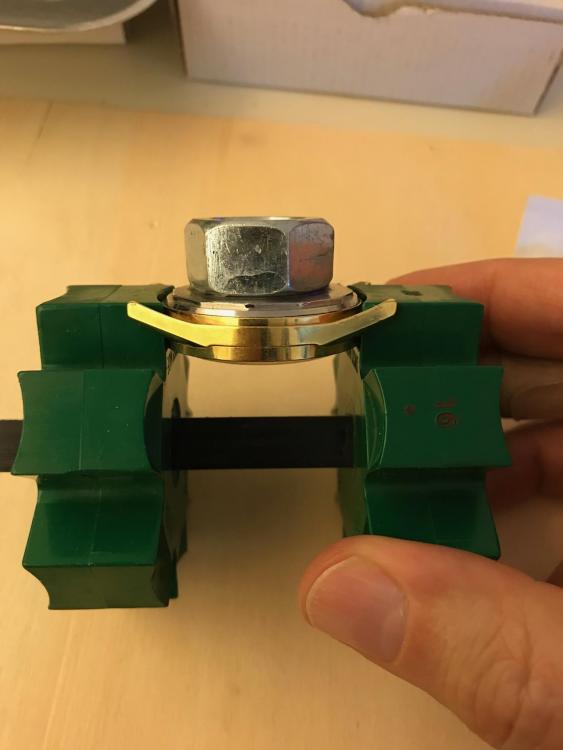

God day, I have designed a 3 part jig for adding a sunburst finish to a watch case restoration available here: 1) Jig: 2) Anvil: 3) You will need 1 of the the following bearings: Here is an example (not my watch) of the type of finish this tool is designed to achieve on the case of the watch: Summary A tool to add a sunburst finish to a watch restoration. you need to add a bearing (see Below) to the anvil and then attach this to the jig, this should allow you to turn the watch 360 degrees. Then using a needle file (sideways) in the groove(s) you can apply a sunburst in a sawing motion as you turn the watch. Details of bearing to be used: Skateboard Bearings: 608-2RS ball bearings Size : 8x22x7mm, rubber sealed deep groove. Available on amazon1 point

-

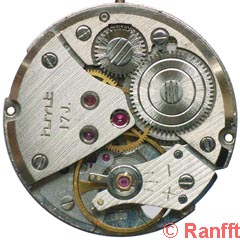

one of the ways to identify watches is with the fingerprint system. Need one of the books that has the fingerprint system in it like the bestfit book and you need the size in 19 lignes. Then ideally we need all the setting components I can only see the setting bridge but let's see if that's enough see if there's anything close. also I assume you looked under the balance wheel to see if there were any markings there? then in the future because you know what the fingerprint system is you can have all the setting parts of their easier to see. I think may be perhaps? Notice the exact nature of the answer when you look at the watch don't worry about the plate layout you only worry about the wheel layout is the place can be shaped differently I think were close but I'm not sure how close notice there's some variations and it's a slightly smaller watch but not much so it's very likely in the same generation may be http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Unitas_429 okay I give you a task below not 100% sure I went back to the main page looked at something farther back like this one a notice of the setting parts are similar http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Unitas_309 so basically you're stuck going through all the watches of this manufacture if you agree that it looks close looking at all the ones that are labeled 18.5 because they don't seem to have a 19 and see which one most closely matches yours. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk then there's another way not as exact but it might get you close that is if the of the measurements of the stem. You can also do the same thing with the balance staff but that means you'd have to disassemble something that shouldn't be disassembled. So you look at the link get the stem measurements see if there's anything close https://www.windingstems.com/product.php or if you're lucky someone will see the discussion come along and tell us what it is which is usually what happens. watch-ligne-size-chart.pdf1 point

-

what if I give up and you're right amplitude is the most important thing and with outstanding amplitude you get great timekeeping would that make you happy? oh by the way yesterday I was thinking about the group when I was at work. Why was that the day before I had almost completed and Illinois watch made in 1888. Is all wound up running lubricated and I just left it in yesterday as when the case it up but has to on the timing machine. The nifty timing machine that does measure amplitude but also looks at the watch and six positions. So I have to please six positions on a timing machine and not please this group on amplitude. I almost thought of bringing the print out home but I said I don't give a darn. At the end of 24 hours the balance wheel looked beautiful the amplitude in the pendant positions claim to be below 200°. That was assuming that the lift angle was correct and I just didn't feel like figuring out what should be. I was happy to set a Delta of less than 20 seconds. it was running a little something so I played with the mean time screws a little bit move the regulator and I'll see how fast or slow it's running today. But I was thinking there I was really worried about timekeeping and didn't give a darn about amplitude obviously there's something wrong with me. Yes amplitude is important but a whole bunch of things determine the amplitude of the watch. Then depending upon things like over coil versus flat hairspring you have the regulator pins. We have isochronism wonder if that's important? It would actually be just much better for watch would keep constant amplitude versus a high to low amplitude. Because of the constant amplitude you can that much more constant timekeeping versus amplitude timekeeping variations. This is why when you look at the technical specifications of giving a maximum amplitude because anything more bad things happen. They like to see a low amplitude but that can be quite low depending upon the watch. But the silly manufacturers still want to see timekeeping.1 point

-

yes isn't it nice when you see a straight line on the timing machine versus lines that wander around a little bit. it'd be interesting to know the life of each of the watches like maybe this one never ran at all and is in really good condition or basically new condition. Plus the factory was there any variations on the output quality from the factory? Or even was or any quality control where maybe this one wasn't as nice as some other one and maybe we should fix it make it better before it leaves or who cares. running at 36,000 versus 18,000 is a different problem or benefit then amplitude. If you look at the discussion groups for watches running at 36,000 the problem is your watches running twice as fast as a normal watch at least at the time now of course we have 28,000 watches are quite common. The problem becomes things like the escapement there a lot of concerns about the lubrication there. Plus if you're running twice as fast you end up having to change the mainspring because you're going use up your mainspring per hour and half the time so there's an issue with that there is additional mechanical issues that come into play not sure that the entire watch will disintegrate because only the balance wheels going superfast. But the concern always was with the escapement. Although there are some amusing reasons why 36,000 or faster is a good frequency but that would open up another theoretical can of worms that I don't want to deal with. In a case I saw a reference once on a watch patents over higher frequencies and they hairspring can have a good vintages and it even comes with a really nifty complicated formula to explain that.1 point

-

No. A brief clean in IPA doesn't do this. They must have been already loose. You often find the shellac on older movements dry and cracked, and even a short time in an ultrasonic (in any solution) shakes it off. Is the much play in the pallet fork pivots?1 point

-

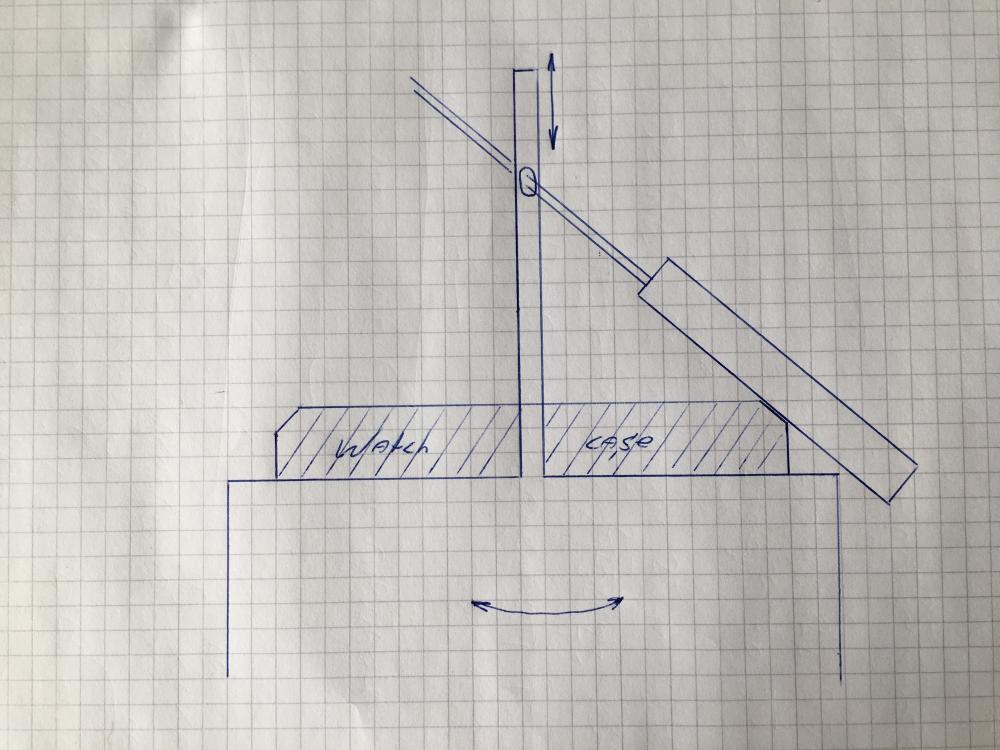

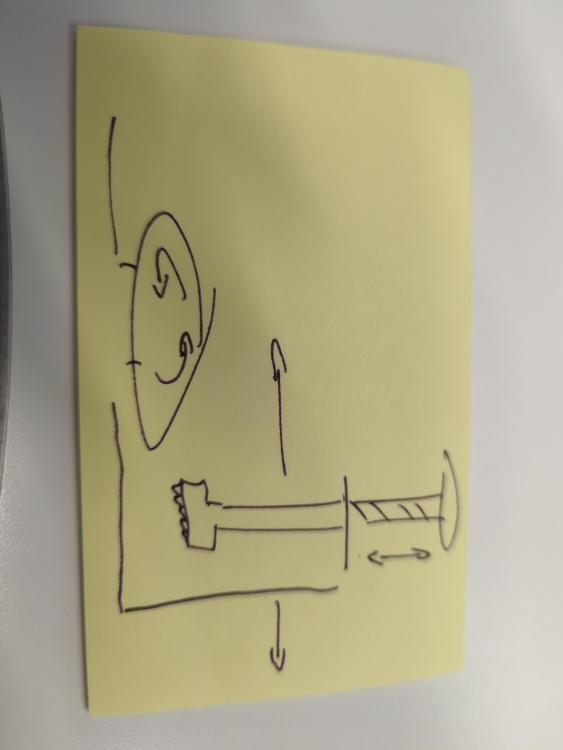

I've been contemplating a design, but never got any further than that , which is based upon a Lansky knife sharpening system, which I own for keeping our kitchen knives (razor) sharp. It's basically a clamp which clamps onto the back of your knife. Both "legs" of the clamp (on either side of the knife) do have equal degrees holes which allows you to sharpen the knife-edge, on either side, to a desired angle. Different grits grinding stone can be attached to a rod, and the smooth rod slides in the clamp-hole and the grinding-stone rest on the knife's edge, assuring a constant angle. There is a commercial (bla-bla-bla) video on Lansky's website: https://ad.knivesandtools.eu/en/pt/-lansky-professional-sharpening-system.htm so you get the drift of the system. For knives this system work excellent. The whole idea is to keep the grinding stone at a constant angle to the to be grounded surface. Now I'm just brain-storming; if it was possible to make an in high adjustable center-post (which would act as one of the Lansky's clamp-legs), the angle of the grinding stone can be seamlesly adjusted and set constant. Either the center-post has to be able to rotate, or as with your design, the table or anvil has to be able to rotate around the center-post. I made a quick and dirty sketch for the basic idea; If the table (or anvil) can rotate, the center post could be made of a threaded rod, "fixed" to the jig, but you have to be able to adjust the height (to obtain the correct angle) and to lock it in place (with a counter-nut?). Perhaps a higher base of the jig with a nut for the center-post included? This still leaves the centering and fixating of the housing Also, my idea is an inconclusive expansion on what I already have, namely the Lansky grinding stones. But even the coarsest grinding stone in my set, is too fine and too wide for a sunburst. It has to be a needle-file, but with a smooth end so you don't wear out the hole in the center-post. Feasible of just wishful thinking? EDIT; what if when you clamp the housing from the inside ?? Kinda a head of a lathe? With a 3-claw lath-head you can clamp on object inside the claws, or you can clamp a hollow object with the outside of the clamps. Of course, in a lathe head, all 3-claws are moving simultaneously, ensuring centrality. EDIT EDIT; One could perhaps also have a fixed center-post, fixed to the jig, and make the table adjustable in height (with shims underneath the bearing?)1 point

-

Thanks for the feedback, I'll tackle your observations one at a time This is correct yes the watch sits on top of the anvil, I secured mine with a lump of rodico. I contemplated integrating some kind of movement holder (like a 4040), but when tightening it you would draw one half of the holder closer or further away from the other, hence, moving the center point of the watch relative to the center of the anvil causing it to gyrate as it turned and guaranteeing that you would have an off center burst. Yes the slots are there to ensure that the individual strokes that are made to make the burst are always in line with the center of the watch (taking the above into account), this ensures the constant angle (as long as the watch is correctly centered [+/- ]on the anvil) This is the hardest bit, I incorporated a cross-hair on the anvil to make it easier to judge the watch case centricity relative to the center of the anvil. My hope is that this will reduce the error as much as possible, but I agree that it is still dependent upon human judgement. But, that being said, I think and error created by doing it this way would be minimal and not noticeable, especially compared to manually going at it. I did contemplate catabolizing some kind of self centering mechanism like those used in a diving watch case-back remover (see below), but I thought that this would be overkill especially as I think the manual method above (whilst not technically perfect) gives the best cost/benefit ratio. However, I am more than happy to try improve the design if you have a better solution I was also toying with the idea of using some kind of pusher arm (like on a hand setting tool) on the same or a similar jig to make a radial finish... but my wife was already upset with me for spending too much time 'playing' on my CAD software, so that's an idea for another day... but happy to take any ideas that are out there! Something like this???1 point

-

Haha. You joke watchie, i know for sure you do better than this. Its good to see you posting more. John tells us ofen that high amplitude is overrated and obsessed over by some folk. I think of it like this, compare a super car running at high revs to a voltswagon golf tootling along, which car will break down first ? Or an athlete giving 100% to their sport compared to joe bloggs going about his everyday so so life, which person will most likely be injured first and most often ? Both first examples are capable of high amplitude and in both cases the steady goer will last longer and wear out slower. I like to apply those analogies to high and medium amplitude. Agreed that a high amplitude is the indication of strong power and performance but to what ends. So my question, is it a good idea to strive for every bit of extra amplitude possible to attain the movements maximum amplitude knowing that the components are working harder and may wear out sooner ? I understand that luck can step in, but i look at figures of 230 - 250 a couple of hours after full wind and sometimes 180 -200 after 24 hours and think yep thats fine its still keeping accurate time. I dont see the point of pushing a movement to its limits, maybe thats just me. Just to add to this, when I've found that a watch has ended up with high amplitude, i make a note to stop short of fully winding it . As long as its making just over a day running time while being worn.1 point

-

Thanks again! I like it too! I sometimes call it my Royal Oakski or Nautilov because of its Gerald Genta "inspired" octogonal case and very Nautilus-like hands/hour markers.1 point

-

We were talking loss of amplitude due to wear in used watches, nevertheless, I should have specified this technique is an option after you have eliminated all other possible causes of amp loss.1 point

-

Oh wow, thank you so much for your comment! It made my day month. I will admit that I had two running 2414 movements and was able to pick and choose the best parts. But it was a tough journey. So the gratification of wearing it and seeing the TM is immense.1 point

-

1 point

-

It maybe is, but thats really a cheat way to compensate for other reasons why that movement has low amplitude instead of finding the actual reason Unless that is the actual reason.1 point

-

Er what was the question again ? . Ah yes the importance of amplitude. The short answer, it is and it isn't Oh wow pivots just fall off, on their own like ? Thats a bummer, this hobby is definitely not for me then. Anyone want to buy some watch stuff ?1 point

-

It was just a warning regarding the cheap ones that use a collar to tighten the jaws. The design looks similar to the Bergeon arbor vice they are really rough inside the jaws. The jaws aren't curved to hold the arbor snuggly and only grip at 4 sharp points. I was actually in the middle of stripping loads of barrels when i noticed the question so i thought a real time test was in order . Under magnification there was definitely some scratching up after some rough newbie impersonating1 point

-

Just bought this PinVice; 0 - 1.5mm. It has two bits, one with internal rounded fingers and the other bit has the edged fingers. https://www.cousinsuk.com/product/single-ended-round-with-2-collets-horotec?code=P58276 So far I've only been using it to hold a 2824-2 winding stem. Seems nicely made, works well and you get "two" for the price of £8.50 excl. VAT. Depending on your location, members Waggy suggestion seems price-wise okay. However if you live in the economic suicidal European union, by the time I get it in my hands (due to duties and registration fees) it cost me over $34 ....... That's the reason for me buying the Horrortec1 point

-

I always used to worry about that before I got my arbor holder. With the arbor holder, I never saw the slightest dent och scratch on the arbor even after having pinched it very hard.1 point

-

Hi, Just replaced a buzzer on my Seiko H601. The replacement piezo actually came with a Seiko quartz chronograph movement and I had saved it just in case. It was the correct size, 18mm diameter and had an array of glue dots on the back. I managed to fit it to the case back as follows. Clean old glue with metal scraper and fine abrasive (I used Scotchbrite grey). Final clean with solvent. Place disc in place and put three pound coins stacked on top for a little downward force as the glue melts. Make sure the disc doesn't change position. Put in oven directly on the rack and switch on at 200 degrees centigrade. Let oven attain temperature and then switch off to cool naturally (I opened the oven door and left for 30 minutes). When cooled the disc appears to be stuck perfectly and the piezo output is now very very good. Hope it helps. Steve1 point

-

Absolutely pinvises especially cheap ones are rough as hell inside and can easily scratch up a polished arbor.1 point

-

1 point

-

Another question; what's the amplitude of the watch with and without the chronograph engaged? It seems, according to your information, that it runs for 3-5 hrs and then it stops with the seconds recording hand just at 58seconds, just at the point whereby the running works experience an additional load. In simple terms; are the running works powerful enough to drive the chronograph or is it running out of steam after 3-5 hrs and can't bear the additional load anymore when it has to drive the minutes-recording wheel at 58 seconds? What's the amplitude when you disengage the chronograph after it has stopped running (3-5hrs) and what's the amplitude at that point, after you zeroed the chronograph, engage it again and measure the amplitude between the 0-58 seconds? You can also visually observe the amplitude of the balance wheel at the moment when it has to drive the minutes-recording wheel. Perhaps there is nothing "wrong" with the chronograph. Perhaps it's a combination of a "heavy" running chronograph, and a not strong enough running work, both in desperate need of a proper service? Which leads back to JohnR725 question above plus; what was the complain / reason when/that you got it?1 point

-

Stopping at just before 60 indicates something with the minute counter. The minute counter wheel needs to be absolutely free, and unlubricated; you should be able to nudge it forward or backward until a tooth just comes over the jumper tip and it should snap into place cleanly under the jumper tension. The jumper itself- clean, totally free, and the jumper spring should be nice and straight with the jumper removed. The sliding gear should be set so that a tooth on its wheel points directly at the center of the chonograph runner. If it's off a little bit counter clockwise the finger on the runner can jam (though hard to happen on this caliber). One thing I've encountered on this caliber is someone in the past screwed down the chronograph bridge without checking that the intermediate minute counter wheel has its pivot in its hole. That wheel is unjeweled; if you screw the bridge down in that condition (and don't break the pivot) it can make a divot in the bushing, sometimes slightly closing the hole. This can cause enough friction to to cause the minute counter wheel to not snap cleanly tooth to tooth with the jumper, or, even stop the watch with the chronograph running. Have a look through, and try to post some clean close up pics of the chrono mechanism.1 point

-

1 point

-

Cylinderhöhenmasse, it's for measuring the cylinder height in the watch for cylinder escapements. Never seen one before.1 point

-

Good day everyone, I just completed a watch for my wife's uncle as a gift, its a Seiko 6309 which was in pretty poor condition and a non runner for obvious reasons. I had to replace the crystal and the ratchet wheel which was completely corroded (see pictures below) I also had to replace a screw and the cannon pinion. A quick lume on the hands and polish the case and it was good to go. Let me know what you think: Before Front: Before Movement: Corrosion damage to ratchet wheel and screw(s) Here is the finished watch along with the time graph after 24 hours:1 point

-

The Bulova 11DP is a licensed version of the Citizen 0241/1802 series of movements, much like the HMT 0231 which coincidentally I've just been looking at as it was in the HMT Slim I posted about earlier today. As you can see, they look remarkably similar, with only a slight variation in the plate shapes. Some of the older HMTs have almost identical plates to your Bulova. My suspicion from the time grapher pattern is that the instability might be related to the escape wheel. Did you remember put a tiny amount of oil on the palette jewel faces? How clean is the escape wheel. Can you examine it under a microscope to see if it looks to be running square and true, and not worn or dirty. I vaguely remember reading somewhere that the HMT version is rated as +/- 20 sec per day, but I've generally managed to do slightly better than that, even with some of the very rough and ready, well worn specimens I've looked at. The fixed stud regulator is a little bit of a pain, as it obviously makes getting the beat error down somewhat of a faff. Parts from the HMT *should* probably fit on the 11DP. I did cobble together a Citizen version with some HMT parts at one stage. Also there are several variants of the HMT version, and all of the parts seem to be interchangeable between those. I make no claims for this being a good idea, but if you are struggling to find parts, that might be one avenue to explore.1 point

-

I bought a nice vintage chronograph watch with a 7733. Nothing fancy but the watch was just appealing to me and a good start in jumping into the topic of servicing a chronograph. So far I did only one, which was a Heuer pocket watch. So I wanted to open the case back with a very trusty old stainless steel opener called Vari-Matic. It did not open, when I tried to clamp the case into a vice and use force with both hands... the HANDLE of the steel opening tool was breaking away! Watch still closed ! I was desperate and after a while chatting with a friend working on cars he explained me that he was wielding nuts to cracked parts to use a ratchet..hmmm..ok wielding might not be feasible but i was trying it with superglue. I took a 23 sized nut sanded it flat an glued it on the back using superglue and let it sit for a couple of hours over night. This is how it looks like: Next i clamped everything in my large vise and used the ratchet: Voila it was open: And the best thing was that i did not even need massive heat to remove the superglue but dropped the nut and caseback into acetone for about 3 hours and it was gone. No residue just wiping of the back. See the pic below.....now i can service this watch. I hope this helps someone if he has no other option beside damaging the watch - give it a try - it worked perfectly. Am I nuts or are there others out there doing this?1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)