Leaderboard

Popular Content

Showing content with the highest reputation on 05/19/23 in all areas

-

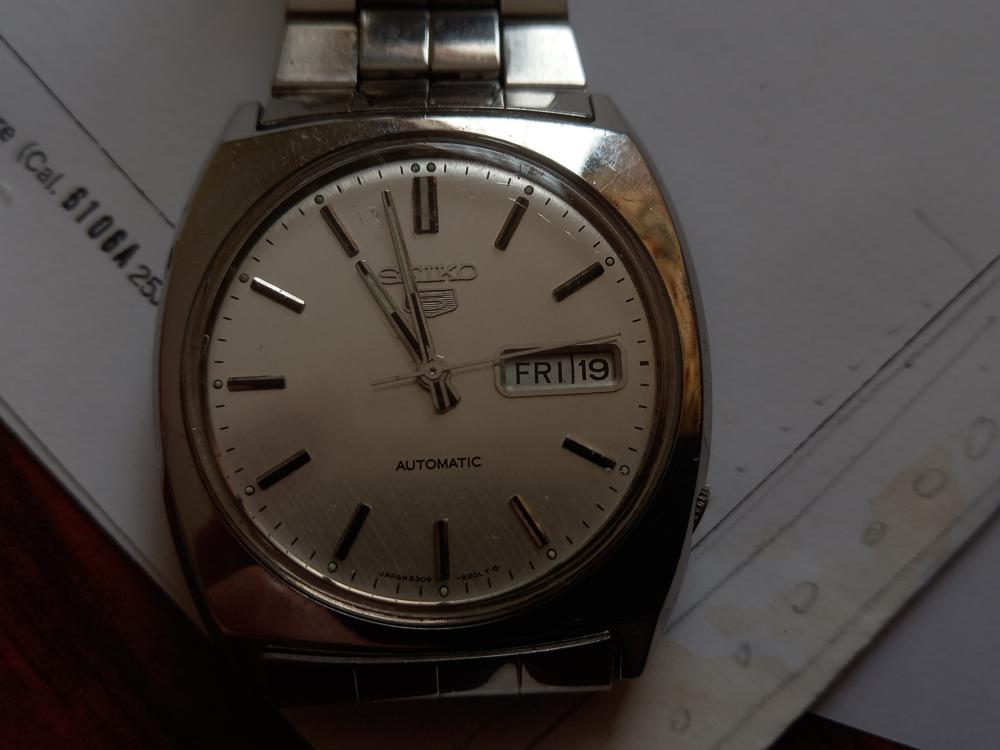

Well, I've done it. Purchased a very dead Seiko 6309. Obtained two, also dead, donors. All looked horrendous on purchase. dirty, screws missing, only one very dirty case. Disassembles all. Checked every item for condition. Picked best. Assembled, oiled. Everything checked on install before moving on to the next part. Biggest problem was balance. All had motion after a while, but none kept motion. 3rd one worked. Demagnetised, Timegraphed, took an hour (+3s, Amplitude 168 - can't get it better, beat error 0.3). Used case from original purchase. Strap from 7009. It works, been wearing it for 3 days now. I know it's not much, a low end watch. But I did it. I've done other automatics, but none have actually maintained their beat without having to be wound manually. So, I'm here...ish. Going away in a few days for my 75th birthday. Back to the enjoyable hobby on return. Regards and thank you to you all.3 points

-

I found that jam jars, mayo jars and mason jars are so thick that insufficient ultrasonic energy gets to the parts. I've switched to using stainless steel jars meant for storing tea. The thin stainless walls allow more energy to pass through and clean stubborn grease. Especially inside the barrel. And another advantage of these stainless jars, it seems to prevent evaporation of the volatile cleaners better. No matter how well sealed a mason jar is, benzine seems to be able to disappear from it.3 points

-

Not passing the exam made it impossible for advancement, no matter my personal skill level. I became one of three in the country at my particular skill, however I could never be promoted to be in charge as I 'was not qualified'. My own fault. If I had taken the exam earlier in my career, before the change, I would have been able to move up the ladder. Never bothered me as I was happy where I was.2 points

-

You only need a tiny bit, I always used the flakes which are brittle when hard so I would just break a tiny piece off. you would be surprised how little you need. The guy in that video was using far to much that is why it always looked a mess.2 points

-

Heat a piece of shellac in a flame until melty, then stick a toothpick or sharpened pegwood in and pull away. When you get the pull-away speed right, you're left with a filament of shellac attached to the wood; break it off a couple of mm from the "handle" and you have an all-in-one shellac holder/doser/applicator.2 points

-

2 points

-

That is a Chinese crown set. They are all 0.9mm tap. The +2, +3 refers to the length of crown pipe. If you need 0 8mm tap, you have to get individual sizes from a supply house.2 points

-

In similar fashion to ASUAG and SSIH, MSR was the grouping of four respected Swiss watch companies in the early 60s Buser, Vulcain, Phenix and Revue. I cant remember what the MSR stands for though. Not sure why USA ?2 points

-

Do not use any oil on this wheel. The wheel has to slide completely free. Oil keeps the wheel sticking on the plates.2 points

-

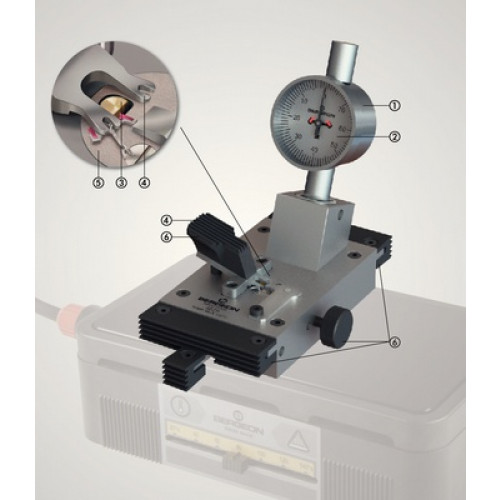

Neither did I Well, if you insist on only having one jewelling tool I'd go for the Seitz. As you say, it has the reamers, but it only has a couple of anvils, and that is oftentimes a problem. However, some of the larger flat Seitz pushers can double as anvils, so it isn't all that bad. So yes, go for the Seitz! Anyway, make sure you get a set in as good a condition as possible with as few missing pushers as possible, and make sure the handle for the reamers is included.1 point

-

Google MSR watchmakers wiki. I have about 10 vintage manual wind MSR pieces.1 point

-

what you're going to find on this group is a sizable percentage of the people have some form of dyslexia. It may be mild enough that they don't grasp they have it but they probably do. I had seen a book once that I wasn't happy with it was explaining where if you took dyslexia out of the equation having dyslexia is an advantage. Then gone through and analyzed and worked out categories and based on the category would say the likelihood of what people would do and a lot of mechanical skills engineering skills even doctors will have dyslexia haven't you ever wondered why doctors can't spell. My favorite was where almost everybody at MIT has dyslexia. Oh the book why was I not happy with the book? The purpose of the book was really to show parents today that your child has a lot of potential look at all these people with dyslexia basically everyone it's a millionaire probably has dyslexia everybody at MIT has dyslexia doctors have dyslexia all kinds of famous people have dyslexia so my interpretation is if were not all millionaires we suck. Because the book assumes that it's today where kids hopefully will get help for dyslexia unlike when I was in school where once they figured out the problem it was too late. Oh and then written tests? When I was school in Switzerland he said don't worry about the test and I didn't worry about it because I assumed I would fail the written which I basically did. Fortunately I was number two on the practical exam. Unfortunately one of the students that didn't do well on the practical was a mechanical engineer and he aced the written exam which meant the average overall score dropped me to fourth place. But who cares I did really good on the practical.1 point

-

Try this for identifying parts : https://www.timezonewatchschool.com/WatchSchool/Glossary/glossary.shtml1 point

-

1 point

-

1 point

-

I learn from the videos and understand a great part of what is shown and explained. I now am able to follow Chronoglide and Alex Hamilton easily. I could give a verbal explanation of the systems in my own words. However I really struggle to remember the names of the parts of the watch and tools used. Even in the above post I had to look up the name of the thing that oscillates. Oh that's right, after looking it up I was able to say, 'the balance'. That's how bad it is for me. I spend time, when doing these posts. looking up the names of the watch parts in Mark Lovick's course 1.5.6 'Identifying watch parts'. Remembering the names of the tools is an absolute pain. I want to look on ebay for something and can't for the life of me begin to think of the name of the item. Infuriating. But I can use the items. Love the hobby though.1 point

-

The melt-on-stick thing really does work. I learned it in school, and have done it ever since and I adjust escapements all the time.1 point

-

Depends on the inner net height of your barrel. Normal with that size you will use inner height minus 0.1 mm, but minus 0.2 will do no harm. The mentioned B-U springs have thickness 0.20 Frank1 point

-

Hi, the height is of small influence to the momentum. It contributes directly, while the thickness contributes with its cubic value! However a too low blade may wobble in the barrel. Many B-Uhren use H=3.5 mm. You will find them on Ebay(german) as Laco or Lange mainspring. Frank1 point

-

you're doing something wrong is the problem. I have a link below shellac mixed with alcohol can be used as a finish on wood. You think a suitable finish for wood should have the properties of never hardening? as a guess you using the wrong form of alcohol. The proper alcohol will dissolve the shellac and evaporate and leave it dry. I was at a lecture once where someone was explaining about mixing shellac with alcohol to make a glue to touch up existing fork/roller. Not as a replacement but just a touch up. Then the other reason to do it is it does allow you to apply it precisely on stuff like the pallet fork or the roller table. But you do have to allow the alcohol to evaporate otherwise it bubbles when heated up. then yes you should heated up the get of the properly melt and then harden up the way it's supposed to. your definitely better than I'm doing. I've seen some of his videos in the past when somebody said look how wonderful this is and I really can't stomach the watch the entire video as short as it looks its way to edge just isn't my thing. But a lot of people in the group slinky's grades and get really annoyed if you suggest otherwise. But it does present the problem with the Quoted section below unless you can point out the exact second were he says that I refuse to watch the video. the problem is escaped that adjustments may require or very likely require you to make more than one adjustment. You're going to be unlikely to make a perfect adjustment the first time. It's one of the beautiful things which shellac you warm it up you can move things around you let it cool down it's nice and hard again. oh and another minor little mistake I believe he said knowledge is required which I agree with but the actual tools to make an adjustment are cheap. So I wish I knew where he purchased will blow because it's definitely not cheap. This is the kind of tool it's really nice if you want to make precise adjustments to your escapement. then it's been updated probably has a higher price in school we use something similar to this to adjust the escapement. As I said it's time-consuming it's not just put it there in your good to go you may have to adjust it which is why shellac is beautiful and can be heated up and moved around etc. https://kmtools.com/blogs/news/all-about-shellac-finish1 point

-

If you come across Bigfoot, please get some decent photos and save them on the cloud.1 point

-

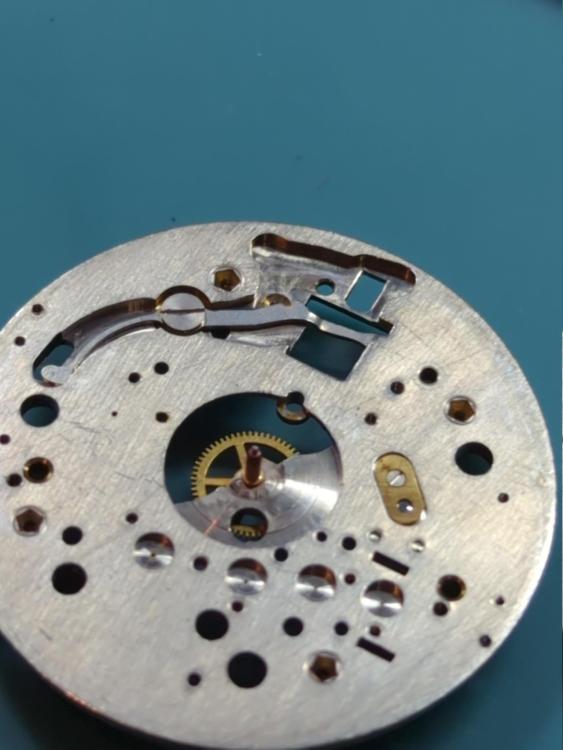

Thanks for your kind comments, fitting the bridge was difficult as everything has to line up together and all at the same time, this is where my microscope was invaluable, although there were a few swear words and more than one coffee break involved . This was a strange one, as it was fixed to the main plate and couldn't be removed, please see picture: Dial side showing wheel: Other side I tried using the ultrasonic to see if this would encourage the wheel to come out but in the end I decided maybe it was a strange design and not supposed to be removed and better to leave it alone as it was moving freely and no obvious signs of damage or corrosion1 point

-

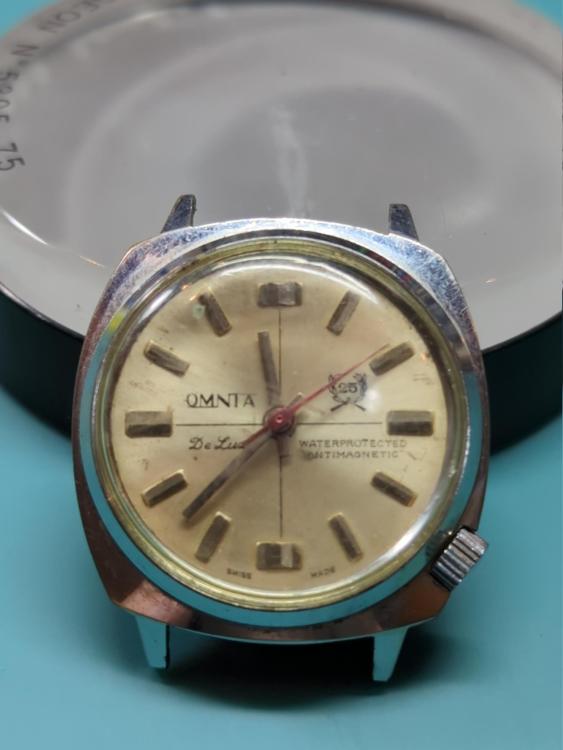

Good day, I have a new OMNTA watch to add to my collection, this watch was one of 16 purchased for £32.00 from eBay, which works out at an average cost of £2.00, so also qualifies for the 404 club The watch was a non-runner and it looks like this resulted from a broken pinion on the second wheel, also, I had to use my staking set to reduce the arbour hole on the barrel bridge as there was way too much play. Finally, the bridal was broken on the mainspring - so after replacing the wheel and mainspring (fortunately there was another watch with the same movement in the lot of 16 which I used as a donor - lucky!!) and the bridge repair here are the before and after pictures: Watch front view (before:) Here is a picture of the movement - I just noticed that you can see the orange smudge of corrosion in the top hole to the right of the ratchet wheel and just under where the click screw is, this is where the wheel pinion was broken and had to be replaced, it looked like corrosion on the pinion, but there was little other evidence of corrosion in the watch: And here is the dial out of the case, this needed a little work, and was better in the final restoration but still not 100% and I didn't want to push my luck and make it worse: And here is the finished watch:1 point

-

1 point

-

If you are using the cold shellec way you will need to heat the tool you are using to harden the shellec. Heaven knows why anyone would want to do it that way. A word of warning I watched his video right through and he uses far to much and how he puts it all across he must think watchmakers who have reached the standard of being able to set pallets stones were born yesterday. He gets a from me.1 point

-

1 point

-

Got the little shit out (three carbide drills shattered). It's a left hand thread! Sort of explains how it got like that I suppose. The arbor has a square top so I didn't think a reverse thread screw would be needed there? Are there left hand thead die plates for making replacements for something like this?1 point

-

I try to keep away from mainsprings that aren't modern alloy and definitely stay away from NOS blue mainsprings because they are prone to have rust on them, which you can't see and this will lead to micro=fractures and breakages. If I can't find anything else for a vintage pocket watch, then I have resorted to using blue mainsprings, but as a last resort. Also blue mainspring sizes sometimes don't directly translate in strength to modern alloy mainspring sizes. I tend to come down half a strength when using an alloy spring as opposed to the original blue spring. A strength is 0.01 mm in the thickness of the mainspring. Half a strength is 0.005 mm So, if I come across a vintage watch such as a Felsa 690 with the original spring and slipping bridle, I will always replace it with a modern auto spring without the slipping bridle. Some may want to keep originality, but I would prefer a good amplitude!1 point

-

I don't suppose you want to take the back off so we can see what's inside? then if you ever do take the back off you want to be really careful as getting anything resembling replacement parts for this is almost impossible. They were made a huge quantity and they're just really difficult to get parts and they tend to be very expensive. I also swiped an image off online the constellation back's are supposed to have that inside. Maybe somebody swiped it for the gold I didn't realize they came off? Then for the crystal it looks like flat glass which means almost anybody could put that in but you don't want to trust that movement anybody as I said getting it fixed or dealing with problems with it will be a big issue. If you want the actual crystal number we would need the number off the inside of the case back as I don't see a serial number on the outside anywhere in your pictures https://electric-watches.co.uk/makers/omega/omega-megasonic/1 point

-

What a dilemma! I thought this Raymond Weil case was all steel. As I went to polish the bezel, the chrome plating started coming off revealing it's true brassy colour! Customer is understanding but really upset. Can anyone recommend a silver/chrome plater who might be able to plate on brass? I've checked all the top lads in Hatton Garden and they're not willing to take it on. Can anyone share some wisdom and recommendations? Thanks in advance, Hiren.0 points