Leaderboard

Popular Content

Showing content with the highest reputation on 05/18/23 in all areas

-

I've only ever seen those used in case backs to push either the movement, or more commonly the movement ring forwards towards the crystal to hold things nice and snug when the back is screwed in place.3 points

-

they should go in the opposite direction of the direction that the mainspring is pulling in. Because otherwise you wouldn't want the mainspring unscrewing it in the barrel. The only problem is a lot of times are on really really tight fortunately you have the two holes. I've had some typically without the holes and I've given up trying to unscrew it. Which is a pain for lubrication then because it's not really accessible enough to try to get the oil the flow in their not good at all. But at least yours looks like it's in good condition.3 points

-

If you are using the cold shellec way you will need to heat the tool you are using to harden the shellec. Heaven knows why anyone would want to do it that way. A word of warning I watched his video right through and he uses far to much and how he puts it all across he must think watchmakers who have reached the standard of being able to set pallets stones were born yesterday. He gets a from me.2 points

-

Most things fall on the spectrum of art => science. Brewing kombucha is pretty far on the left, and rocket surgery is pretty far on the right. My take is that watchmaking is fairly unique in that it's simultaneously on both ends of the spectrum. There are parts that are deep on the far right, and parts that are deep on the far left. Things that are on the right hand side of the spectrum, need to be done a particular way very specifically. Things on the left you can do however best suits you for purposes of simplicity, resources, marketing, or what have you. When I see a dozen different options for (pick a thing) with equal claims to success (i.e. cleaning method), it appears clear to me that the position of that element is on the art side. If there's only one way to do something (turning a balance staff), it's clearly on the science side. Most of the things you listed on are the art side of the spectrum. Some things are movement-specific science-side. It's a different take on the curve you invoked, but along the same line of thinking, and how my mind tends to work around these sorts of things.2 points

-

2 points

-

2 points

-

In similar fashion to ASUAG and SSIH, MSR was the grouping of four respected Swiss watch companies in the early 60s Buser, Vulcain, Phenix and Revue. I cant remember what the MSR stands for though. Not sure why USA ?1 point

-

I can't remember where I originally downloaded it from. More than likely Mikes website at MyRetroWatches.com. He has an impressive library of manuals available for download. Here's a copy of it.Seiko-6138A-Service-Manual-Colour.pdf1 point

-

Hah I just came back here because I watched Mark's re-assembly video of the same watch, and what do you know: I'll check out yours as well, thank you! Also, I have the 6139A and B manuals, but the B is just an addendum and doesn't have that nice image you posted. Any chance you have a link to a copy of that manual?1 point

-

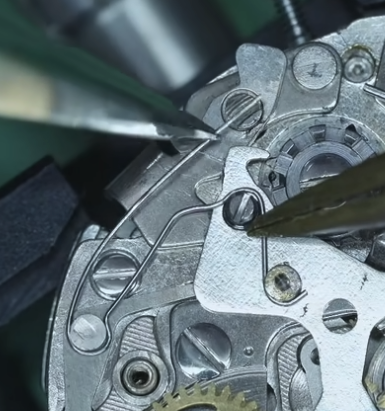

Interesting. I was using Mark's disassembly video as a reference, which shows it around the other post and I figured that would also explain why it was so misshapen: And sorry for mis-naming it. I'm still learning all the bits and bobs in here! I also (embarrassingly) forgot that we're looking at the back of the movement and got the flyback and start buttons reversed in my head.1 point

-

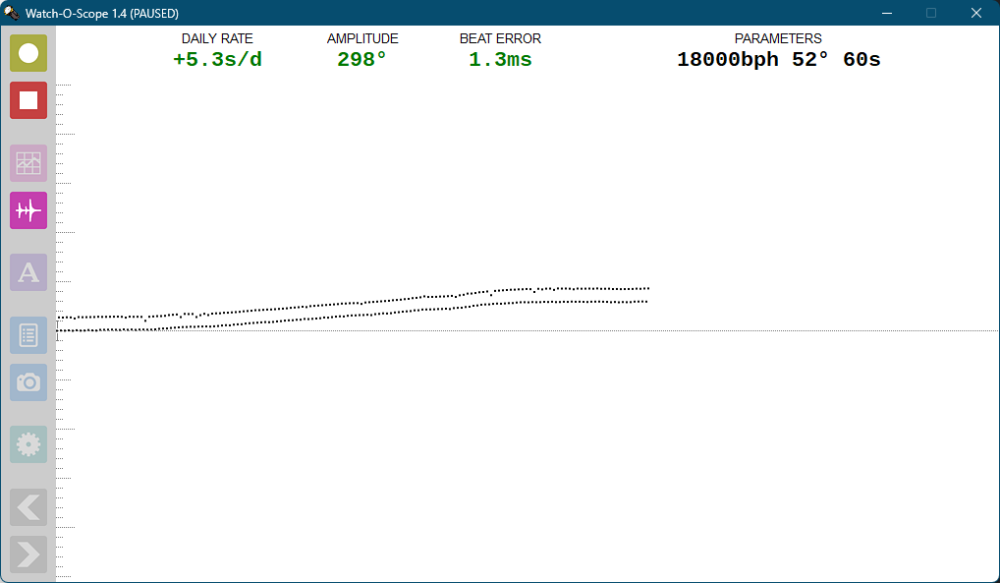

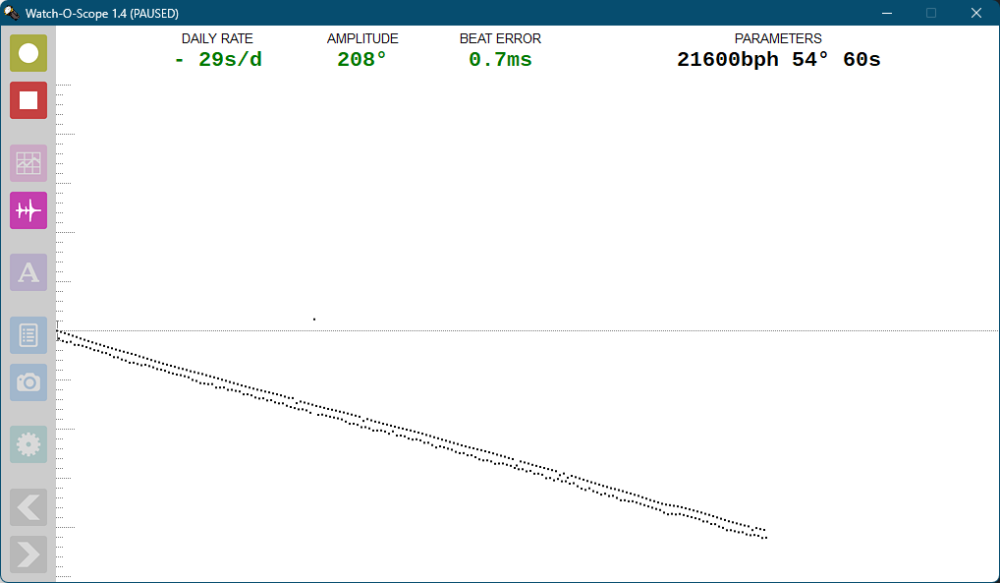

Finally remembered to check the timegrapher before disassembly! Looks like a solid starting point. More disassembly. Taking off the automatic works, the first thing I notice is different screws holding it down. An ominous start. Although right below it, we may have found the correct screw, but also one with half rusted off. I was able to clean out the slot and very gently turn it out. A little further down the movement, found a screw that is completely broken in half. I was luckily able to push on the corner of it to get it unscrewed. Dial side looked pretty good overall. And here's the whole thing apart. There's a kink in the mainspring that I don't love, so I'll be replacing that. I also noticed a cracked upper pallet jewel, and some of the bushings have a lot of wear. If anyone has resources for replacement jewels, I'm all ears, otherwise it's research time.1 point

-

The two main advantages of the Bergeon and clone base shown above are that 1). The holder slots into the cup on the base of the hand setting tool such that the pusher is perfectly lined up over the hand; you don't need to slide the holder around trying to get it exactly lined up for each hand that you put on. And 2), there is a support on the holder that will keep the center jewel from being accidentally pushed/moved when pressing on the hand. I did come across this 3D printed base, but while this would work it would it removes the advantage of not having to line up the movement and the pusher each time you put on a hand.1 point

-

I have a Chinese one that works well, in fact I just fixed the arbour hole in the barrel bridge with it so quite pleased with myself, only the second time I have tried. Would recommend the one I have. https://www.ebay.co.uk/itm/314091548925 Hopefully father Christmas will be good to you1 point

-

I won a salesman sample watch on ebay last week. Just under $20 with shipping. It arrived today and I have taken it apart to see if there is anyway for me to add in a dynotron movement to have it be a function watch. at this point its is a "maybe". If not I should at least be able to use some of the parts for other projects. Will post of progress. I have three of the divers like this so why not swap the dial. Yes, No?1 point

-

It's not how I would have designed it, but the part provides a hard platform for the pushers to push against, if it was a cushion then it could (in theory??) deflect to the side slightly so the movement was no longer perfectly perpendicular to the pusher hands and skew the hand setting. Additionally, you need some sort of platform so the pusher hands can reach the movement. Also, there is a cup on the base for the movement holders to fit in which means you would have to try and balance the cushion on this during the hand setting process introducing a whole other level of wobble (like I said it's not how I would have designed it). The hand setting device comes with half a dozen cal specific movement holders which grip those specific movements (unlike the platform), for everything else (99.9999% of all other movements ) you need the platform. The movement holders (and platform) slot into the bottom cup, but I suppose you could use a regular movement holder (eg like a 4040) as long as it straddled the cup and didn't impinge on the hand setting mechanism and the hand pushers could still reach the movement. All that being said, if you use the platform its a great bit of equipment and takes a lot of the guesswork out of setting the hands. Sorry not my best explanation ever, hope it makes sense.1 point

-

One step further The two needles inserted in the holes were too weak and one needle snapped off. Carefully with two pliers, one on the winding-square and one on the arbor, turning in this case counter-clockwise, did the trick. Nothing scratched, damaged or broken Apart from the balance assembly, all other parts are now stripped, ready for cleaning and inspection. BTW; I had contact with the seller, who's a collector and he also thinks that the crystal is the original Bulls-eye crystal. The flat piece should prevent the watch from "wobbling around" when laying Dial-Down.1 point

-

I just got one of these delivered from Ali Express on Monday of this week. I couldn't find one of the Bergeon one's in stock anywhere outside of eBay, but I just refused to pay the prices they were asking. The Ali Express version is a manually adjusted unit with a grub screw and a set screw, but it seems to work just fine. It's right at 31mm at the base so it fits in the hand press tool nicely. It seems good enough!1 point

-

You are lucky not all have holes. JohnR725 has explained perfectly on how to go about the task.1 point

-

The movement sits on top. so you have to hold it steady with your fingers, it is not gripped by the device I think the actual Bergeon version is spring loaded, but this copy uses a grub screw, so you have to manually adjust the height of the table to expose more or less of the support pin each time. To be honest I have raised the 'table' above the height of the center support pin (so you can no longer see the pin) and leave it there all the time and it seems to work fine.1 point

-

Once again, I learned something today thanks to @JohnR725. I had demagnetized before timing, but I left it on the movement holder. Taking the movement and placing it directly on my Elma Antimag yielded much different results. I wonder if having it at a distance from the surface of the demagnetizer actually induced magnetism in the movement. Now this is a service I can be happy about. And this is with the original mainspring, no less.1 point

-

This video explains the geneva stop work. The most common reason the stop work would be removed is the small tongue would break off.1 point

-

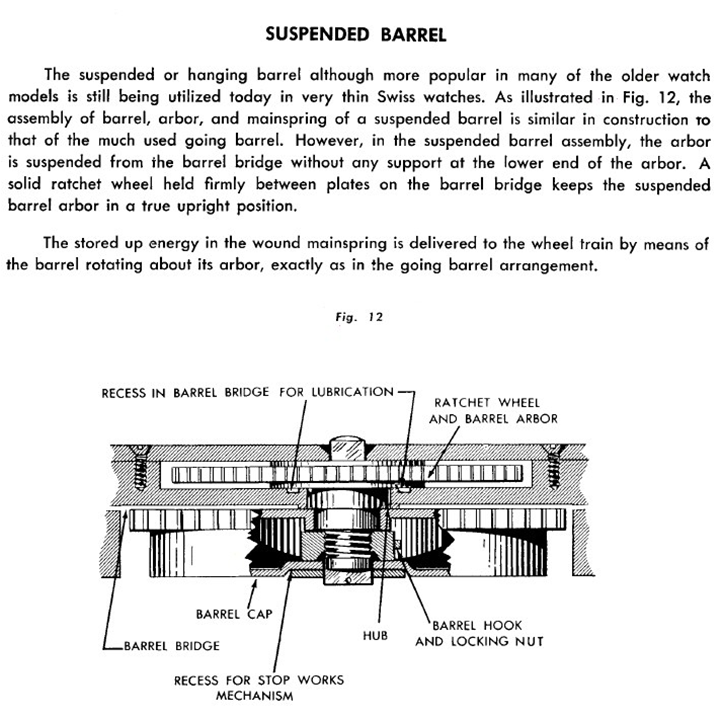

there are certain things that watchmakers like to collect. We like to collect the jewels out of the watch because are extremely valuable and someday will sell them and retire and a life of luxury. I actually saw a small bottle of jewels on eBay for the person selling them said that these of the jewels the watchmaker took out of watches. Then the next thing the steel is the stop works because we can and nobody will see that. The unfortunate reality is people of no idea what it is and setting it up can be confusing so the simpleminded watchmaker the past just never put it back in. then yes the watch will work fine without it's the big thing that the stop works did was with the mainsprings in the past the power was very on the even so you could pick a better section of the mainspring. Or basically you didn't use the extreme ends of the spring it also met when the watch came to a stop it came to instant stop it ran X hours exactly but he still had much better power reserve can zero in the hopefully middle part of the mainspring then I have a link scroll down until you get to Bullseye Crystal. At least that's my guess usually when it's in the center that's what they are although the true bull's-eye as on the website can be quite aggressive as to what they are yours is much more subtle but it still could be of manufacturing thing. It's one of the reasons I don't like to change crystals like this unless is an absolute necessity because getting an exact crystal is difficult. http://www.pocketwatchrepair.com/how-to/crystals.php as reminder a watch like this was made before people can afford to buy a Chinese or Swiss timing machines so without a timing machine and without a lot of the knowledge of understanding watches we can end up with lots of very interesting things like your pallet fork also which end up with all sorts of interesting lift angles so 59° conceivably is extremely valid I think I've seen as high as 60 something on a watch I was doing and as low as maybe in the 30s and have to go find my list to see what I've done in the past so yes you can have a big variation. Oh and did not expect to get 300° of amplitude because they didn't have a timing machine and that was not their attempt oh and before we get any further on this this was not a mass-produced watch made in a factory basically this is a classic Swiss cottage industry watch everything was made in separate cottages at some point in time it came together somebody purchased the wheels and typically under the dial and I enhanced your image a little bit notice the scribe marks somebody hand laid out each of the wheels in this watch. This is where when people are asking about these type of watches I want to identify it to purchase spare parts which unfortunately are not available because everything was basically handmade for this watch to a certain degree or definitely hand if it would be a better description classically on a lot of vintage watches and even quite a bit later the pallet jewels are found exactly as you half. So they're not visible where you normally think they are but they are there. Then all of the jewels in the watch are going to be natural this was before synthetic are typically the garnet or possibly synthetic sapphire in some English watches their quartz crystal. Then there usually really nice and take a look really pretty. this is a perfect example of a classic suspended mainspring barrel I'm going to attach an image. So basic disassembly is sort of like a conventional spring you remove the lid. The mainspring comes out and still depend on how well they manufactured this or how much time they spent in doing things which are helpful. The arbor in the center the part that the mainspring goes on unscrew's center parts usually. Sometimes they'll put two opposing holes to allow you put something in the basically unscrew it her times you have to grab it like with a really large pin vice if you can and then sometimes is frozen on it will never unscrew. Then that becomes an issue as you'll have to get lubrication to go where it needs to go the HP 1300 oils are good because of tend to flow everywhere. So basically unscrew as it can all be disassembled cleaned lubricated reassemble. Oh and then for my amusement they steal the stop works and in some rare cases for a variety of reasons known and unknown somebody machines the main plate inputs in a plate so it's no longer suspended and usually they don't do a real good job when they're doing that.1 point

-

1 point

-

older like vintage? When was this watch made that you're trying to repair? one of the problems and watch repair is there a lot of watches out there. not just the quantity of watches like Seiko makes 1 trillion watches a year but the quantity of different styles grades models whatever from beginning of watchmaking until now there's a lot of. That means you won't necessarily find technical sheets service bulletins parts lists and if it's anything vintage then things become even more problematic. for instance looking at American watches like Elgin for instance there is an 18 size balance staff you look up your watch you get a balance staff number you order it it won't fit. That's because it came in four different variations all the same part number and each of the variations had different pivots sizes. A lot of times this is documented other times it's not then looks like your watches in the bestfit book. but I'm afraid that may only add to the confusion as there's lots and lots of them.1 point

-

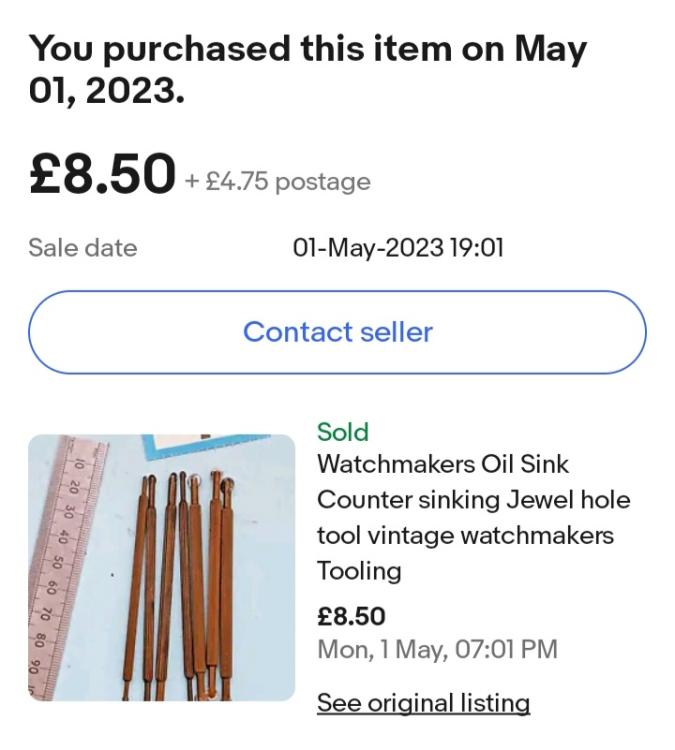

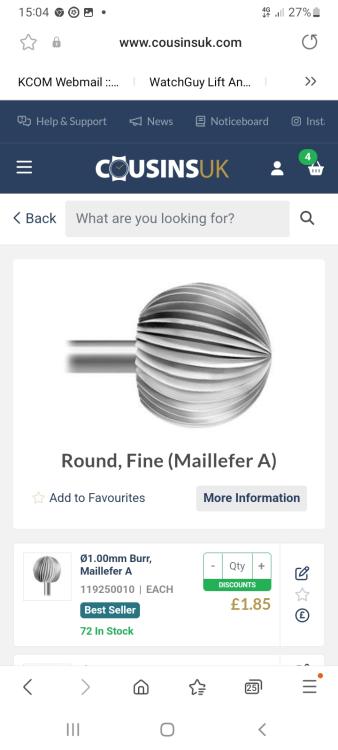

It's always crazy to see old used, sometimes broken stuff on Ebay for more than new price. Full set is just of 60 pounds at Cousins, 20 something individually. I have a couple of old steel sets that have seen a lot of use; recently got some tungsten carbide ones from Slick, quite a bit more at 260 CHF, but worth it for me. The steel ones do do a good job.1 point

-

I noticed the bergeon ones at the same time these came up and another set of four went for 30 quid. If i see any more Steve i will give you a nod. Yes matey i usually do well when I'm buying, patience and being a tight arse works for me I actually used these in a pin vice while i was looking for the sinks.1 point

-

1 point

-

1 point

-

when replacing jewels it's nice to have a reference book like the link below. Then even look at the reference book and see what standard jewels are available so I've attached an image of a chart. You've indicated it's a plate jewel 14 x 100 or I guess technically to be 0.14 x 1.00 which I circled it's a standard plate jewel of a standard size. okay so cousins have lots of jewels but of course as you may have found out we have a problem it's no longer available it's been discontinued. As watch repair moves more for well basically no parts being available parts will slowly disappear so your size has been discontinued but if you're willing to open the hole up a little bit you can have a 14 x 1 50. then of course the other thing to do is if you look in the book there's a way of closing a a hole although I don't know if you could drop it from 1 to 90 because that's available also so if you're buying from cousins you would have to open up your hole to accommodate the bigger jewel or continue searching online and may be fine the link below. then I snipped out an image on the page below I believe that's what you're looking for plus you'll notice they have other sizes to and there on sale. https://www.ofrei.com/page942.html Seitz book.pdf1 point

-

You can find them in either 3mm or 4mm. I bought a 4mm set, and had to sand down flat a couple of the anvils as they had a few pieces from the casting still attached, but since then it's done a wonderful job. I've done several jewel replacements and adjustments with mine since receiving it. I find I use it quite regularly. Now that I have one, I've been meticulous about checking and adjusting end shake. It was my first purchase from Ali Express. While it took a couple of weeks to arrive, I certainly don't regret getting a clone tool in this instance. This is the one I purchased: https://www.aliexpress.us/item/3256802886227821.html?spm=a2g0o.order_list.order_list_main.5.1e041802MHfxnd&gatewayAdapt=glo2usa&_randl_shipto=US1 point

-

a real lot of variety there. watch parts for sale in bulk as parts for art projects and alot of stuff for watchmaking on there...Well woth a look...Tends to beat Amazon, Ebay on price and the sellers are often from Europe so it means you arent waiting forever for your disapointment... As that has been my overall experience of buying anything online. if you can't get your hands on the goods to inspect them all you are working off is a picture, the sellers tend to make everything out to be better than it is and when you get it its usually useless... I have stopped buying from China and chinese sellers for that reason and that reason alone as I got sick of wasting my time and money. This opinion has not only been formed over watchmaking. I restore cars, I used to buy chinese tools off ebay, found out they were good for one use maybe two then useless... Now I buy snap on or a couple of other better brands works out cheaper in the long run. I also build and restore guitars, used to buy cheap pots and some components from chinese manufacturers, nothing but constant disapointment in the quality, fitment and reliability. Now I buy from us suppliers that don't use their goods. More expensive but right every time, thus saving me time, trouble, returns, language difficulties and the all round general aggravation of dealing with people that only give you sorries and excuses for why they're constantly **BLEEP**ing up and selling you rubbish that isnt worth what you pay for it cheap as it is... So anyone can make a chocolate spanner, coat it in silver paper and sell it on Ebay or whereever but you won't get very far with it and i've found in my experience that tools are 90% of any job and skill the rest. So If i'm using bad tools the work I do suffers and that is not what i'm about.1 point

.thumb.jpg.5b507801efa69acbba40ce6424f5611d.jpg)

.thumb.jpg.de40ad7c6efd1f448bc7e5c2879e56ff.jpg)

.thumb.jpg.39d4a87e3255c1822598d0a2f9519491.jpg)

.thumb.jpg.7752472f067b0e0f30414a5ce252f0a1.jpg)

.thumb.jpg.b71a39aee3cc003496468916f90cf238.jpg)

.thumb.jpg.e842823593c663c24b75f8750801ee83.jpg)

.jpg.6485c64c94f75582dbd3f4b0fc03bebb.jpg)