Leaderboard

Popular Content

Showing content with the highest reputation on 05/17/23 in all areas

-

6 points

-

I did try using a pressure jetting method of cleaning. I used a vintage glass syringe, as I didn't want to put any cleaning solution in my waterpik. But the results were not good. It cannot remove dried up oils. And for those who think the waterpik is the answer to flossing, it isn't. The waterpik can only remove loose food particles. It can't remove plaque, it can't remove food particles pinched in the contact area of the teeth I was taught that too. But when I thought about it, with the pressure applied when the pegwood is rammed into a hole, whatever facets on the tip would be crushed until it ends up smooth and round. Just look at the pegwood when it is removed from the hole. We were all taught things that have no scientific basis. We need to sit down and distill fact from fiction.3 points

-

I would say the glass is the original one, imperfections were common back then. The pallets are what I would expect to find however someone has heated them that is why they are looking blue and I have noticed a slight bend in the pallet, for my eyes it is a bad photo of the pallet stones so I can't comment on them, but repairs have been carried out because the pallets should not be blued. The barrel is something you will not have come across and it will be a puzzle. You need to remove the mainspring, put the key on the arbor and with a pair of smooth jaw pliers hold the outside of the arbor and unscrew it, when unscrewed you can remove it from the plate. I see the Geneva stop work is missing, many are missing. The watch would have been made near the French Swiss border, date around the 1860 could be a little later. Made in there thousands, but parts are very rarely interchangeable. I have repaired pocket watches with the same style pallets with banking pins so I'm not sure if the style has anything do do with not having banking pins, if I had to guess I would say no. I think I have covered your questions, if you have any more just ask.2 points

-

That is no question here. Repinning is possible with flat hairsprings. The above watch has a Breguet hairspring however, where repinning is forbidden and only use of timing washers is possible. Frank2 points

-

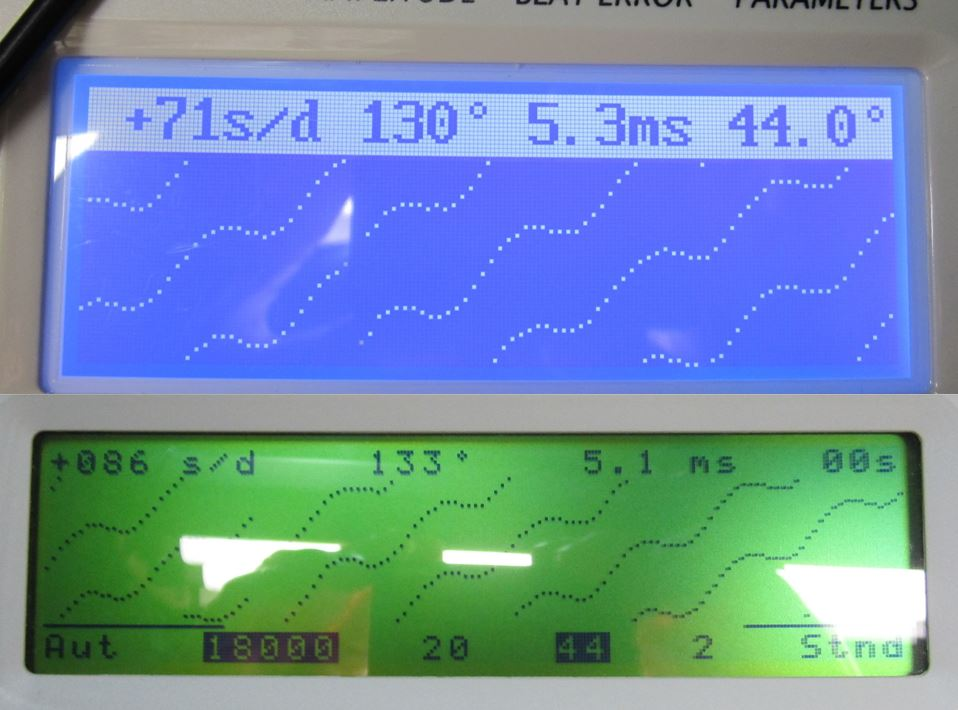

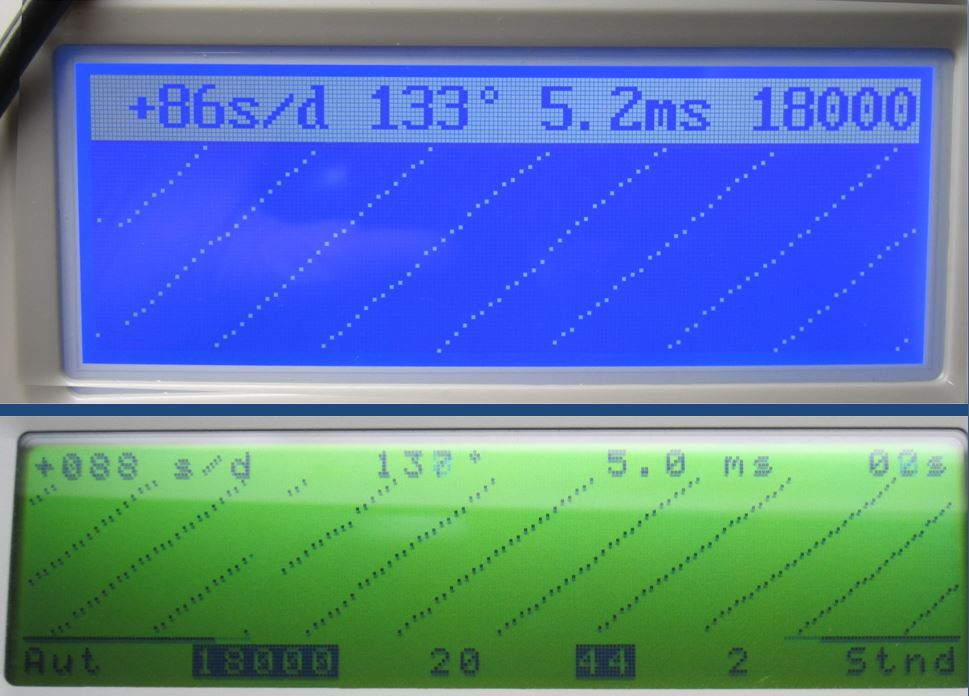

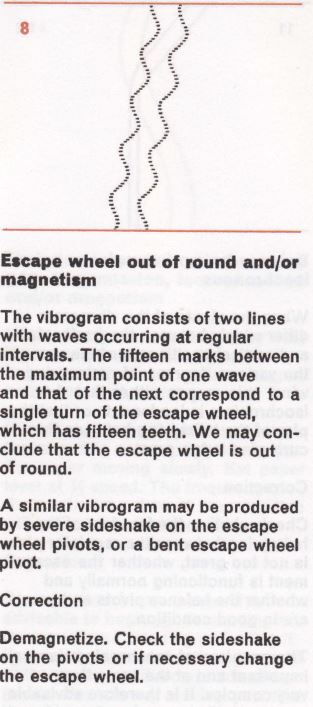

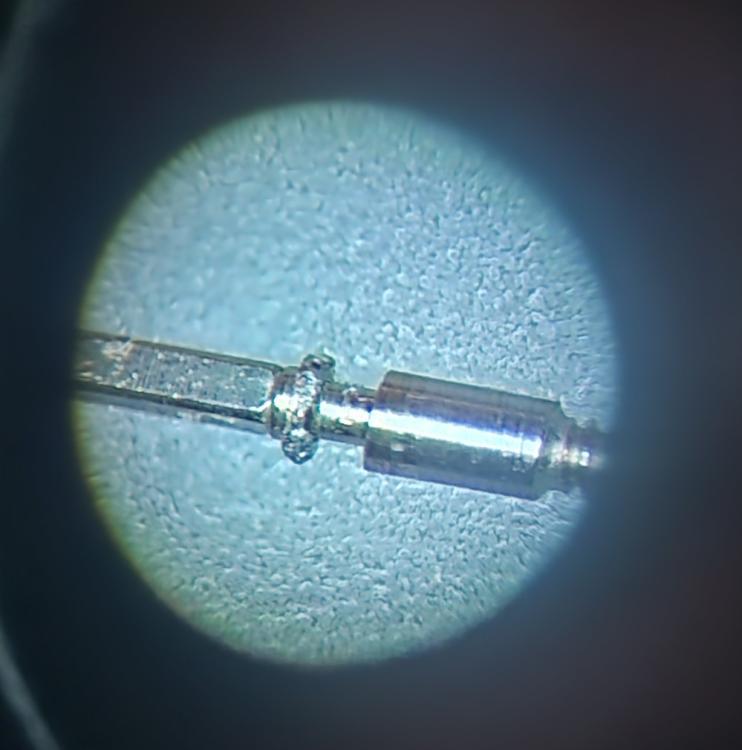

not weird it looks classic one of the reasons for before and after is to see if you've actually improved things and is not quite there yet the improved state I actually know I've seen that before normally in my life because the way I was taught in school I would've never seen anything like this ever but when is doing a timing machine comparison I found something similar although yours looks way more spectacular? It also looks like really two things are going on your getting some amplitude fluctuations. This is where when the lines separating come together that could be an amplitude fluctuation and the other looks classic for something else okay let's look at this image does it look similar? yes I know it's grossly out of beat the watch desperately needs to be serviced. But it worked really perfect for doing a timing machine comparison showing how well the Chinese 1000 compared to the witschi. Then look at this image I wonder what I did? then there's another thing that will produce the same thing which would be uneven power like if you had a bent wheel or something you can get a sine wave effect from that but classically the sine wave effect is caused by magnetism that's what the images are before because when I did the timing machine comparison the person who loaned me as timing machine gave me his watches because he was puzzled by the readings and I didn't do anything to change them and did them before exactly is found and then did things like remove the magnetism and look a much better it looks if you've already done that then it's probably uneven power and we can try something else in the software and see if we can figure it out but it's probably this. But notice how use the word probably because in the next damage it explains like if it's the escape wheel it's a set pattern and in the case of this watch it was very set as to what was going on yours looks more than one during and wondering is also uneven power conceivably sorry timing machine diagnostics is not always crystal-clear which is why make jokes about reading tea leaves or looking at a crystal ball it subject to interpretation and you have to understand the condition of a watch oh and yes notice how it does talk about the pivots that's backed uneven power again then because he of timing software with more features than the Chinese timing machine you could try doing what set the link below.long term the testing now the problem is I'm used to looking at this at the witschi at work so I understand exactly what I'm seeing their I haven't played enough with the software to see how this compares if you have gear train power fluctuations it will show up here although you should demagnetized the watch first and see if that helps as that would be the easiest and fastest thing to do. Then try doing this and seeing what happens http://www.watchoscope.com/manual.html#longterm also what has looking at the sample of the link above it looks like about eight minutes they are probably try a 10 minute run C Outlook see if we can see anything all gear trains will have random fluctuations is when you start to see patterns then that will point to specific problems.2 points

-

I won a salesman sample watch on ebay last week. Just under $20 with shipping. It arrived today and I have taken it apart to see if there is anyway for me to add in a dynotron movement to have it be a function watch. at this point its is a "maybe". If not I should at least be able to use some of the parts for other projects. Will post of progress. I have three of the divers like this so why not swap the dial. Yes, No?1 point

-

If you look at the ebay history of sold items, there were a few of his books that sold not to long ago for reasonable prices. https://www.ebay.com/sch/i.html?_from=R40&_trksid=p2334524.m570.l1312&_nkw=Jendritzki&_sacat=0&LH_TitleDesc=0&rt=nc&_odkw=The+Swiss+Watch+Repairer's+Manual&_osacat=0&LH_Complete=1&LH_Sold=11 point

-

If you got a good overcoil, don't touch it. I have a few unidentified scrap balances which I keep for the screws, no washers so I often end up filing, I can't recommend filing. Never seen scrap screws mention on discussions, wonder why, thats a source.1 point

-

I wouldn't blame tinkerers or hobbyists basically somebody in the past did something there not supposed to. It is truly amazing how many watches have bizarre timing issues like a 992 Hamilton came in the other day needed to be regulated but the regulators all the way to the Max it's a railroad grade watch with no mean time screw ups it should have them for railroad grade watch don't know where they are but they're not on the balance wheel anymore. Or even Rolex watches which are not your usual watch for people to play with and they will be grossly out of regulation and employees because somebody had no idea what they're doing. yes back to the basics with the balance wheel back the way it's supposed to be.1 point

-

Got the little shit out (three carbide drills shattered). It's a left hand thread! Sort of explains how it got like that I suppose. The arbor has a square top so I didn't think a reverse thread screw would be needed there? Are there left hand thead die plates for making replacements for something like this?1 point

-

I find, it's past tinkerers that have removed weight from the balance because they didn't quite understand what they were doing. Now the weight has been removed, it needs to replaced, otherwise the balance will move faster and the regulator will need pushing to the slow (-) side. Before adding or removing anything, I find it a good idea to statically poise the balance to get it true and perfectly weighted. You may even need to bend back into shape a bimetallic balance with cut-outs back into shape first. Once it has been 'balanced', then I have a good start point to then statically poise the balance and add or loose weight accordingly, so my regulator index arm is as close to the centre as possible. If you rob Peter, Paul wants paying1 point

-

no not an idiot you made the classic mistake of thinking you shouldn't read the users manual. after all it's only a watch why should you read the manual so in case you through the manual way they didn't want to read I've attached the PDF. Then I found a couple links describing your movement https://calibercorner.com/seiko-caliber-8r46/ https://www.seikowatches.com/us-en/products/prospex/8R Seiko users mail JSY8R4C1_EN.pdf1 point

-

That's a pity, it Looks like you may have to hunt for a donor or spare part unless anyone out there has a solution we haven't thought of.1 point

-

A little out of my league, perhaps someone tries a clock fix on a watch? Maybe someone else will have a good fix for this if you give it a few days to give people a chance to see this post. If not you have nothing to loose by trying to close the hole with a staking set as I don't think you can't leave it the way it is. Death or glory! Hold on..... I just had a thought, maybe you could open up the hole with a reaming set and put a jewel in there, I think I saw a YouTube on this... Will try to see if I can find it. Here is a link to a similar video as I can't find the exact one I was looking for, but I think it covers the same stuff, I think VTA on eBay supplies the kit.1 point

-

It's my fault really. I didn't bother to make different length tweezers. Next time I will file some tweezers down. As I only have timing washers for small pocket watches, I sometimes have no option but to move the stud. It also depends on the watch - if it's one where I can always find a new hairspring, I might tweak the stud. But if there's no chance of a hairspring replacement my first choice would be washers.1 point

-

All of the above or - Remove timing screw, add washer, re-insert timing screw1 point

-

1 point

-

Don't straighten the pin, the bend is intentional. The friction between the bent pin and the inside of the center wheel arbor is what provides the coupling friction for the train to turn the hands. On this type of movement the canon pinion and the pin rotate together. If you straighten out the pin you will uncouple the hands from the movement and they won't turn.1 point

-

SU is nearly always on Raketa movements but they made nothing that small. Could try Luch or Chaika they make small ones. The brass shim is a give away and the marked up left hand thread screw. Chaika make a 1601 calibre but its a single ligne measurement.1 point

-

The multi angle aspect of pegwood has been mentioned many times by professionals on the internet. Maybe its just that initial extra edge when starting to peg out before it takes a uniform shape. Some pegwood is harder than others and take longer to lose the cut angles.1 point

-

You have had bad luck, yes it can depend on the hairsprings condition. Get hold of a few old movements and practice on the hairspring removal you will soon get the hang of it. Use a a pair of tweezers with very fine points I used Dumont tweezers number 5. Good luck. Providing all the timing washers are all the same in size and weight and the timing screws are all screwed back in at the same depth no poising is needed.1 point

-

My understanding here is that adding the washers symmetrically, on opposite ends of the wheel, will not alter the poise as the torques will balance during any repoising. In other words the moment of inertia is modified, but not the center of mass.1 point

-

I have heard it said you are not a collector of a brand unless you have 3 examples. I have 4 Clinton's with3 of them FE 3612s (day-date automatics). All 4 have bidirectional diver / world time bezels, except for the blue dial one for which I am hunting for an original bezel. 2 of the 3 autos have a problem with the winding stem mushrooming from the the setting level stud, I believe. The third auto has a very dificult pull on the stem to get into setting mode so it seems to be a design flaw as the others were a total nightmare getting the stem out of the movement. Waiting on a replacement stem that I will use to finish the rebuild of the blue and black dial version then likely order another 2. The blue dial is in very good shape with what I think is an original blue rubber band.1 point

-

I received a single glass tube topped with a cork plug. I had to sort through the contents of the tube to find a matching pair that fit my purposes. I can see now there is a debate about whether it is better to add timing washers or re-pin the hairspring. I have never done the latter, but I can report that adding the timing washers was not difficult for me and I am quite pleased with the results.1 point

-

1 point

-

1 point

-

New winding stem came in and was able to put together the blue dial one with a new premium crown. The mineral flat top crystal hase a couple of marks but still looks good. Just need that bezel now to go with this stunning blue dial and band. When trying the new stem in the black dial and band version found the teeth on the clutch wheel that interacts with the intermediate wheel were ground away...now not sure if a design flaw or operator error putting way too much pressure when winding or setting the watch... ordered another stem and clutch wheel.1 point

-

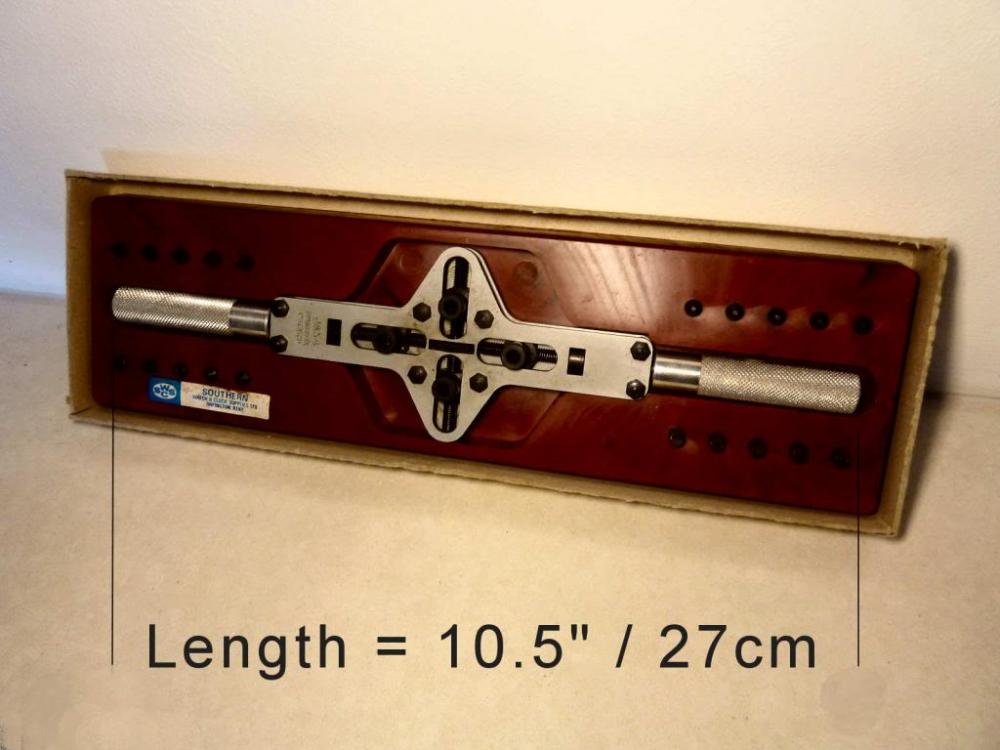

to understand what you're dealing with I have images snipped out of a book. it was a little bit older it would've been much easier to spot. Because the early ones would been key set and it becomes quite obvious that things don't quite look right well sort of usually if I see anyone struggling with I can't take the cannon pinion off especially in older watch then this is usually the problem and yes when you look at the other side it would've been nice for more pictures but yes you can recognize the style even without seeing everything. But a lot of times people would ask ahead of time if things don't seem right.1 point

-

Hello. Thank you all for the response. M. Klassiker solved the problem by telling me to press the top button...Thanks a lot. I'm an idiot!1 point

-

I second the watch paper. Frankly though, once I do the rinse in the IPA, I have found they dry very fast even without a food dehydrator or anything. The IPA just evaporates very fast I have found.1 point

-

Eyup watch peeps. As we all know buying watch tools is never ending and can be extremely expensive for specialist item such as jewelling and staking tools. But it is possible to find great items at a good price if we keep looking and finding an honest seller that deals regularly in the same kind of gear can help make that happen. Here i have some cracking ones, one probably a bit more collectable than useable. A tiny staking set in a lovely walnut burr container, two steel lapping plates and an ancient hairspring vibrator which does need a good clean up and a new hairspring grip. Total cost 28 new British pounds at todays prices thats a carvery lunch a cuppa and a pudding for me and the missus. There was a bit of work involved as well though i missed the postman knocking at my door to deliver and ended up having to chase him round my neighbourhood in my van for 10 minutes. Good fun and a great start to an otherwise boring day off.1 point

-

One of the more "interesting" properties of some older clear plastic objects (and this includes old film stock, and some old watch crystals) is that they are made from nitrocellulose. Of course this makes them interesting in a similar way to the way that radium dials are interesting. They have a certain level of mild peril associated with them. Nitrocellulose is the main component of old fashioned "gun cotton" explosive. Nitrocellulose film stock for this reason is notorious for spontaneous combustion, and furthermore for being almost impossible to extinguish, since it contains its own oxidizer. The reason more recent types of film stock are called 'safety film' is because they don't have this rather inconvenient property. With this in mind, and if you are up for a small and mildly hazardous experiment, you might want to replace the yellowed crystal with a modern alternative, and then try burning the old one. If it burns rapidly and rather alarmingly, then it is made from nitrocellulose. If it melts and burns rather poorly, then it is a more modern acetate based crystal. The usual caveats apply, you obviously do this entirely at your own risk. Don't forget to film the results. Burning down your entire neighbourhood may well net you a viral video. You can thank me afterwards.1 point

-

I found this info for you. It is a swiss movement. The term Ancre Ligne Droite had a specific meaning. The Swiss styel lever was emerging as a standard form in the 1860-1880 time frame. It mean that the three pivots, escape wheel pallet lever and balance were in a straight line. The English style had the three pivots in a triangular lay out.1 point

-

I agree with @GuyMontag, a stereo microscope is a game changer. Once you've used one there's no going back.1 point

-

1 point

-

Well of course, Mark has his courses (which cost) here: https://www.watchfix.com/ This web site has an amazing amount of animated information: https://ciechanow.ski/mechanical-watch/ Alex's tutorials are also pretty good if you follow them in sequence: https://www.youtube.com/@watchrepairtutorials1 point

-

Where did you buy the timing washers from? I've been searching for wristwatch sized ones for ages. I have an Omega T12.6 running +400s/day. The smallest washers I have are for '0 Size' pocket watches. I can use them on larger wristwatches, but on this Omega, they are a bit too big and are catching the mainplate. I can file the edges off, but would like to find some smaller washers.1 point

-

1 point

-

1 point