Leaderboard

Popular Content

Showing content with the highest reputation on 05/15/23 in all areas

-

My wife took these pictures today. Not sure if there is a message that I am supposed to get The first bench is the one from my Dad. The second is the one I bought from Maine. The third I bought from someone in Wyoming. The last watch bench came from Dallas. The other bench is just a converted office desk. The last picture captures a portion of the room. This was not staged...and I am a little embarrassed about how it looks. That's me and Cromwell.4 points

-

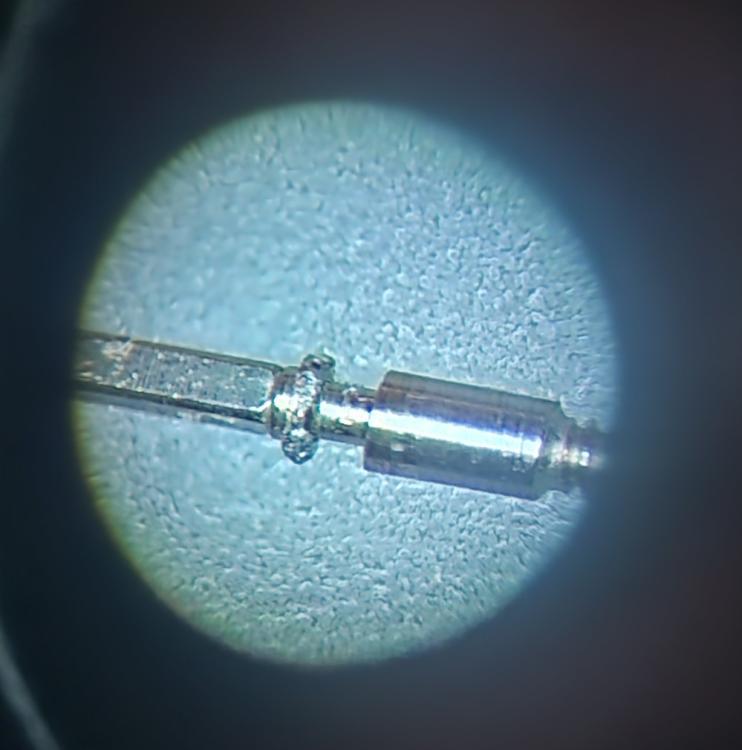

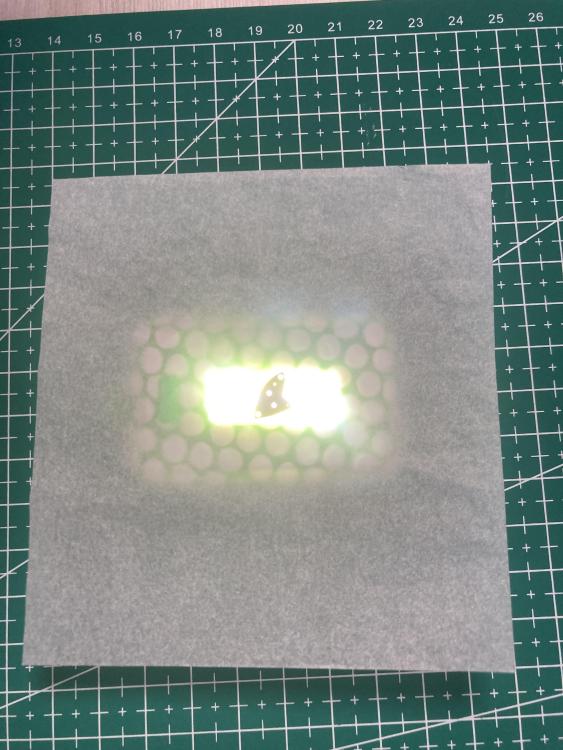

Eyup watch peeps i hope we are all well. Does anyone know what these capsules are made from ? The closest i can find to these on the internet is gelatine capsules. Answer sorted. Yes they are gelatine, popped one in my mouth and it dissolved. I now just need to wait for the balance staffs to come out my other end.4 points

-

4 points

-

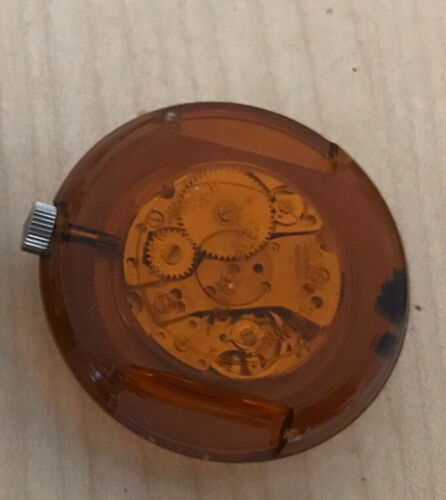

I have heard it said you are not a collector of a brand unless you have 3 examples. I have 4 Clinton's with3 of them FE 3612s (day-date automatics). All 4 have bidirectional diver / world time bezels, except for the blue dial one for which I am hunting for an original bezel. 2 of the 3 autos have a problem with the winding stem mushrooming from the the setting level stud, I believe. The third auto has a very dificult pull on the stem to get into setting mode so it seems to be a design flaw as the others were a total nightmare getting the stem out of the movement. Waiting on a replacement stem that I will use to finish the rebuild of the blue and black dial version then likely order another 2. The blue dial is in very good shape with what I think is an original blue rubber band.3 points

-

Washed them down with a cuppa My doctor said i needed more iron in my diet So no I'm not crazy , well actually yes a bit sometimes. The idea was to increase my storage space, i have so many balance staffs taking up almost a full chest of draws. So i bought these little beauties that hold just short of 1000 balance staff calibers each. Problem is the individual sections only measure 20mm x 8mm which coincidentally happens to nicely fit a size no. 1 pharmaceutical gelatine capsule. After some research i almost came to the conclusion that the capsules would not be suitable for storing highly polished teeny metal parts as they do have a certain level of moisture content since being made from animal collagen. But as i hardly ever listen and take matters into my own hands the need for experimentation took hold. I assumed the original storage capsules would be made from acrylic or some other such very stable plastic material as the staffs i have in these already are very old and have no corrosion. Not being completely convinced of this after spending hours trying to find out what material they originally used i decided to pull one of them apart along with a new drug gelatine capsule. Plenty of poking prodding pulling and ripping with tweezers took place and they seemed very similar. Wanting to go a step futher involved what a gelatine capsule is actually used for and goes through and a tentertive lick showed promising signs that the old capsule was in fact gelatine. Anyway in for a penny in for pound lets go the whole hog and see what happens when i pop it in my gob. Yes indeed the old balance staff and stem storage capsules are 100 % pharmaceutical empty drug capsules made from gelatine . Now then did i empty that capsule first before downing it ? , ahh whatever i got my answer.3 points

-

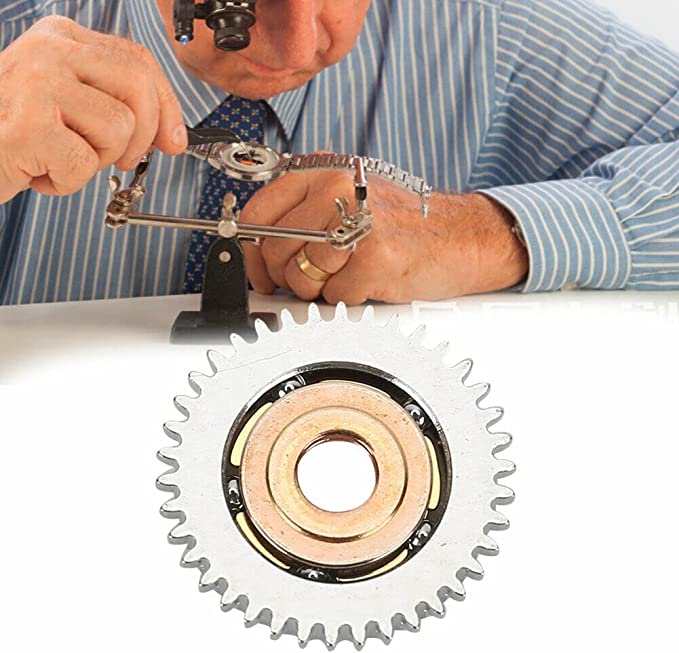

How lucky was i ? While sorting out storage for the balance staff stock i noticed a staff container with around 50 of the AHS 43 staffs i had been looking everywhere for on the net, yey staff stock comes in to play . This was my first go at replacing a friction fit staff, easy peasy. The hardest part was lining up exactly the roller cresent with the impulse pin. This was done from both sides of the staff, firstly free hand from underneath by loosely staking the staff down on to the balance wheel so as to line things up. Then to flip over to tap the balance wheel down. Fitting the hairspring back on and to install the balance assembly left to do, fingers crossed I've made a fair job .2 points

-

WD40 straw was my first tool for pressing on hands.2 points

-

2 points

-

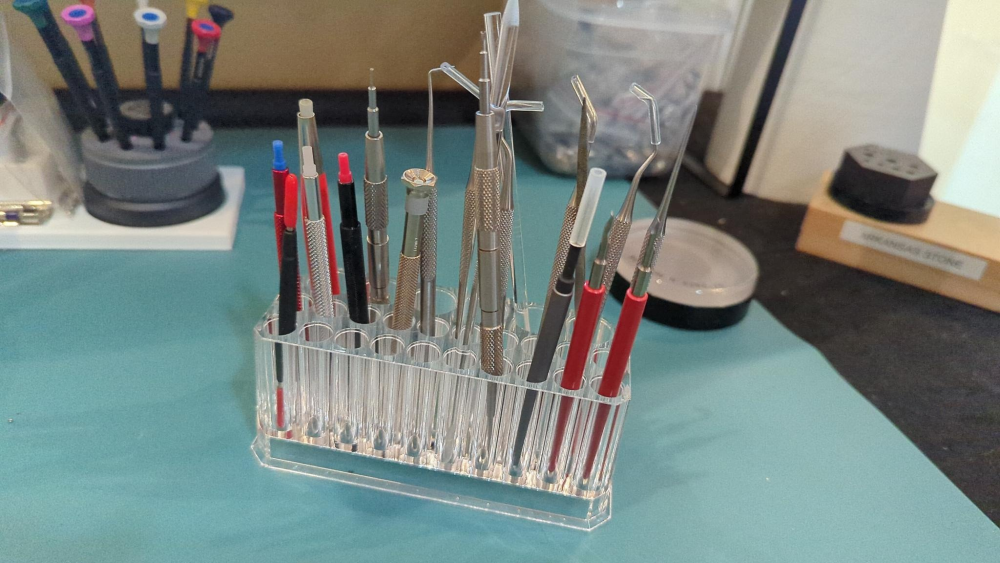

Hello all, I wish to start a new thread as a bit of fun that has examples of thinking outside the box when it comes to finding watch tools and equipment, either by making or modifying existing equipment or by repurposing a non-watch product in a new way - all with the aim of smartly saving money without sacrificing usability and quality. Extra kudos for excellent examples of lateral thinking! To kick things off, I include below a re-post of something I repurposed: Example 1) From this makeup brush holder: To this stylish tool stand: Example 2, I just purchased this to keep my reclaimed watch dials in good shape: I am sure you can do better than the above, post your best ones here!1 point

-

Hi folks, hope you are all well. I'm going to guess that I am a common occurrence here in that I found watch repair videos on YouTube fascinating and such a relaxing way to pass an hour or so that I started to think about taking it up as a hobby. It doesn't look like the kind of thing you jump into without backup and expert advice, so after much looking around, here I am. I have a military aircraft engineering background (23yrs) and have good basic skills and engineering principles, which I hope will help me understand the mechanics etc. I have some basic, good quality tools for now and am looking for the best way to start. My aim is to eventually (one day) have the skills to renovate my grandfather's Timor (issued to him after he fought with the 8th Army in N Africa, he received the watch in 45 or 46, I'm not sure which). I wore the watch through the Falklands, Gulf War1 and in Bosnia - where it stopped working. It is dear to me so I have much to learn. Anyway, thanks for letting me join and I look forward learning from you as I go.1 point

-

As suggested to me by Hector, I contacted the Nekkid Watchmaker. He sent a very polite and friendly reply to say that he didn't take on subscribers watches - I had said that I was happy to be a paying customer but he gracefulloy declined. Since joining this group I have been going through the posts making notes and learning a lot. You guys have covered just about every watchmaking subject there is - I haven't had to post a single question yet! Standby though as I have received some of my tools this week and once I have familiarised myself with them and their correct use, I shall probably get myself into question asking territory pretty quickly, so don't go anywhere! Great site, well done all.1 point

-

I was searching for something ETA 2836-2 related and came across this photo on Amazon. The genius of this method had escaped me up until the moment I laid eyes on this. Could this watchmaking technique help me take it to the next level? Why have I been wasting time on "traditional" movement holders. Clearly, this is where it's at. What is this method called? Is it the Floating Alligator Clamp Borg Optic (FACBO) Method? Whatever it's called, sign me up!1 point

-

1 point

-

Or follow someone else who's been brave enough to take the risk! Thanks for taking the initiative, and I really hope it works.1 point

-

I found that I could not get a good angle for tilt without making it uncomfortable to view. What I do instead is just tilt the movement holder when I need to screw something down. Works much better for me.1 point

-

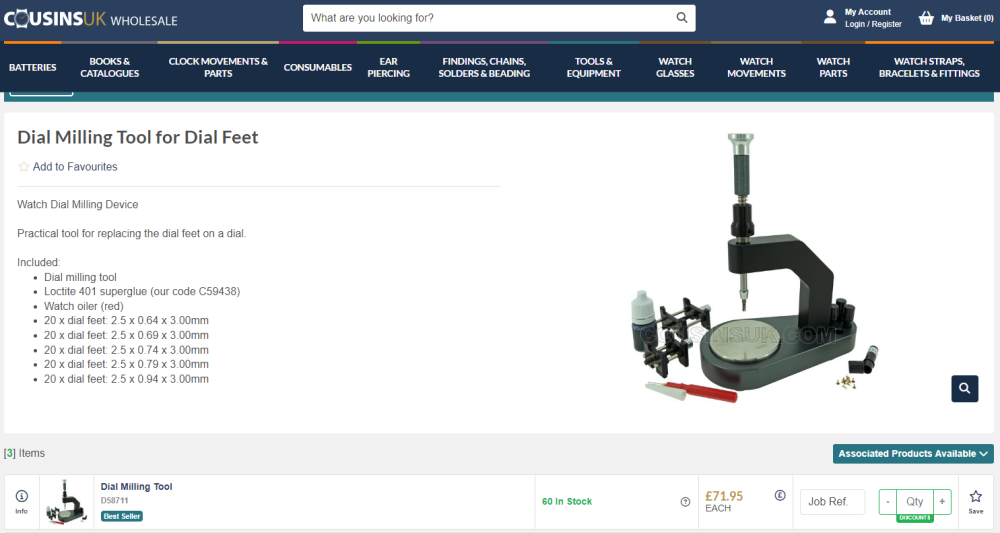

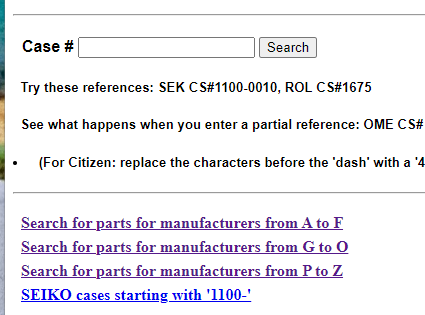

New dial feet can be attached to the existing dial. If you have the right tool it is a 10 minute job once you have the dial out of the watch. The upside is that you get to keep the original dial and should work out cheaper. The dial feet are pennies and a blob of epoxy to stick them to the dial compared to the cost of a new genuine Seiko dial (if you can find one) which may or may not compliment the existing watch. The difference in time for the repair between replacing the dial and adding feet to the existing one will be 10 mins. To to echo the others I would speak 'person to person' with the watchmaker (not a jeweler) and ask about replacing the dial feet onto the existing dial (which looks in great condition by the way). I have done this myself, the tool costs <£75 (see below) so most good watchmakers should have no excuse not to have one on their shelves.1 point

-

Thanks for the above picture, I just sent it to Mrs W and sais "see ...see... mine isn't so bad after all!" Don't expect it will stop her telling me off, but at least she doesn't think I'm the only one now.1 point

-

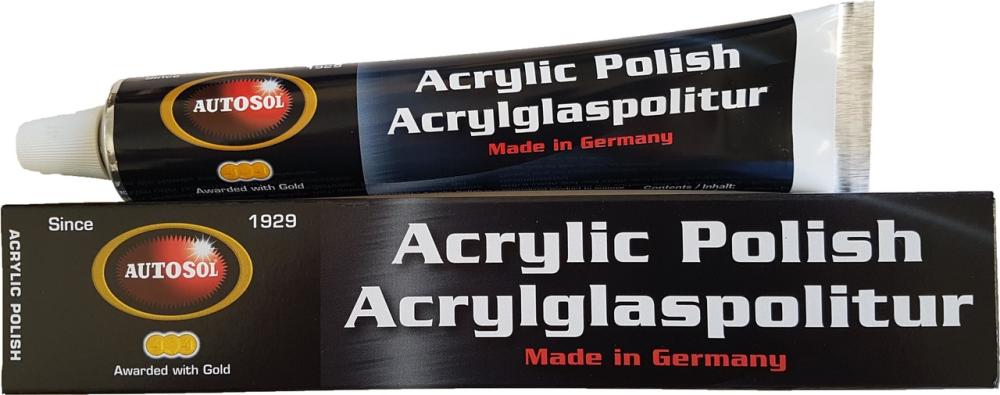

Below is a link discussing in great details the issues with polywatch and older cellulose crystals together with several methods to clean them and other types of crystal. Unfortunately I think it is too late for your crystal, but at least you will know for next time As an aside I use Autosol acrylic paste, which I have found to work just as well as polywatch (I think its pretty much the same stuff - just in a bigger cheaper tube):1 point

-

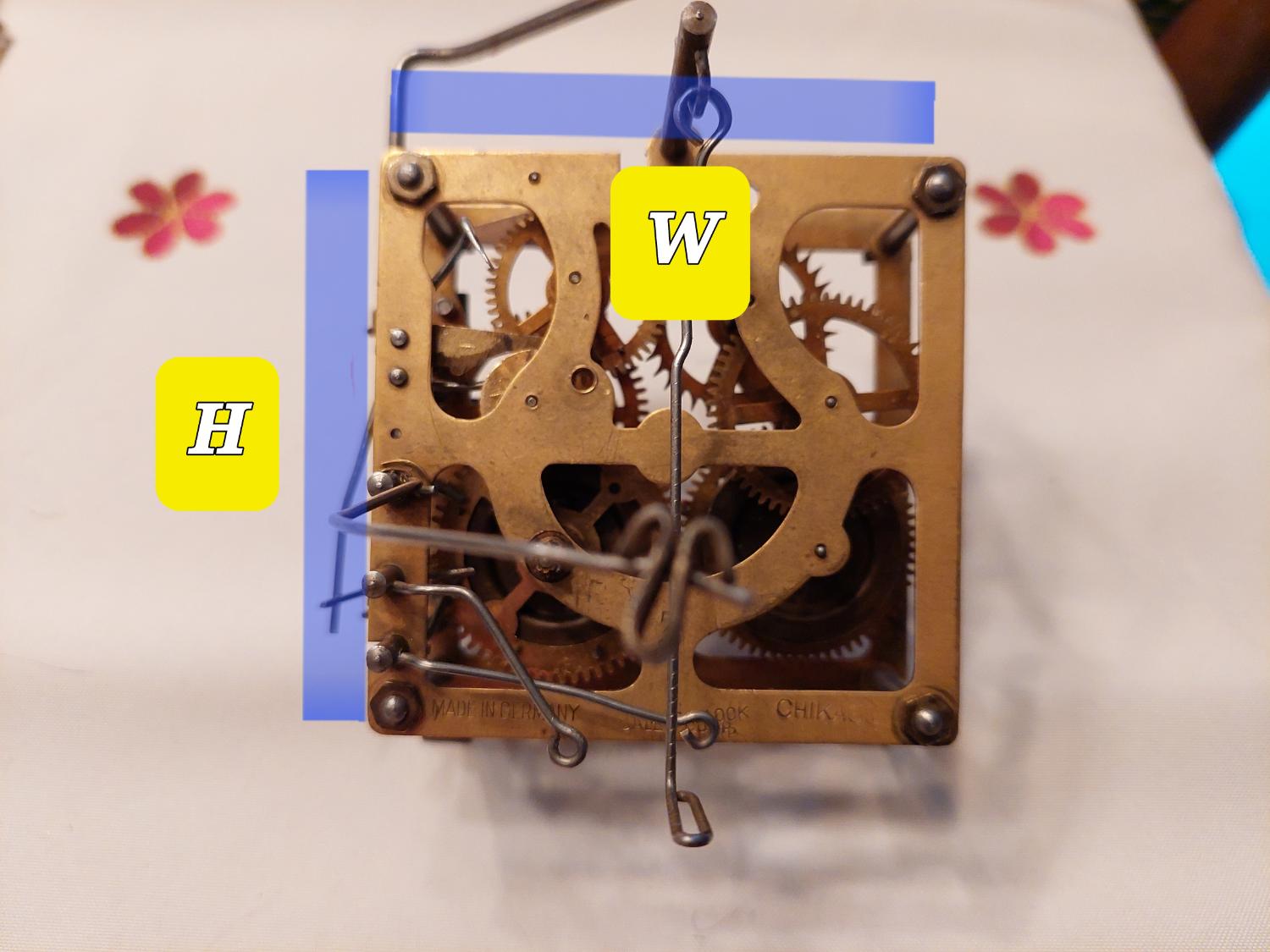

Does anyone have videos of adjusting the wires from the movement to the music box, once installed in the house? This model has the music box over head of the movement. The movement works fine, as well as the music box. I am interested in the two wires that release the stop on the music box, and the other which blocks the Governor fan. Thanks for any assistance.1 point

-

I find your wording interesting here. Did you use epilam or the equivalent? then by properly oiling you mean no oil on anything of the reversers other than center axle which is why the epilam is there to keep Lubrication from spreading outwards. one of the problems and watch repair is what is the problem when you fix the broken rotor axle was this problem there before and without the rotor there was no way to tell. So we don't know if it's a new problem or an old problem. Do you have the service manual Rolex has all sorts of specifications for end shake your supposed to check including on the automatic mechanism so have you verified that there within specification oh and one other little thing do not assume when the Rolex caravan that everything was right. A lot of times people of worked on the watch before you didn't have a service manual and didn't seem to grasp how things were supposed to be which is why the service manual goes and exacting specifications to everything to put it back where it's supposed to be. So the old saying and watch repair it left the factory running it must build a run now doesn't entirely apply if other people of service did with no idea at all what they're doing C may be dealing with somebody else's problem that you've inherited.1 point

-

Your watch, do what you wish, but my recall is that this style never had black hands.1 point

-

One of the more "interesting" properties of some older clear plastic objects (and this includes old film stock, and some old watch crystals) is that they are made from nitrocellulose. Of course this makes them interesting in a similar way to the way that radium dials are interesting. They have a certain level of mild peril associated with them. Nitrocellulose is the main component of old fashioned "gun cotton" explosive. Nitrocellulose film stock for this reason is notorious for spontaneous combustion, and furthermore for being almost impossible to extinguish, since it contains its own oxidizer. The reason more recent types of film stock are called 'safety film' is because they don't have this rather inconvenient property. With this in mind, and if you are up for a small and mildly hazardous experiment, you might want to replace the yellowed crystal with a modern alternative, and then try burning the old one. If it burns rapidly and rather alarmingly, then it is made from nitrocellulose. If it melts and burns rather poorly, then it is a more modern acetate based crystal. The usual caveats apply, you obviously do this entirely at your own risk. Don't forget to film the results. Burning down your entire neighbourhood may well net you a viral video. You can thank me afterwards.1 point

-

I've got to concur with @MarcIt is more than likely a cellulose compound the crystal is made from. If it had a yellow sheen to it and had some serious age to it, then it's very probable. There is nothing you can do to resurrect this one, I'm afraid. Always best to replace one, as you can't even see through some of the really bad ones , unless it isn't too bad then you might want to keep the originality of the timepiece. Some will have their views on patina of dials and hands, etc. Personally, I like to see some history that has been etched into the watch case; not necessarily the acrylic though. I do like to give an original acrylic a polish to remove the major scratches by starting off with some 1200 grit wet and dry, or powder charged on a cotton bud, then go through various grit counts to end up using something like cerium oxide as a finish. I find original acrylic crystals, say from the 60's or 70's have a nicer smoother rounder profile than the modern day ones which are a bit blocky in my opinion.1 point

-

In days gone by they used a rolled up piece of bread to mop up anything, Blutack is in effect Rodico, except Rodico has less oil in it so it is able to mop it up better. I think the idea of using blutack until you have some Rodico was a really good idea. If I find something works for me, sod what anyone else thinks about it!1 point

-

It's quite possible that the problem is that your crystal isn't acrylic at all, but rather celluloid. Celluloid was the early "unbreakable" alternative to glass for watch crystals long before we had acrylic and one of the problems that you get with celluloid is that it discolours with age, typically yellowing. You can't polish it out either as it is all the way through. I suspect that there is something in the Polywatch that dissolves celluloid, it ought to be absolutely fine with acrylic since that is specifically what it is made for polishing. One of the other undesirable qualities of celluloid is that it degasses, the products of which can accelerate rusting of steel.1 point

-

What did you use to polish it Steve Before acrylic crystals, cellulose was used. Aged cellulose is likely to be more reactive than acrylic.1 point

-

Now that is what I like to see a lovely mess. Providing you know where every thing is. My work bench was always in a mess, my master would always tell me to clean it. When I had my own workshop it always looked as if a bomb had hit it. Funny really as I like to keep my home very tidy I do not like things out of place.1 point

-

I'd say this is a very early pin-set, maybe mid-to-late 1860s. Looking at the pendant tube, it is still round like it would be on a key-wind case. But I do not think this was a converted case, because they also would have needed to drill for the setting pin, and the cuvette has no key holes. The style being reminiscent of key-winds makes me think this may be from that early transitional period. And the movement looks right for that time. But being unmarked, likely a generic ebauche (maybe A. Schild or FHF or such like) that is as much as I can guess about it.1 point

-

That all makes sense. Although here, since I already took off the click and ratchet wheel, I would have found out a lot sooner. In my mind, taking off the click and ratchet wheel first insures that there's no power down to the fork so I can't be surprised. But I'm no professional, so I'm always ready to learn. Definitely agree. The pallet is always the last thing I put in before the balance. I very seldom reassemble in the reverse order I disassemble. As you say, how else would I check for a free-spinning train?1 point

-

1 point

-

1 point

-

1 point

-

Thanks for that. All advice gratefully received! My knowledge so far consists of having spent a few weeks learning names of parts, what they do and what they look like. I'm now studying how they work together to tick! I have to say I admire anyone who can strip all this down and rebuild it confidently! My hat's off to you all and I'll get there slowly and steadily.1 point

-

The "Montine of Switzerland" slim GP 17 Jewel dress watch got a few cosmetic touches last night. The hands were straightened out, repainted and re-lumed, and the case back was re-finished, and of course the crystal and strap are also new. Ignore the slight grubby marks round edge of the new crystal in these pictures. They are caused by the polish I was using, and I did remove them later. The new lume is actually surprisingly bright, even with a small amount of pigment added to tone down its overly new looking yellow colour. Much more so than the original tritium pips on the dial, which have pretty much lost their luminosity. This is what I started with.1 point

-

Hi Mike I used the same stuff (typeclean) when servicing typewriters may years ago for cleaning the type heads once it was used up and dirty it went in the bin. The old stuff from using on watches can be reused for holding parts on the bench when measuring or other like tasks but the bin is where it usually ends up. Premium Rodico is likly to be an altered formula designed to remove money from your pocket it will be a bit more tacky so it collects more dollars/pounds .1 point

-

The other MM watch I am fixing is a 17J watch that I posted about elsewhere on the forum. I was home free until I was putting the back on the case when a lug just broke off in my hand. There was lots of corrosion visible, so I guess it is no surprise. I found another MM watch on ebay that had the same dial design, and was also 17J. I bought it. Today, I was going to re-case the original movement in the case from the ebay purchase. Cases look so so close...BUT!!! The ebay case is a couple hundred microns shallower. No way to force a fit, so I am burned. Thought of some innovative ways to make it work, but well beyond my pay grade. I am really bummed out.0 points