Leaderboard

Popular Content

Showing content with the highest reputation on 02/03/23 in all areas

-

I have a pocket watch that does that when I try to get the threads lined up before closing the case by rotating the case back counterclockwise while applying a little pressure with the 8-ball. Not sure why, but it gets stuck and misaligned like yours. Only way out is more counterclockwise rotation. As soon as it breaks free, put the 8-ball away and gently line everything up by hand to thread the back on properly. Now I only use the 8-ball to break the case back loose or for final tightening. Everything else is by hand gently and carefully. Best of luck.3 points

-

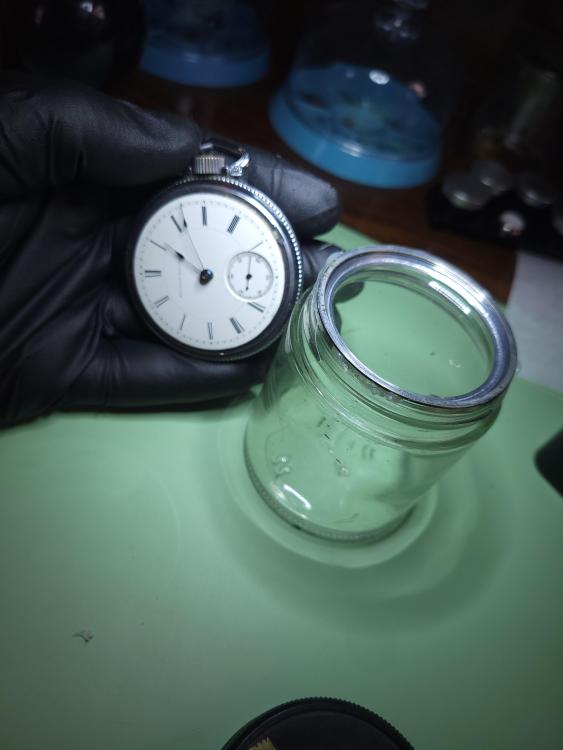

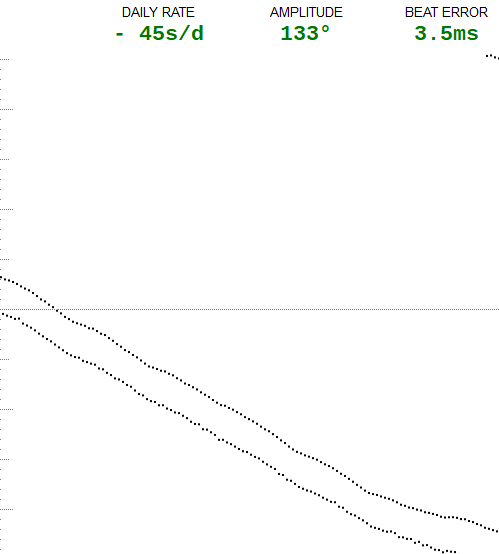

I was afraid this would be the answer. I will try a drop of oil, and also may try a method I saw where you hot glue an appropriately sized jar lid to the bezel and use that to turn it. I feel like it would be better than the ball in this case since I won't have to apply downward pressure on the threads to generate friction, like with the ball. A drop of P'Blaster and the hot glue got it done. Really interesting that you need to take the bezel off to set the watch and pull out this little lever. To add a little historical info: I own a brewery, and one of my customers brought this in for me to look at. It was his grandfather's, and no one knows the last time it was used. I wound it up and it sprung right to life. Not only that, but it looks better than a lot of more modern watches I've had on the timegrapher. Not bad for 140 years old! Here's a little video of it merrily tick-tocking away.2 points

-

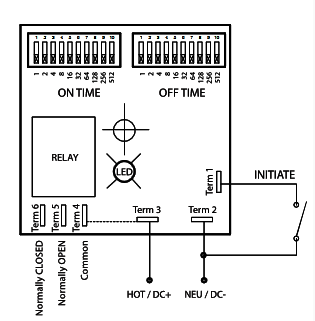

Those cycle timers are available in the same configuration by many different manufactures. They are fairly common for use in machine automation and prototyping. To your second question, are you talking about the plumbers test cap for 3" Pipe? the Janta jar lids do not seal completely, the gaskets are horrible so to prevent evaporation and odors I fitted a plumbers test cap to seal the jars and not use the Janta lids. Just insert the test cap and tighten the wing nut until sealed. Price is about $8.00 US for 1 test cap. Please post your results when you get your Janta modded, best regards Trey, James.2 points

-

Sorry, this cannot be left uncommented. Even in the picture you can see, that the released spring takes less than 1/3. He also mentiones it in the text. Mr. de Carles statements are not correct, misleading and omit the main reason for dimensioning a spring. In short, such "1/3 rule" is nonsense. Why? The optimal mainspring will give the maximum possible number of revolutions. And this spring will occupy exactly 1/2 of the remaining barrel area (a real rule). In the picture: the area of the released spring is the same as the empty area, which will be occupied by the wound spring then. Everyone with some geometry knowledge will see that the released spring packet cannot have the same thickness as the wound packet... For all others: released packet = 0.25 R (not 0.33 R!) wound packet = 0.41 R (not 0.33 R!) Frank2 points

-

Hello all you watchmaking peeps, i trust you are happy and in good health. Well I'm back, missed me ? Please don't all sigh at once. Work commitments has kept me busy and my watch repair interest had to take a temporary back seat. But its now time to return to it with a vengeance. Starting with my latest acquisition of vintage tools. Nothing spectacular but some food for thought for beginners on a budget and maybe some interest and a question or two for the more advanced and pros if they would indulge me. So lets start with a source and a figure of cost. My favourite buying site Ebay, this can be a waiting game for the right tool at the right price. Which can payoff if you are like me, I'm never in a rush to buy anything in particular. But always keep an eye out for something i like and might use for when my skill set improves. I never get into a bidding war, i decide what i want to pay long before the auction ends and submit that figure around 6 seconds before the auction ends ( known as sniping, unethical ? As has been discussed before, you have to play the game same as everone else). These are actually two ebay purchases, one at 6 quid and one at 14 quid so including postage came to around 24 as they were the same seller and he combined the postage for me. The majority of the two buys are cutting broaches and files. A lot of large sized broaches probably for clocks and some smaller ones for watches. Some nice part making files, names include stubbs, favourite and one the oldtimers may know Gantoine Glardon. A graver and a few homemade gravers from square files handles i think . Something of particular interest to me is a pivot burnisher with the name David Borlo A. Vallorbe. Also in the bundle is a solid ss one piece case knive, love this as it has a cracking Marvin logo on it. An unusual staking block with v slots at each end. Three agate oil cups that i am keen to replace the plastic ones i have been using, since reading some discussion regarding some plastic components can leach into the oils placed in them. And lastly the quiz tool that has 3 accessories slid onto the handle shaft. Happy reading and any input would be welcomed and appreciated thank you.1 point

-

1 point

-

As I understand it the breaking grease has two jobs to do, one of which is to provide lubrication between the bridle and barrel wall as the bridle slips, the other is provide the right amount of stickiness or grip such that the bridle slips at the right torque threshold but also stops slipping at the appropriate threshold as well. I have tried not using any breaking grease on the walls of an auto barrel and the result was that it simply refused to slip at all, so grease was necessary to lubricate the slipping action. I suspect that once the bridle is slipping though it is better to have it slip little and often rather than a lot every now and again as this would result in a more even power delivery and therefore better time keeping. The breaking grease controls the amount of slip by virtue of the shear properties of the grease between the bridle and the barrel wall, low shear strength gives more slip, high shear strength slips less, zero shear strength and the bridle slips continuously.1 point

-

I like your brilliant detective work except it conflicts with my memory at school so perhaps you could help me out Here's the problem I had at school in the early days the lubrication's didn't have numbers I'm not even sure they had their name on the Bottles, grabbed the bottle looked right I'm sure it was the 8201 so you would be proud and it slips. So far sounds fine except if you look at the link below this is basically 8200 which is a general-purpose lubrication for mainsprings where you want them to slip all the time with zero breaking effect with the bonus of the high-pressure Molybdenum disulphide. In other words you have a really really nice lubrication with zero breaking effect which is what I remembered wind it up it slips and it slips until is no power So basically I found it sucks for mainspring breaking grease as it has zero breaking effect. In other words I found it does exactly what it specified as a really nice high-pressure lubricant with zero breaking effect. If you look at the link below they do tell you which ones are supposed to be the breaking grease 8012, 8013 and 8017 They even specifically use the word breaking. Breaking is the purpose of breaking grease. It's supposed to hold the mainspring in place and not allow the mainspring to slip effortlessly which it will do if you use the wrong lubrication. Then the purpose of the grease is also to keep your barrel wall from disintegrating. So it serves two purposes it's a lubrication only when enough pressure has been applied to break free. Then just to make things confusing all lubrication's have a breaking property just some of them it's much better for this application. Then if you wanted to run tests occasionally will see a reference to this in the tech sheets and that is you wind up your watch until the mainspring slips counting how many turns it took to reach that point and then you see how much slippage you have. So view using a really nice lubricant that with zero breaking a fact you probably won't even build a reach the end of the spring before it slips and when it does slip it's going to unwind a heck of a lot and if you use something really sticky. I get a better effect but if you use something like p125 which to me resembles tar and if the person who asked he advises you incorrectly like what's happened the may then it has extreme breaking properties with almost no lubrication effect at all. I was doing a Seiko at work which I almost never do ask the idiot head watchmaker and he said put all around the barrel which is not what people recommend it's supposed to be a little spots on a couple of places on the barrel and when I wound it up to the end I thought as you break the screw head off the ratchet wheel it was so tight so we have kind of a balance here you have to have slipping or you could break your automatic or you will screw up timekeeping if you don't have any breaking at all but ideally the watch should bill a run a few hours after it slips. So an interesting compromise we have. https://www.moebius-lubricants.ch/en/products/greases1 point

-

1 point

-

Hi as Mikepilk stated I have attached the tech/parts sheet for you 923_Venus 170.pdf1 point

-

Hi Guys find attached pages from Laurie Pennman (Master clockmaker) and his calculations for the mainspring acommodation as regards to the barrel fitting. This man is spoken of in the same terms as Brian Loomes also a master clock maker. Not having done Geometery scince leaving school in the 50s I would not attempt to dispute Frank's figures but as a rule of thumb its a fair guide, not as proven the hard fact. We are unable to determine in what context De Carle used the diagrams without him telling us which is impossible. So best probably to put this one to bed.1 point

-

From Esslinger website: This special purpose Moebius grease contains Molybdenum disulphide to enhance it lubricity and resistance to pressure. It is designed for use on automatic mainsprings, to ensure proper functioning of the bridle. It is also recommended for use on the Bulova Accutron watch movements. Moebius 8201 natural watch grease lubricant Contains Molybdenum disulphide -------- I use this.1 point

-

It is just basic there is no real math to it. You do not measure the barrel and work calculations out. I learned it just by word of mouth by my master.1 point

-

True. But you can use the numbers above: Thickness of released spring packet = 1/4 barrel radius And I want to apologize. Not you were wrong but Mr. de Carle was. Frank1 point

-

You don't have many options. Zenith does sell parts to watchmakers who have an account with them, but they made it essentially impossible to get the account several years ago (a friend had and then lost his account then). Your options are: send it to Zenith, who will do a full service including repairing/ replacing the hand, or, take it to a watchmaker who does have a parts account, or, be patient and hunt Ebay until a new old stock hand comes up for sale. A 1970 El Primero will be in dire need of a service (unless done in the last few years), and may need other parts as well.1 point

-

That makes perfectly sense! Nevertheless calculating areas is a bit difficult for a rule of thumb. So the 1/3 rule is not useless as a first approximation imho.1 point

-

Cross threaded and screwed up threads on pocket watches unfortunately is all too common. Sometimes some penetrating oil helpful otherwise you just keep screwing it together and trying to screw it apart.1 point

-

Hey CGC , its doable for you but probably not as a first try. You'd be well advised to practise on some scrap quartz watches first to get a feel. I did this at the start of last year with a whole bucket load of quartz movements, it went a long way with my understanding and testing of them. If i remember rightly a lot of the circuit boards even some pretty old ones lifted straight off held in place by a few screws. I cant comment on yours in particular without some research but its very possible. The coil could also be faulty as well as a gummed up movement, even the quartz crystalcan fail, but thats quite rare. All are testable and fixable with some learn and skill advancement. Even the basic test equipment i have can manage the quartz, coil, circuit and check the cmos for working or non working. The cost for the circuit board sounds way over priced unless these have gone up dramatically since last year. Personally this is something i would be attempting, mayby not for everyone. You could potentially do more damage to the dial especially as hand removal and remounting has its risks for a beginner. This is something you dont want with it being the most viewed part and central focus of the watch. My advice if you have no experience in watch repair is set it aside and then get some. Practice practise and practice then evaluate you skill set and then decide whether to dig in or not.1 point

-

@jimzzillaI really appreciate your sharing on the wiring diagram , the 21E92 Cycle Timer is not avaliable in my country so I managed to find a alternative module that also featured with cycle timer, will share mine once I set it all up. By the way, I am curious why your jar lip looks like that? did you make some modification as well?1 point

-

1 point

-

I was an apprentice to a watchmaker for a couple of years, but I was young and wanted more excitement. So I signed up and joined the Army, my pathway through life took a different direction. Your doing the ultimate thing I believe a decent human can do and that's helping others in a way that you choose to do. And I'm looking forward to you continuing to do so and I certain I would win the bet if I said others on this forum think the same.1 point

-

I should have a chat with daveswatchparts.com in the states, as a supplier and repairer of Elgin/Waltham pocket watches or JohnR725 our vintage watch Guru, These guys work on the vintage stuff regular.1 point

-

Before we loose track of what is and isn’t right Donald De Carlo in his book which I have all of them states as Kalnag said. As a professional WATCHMAKER not repairer who built watches for a living came up with the theory so who are we Amateur repair men to disprove his theory, you might as well challenge the theory’s of George Daniels or Henry B Freid. The basic fact remains that the working space for the spring is wrong. So at this point Willow has a clock that works but the spring winds short (not enough space). The spring was broken when he got it and naturally got a new spring which according to the old spring measurements was almost correct and should work, but no not enough on the wind. Therefore my theory is that the wrong spring was in the clock and probably the reason that it broke being constantly being wound to capacity all the time. So no matter proving or disproving the theory there is not enough space for the spring to operate correctly and is if not corrected going to break again or damage the clock.1 point

-

1 point

-

I agree with @Cad101, sounds like the cannon pinion is loose, or possibly loose hands. How tight does it feel when you set the hands? Try pushing the hour and minute hands gently with some pegwood to see a) if they are loose, b) the hour hand isn't loose but the hour wheel turns1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

sorry for the late reply as I am not getting any notices about replies. as I found out, this was waaay above my experience level and proved to be much more difficult. before I did anything I got a donor plate just in case before I dove in and I'm glad I did. I did manage to find the tools and they do make slightly easier but not much. very fussy tedious work and have to be very very careful. I found swedging(or rubbing) the beveled lip back in to place to hold the new setting was the most difficult. long story short-I hope I don't run into this again anytime soon. was kinda fun though? does that sentence even make any sense?1 point

-

1 point

-

Looks like he's using OneOf Accuracy2, it's an app that works with their sensor (275 pounds at Cousins). https://h2i.ch/products/accuracy2-watch-acoustic-measurement/ https://www.cousinsuk.com/product/oneof-accuracy-2 It's a simple sensor, no positioning (probably why he's using the Chinese machine later), but good software. Praezis (Frank) here on the forum can also supply excellent software, with a simple sensor (or it can work with old positionable mics from Vibrograf and similar machines) for a better price. I have it and it's really good. I use it with a Vibrograf mic plugged into my computer. You can pic up the mics for 50 bucks or so on Ebay. The only difference I can see between it and my 7500 buck Witschi is the Witschi has an automatic mic and printer (you can easily print the results with Frank's gear, and fill in caliber and other info for future reference- and also store it as a file). Something it does the Witschi doesn't do is tell you where the heavy spot is on the balance when doing dynamic poising!1 point

-

I find it is more convenient to mount a large cylindrical neodymium magnet on my workbench. That way, the case is affixed to a known stationary position while I work. I NEVER lose parts with this method either.1 point

-

It's great software - but it's not been updated in years and its terrible for touch screen laptops because you cannot change the size of the buttons and this means you need a mouse or laptop with trackpad. So it takes a lot of space up. No but graham used to sell converted mics from vintage machines or he will convert yours. I supplied an old one from a Greiner machine I had and he converted it and did a bit of referb. Incidentally, I now use the OneOf Accuracy Pro now and the software is excellent and touch screen friendly. https://www.cousinsuk.com/product/oneof-accuracy-pro One side bonus is the OneOf microphone works well with Graham Baxters eTimer software too so best of both worlds.1 point

.thumb.png.7d7b7e6e162c1bc4c16e6ab14bd39800.png)

.thumb.png.e3cf5d1a05171a4b3614c974857c9058.png)

.thumb.png.e079e7d9ffe7d2d6e599b837f69d6d2c.png)