Leaderboard

Popular Content

Showing content with the highest reputation on 01/19/23 in all areas

-

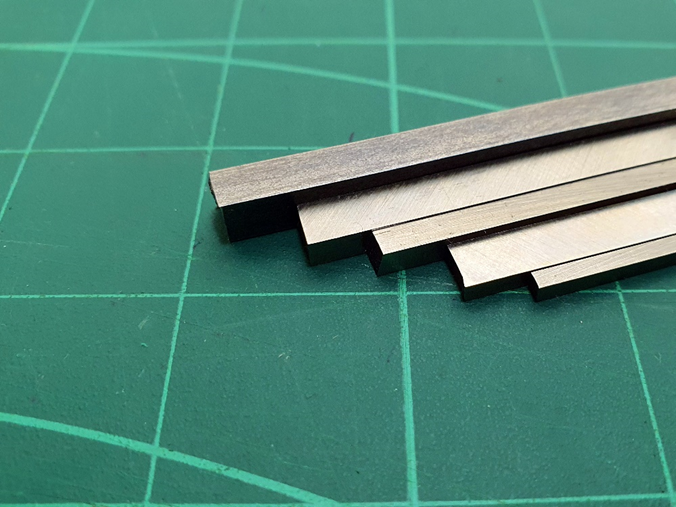

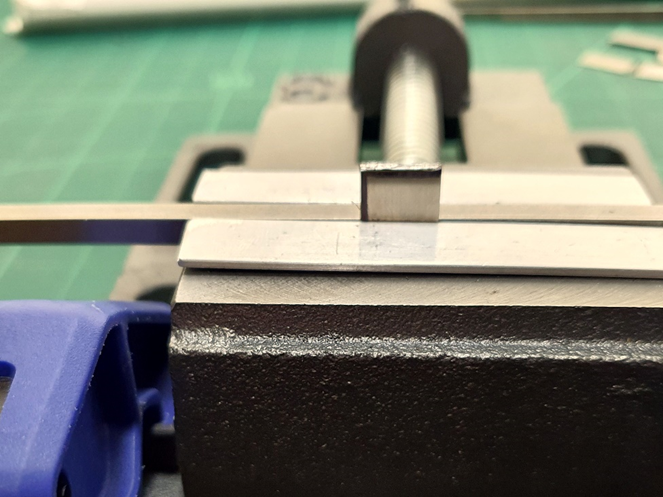

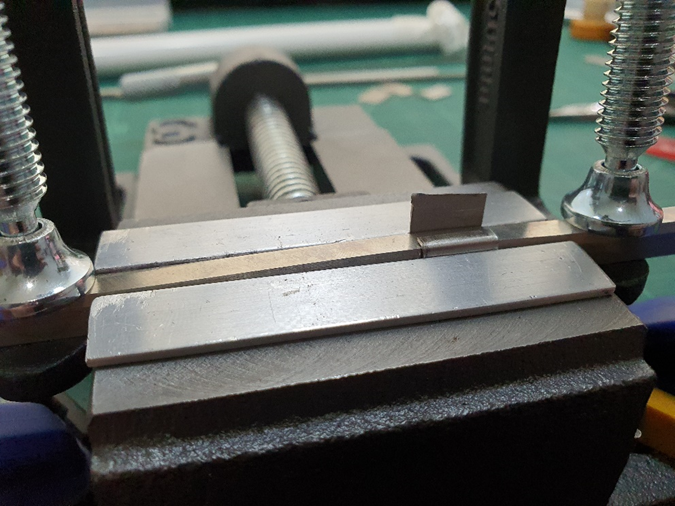

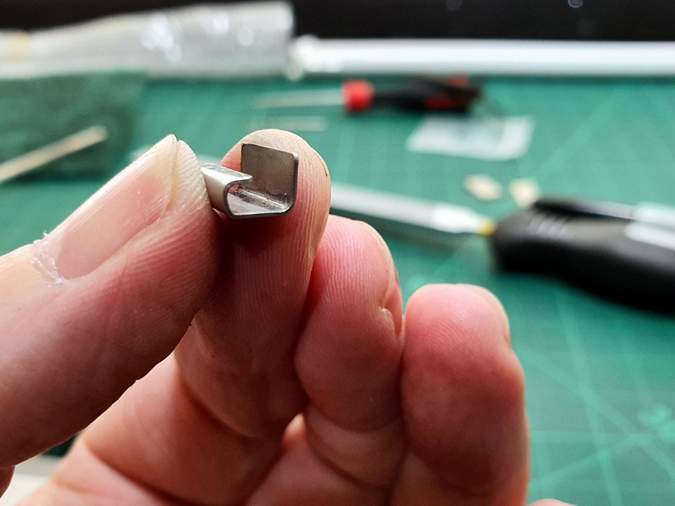

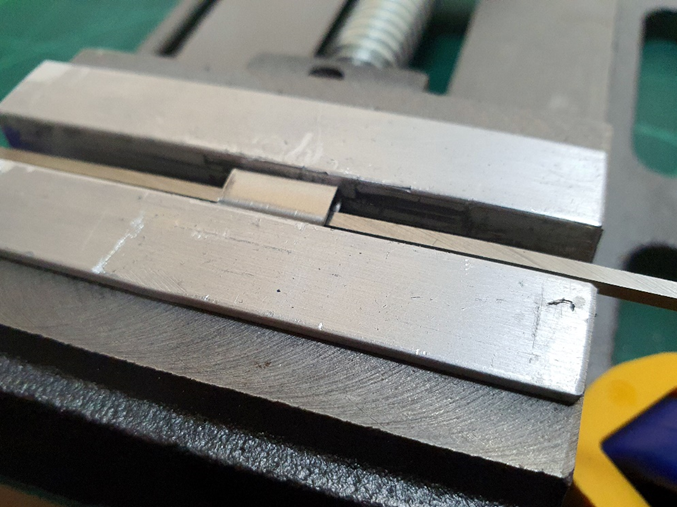

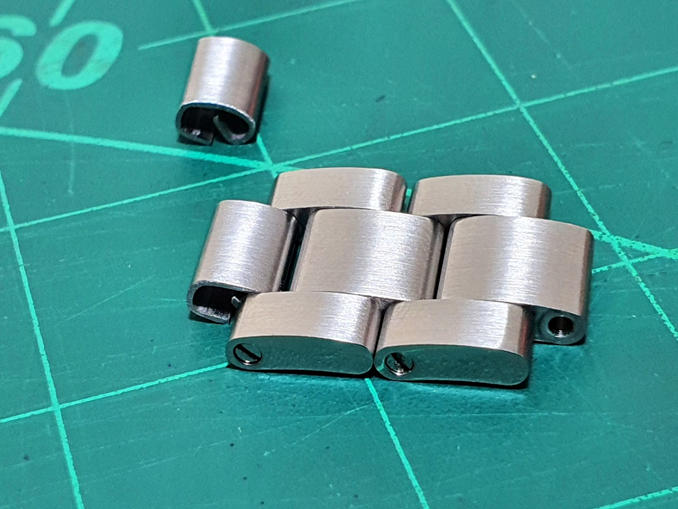

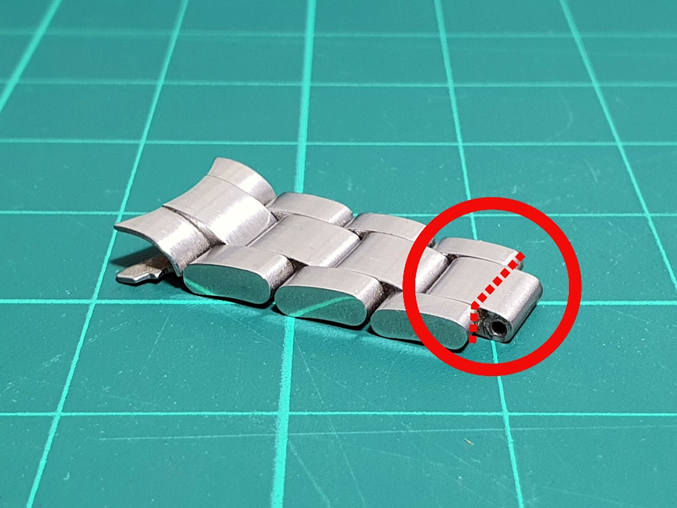

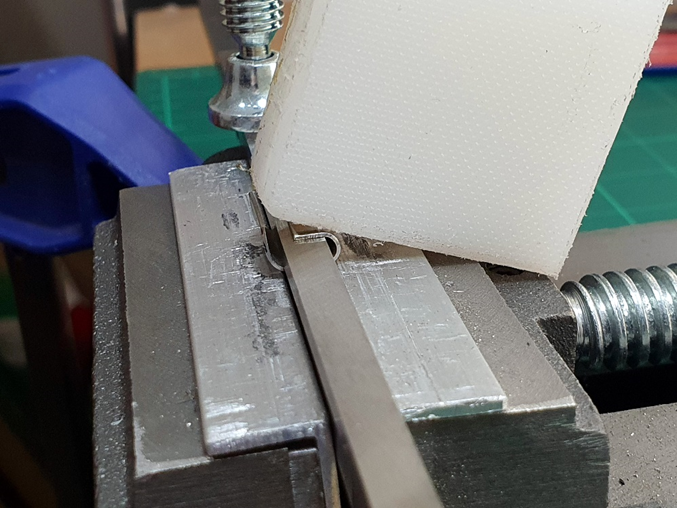

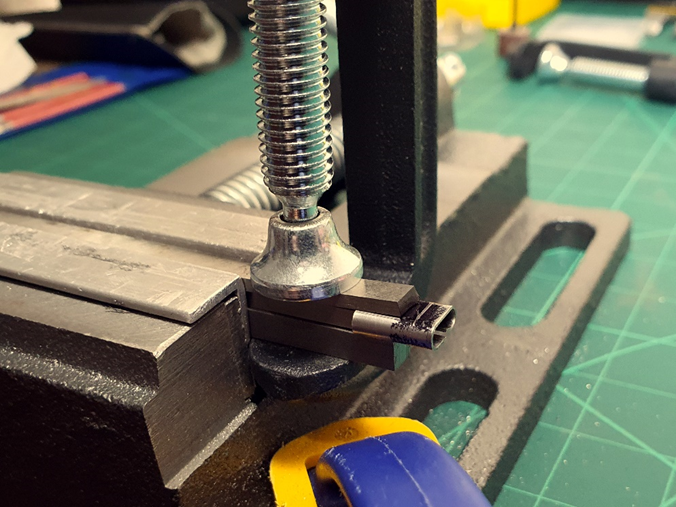

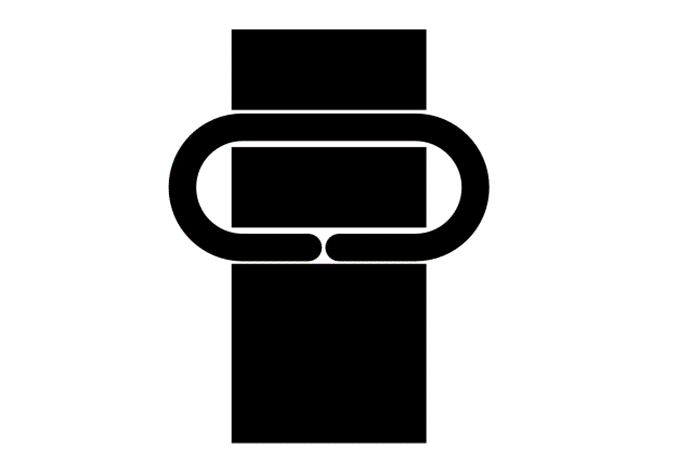

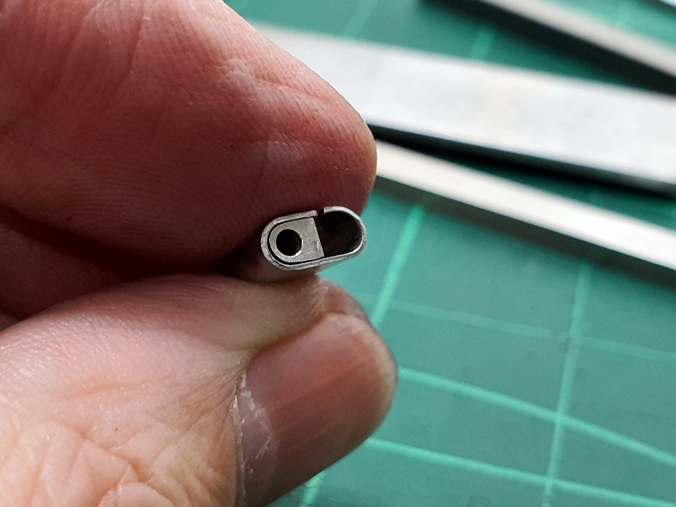

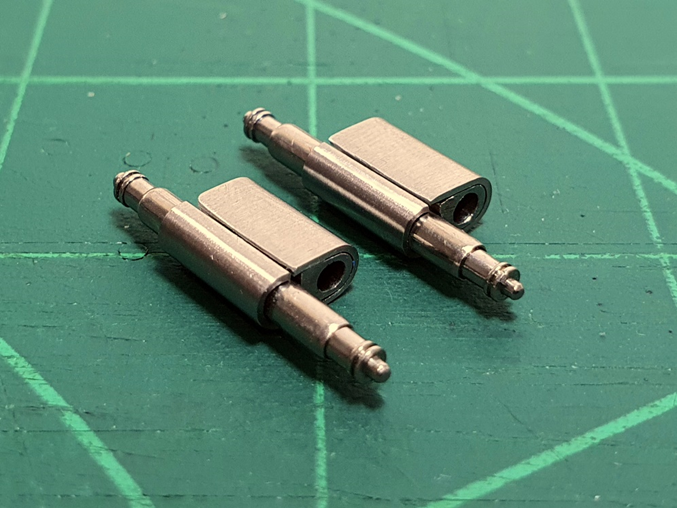

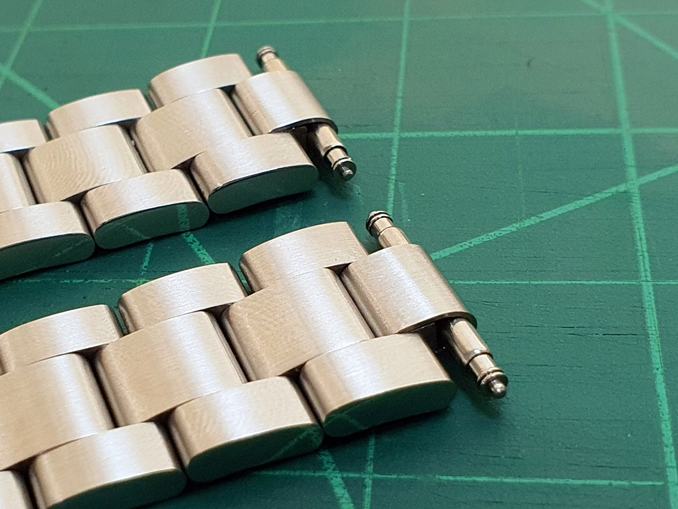

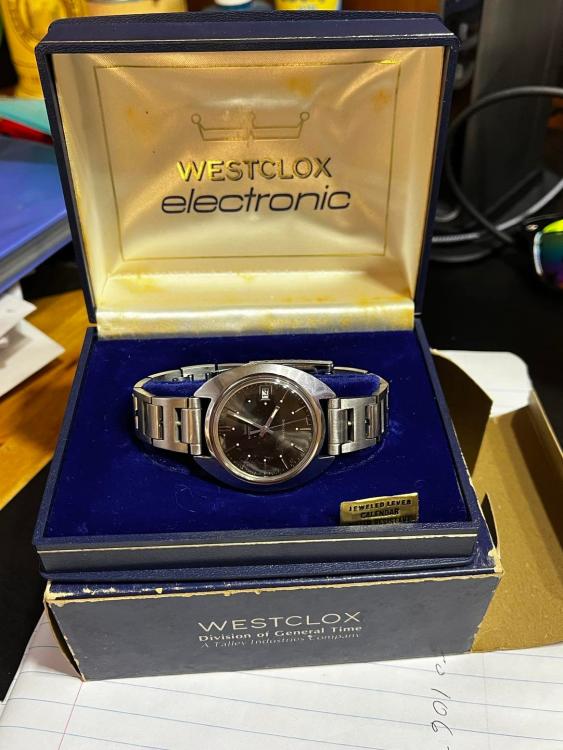

A very belated Merry Christmas and Happy New Year everyone! I finally got around to following this tutorial. And I have to say that it was a thoroughly enjoyable tinkering session that involved the simple tools that I had on hand. My reason for doing this was to fit a bracelet with female end links to an aftermarket 62mas style watch case. No bracelets with female end links exist for this particular watch case. The case is a scaled up 62mas style case that has nothing dimensionally in common with any of the Seiko 62mas, SLA, or SPB1xx watches. It does however share some commonality with SKX parts. It has a long lug to lug distance of 49.5mm and with solid male end links fitted looked rather long on my 7 ½” diameter wrist. The end link I ultimately used is hollow and from a cheap bracelet that I bought on ebay. The link I made using this tutorial is circled in red below. This connects the case and end link to an aftermarket bracelet for a Seiko SPB1xx series watch. A 62mas homage case that does not fit to any existing Seiko bracelets. I followed every step previously mentioned on how to do this, so I will hopefully not repeat what has already been said by others here. I will however mention the things that I did that were different and other things that occurred to me along the way. Below are all the tools and materials that I used. Nothing too exotic at all. I only had to buy some cheap steel flat bar in 5x5, 5x3, 5x2, 3x3, and 2x2 mm sizes and some stainless steel sheet in 0.6mm to use as mandrels/ forms. I purchased all of these materials on ebay. I did not use all these pieces in directly forming my link parts, but they did come in very handy for picking up and holding the small pieces of metal that I was cutting. I cut the stainless-steel sheet to 20x12mm with my Dremel with a 420-cut-off wheel attached. I scribed a perpendicular line around the 5x5mm steel bar and cello taped a cut piece of the stainless-steel sheet perpendicular to the edge of the 5x5mm steel bar. The 20x12mm pieces are small and the cello tape allowed me to hold and align them against the steel bar. It also made it easier to place them both into my vice. I also made some soft jaws out of aluminium to avoid marking the stainless steel sheet. For sharp bends, a flat blade screw driver worked well to fold the stainless steel over. I also found it easy to use a piece of an old plastic cutting board for doing this and bending radii as well. In this image I have a piece of stainless steel clamped between a piece of 5x5mm and 5x2mm steel bar which is held by my vice. I have cut and folded one edge and am getting ready to cut and fold the other. I was able to make a very square tube by clamping this in my vice again with a piece of flat bar inside and giving it a squeeze and a gentle tap with a hammer and a piece of an old plastic cutting board. I was quite excited by the result here. But I needed my links to not be so square in profile. I placed my metal links join side up on my work bench and bent one flap down with a hammer and a flat blade screw driver. I neglected to take a photo of this but the resulting shape of the stainless steel is like the diagram below. It is mentioned in the original tutorial that you can gently squeeze the shape you have made with pliers to give a curved/ rounded profile to your links. I did this slowly with my vice. I stopped the piece I was bending from jumping free from my vice by holding a piece of 2x2mm steel bar inside it. You can see this in the picture below. With some trial and error, I was able to fashion some end links that while not quite identical would serve the purpose. There was an unforeseen problem however… The thickness of the stainless steel sheet that I used left an unsightly gap between my newly made link and the existing bracelet. The steel I used was too thin. Luckily, I had an old steel bracelet handy, from a watch I bought in a dimly lit Tokyo back street long ago. I could cut and use the ends of its links as an insert in some new folded links. The reason I could not just those old links is that the watch case in my project only accepts fat spring bars- 2.5mm in diameter. Donor link from Tokyo watch bracelet about to be cut and filed to shape. Prior to remembering I had the old bracelet; I was considering purchasing some 2.5mm diameter stainless steel capillary tube from ebay which would serve the purpose of reducing the inner diameter and increasing the wall thickness of the link at one end to avoid an unsightly gap in the bracelet links. So, I decided to make some more links but with radii and no square corners. Forming a radius was surprisingly easy. It rolled over with a little bit of force. A piece of an old plastic cutting board makes a great tool for forming stainless steel as it is quite solid but will not scratch the surface. I also used a hammer with it to persuade the stainless steel a little. Just a gentle tap worked nicely. I formed one half of each radius and then flipped the stainless steel over to do the other side. I later realised I probably could have filed some radii on my steel flat bar, but I achieved a reasonable result without doing this. Three pieces of steel flat bar allowed me to hold my links so I could cut them to length without crushing them or them taking off into orbit. Below is an end view of the previous photo showing the link being held between three pieces of flat bar securely without crushing it. So, a little more trial and error followed. I massaged the links with a hammer and the plastic cutting board off cut to create my two links with inserts. These have the correct thickness at one end to fit the pins in the bracelet and the fat spring bars at the other. A little bit more tweaking followed by giving the links another squeeze in my vice to achieve a more curved profile. I spent a bit of time filing and test fitting the new links to the bracelet. Diamond files are a definite must, as are small Eze-Lap diamond sharpening plates. Eze-Lap plates have a large surface area for their size compared to diamond files. I then rubbed these evenly with green, and then blue Scotch-Brite pads to achieve a nice brushed surface. Not exactly a pigeon pair, but they fit and work quite well. I am still wondering if I should silver solder the inserts in place and silver solder the join on the back…? Getting ready to fit the bracelet to the end links and case. And here they are fitted to my home made 62mas homage. It is an assembly of some genuine Seiko and aftermarket mod parts. Finally, I just want to say thank you to the author of the original tutorial that allowed me to make these links. It was a pleasure to show how easy and fun this is to do. If anyone has a question, I'm more than happy to help if I can. And any suggestions will be greatly appreciated too! Cheers, Stevo4 points

-

I received my new shellac today and ran some tests, this stuff melts great and works best at 110c-115c (made a new pallet heater too). Everything went well, got bit too much on one stone, but it looks ok. I left the original "epoxy" in place and just added new shellac at the back of the stones. (some shellac flowed over and around that old epoxy). The stones now feel tight and look ok to me. I installed the pallet and ballance and everything is back up and running. Thanks for the help- Bill3 points

-

2 points

-

Remember that I am a novice and an idiot so this is probably not your problem but assuming it ran ok ISH before you worked on it, could it be the fourth wheel you changed, maybe it was off a different model and it has a different number of teeth. I know I am talking out the back of my hat again as I am often told but its worth a look, do you still have the old 4th wheel, give the teeth a count. it will give you something to look at while waiting a more knowledgeable reply.2 points

-

2 points

-

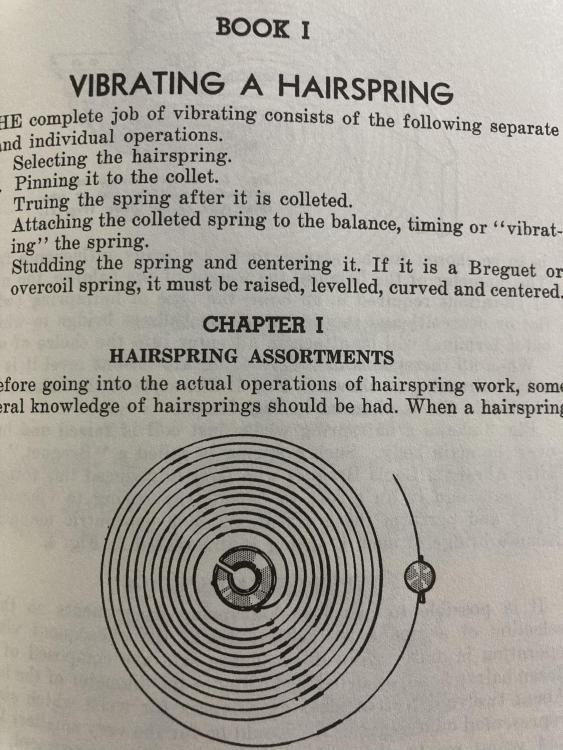

I can't help but notice the elephant in the room. If the existing hairspring is well and truly knackered as you say, then there is zero chance of doing damage to it by taking however many sessions you can stand and working on straightening it out. It won't hurt, and you'll probably gain significant experience, and the chances are heavily in your favor that you can make it better than it useta was and come out the other side with a bit of confidence boost even if you don't actually succeed. Also, this conversation inspires a question: I constantly hear that a hairspring and balance are a package deal and one just needs to find a replacement. OK, maybe it's not trivial at all, but it's not like these paired up assemblies drop from the floating fairy dust left over from unicorn farts These are made by human people things. If you can get an accurate measurement of the spring wire cross section and number of winds, then it seems like a courageous feller could jump in with both feet and accomplish the task somehow. Why should watchmaking include all these many skills and tasks except for, dog forbid, replacing the magic hairspring? Honest question.2 points

-

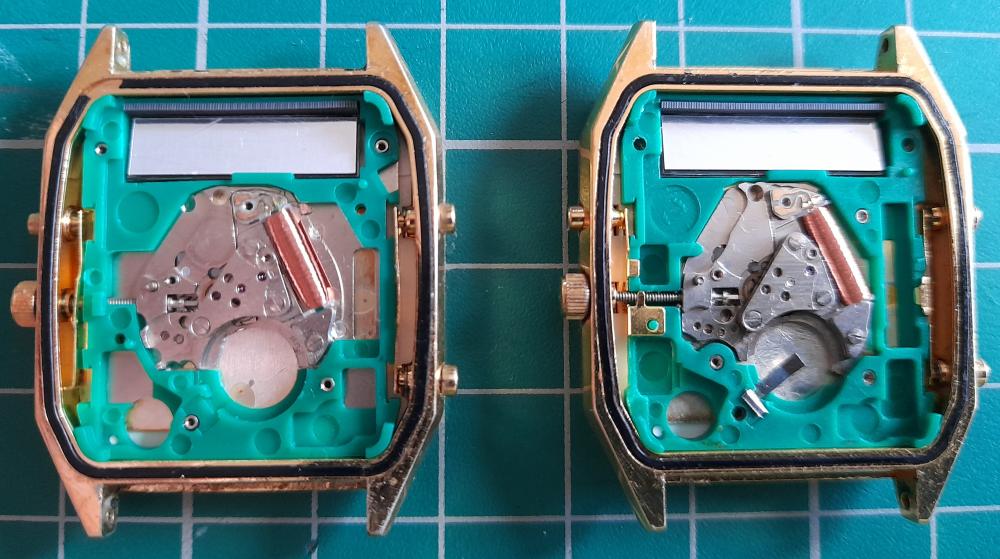

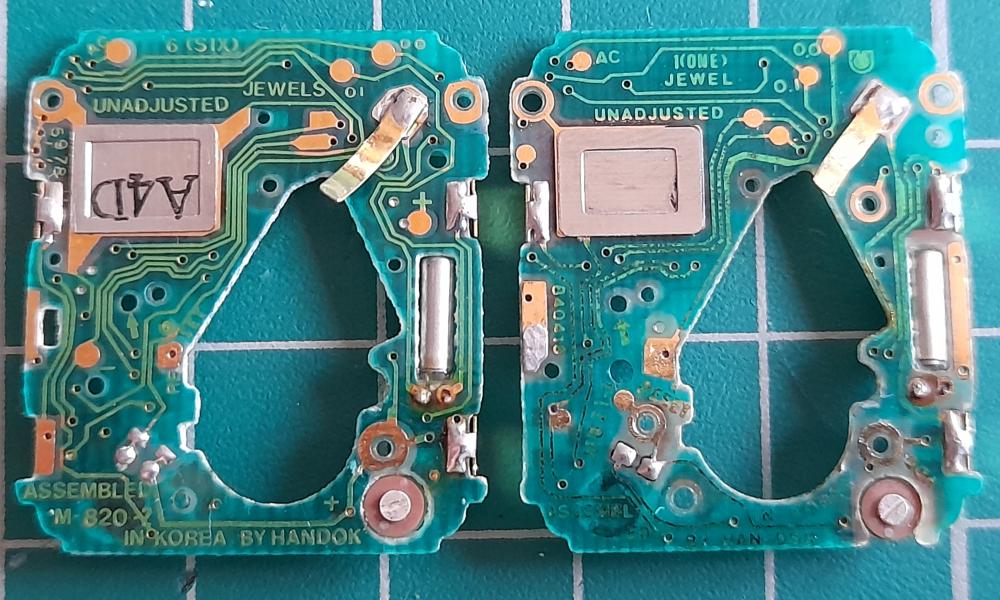

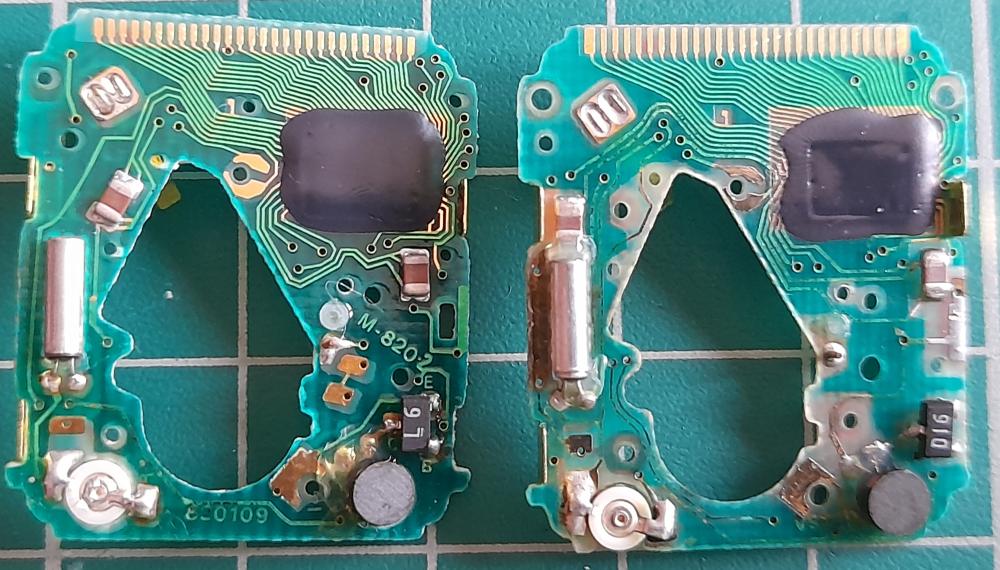

I've been meaning to post this in the hope this may help others as I know there is a following for these. I didn't come across much on the old internet. It's been a slow burner (well over a year) as when another pops up. Most I've seen have all had battery leaks and/or missing battery contacts. As with this hobby you seem to end up with another watch in the hope of fixing the one you have! Mine started with one that came in a job lot, managed to get the digital side of things working, but the very fine wires on the coil are broken. Analogue side no go. I didn't have enough magnification at the time. Then I managed to get a second one in the hope of swapping parts to make a working one. That's when it got interesting as it seems a Timex V Cell Ana-digi is not all it seems I guess on at which point in time it was made. From the outside they look almost identical. Once you get inside you can see the subtle differences between them. This sadly prevents swapping the circuit board, coil or even the movement holder, or to fault find/getting it working I guess the 6 jewel version is the older one and over the passage of time to cut costs by Timex and HANDOK (Which I still think are around) the jewel count was reduced, along with a few other changes. By good fortune and a lot of patience third time lucky I got my hands on my third which is likely late 1980's. This time after a bit of cleaning and repair to the battery contacts this one worked. Any way the one above sits proudly in the collection now. I hope this may help someone on a similar quest, not all Timex V Cell Ana-digi's are the same..... perhaps there's another version out there to add to these?1 point

-

Hi, just introducing my newest addition. I am not usually interested in battery watches but this one caught my eye as it is rechargeable and came complete with the charger and spare bracelet links. It's keeping perfect time and appears to be virtually unworn. I don't know anything about this watch, age etc and if anyone can enlighten me I would be grateful. Bought at car boot sale for £12.50 so it didn't break the bank and seems very well made.1 point

-

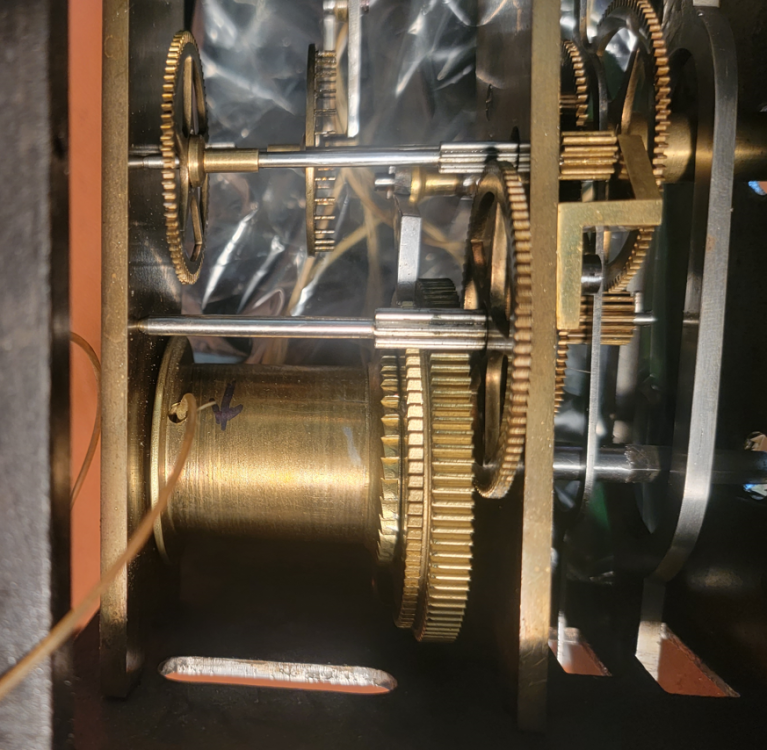

This came to me the other day. Needs the chord replaced. The owner researched and determined that 20lb test braided fishing line was in order. Not gonna argue. Looking at the barrel, I do not see a way to get into the barrel and replace the cord. I want to avoid taking the thing apart. It is another freebie job for a friend of a friend of a friend... BTW, that is just a baggie on the other side of the movement. I could make a wooden conical pin to hold the line in, or 3D print one. Thoughts? Here is a video of a guy working on one, but the cord magically appears at the end of the video.1 point

-

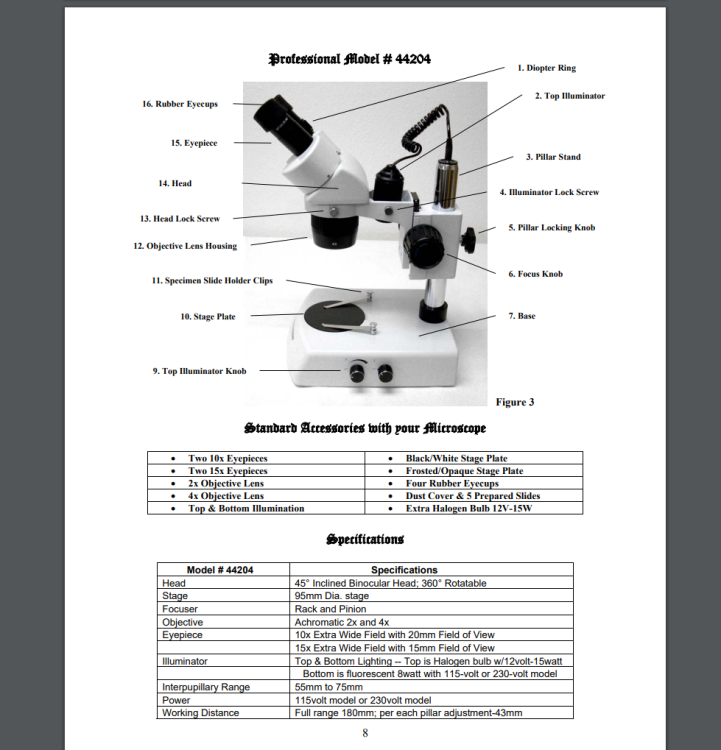

I picked up a used Celestron stereo microscope on Ebay for less than $100...delivered. It only came with the WF10x eyepieces and was missing a lower bulb and the translucent stage plate but other than that. it works perfectly. I'm looking into getting some 15x eyepieces for higher mag with the 2x objective which would allow a 30x total and would give me 60x mag with the 4x objectives....more than I'll ever need as a hobbyist.1 point

-

there different version of Timex watches with Electronic on the dial. so it would help to see a pic. but, in general the issue could be a bad circuit board, open balance coil, poor continuity and so on.1 point

-

1 point

-

Hi Ross its not too bad but bad enough, as said nothing to loose and everything to gain, just do it slowly and quit when tired only to pick it up again. Done by degrees. dont bend it use a stroking action to re form the spring. good luck1 point

-

Normally they are red. Here is a link. It says for comtoise clocks. They are the same the reason the names are different is because they were made in a different area in France. https://www.cousinsuk.com/sku/details/lines-ropes-cords/r552491 point

-

Actually even way back then I guess depending upon the way back when was hairsprings were still available. No skill required other than to send it off and a new one would come back. I remember when I was in school we did that we needed a hairspring for something Off it went and then it came back brand-new.1 point

-

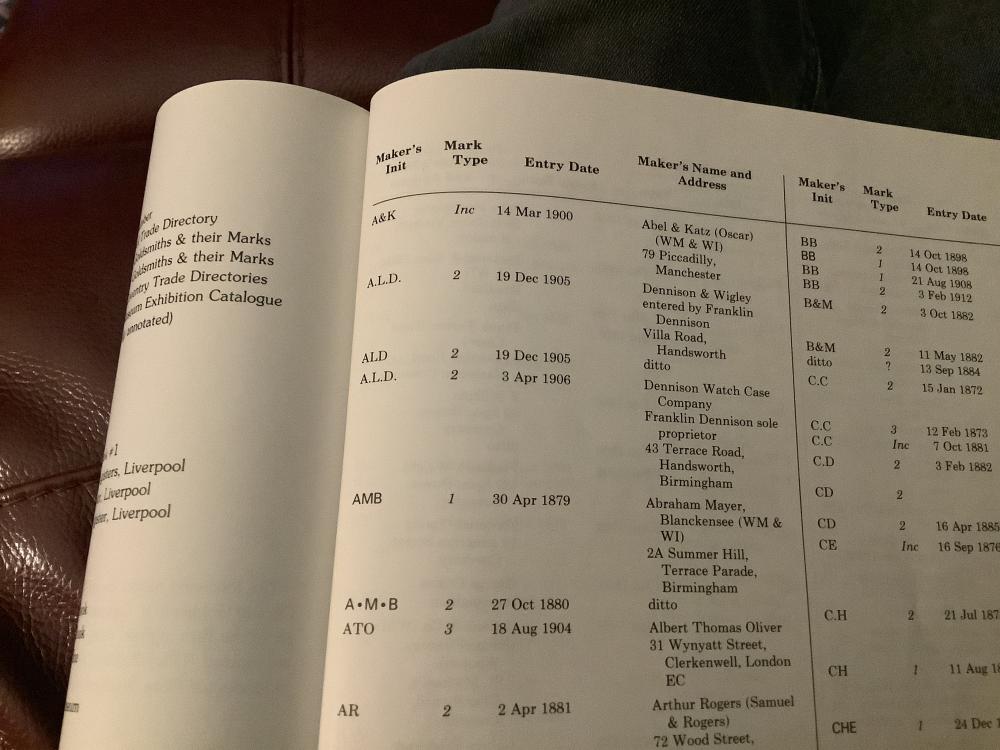

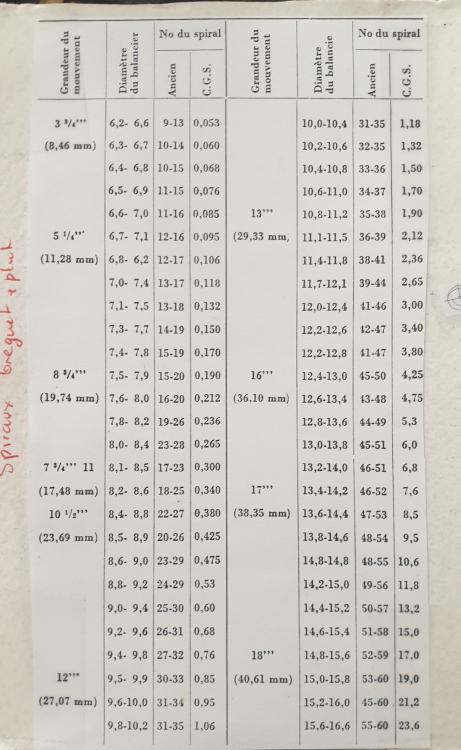

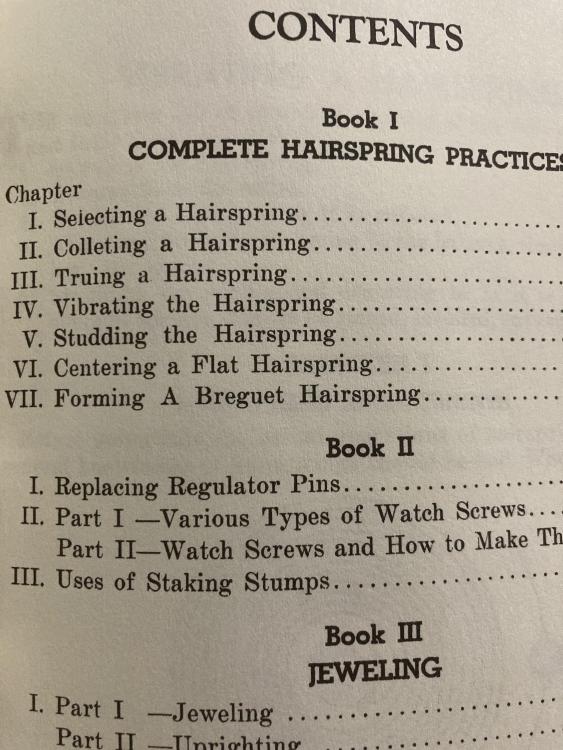

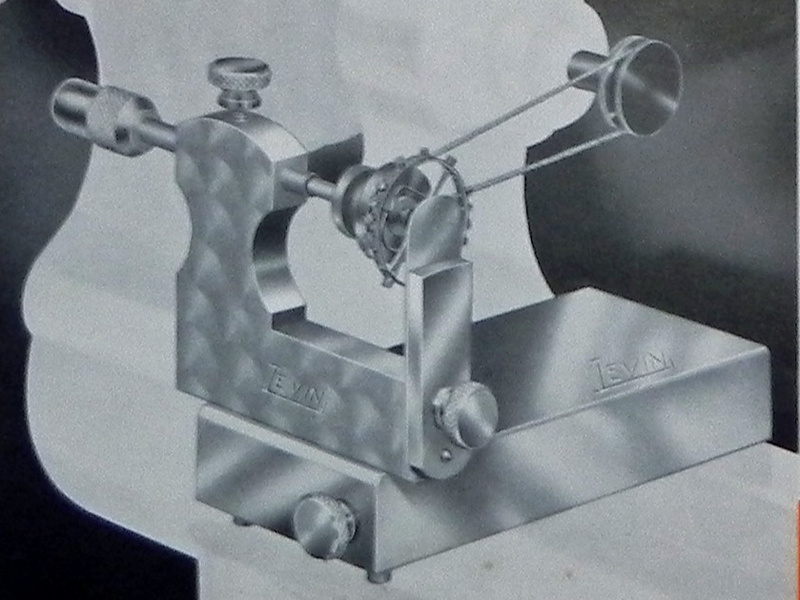

Watchmaking schools still teach hairspring vibrating, some more than others. The skill built doing dozens of them under expert instruction translates to everyday hairspring truing very well. The big issue if wanting to replace a spring is sourcing them. Way back in the day you could buy a packet of graded hairsprings from a supplier, in steel or more modern alloy. Today there are a few limited sources, usually with a small or oddball range of sizes. The manufacturers, Nivarox being the big one, don't want to sell a few springs; they want to sell thousands. You can usually negotiate for perhaps 100pcs, of one size, so there's that (but they aren't cheap). So one either spends time and money slowly collecting an array of different CGS numbers (the grading system for hairsprings), in both steel and Nivarox type alloys- though- often the steel ones will be graded in an older system!- and hopefully have some that might correspond to a given balance. Then, really, you need a Luthy tool to count the spring, the link in JohnFrum's post above shows it well. These have reference platforms for specific frequencies, 18,000 being the most common. A different platform is needed for each different frequency (or- Frank Praezis above can supply an electronic platform that does any frequency!). Springs can be counted without the Luthy tool, but it's a miserable process. You can usually reuse the original collet and stud if replacing a mangled spring, but it's nice to have an assortment of them as sometimes you may have no spring at all, or the collet is split, etc.- and there are many different sizes, so again, a lot of searching and buying and hoping. Back when Fried and others were writing their books, let's say the first half of the 20th century, modern manufacturing methods had made replacement parts plentiful and affordable, so a lot of manual skills that were focused on in schools or apprenticeships faded a bit. But there were still many older watches, older being what we would call antique now, where no material is available at all. Thus the chapters on vibrating springs, or repairing fusee chains, and so forth. Attached is a list of common CGS numbers and the approximate balance size they might correspond to, and a convienient conversion to the old system.1 point

-

Sorry, no idea what this is. If you specify the calibre, we could look up our inventory for a balance. Frank1 point

-

No easy way of replacing the line. You will have to take it apart. These movements are very well made nice thick brass plates and I see this one has maintaining power.1 point

-

IPA is common to used in the electronics industry to wash circuit boards today. But this is mostly for cleaning off flux, not oil. I think it would be fine to use, but IPA doesn't seem dissolve oil as well as naptha/lighter fluid/benzine does. Those however are not typically used to wash circuit boards.1 point

-

1 point

-

Yes he definitely was a very interesting person. I always think every time I hear his name I can remember the last conversations I had with him at a national meeting in Chicago. That's a partially correct answer. If it's a flat hairspring that hairspring was vibrated for that specific balance wheel. Silly in general cannot swap flat hairsprings which is why there never listed as a spare part on a parts list. If you have an over coil hairspring the over coil hairsprings typically are premade to very exacting specifications. Then the balance wheel is matched to the hairspring but the factory as a infinite supply of screws and conceivably custom makes the screws to exactly fit. But over coil hairsprings are listed on parts lists along with the associated timing screws that you need to match them to a balance wheel. Your hairspring appears to be flat. It does appear perhaps that those are timing screws but I'm not sure that they actually come off and I'm guessing in real life the best thing to do would be balance complete because matching a hairspring to your balance wheel is going to be very challenging. Or in general almost impossible.1 point

-

1 point

-

I've been very curious about balloon chucks. I haven't really been sure how they are supposed to be used, I wasn't even sure what they are for! I'm guessing from the comments that they are for polishing pivots, but I don't see how that works. To me, it looks like the balance is mounted inside the chuck, but I don't see what keeps the balance from spinning freely inside the chuck. Now a Jacot tools I understand, I just have to get better at using it1 point

-

Opinions are worth considering when they are offered with reason. Yours were not; All Chinese made tools are crap. End of story. You are telling us that all of the tools that I and others here have bought and used are garbage. Why? Because you say so. Well, you are wrong and you have shown that you are totally unwilling to listen to other viewpoints that contradict your own, viewpoints that are based in actual hands on experience with the tools mentioned in this thread. If you have actual experience with any of the products mentioned in this thread then please quote the original post and give your feedback. That is what this thread is for. But please don't come in hear and take a huge non-reasoned dump in the middle of the topic and then expect everyone to, for some reason, respect that. That's not how discourse works.1 point

-

I just look at vintage tools, myself. That is chancy too because you might get a pin vise that has been mistreated. I have a few of those!! I watch ebay every day and have a long list of saved items. I have gotten some very good deals and some not-so-good deals. I shop FB marketplace as well. That is where I got my Levin lathe with cross slide and 4-jaw chuck for $300. That was the best deal I ever got!! You just have to watch constantly and keep track of what stuff is going for.1 point

-

If you really look at that Etsy shop it is selling stuff you buy on aliexpress or bangood. There is nowhere outside of China and India making these tools cheap enough to sell for those prices. Tom1 point

-

We had some in school, I found the same, not very true. Our teacher mentioned that when new, the cap has no hole, and you were to drill it in the lathe it would be used in. I kind of doubt that; the ones I saw were on 8mm collet shanks, which if made well, should seat in a good lathe spindle within a few microns each time. But there's the thing; a set of balloon chucks from Levin would pretty certainly be excellently made, and work well. A set from Marshall, they might make the body diameter a bit smaller to be sure it would fit in whatever spindle. That won't repeat very well at all- the body diameter is very, very important- it's not just the angle on the collet head/spindle bore that gives repeatable precision. I never saw the attraction of balloon chucks or some of the little "pivot polishers" that hold the balance between centers, with the pivot to be worked on sticking out a thin support. But we were drilled on Jacot tool use in school, and I keep one set up a meter from my bench at all times.1 point

-

Xenophobia was exactly what put the Chinese back a hundred years. How many ideas did the West borrow from the East? We all learn from one another. That's how we progress. If one closes his doors and mind to the outside world, that's when stagnation and decay starts. Competition is good. It keeps one moving forward.1 point

-

I have quite a collection of high quality well made Chinese tools that are so identical to the Bergeon and Horotec tools that I am totally convinced that Bergeon and Horotec and many others all have their tools made in China and then just pack them in boxes with made in Switzerland printed on them. The tools are absolutely identical in every way apart from branding, they have identical machining marks, the parts are fully interchangable. The only difference is the price. Don't think the Swiss would do such a thing, remember the whole Swiss watch industry is based on a lie, many claim to be watch makers but are only bracelet and case makers, dropping in some generic movement they bought from the likes of ETA etc, then charging a high price just based on their name. Some of them even though they have a multi million turnover are listed as charities so don't pay a cent in tax (Rolex) for example. If they are dishonest with their tax they are going to be dishonest in ather ways as well. The Swiss watch industry is a shady business from end to end so I find it quite easy to find they have products made in China and claim they make them themselves so they can hike the the price by in some cases a huge amount. Take the Bergeon 4 plunger hand setter, almost a grand, the identical one from China is £100. I have one and compared it side by side with the Bergeon, other than the branding and box there is absolutely no difference with all the parts being fully interchangable. Obviously not all tools from China are worth even their low prices but many are, just do your research before hitting the buy button. That's it, off my soap box. Hat coat door bye1 point

-

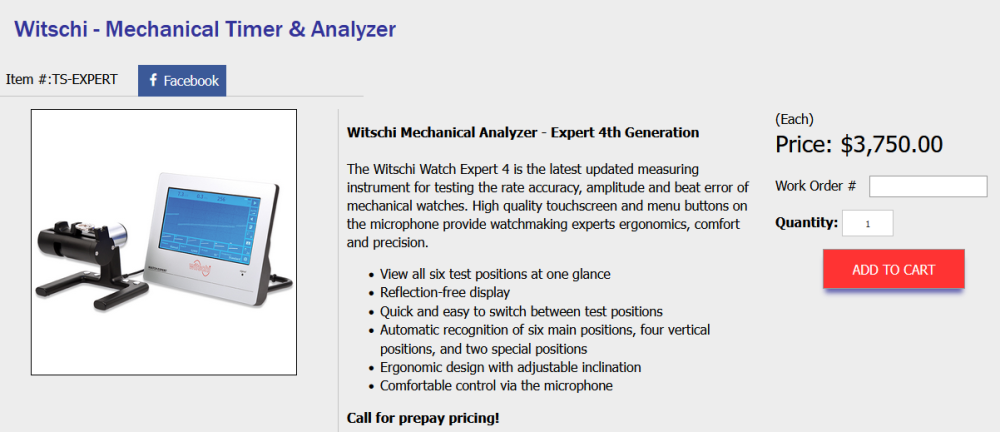

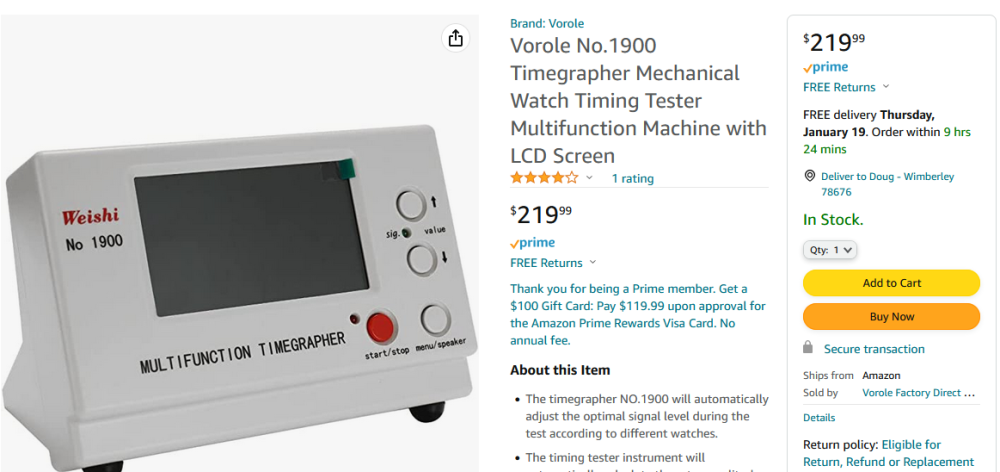

I’ve got a Chinese timegrapher, stereo microscope, ultrasonic cleaner, Horia jeweling tool clone etc that I’m quite pleased with. As a hobbyist these Chinese tools have allowed me (as my skills slowly develop) to progress in watch repair in a way I did not think possible when I started. Yesterday I replaced the balance staff and palette fork pivot jewels of a Seiko 1104A practice movement. Have an issue with the hairspring but I’m getting better. The equivalent Swiss tools are not affordable for the hobbyist. My 99 USD jeweling tool clone from China works just fine for my occasional usage. There is also nothing shoddy about it. The Swiss original is 500 GBP for the tool and another 1000 GBP for the set of pump pushers. The original undoubtedly has better fit and finish and for a professional are a necessary investment in their business but I am just a simple hobbyist reading Fried and De Carle books and practicing on a few dozen old ladies movements I bought for 2 USD each from SpeedtimerKollektion.1 point

-

This is true. I would say that it is an excellent machine at a very reasonable price compared to the Witschi. I think you paint with a broad brush. Virtually every hobbiest/amateur on this board uses the Weishi and are happy with it as far as I can tell. Furthermore, the Chinese have several semiconductor foundries that produce world-class chips. So they can go to space and mass-produce good semiconductors. I am not offended by your rant...quite enjoy it. But I think your argument is too simplistic...too binary. Buy a Chinese screwdriver and put a Bergeon blade on it. Voila...you have a quality product. Or pay twice and get a Bergeon. I have lots of Bergeon and a couple of Chinese, so I can compare the quality...pretty close except for the blades.1 point

-

1 point

-

An interesting Q&A video with Sébastien Chaulmontet of Sellita in which he answers an assortment of questions about Sellita. Worth a watch, especially if you think Sellita is a just a subpar clone ETA.1 point

-

Hi Neverenoughwatches, Yes, it's a really interesting thread that opens up a lot of possibilities. And the best part is that it can be done with simple tools. I have some holidays coming up soon and I'll be following this technique to link an oyster bracelet to some flat end pieces. I'll definitely post some pics once I'm done to show my thanks for the sharing of this knowledge! And thanks for the compliment Mate! Throw your razors away, is my advice to every man. Save your money from expensive shaving products to buy watches! Cheers, Steve1 point

-

thi is how this forum works, a lot of knowledge ready to share...welcome mate1 point