Leaderboard

Popular Content

Showing content with the highest reputation on 01/18/23 in all areas

-

Xenophobia was exactly what put the Chinese back a hundred years. How many ideas did the West borrow from the East? We all learn from one another. That's how we progress. If one closes his doors and mind to the outside world, that's when stagnation and decay starts. Competition is good. It keeps one moving forward.6 points

-

@LittleWatchShop when I look at UK vintage tool auctions on eBay it is the only time I wish I lived in the USA, a lot of more sensible prices you folks have. Just the other day I saw a couple of buy it now bergeon crystal lift platforms for £35.00, I bought mine new from cousinsuk for £15.00. seems watchmaking stuff has gone the route of marine stuff, inflated because people have a strange notion that they are worth a lot of money. Tom3 points

-

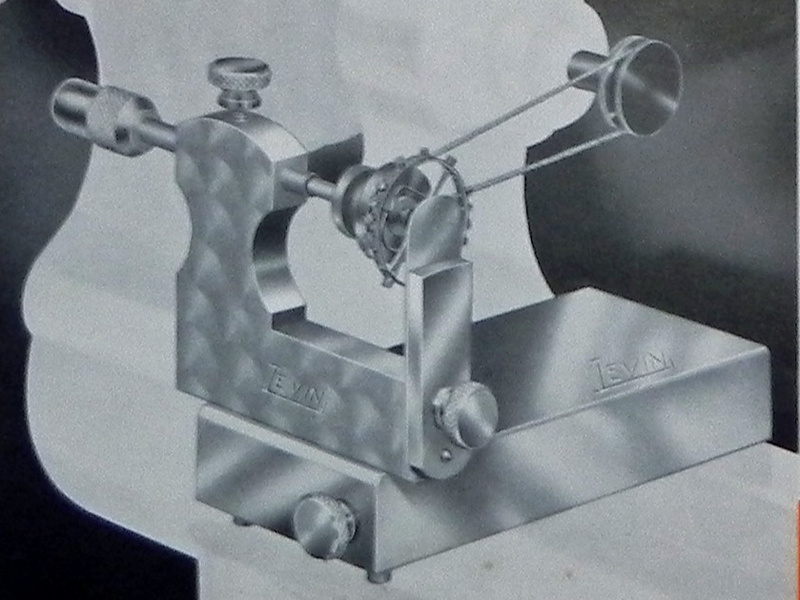

I'm always amazed jd uses his crappy Peerless lathe so much when he has like a dozen others including a beautiful Paulson (made by Boley Leinen). As you can see, you polish the sticking out in the air pivot, in his case with a burnisher, but many in the past used bronze or even wood with polishing paste. In a Jacot, one side of the pivot is supported in a beautifully made bed of its exact size. It becomes almost a challenge to break a pivot. But pivot unsupported... yikes. The Jacot didn't catch on in the U.S. like in Europe, way back early 20th century skilled yanks used "pivot polishers" which were actually sophisticated live spindle grinders to shape and finish pivots. While really useful for many things, I can do both sides of a new staff in a Jacot before you'd even get one of those devices clamped in the lathe bed.2 points

-

Opinions are worth considering when they are offered with reason. Yours were not; All Chinese made tools are crap. End of story. You are telling us that all of the tools that I and others here have bought and used are garbage. Why? Because you say so. Well, you are wrong and you have shown that you are totally unwilling to listen to other viewpoints that contradict your own, viewpoints that are based in actual hands on experience with the tools mentioned in this thread. If you have actual experience with any of the products mentioned in this thread then please quote the original post and give your feedback. That is what this thread is for. But please don't come in hear and take a huge non-reasoned dump in the middle of the topic and then expect everyone to, for some reason, respect that. That's not how discourse works.2 points

-

The vast majority of staking tools use 4.7mm punches, including U.S. makes. 3/16" is 4.762mm, that extra 0.06mm is enough that it won't fit.2 points

-

Try removing the barrel arbor from the barrel and fitting just that onto the plate and see if the barrel bridge can seat fully. The hole closing punch can distort the plate and affect endshake.2 points

-

Some of these tools are so specialized and have such a limited market (the GY0105 Hand press comes to mind) that I doubt someone in China just decided to copy it. Some are undoubtedly made in the same factories that produced the original for western clients. Does anyone complain about their Iphones made in China (but designed in California) ? Anything shoddy about it? Even in cases where the Chinese version is demonstrably inferior, it may be good enough for the hobbyist especially when the cost of the original is high. My Amscope is no Zeiss. I have used Zeiss microscopes and the optics and general fit of the Amscope are far from them. But it is perfect for the hobbyist I use a cheap Chinese micropipette to dispense the expensive Swiss oil from the tiny bottles. It is no Eppendorf but it works just fine and is affordable. JMT2 points

-

I have quite a collection of high quality well made Chinese tools that are so identical to the Bergeon and Horotec tools that I am totally convinced that Bergeon and Horotec and many others all have their tools made in China and then just pack them in boxes with made in Switzerland printed on them. The tools are absolutely identical in every way apart from branding, they have identical machining marks, the parts are fully interchangable. The only difference is the price. Don't think the Swiss would do such a thing, remember the whole Swiss watch industry is based on a lie, many claim to be watch makers but are only bracelet and case makers, dropping in some generic movement they bought from the likes of ETA etc, then charging a high price just based on their name. Some of them even though they have a multi million turnover are listed as charities so don't pay a cent in tax (Rolex) for example. If they are dishonest with their tax they are going to be dishonest in ather ways as well. The Swiss watch industry is a shady business from end to end so I find it quite easy to find they have products made in China and claim they make them themselves so they can hike the the price by in some cases a huge amount. Take the Bergeon 4 plunger hand setter, almost a grand, the identical one from China is £100. I have one and compared it side by side with the Bergeon, other than the branding and box there is absolutely no difference with all the parts being fully interchangable. Obviously not all tools from China are worth even their low prices but many are, just do your research before hitting the buy button. That's it, off my soap box. Hat coat door bye2 points

-

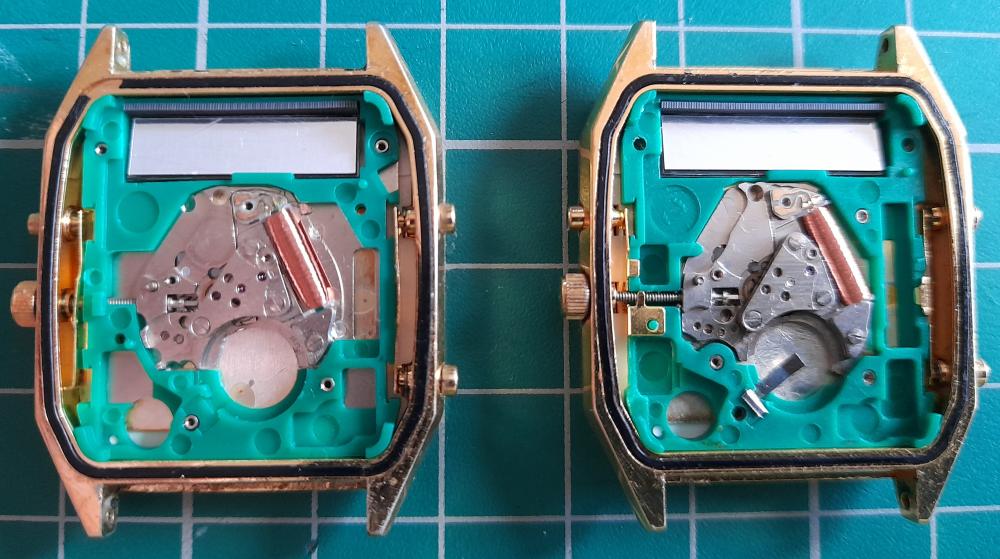

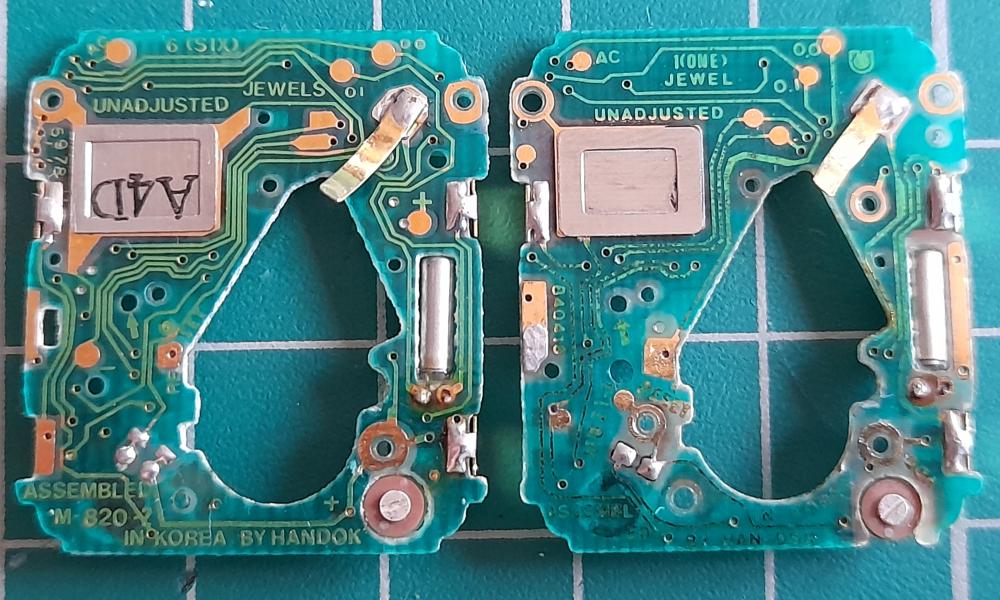

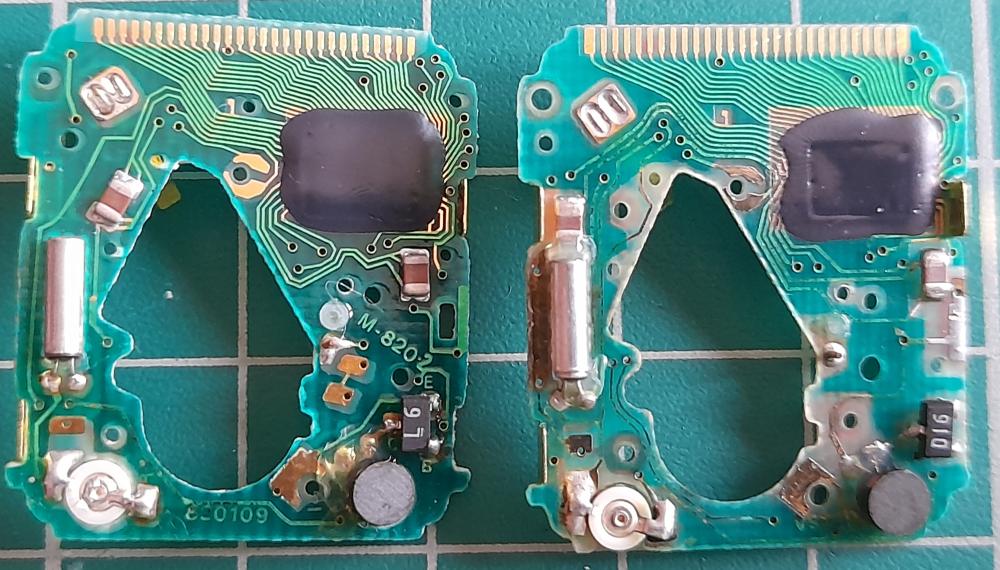

I've been meaning to post this in the hope this may help others as I know there is a following for these. I didn't come across much on the old internet. It's been a slow burner (well over a year) as when another pops up. Most I've seen have all had battery leaks and/or missing battery contacts. As with this hobby you seem to end up with another watch in the hope of fixing the one you have! Mine started with one that came in a job lot, managed to get the digital side of things working, but the very fine wires on the coil are broken. Analogue side no go. I didn't have enough magnification at the time. Then I managed to get a second one in the hope of swapping parts to make a working one. That's when it got interesting as it seems a Timex V Cell Ana-digi is not all it seems I guess on at which point in time it was made. From the outside they look almost identical. Once you get inside you can see the subtle differences between them. This sadly prevents swapping the circuit board, coil or even the movement holder, or to fault find/getting it working I guess the 6 jewel version is the older one and over the passage of time to cut costs by Timex and HANDOK (Which I still think are around) the jewel count was reduced, along with a few other changes. By good fortune and a lot of patience third time lucky I got my hands on my third which is likely late 1980's. This time after a bit of cleaning and repair to the battery contacts this one worked. Any way the one above sits proudly in the collection now. I hope this may help someone on a similar quest, not all Timex V Cell Ana-digi's are the same..... perhaps there's another version out there to add to these?1 point

-

Yes he definitely was a very interesting person. I always think every time I hear his name I can remember the last conversations I had with him at a national meeting in Chicago. That's a partially correct answer. If it's a flat hairspring that hairspring was vibrated for that specific balance wheel. Silly in general cannot swap flat hairsprings which is why there never listed as a spare part on a parts list. If you have an over coil hairspring the over coil hairsprings typically are premade to very exacting specifications. Then the balance wheel is matched to the hairspring but the factory as a infinite supply of screws and conceivably custom makes the screws to exactly fit. But over coil hairsprings are listed on parts lists along with the associated timing screws that you need to match them to a balance wheel. Your hairspring appears to be flat. It does appear perhaps that those are timing screws but I'm not sure that they actually come off and I'm guessing in real life the best thing to do would be balance complete because matching a hairspring to your balance wheel is going to be very challenging. Or in general almost impossible.1 point

-

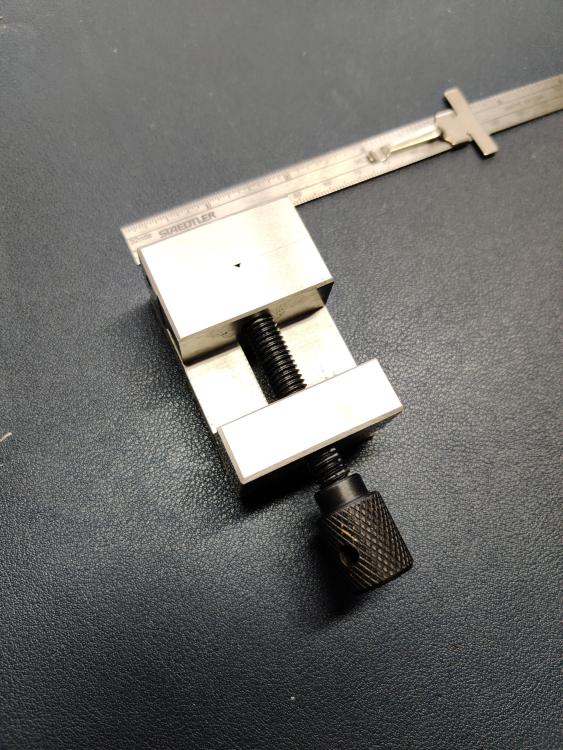

I ordered a little machine vise from AliExpress, so that it could sit flat on my bench. Doesn't add a lot of height, so It all fits under my microscope. Hefty little piece of steel, but this one is a bit small. I would set up a mounted vice, but it's a little tricky drilling holes in a glass top https://www.aliexpress.us/item/3256803197259569.html?spm=a2g0o.order_list.order_list_main.5.7370194dDaqeYh&gatewayAdapt=glo2usa&_randl_shipto=US Mine is the 1.5". There is one that is bigger, The QGG50, that is 2" that I think would work even better. Cheers!1 point

-

I'm curious about which school. The first school the instructor used a balloon chuck For polishing the pivots and it worked fine. Like any tool if you understand how to use it you can make use of it some tools of course work better than others. The second school I don't even remember seeing anything for polishing pivots at all. But way back when they didn't have Deeper pockets as they did later on. Like anything you just have to be careful. Although I would agree the term burnishing isn't exactly what I would think in this set up because I don't think you can get enough pressure but Indefinitely polish the pivots and make them look nicer which a lot of times is all you need. I once had some old-time watchmaker show me how to use the tool. When he did it it produce the most beautiful black polish I've ever seen so tool is really outstanding but. As he pointed out if you want to be good at it you have to use it in practice every single day basically into a really really good and you probably should still continue to practice. It's like everything else in watch repair it requires lots of practice. Then his other comment made was that your bird assure basically should conform to the shape of your pivots so conceivably you might need more than one burnish her because you may have different curvatures although you may not be concerned about polishing the curved partier pivot. So for me since I didn't practice and finally sold my tool because I was never using it anyway I just use the balloon chuck. Which for the most part works fine. No matter what if you have some staffs you really should just replace them neither tool necessarily is a miracle fixed to make you a new pivot.1 point

-

Thanks for the link. It answered the last question I had, which is that the balance is held by friction, it has to be tight enough that it doesn't spin inside the check as you burnish. I'll stick with the Jacot, and as usual, practice, practice, practice. Cheers!1 point

-

The index pin rides in a bore, and that bore may not be perfectly true to the rotation of the lathe spindle. It's quite hard to make a small bore like that in (what should be) hard steel perfectly. But if the pin is rectified in the bore, in the lathe, it's now true- as long as it doesn't turn in the bore. Thus the indexing pin and slot. When we used faceplates at school, we got the part close with the pin, then bang-on with a wobble stick. Nowadays, I use optics to center in the faceplate.1 point

-

I've been very curious about balloon chucks. I haven't really been sure how they are supposed to be used, I wasn't even sure what they are for! I'm guessing from the comments that they are for polishing pivots, but I don't see how that works. To me, it looks like the balance is mounted inside the chuck, but I don't see what keeps the balance from spinning freely inside the chuck. Now a Jacot tools I understand, I just have to get better at using it1 point

-

See the section in grey https://bhi.co.uk/wp-content/uploads/2021/05/HJ-Mainspring-Winders.pdf1 point

-

18000 bph is correct. Sticky hairspring due to contamination or magnetisation, sometimes intermittently which is hard to spot with naked eye, making a vid of oscilator running helps to spot hairspring issues.1 point

-

We had some in school, I found the same, not very true. Our teacher mentioned that when new, the cap has no hole, and you were to drill it in the lathe it would be used in. I kind of doubt that; the ones I saw were on 8mm collet shanks, which if made well, should seat in a good lathe spindle within a few microns each time. But there's the thing; a set of balloon chucks from Levin would pretty certainly be excellently made, and work well. A set from Marshall, they might make the body diameter a bit smaller to be sure it would fit in whatever spindle. That won't repeat very well at all- the body diameter is very, very important- it's not just the angle on the collet head/spindle bore that gives repeatable precision. I never saw the attraction of balloon chucks or some of the little "pivot polishers" that hold the balance between centers, with the pivot to be worked on sticking out a thin support. But we were drilled on Jacot tool use in school, and I keep one set up a meter from my bench at all times.1 point

-

Any time you're having a problem putting a bridge on its best to remove everything under the bridge and just try the bridge itself to make sure you not having a problem there. A lot of times the pins in the plate the steady pins are really tight you want to verify whether that's what's going on or whether there's something else going on. Then hole closing can seem simple and easy but you can end up with interesting issues. Like for instance of the hole was oval in shape and you close it, is now no longer centered.1 point

-

I'm not quite sure what you're saying here? I have found it typically there is one of the bluing shocks that I have that I prefer so I had the mark that so I know which one I preferred because some they well I just typically don't use some even though I have five or so what work I usually have one that I marked because I know what works well. Sometimes it looks like it's wobbling I just taken out of the 5 mm Chuck that it's in and just put it back in again and it seems to be fine. Casually from memory any of the ones that have the end that screws off I don't recall them ever being where there supposed to be. But I suspect if they get dropped that's going to be an issue.1 point

-

You will expectedly improve amplitude with new/ stronger mainspring. Rgds1 point

-

Up until now everything I'd read said don't put those parts near IPA due to the shellac. I'm just a goon working on cheap garbage watches for fun, I don't really have the ability to re-set pallet stones if I screw up. I'm gonna try a very, very quick dip in IPA for this 6309a I'm working on next, but so far I'll say there haven't been any issues that I can see with the shellite. It seems especially good for cleaning up balance jewels, I've not seen any residue left behind. But again, complete amateur.1 point

-

Hi have Chinese tools alongside Bergeon and Horotec. The Chinese tools I fully expected to have to fettle them to make them better. I was disappointed that I had to do the same with the Swiss tools albeit to a lesser degree. However if I spend £100 on a Chinese tool and need to spend 3 hours fettling it compared to an hour fettling a £500 Swiss tool I think I have still won out. Tom1 point

-

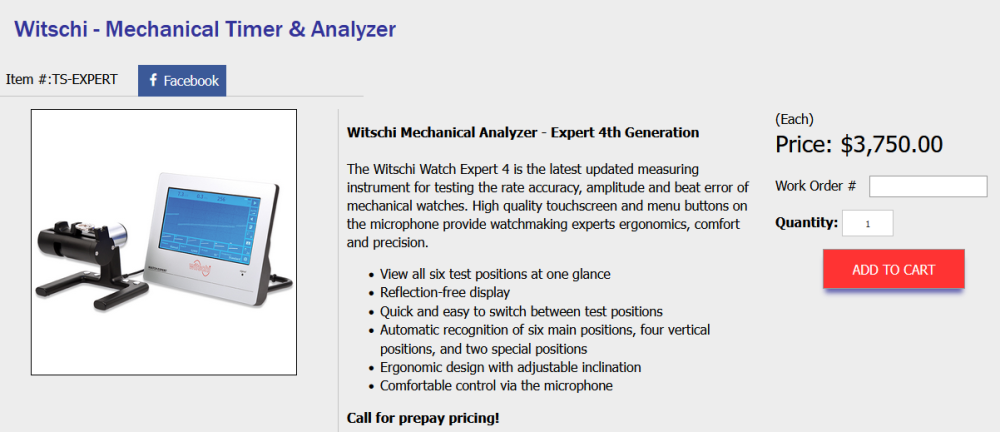

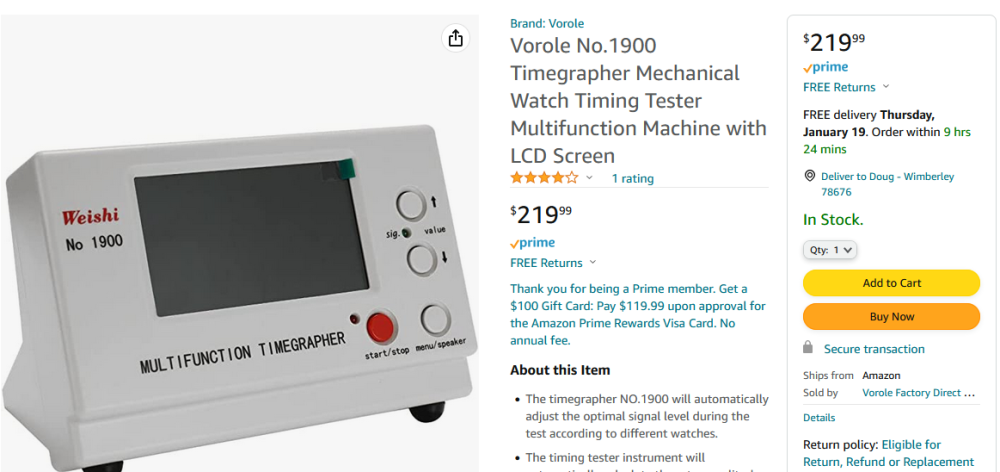

This is true. I would say that it is an excellent machine at a very reasonable price compared to the Witschi. I think you paint with a broad brush. Virtually every hobbiest/amateur on this board uses the Weishi and are happy with it as far as I can tell. Furthermore, the Chinese have several semiconductor foundries that produce world-class chips. So they can go to space and mass-produce good semiconductors. I am not offended by your rant...quite enjoy it. But I think your argument is too simplistic...too binary. Buy a Chinese screwdriver and put a Bergeon blade on it. Voila...you have a quality product. Or pay twice and get a Bergeon. I have lots of Bergeon and a couple of Chinese, so I can compare the quality...pretty close except for the blades.1 point

-

It seems that an attempt to correct the poise was made in the past; if it was at the factory I would think it would be poised without a clear heavy spot, but if it was restaffed, and the staff was a bit undersize for the balance (could be from punching out the staff, or a poor replacement) that can introduce a large poise error as there's no assurance the staff rivets in perfectly centered. Perhaps someone tried to get it better and stopped before it was right. If there's the slightest bend in a pivot that will show as a large poise error. Pivots should be cleaned in clean pithwood, and the ruby jaws of the poising tool likewise cleaned (the pith batons are nice for this). Tool should be level, and make sure the jaws are on the cylindrical part of the pivots, not the cones. I know that all sounds obvious but I've seen grads from watch school not check all the above...1 point

-

I think you'll find that they never had a replacement jewel for something like this. That's Pressed in jewels all you need to do is find one that fits your pivot and That depends on how you answer the question below. Do you have just the jewel of press or the complete set with the reamers? I'm attaching a book of the light reading. So in a jewel like this the easiest way to fix the problem would be to get a jewel that fits your balance pivots and the ideal fantasy would be you get one the exact size of the hole of the old jewel and just push the new one in. But seldom do you get that luxury so you would user Raymer to open it up a little bit to fit the modern jewel but no knows you might be lucky and just peel the press one in. Seitz book.pdf1 point

-

Part of the reason for that is everybody has a different experience. I'll have to remember to check the machine at work to see how long it spends in the isopropyl alcohol. But the last rinse is isopropyl alcohol recommended by the manufacture. I think you'll find that some alcohols will dissolve the shellac faster than others and isopropyl isn't super fast. Because as far as I know we've never had a problem with the isopropyl alcohol.1 point

-

Hey, have you checked ofrei.com? If you know the dimensions of the jewel you may be able to source a replacement on their site.1 point

-

Generally consensus is it's a bad idea to put pallet fork and balance in IPA as it will likely dissolve the shellac on the pallet stones and the impulse jewel. Personally I use shellite (naptha) as the final rinse when I'm cleaning. I've found you can ask 100 watch makers this question and get 147 answers though. I would defer to Mark on this one, that's for sure1 point