Leaderboard

Popular Content

Showing content with the highest reputation on 01/14/23 in all areas

-

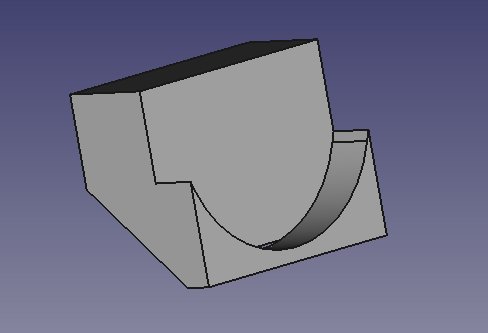

I'm getting better. Really enjoying myself. However, as most beginners do, I have started on cheap watches. They are more prone to damage, wear and tear. Many of them have problems with the barrel bridge. The barrel hole for the arbour is worn and too large. On many of them I can insert the tip of the tweezers there is that much movement. I need a Staking set, I think to myself. On my £10 a week spends that is 3 month saving and not purchase anything in between. Boohoo. Why not DIY? I have a hand press for £11. I purchased a set staking punches for £11. Cut holes in a plastic holder. Woohoo! A staking set. A rubbish one compared to proper standards. But I have to tell you it worked. I closed my first arbour hole and it has worked. Hammer time was gentle.6 points

-

I like that channel too. I do wish he was a little more concise. He can, literally, take an hour to get across a concept that could be summarized in a paragraph in 2 minutes so I find that I don't watch his videos as much as some others. But he seems such a nice and friendly guy that sometimes I don't mind the time sink. This was a really cheap ebay find that came with the original (I think) band which was the main reason I bought it. The listing said it needed some TLC and that "Keeps time but sometimes you can't set the time". Just needed a cleaning and is good to go.4 points

-

One of this forums strengths is its openness and genuine help and advice from experienced and less experienced members. Sometimes it can get a bit heated but not often. Since joining the forum (2014) the membership has grown from approx 2k to over 11.5k so we have things about right. Personally I just found this hobby fascinating and the deeper I went the more tools I needed to tackle all of the tasks. Generally it’s not the tools or lubricants that make the difference it’s the repairers experience and skill.3 points

-

By the way didn't bring up the square versus round jars? Yes and watchmakers aren't bickering over lubrication they might bicker over having a square jar causes some sort of flow a difference versus around jar. Then yes there is a mental thing that goes in the bottom of the jars and as quoted below there is also must remember how one of the machines did it I think it was in the way it held the baskets it has a propeller like effects what causes the fluid to not just spin but also pushes it down her upper something so there's more movement of the fluid because yes if you're spinning it at some point time conceivably the fluid will synchronize with speed of your spinning and not getting enough motion Oh and if you really want to do some cleaning what about this. This is a machine we use at work it comes at a bargain price of around $16,000 will let Sewall price and it's gone up a little. Everything is programmable were at least as a lot of programming is a rather sizable book that comes with it and I'm currently waiting for its 50,000 mile checkup what has to go back to do some place to have a whole bunch the valves and other stuff replaced. We've already done the 10,000 mile and no it's not based on mileage there's calendars in their. Like when you change the fluid and reset the counters ill keep track of the cleaning cycles and remind you that you should change the fluid and then I push the button I'm going to ignore you and that will remind me later in a push the button again and only when it starts looking like maybe it's not cleaning which is a very long time for us do we change the fluids. But think the 10,000 mile checkup was we had the change the carbon filters change the internal filters that filters the fluids and something else we changed but we already have all of those. So you want the ultimate of cleaning this is it because of you could add in the vacuum feature with ultrasonic the vacuum sucks out all the little bubbles and stuff and against the fluid in the places they normally wouldn't get so in the case of American pocket watches you do not have to take the jewels apart and typically they do clean perfectly https://youtu.be/SCbFHf1BCdg Here's the problem with technical literature and why you've never seen this before it will never see the entire document. The watch companies have had supplemental information for a very long time for instance eta has technical communications that you can download off their website and sometimes they have the manufacturing information? Manufacturing information sheets I love those all the technical specs like the timing specs and other miscellaneous bits of interesting information but most people are unaware because they're seeking the service guide Omega for instance the delay bought out a watchmaker so I ended up with physical documentation from the 50s early 60s they had a cleaning guide back then it also talked about epilam and lubrication. But if you look at their service guides they don't mention that up until modern times were they were refer you to working instruction number 40. So they still won't even talk about things because you need the supplemental information so for instance where those images come from one of the Omega working instructions 27 I believe. Now what's the problem today with the technical literature for instance you go to the link below you use to build a search for the word working that now you have to specify much more the title you can even search for lubrication to find the link below which is really weird in case you look at the link there is working instruction number 40 hopefully on lubrication. Look at the corner of every single page notice it tells you exactly who download that's why you're not going to find in a modern literature on the web because somebody risks losing their parts a And nobody's going to risk that for discussion group. If you're lucky somebody might snip out something for you and airbrush out any corner marks that may be seen that's the best year ever going to get. https://www.cousinsuk.com/document/search?SearchString=Rules+for+lubrication3 points

-

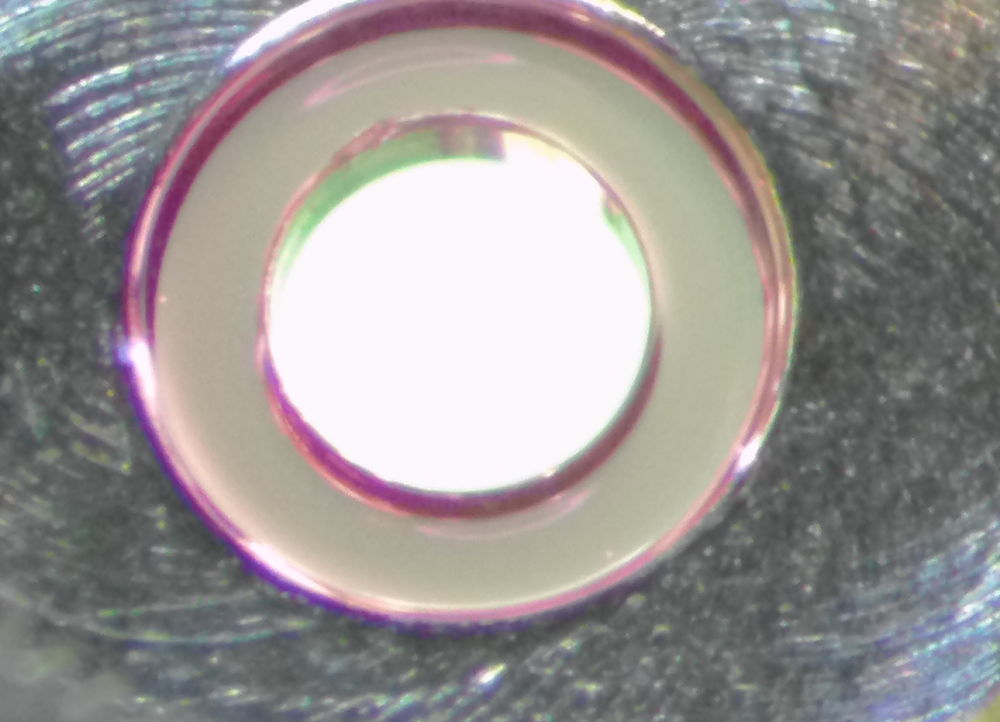

I've been working on a Seiko 6138-0040 Bullhead that belongs to an acquaintance of mine. He bought it new in the 70's, wore it until 1985 when it quit working, and it has sat in a drawer since that time. The issue of the watch not working was simple enough to fix. The hour recording wheel would not reset, and I found that the hour fly-back lever had snapped. Once I got the replacement part in I serviced the movement. After the initial inspection everything appeared to be in good order aside from some play in the upper barrel arbor port. That steel bushing was replaced with a jewel from Vintage Time Australia. Everything went back together nicely, but I was getting amplitudes in the 180-195 range. The Seiko 6138 generally runs at a lower amplitude, but this was too low. I took the watch apart again, thoroughly cleaned everything (again), and set myself to the task of rechecking everything, include end shakes and side shakes. Although the original mainspring looked to be in really good shape, I sourced another. Even with the brand new mainspring, the amplitude still wouldn't get above 200 degrees. At my wits end I took the watch down for the thrid time. This time I removed the barlow lens from my microscope, lessening my available viewing area and work space, but allowing me to zoom in much closer. I finally found that the inside lip of the lower barrel arbor jewel (located in the calendar plate of the 6138 movement, not in the main plate) had a very small chip in it. It was very difficult to see due to the way the light was reflecting from the jewel, but I finally managed to get a picture of it. The chip is at the 11 o'clock position of the inside jewel rim. After finding this chipped jewel I doublechecked the barrel arbor and did not see any scratches or other evidence of damage. Unfortunately this jewel is not the same lower arbor jewel that comes in the standard jewel upgrade kits (for the 61 & 63 series movements) because on the 6138 dual register chronograph movement the barrel arbor goes through the main plate and sits in a jewel on the front calendar plate. I sourced a cheap 6138 calendar plate but the barrel arbor jewel was in good shape. After swapping the jewels out and adjusting end shake, everything got cleaned (one last time), reassembled, and I'm happy to report that the amplitude issue has been solved. This one tested my ability, and most of all my patience. I wish I had a deerstalker hat so I could have called upon my inner Sherlock Holmes and figured this out sooner, but at the end of the day(s) a successful repair has been completed.3 points

-

Hi Anthony tother way round with me Scottish mother and Lanc Father brought up in Yorkshire an like your self not disposed to throwing money around. I have three sets of screwdrivers two I bought many years ago and still good, and a french set from redrooster uk they all need dressing but using fine grit wet and dry on a block with a little oil works wonders. Unfortunatly watch screws differ in slot width with different manufacturers so having a few screwdrivers dressed differntly is handy. cheers1 point

-

Challenge accepted! I vow to engineer a movement constructed completely of transparent cyanoacrylate !! Maybe I'll cast the parts with molds made from duct tape.1 point

-

Depending upon the setting the jewel Chuck is very nice. A lot of the settings are basically a disk and trying to hold a disk of thin disk the lathe collet and have it remain Absolutely where it's supposed to be when you're tightening it up as problematic. So having something to press against on the backside and then push against on the front side allows it to the absolute perfect word supposed to be so yes they are really nice to have. While superglue is frowned In watch repair it definitely can have its place don't know if I've heard about duct tape in watch repair though. It's the classic problem with pocket watches especially if they're made over time will be variations. I rather like discussion on another group somewhere where someone saw a video and decided that his watch was all wrong and had been retrofitted modified hacked because it didn't match the video on YouTube. So then I had to go through employed out then I believe is a Hamilton that certain serial numbers were single roller versus double roller. In their own whole bunch of other things that had been changed it is very hard to convince this person that his watch was right because it was after all this other serial numbers. But it's very hard to convince somebody when you see a YouTube video the perception is it has to be right no matter what who cares what the parts book said. Then if the watch was made over the years like there's a 12 size Illinois that I have experience with you end up with lots of lots of variations and unfortunately a lot of them are never documented. See basically stuck having to compare the two watches to see what if anything will interchange even though according the parts book there are identical.1 point

-

Fitting the screws perfectly is due to dressing, not the blades. New Bergeon blades do not fit many screwheads properly and require some time with India or Arkansas stone to get just right. If you then switch calibers (from say a Japanese Seiko to a Swiss AS movement) you may then find your carefully dressed blades don’t fit those screws and need to be reshaped. At that point, swapping in a set of replacement blades may save time and effort, especially if you’re continuing to work on the previous caliber. CousinsUK sells a range of “Swiss Quality” screwdrivers (made in France) for 2.65 GBP each. They take the Bergeon 6899M hardened stainless steel blades, the Bergeon grub screws etc and are highly recommended. The Chinese Kwong Yuen screwdrivers are also well recommended.1 point

-

Cool - I made a tadpole of progress. I've got a pot connected so I can change the speed of the oscillating motor. I need to add the switch so I can select between constant spin and oscillation. Also, I'm sure once I implement interrupts, I can simplify the code and at the same time, smooth the motor up too. Hopefully I'll figure that out soon. I'm kind of learning to code from scratch again. I can't remember the simplest of stuff from back when I kind of knew a little of how to do it several years ago. I hate considering the difference between how much I've forgotten vs. how good I'd be at it had I stuck with it all these years instead of totally ignoring it.1 point

-

I'm glad I'm not the only one. I feel the same way. I know English isn't his first, but often I sure find myself wishing I could urge him to "get to the point". Still, the guy knows his stuff and is nice. Not that I would do any better at all, but I'd try to keep working on getting better if it was me. Maybe he'll keep working on it and the quality will steadily improve over time. I hope so.1 point

-

Hello Anthony, the short answer is yes, high quality tips in cheap bodies is a practical way to save money. You can get better value for money than the Bergeon ones, too. Whatever you get, you will still need to dress them regularly to keep them sharp, so get yourself an Arkansas stone. If the blades don't fit your screw slots, that has nothing to do with the brand name, and everything to do with how you have shaped them.1 point

-

Sony TC-K61 Got this with a Thorens TD 160 record player together, unfortunately it did not do anything, it had watch issues. No lubrication at certain places or it had old lubrication acting as glue. So it was cleaned up and re-lubed with watch oil and molykote dx grease it was a bit tricky to take it apart but all functionality is restored. It did not play at all and there was no rewind or fast forward. With a pair of headphones I can enjoy 80s music again1 point

-

The movement is a French Morbier. Here is some info on them. http://www.antique-horology.org/_editorial/comtoise/intro.htm1 point

-

Hi Ross full marks for ingenuity and thinking out side the box. A creditable diy solution to your problem. That will suffice untill you get a proper one. Well done.1 point

-

1 point

-

I don't know much about any specifics on how these machines work, but I'm willing to recklessly throw some thoughts out there regardless... First of all, that's some cool Rube Goldberg rocket scientry mechanism. Looks like it does the business and nothing made from unobtanium at all. Congrats on that. The RPM shown seems to me like it would be adequate for washing parts. Maybe a tad slower than I've seen elsewhere but whether optimum or not, it's just my gut feeling that it should do the trick. If it would oscillate, it might be more effective, but the RPM itself seems to be in the ballpark. I feel like the fluid level shown is a bit shallow and likely to pull air into the fluid pretty easily. I don't know for sure on this either, but it seems like at rest, the top of the "fan blades" of the basket should likely be submerged (maybe a half inch?). Otherwise, it appears that the various baffling materials you put into the jar are doing the trick and dampening down the vortex adequately. This is just what it looks like to my eyes. Understand that no matter what you do, a spinning basket (or honestly even a smooth marble) will create some amount of vortex. The baffling is only reducing it down to an acceptable level, which you appear to have accomplished For a test, you could probably just come up with a commando home-brew DIY torture test and try it out. Simply do something like picking a couple parts with large enough flat & smooth surface that it's easy to see, like maybe a mainspring barrel disc or the like, and maybe a cap jewel or something too. Put a small drop of used motor oil on it, or maybe something waxy & sticky like some kind of grease, and maybe even some sharpie marker. Use your imagination and spend some time trying different substances. Anyway, after checking out the dirty test piece, run it through and check the results afterward. Whether or not you get some "official standard" or not, this will give you a good idea what kind of result your cleaner is able to accomplish. I suspect that your device will work well. My only criticism is the level seemed low and likely pulling more air down into the fluid during the stir than you want. All my thoughts are unqualified and just gut feelings. Defer to experienced replies if possible.1 point

-

I found the two main sources I used to buy American pocket watch parts from - especially jewels. They don't have websites, you have to email. It's been a couple of years, so I don't know if they're still active: Bob McKnight : tbob45 @ aol.com Brian Cavanaugh : pwpartsetc @ pwatch.com and plenty of links here : http://watchrepairinfo.com/pwparts.htm1 point

-

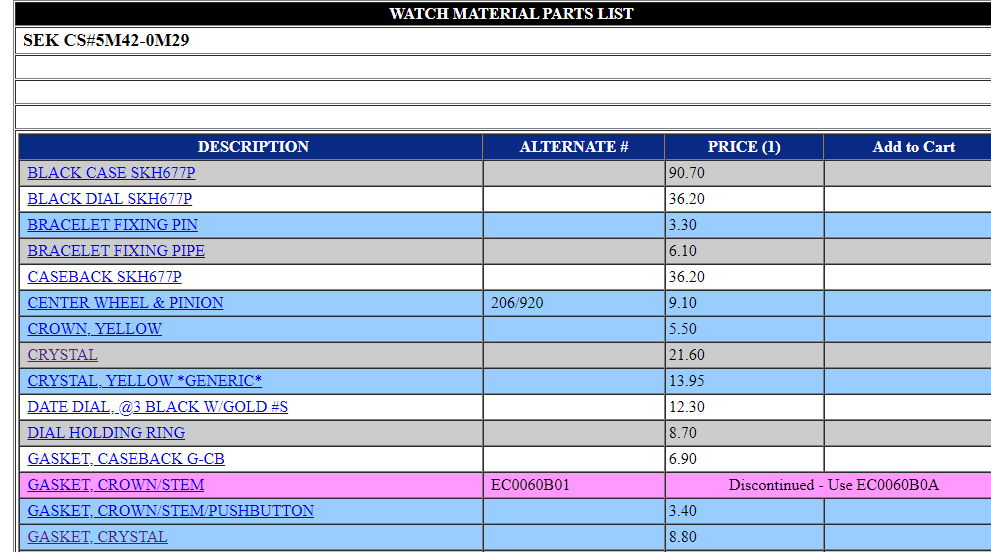

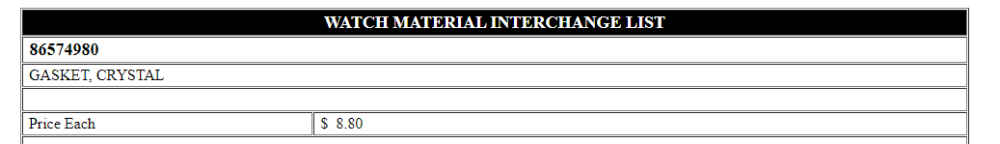

As we have a gasket for the crystal in the West we can see a gasket it should just push out. I would support the bezel because you probably don't want it popping off I have no idea what holds the bezel on though. Sometimes it helps to wait until you actually get the gasket to look at it just to make sure there isn't some bizarre surprise that were unaware of but you should Be able to just push the crystal out.1 point

-

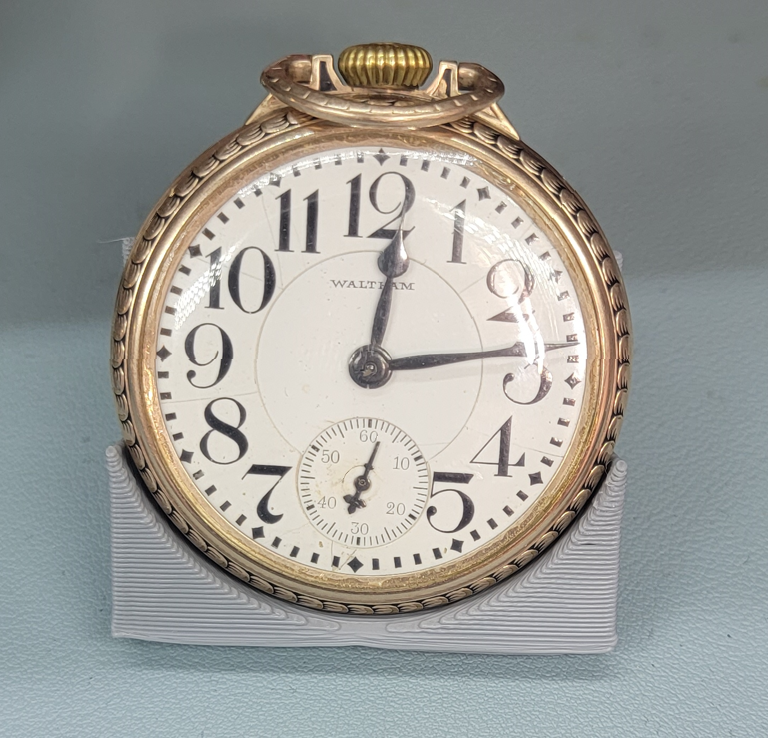

The other thing in addition to outright replacing the jewels would be to replace them with the modern jewel. Looks like there's enough for the brass setting that you could probably smash the old one out as us easiest way to get to them ream out for modern jewel of put a modern jewel in. Of course the only issue is no now be a pretty red color rather than the original color. But if you can't get an original that is something you can do as you not worried about un-burnishing the old one in burnishing a jewel in then putting a modern in is fine. Although I have seen on eBay Waltham jewels for burnishing in not sure they're ever met the burnished into these settings that? Oh snap much of rust on the hairspring I'm assuming they're still Russ on the balance staff C might want to try polishing the pivots that might improve things otherwise replacing the staff would probably be a good thing to do. This is a interesting website I notice he says balance jewels but he also uses the word plate jewels C a might ask if he has anything. https://www.daveswatchparts.com/Jewels.html1 point

-

Beautiful watch. I'm always on the lookout for a 1970s Bulova. I've restored two up to now, a gold plated Seaking for my neighbour and a silver sector dialled model. They are really nice quality inside and out.1 point

-

OK, So I made a simple pallet warmer and tried to re-melt the shellac, but the stuff just would not melt, in fact one piece came loose and I put that piece on a separate copper plate and tried to melt it, it simply got darker and darker but did not melt. So I guess I'll have to order some shellac and and replace what's on the pallet currently. Great learning experience, sure hope I don't mess it up, LOL!1 point

-

@JohnR725@gbyleveldt thank you guys again for the great help! here is some progress i have. Adding a metal sheet around the square jar, star shape baffle in the bottom, and my fluid just enough to submerge my basket (including the basket cap/fan), it looks like the vortex is gone and waves go into the basket. I don't have RPM meter so I couldn't be sure if it's the right speed but there's no bubble as I read from one of the threads that it shouldn't have. Is there any way I could verify the efficiency of cleaning watch parts? (even for the commercial watch cleaning machine, I couldn't find any metrics or documents indicate that) Pardon me for keeping asking stupid questions. Video1 point

-

Like I said somewhere else on WRT, the way to make a small fortune in watchmaking is to start with a larger one.1 point

-

Thank you Mark! I can see it's back up. (Just performed my first complete teardown- all went well except for a sproing of the yoke spring. Thought I was holding it down right but I wasn't! Found it again fairly quickly, thankfully.)1 point

-

I've put that mainspring calculator in my cloud storage, so feel free to download it. https://docs.google.com/spreadsheets/d/17noK3_STuT7pQCAqFjIpUyZ4XweRyGdK/edit?usp=sharing&ouid=117325986396951414363&rtpof=true&sd=true Enjoy!1 point

-

1 point

-

Great chart. First I've seen it. That stuff should be easier to find. I'm gonna try to shout it from the rooftops from now on.1 point

-

Another find at a local flea market: a 1918 Elgin trench watch. It was in sad shape when I found it. Needed a thorough cleaning, might have had dirt from a bloody ditch in France clogging some of the nooks and corners, the hands were bent. But outside of all that, hardly any scuffs and no dents or dings. I did the usual COA, straightened the hands as best I could, did a bit of light cleaning on the dial, and got the old thing going pretty well again. I'm glad I didn't need to swap out any parts because I'm understanding that, particularly with antiques that also count as war memorabilia, it is important for the piece to be as original as possible. That said, it had no strap when I found it so I had to replicate a strap (could not afford a genuine vintage strap). I'm enjoying wearing it, but this one is listed on Ebay because I need the money. Rough patch right now and I am switching to a different day job, which is horrible timing but I can't go along with certain matters of ethics where I am now. But I may wear it now and then until it sells. It's not really my style, but it's an endearing old thing.1 point

-

1 point

-

1 point

-

1 point

-

Do your jars have baffles in them? Each jar in my L & R cleaner has a baffle in the bottom which creates a bit of turbulence in the cleaner as the basket spins. These baffles, along with reverse cycle, help clean around all the parts. @jguitron is correct that water contamination will cause problems. I'm pretty sure Zenith cleaning solution and water are immiscible. Also, if your cleaning fluid hasn't been changed for a while then you'll also see a film build-up on the parts.1 point