Leaderboard

Popular Content

Showing content with the highest reputation on 12/21/22 in all areas

-

Hi everyone, I’m not exactly new member, but since after my short appearance here 2 years ago I’ve been silent to community I think a bit of update is good comeback. Yes about 3 years ago I’ve started watchmaking hobby due to lack of good quality puzzle. Few Amazon purchased tools and flea market soviet watch got me started all right. Number and quality of tools, new and ambitious projects eventually brought me up here. I have to say community here always helped me with my questions and I always remembered this forum as great knowledge resource. Eventually sign up for Distant course in BHI and decided to pursue watchmaking as my profession. Age 32 not easiest decision to make specially for my GF. Since all future plans and me wanting to move from Estonia to Slovakia because lack of watch interest and opportunity there. After longer talks we all were confident, this is way to go for both of us. For my surprise, took me 2 weeks to find a job in local watchmaker shop as apprentice. Basically they gave me poor salary and table under staircase (pure Harry Potter style). Long story short, I worked harder and longer then others and soon became shift leader, then mechanic watch repairer to junior manager of two workshops with team of 5 watchmakers. Meanwhile working on setting up my own shop, that consumes all of my money (honestly, learned to live of 2 digit numbers on bank account) I’m coming back here since all this time wanted to join community that I liked, helped me and inspired me to all this adventure. Cheers guys, glad you’re still rocking here! Jakub2 points

-

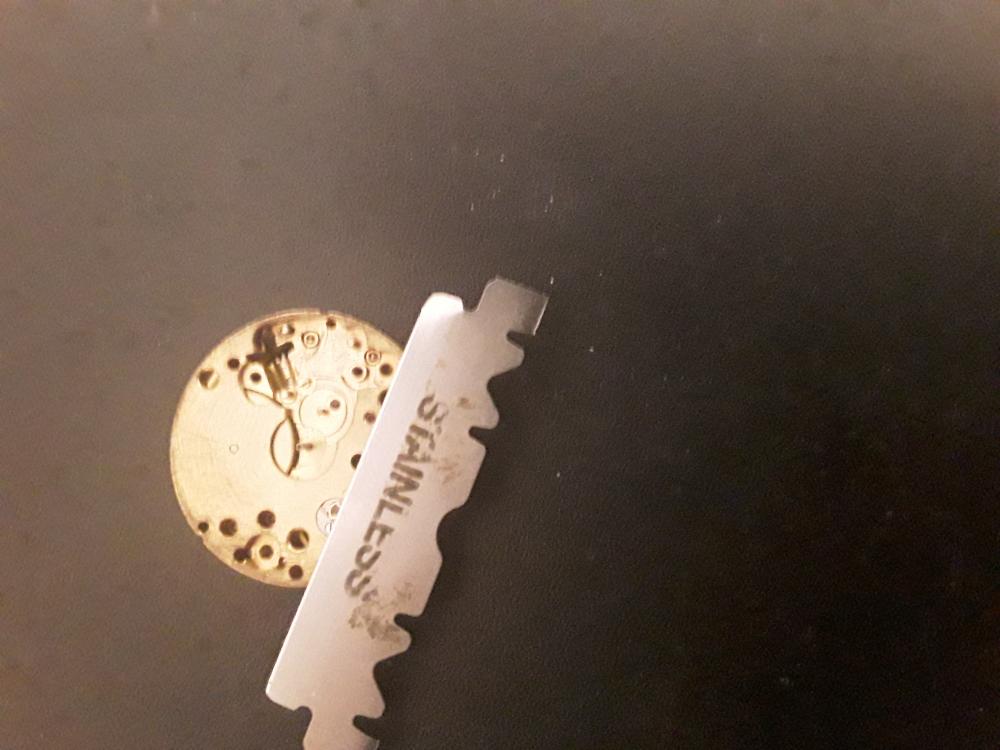

No, I managed to confuse you with my broken English again. Drop the flat face of the razor on the spring ( not its cutting edge or corner...) as long as you keep your finger on the razor , the springs can't get out. You then can slide a prong in groove. Will hopefully post a better picture . Mine smart phone isn't as smart as yours, low pixel pictures.2 points

-

\ That spectacular Girard Perregaux Gyromatic and the diminutive Suizo above reminded me a somewhat of this ETA 1080 based 1950s Linaso Candido, so I dug it out and gave it some fresh air too. I'm fascinated by the elegance of these smaller 1950s watches. So much more refined in my opinion than the majority of recent designs.2 points

-

If this is a 7s26-02J0 or similar, the crown code is 9M40B3SNW0. It looks like Jules Borel is selling it for little money (http://www.julesborel.com/home?search=9M40B3SNW0) There are also some replacements available on eBay.2 points

-

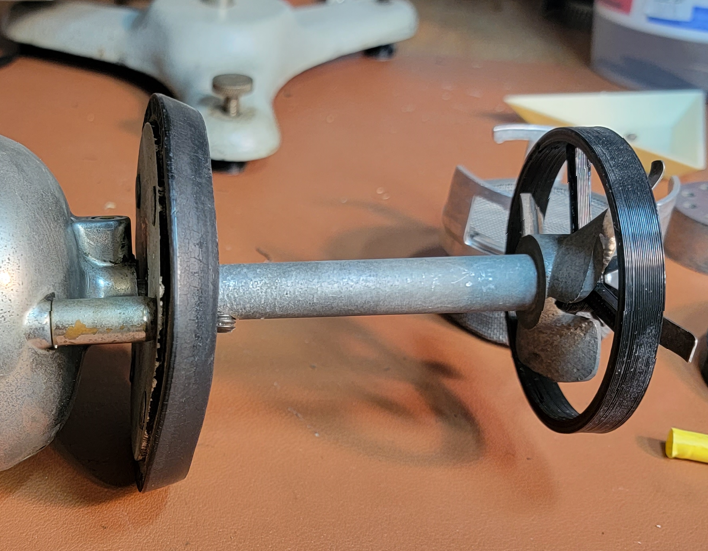

Nice work. What filament did you use? PLA? Recently I had to deal with an accident where the aluminum spinner of a L&R Watchmaster cleaner was shattered. After scratching my head, I came up with a 3D printed piece that retrofit to the undamaged spinner shaft. Here I show the piece I printed and the finished product. I was, at first, concerned about the interaction of the L&R solutions and the PLA material. I did several tests and concluded that there was no chemical reaction with the PLA--happy about that.2 points

-

Why is there even oil on the coils? I would use rodico to remove most of it, then give it a quick dip in lighter fluid and a blast of air to dry it.1 point

-

Hi everyone! As promised I managed to finish the overworked prototype of the 3D printed watch baskets before christmas! Here are some pictures so you can see the current build: And here is a link to the short video explaining everything! https://www.youtube.com/watch?v=MecNpr7wiGc Hope you guys enjoy the design ! There is still room for potential improvement so please leave any questions, comments or suggestions. Always curious to hear from you all!1 point

-

1 point

-

1 point

-

Another option for a dull safety razor is like the second one above, the single sided one but made out of hard plastic, often sold for the removal of mobile phone screens. Another option for a good hold down is a rubber tipped brush sold in art shops for blending pastels etc, those are also useful when cleaning a watch dial as the tips are really soft.1 point

-

I don't know how JB name their gaskets, I also use Cousins gaskets, mostly 29.8x31.4x0.50 and 29.20x31.00x0.50 depending on the watch, and for the stems usually the D ring gaskets 2.05x0.60x0.80 that are equivalent to the Seiko DJ0060B01.1 point

-

Since there's no stem, it can be either, it depends on the case and dial. I don't think they changed the movement with keywinds for open face/hunter, just adapted dial and case to suit.1 point

-

Slide one prong in the groove at a time. All Rodico does is to keep the spring from flying, it will not secure the prong in the groove of the setting so, I PUT THE SRPING ON TOP OF THE END STONE. SLIDE ITS BOTTOM SECTION IN THE GROOVE. COVER THE SRPING WITH A DULL SAFETY RAZOR ( GENTLY PUSH ON THE RAZOR TO SECURELY KEEP THE SPRING IN PLACE ) WHILST THE TIPS OF BOTH PRONGS REMAIN UNCOVERED / EXPOSED AND ACCESSABLE. SLIDE THE PRONGS INTO THE GROOVE ONE AT A TIME , WHILST YOU HAVE THE SPRING WELL COVERED AND SECURED IN PLACE. You have automatic oiler, so why not rinse the plate, including jewels , dry , and ubricate with auto-oiler, then start putting gears in. Rgds Here I am unlocking an incabloc spring, only one prong of tweezers and one of the spring.1 point

-

Diamond burs are good for cutting brittle materials like tooth substance, obviously, glass, ceramics, stone, stuff like that. But it isn't that good for cutting metals, plastics, wood, etc. The optimal cutting rpm for small diameter tools like these is about 125000 rpm. Our air driven drills run between 220000 and 400000 rpm. Our newer electric driven moters run at 40000rpm. When coupled to a 5X speed increasing handpiece, it runs at 200000 rpm. When I retire in 10 day's time, I'm bringing home one of my air compressors and getting a standalone portable dental drill unit from AliExpress to run my drills. One of the stranger things that I use diamond burs for are emitters for negative ion air cleaners. The steel emitters in negative ion generators normally wear off after awhile. But diamonds don't wear out. And a diamond bur has hundreds of little sharp points to act as multi-point emitters.1 point

-

Try releasing one prong of the spring at a time from the setting lip, when you tweeze both prong simultaneously you are stressing the spring twice as strong. There is no need for any special tweezers, I use one prong of No 4 tweezers. Good luck1 point

-

Hi Zeke! I believe I know you. Are you a member of the Oklahoma Watch Collector's Guild? I'm on there as well!1 point

-

I recently fell down the rabbit hole of jump-hour watches, which somehow led me to the Omax Spaceman. It's bizarre, it's retro-futuristic, and now I want one for my budding watch collection. How cool is this thing? The older ones are pretty wild, too. I've read that there are fakes out there, and I'm trying to learn how I could tell the difference without having one in my hand. I see a bunch on Ebay from India, which surprised me, but this post talks about how they were popular in India and the Middle East, so it makes more sense. Prices on eBay seem to range from around $100 to upwards of $700. I can look at a dial like the one below and have a pretty good guess that it's been repainted: But that about ends my skill at spotting fakes. I've read that the stamping on the bracelet can be poor for fakes, and that real ones should have a black crown, but is that always true? I'd love to hear from anyone with experience with these guys, or just generally the sorts of things I should look for when shopping. Cheers!1 point