Leaderboard

Popular Content

Showing content with the highest reputation on 12/18/22 in all areas

-

Boy, did I ever get lucky! I went back to a local antique mall (more of a flea market, really) early this morning to buy something I'd seen several days ago. And it was still there! And this time, I had money! A Girard Perregaux Gyromatic. Not running, so they weren't asking much. I bought it and went straight home to my bench. Cleaned, inspected, oiled, regulated, and now it runs quite nicely. Fitted with a nice patent leather strap, and I've been wearing it this evening. I often turn about and sell many of the watches I rescue and repair, but not this one. Not this time. I took a liking to it rather quickly. Addendum: it has a 17j GP 21.19 plated with gold. It's a jem to look at. And a 14k gf case which took a nice polish. The original crystal is not too terrible at all, so I'm thinking of leaving it on.9 points

-

Probably the majority a time new parts are just fine. But sooner or later there has to be one that fell through the cracks. My favorite over the years have been brand-new stems in this particular case they had crowns already attached. So in other words accompany cut of the length and attach the crown and no square. I think there was one that had a three sided square. Here's an image showing how you're supposed to make the end.3 points

-

Even if you have somebody who's experienced there's a problem? Were still missing some key information at least we got a nice picture of one side but we still need a picture of the other side. Also we need the diameter the movement and for that I've attached a PDF. Typically diameters of movements are not measured in millimeters Okay you measure in millimeters but you look on the chart And then you give us the ligne sizes. Then the reason why we need the dial side is for a time span of I'm not sure how far back and how far into the future went but was a time span where all the setting parts of the watches are unique. So if you have typically a Swiss watch you know the size into what the setting parts look like you can look in the bestfit book an attempt to figure out what watch you. I did look bestfit book has some Seiko watches so may be but even if we identify there is no guarantee of parts because this is a vintage Seiko or be technically correct a vintage pre-Seiko watch. But still it looks like a nice-looking movement it be nice if we could save it. watch-ligne-size-chart.pdf EBay is nice in that with enough research you can find this looks very similar. Dials not exactly the same but movement looks really close. Say goodbye it and take the pallet fork bridge out use it for spare parts. Then yes prices interesting isn't it. It's a problem with the early Seiko watches like this there collectors items and yes there is a very interesting family of Seiko watches some of which there worth way more than this so it's well worth trying to save the one up above and probably not worth Two scrap the one below for parts even if it is identical. https://www.ebay.com/itm/2041511662302 points

-

I know I shouldn't brag but a casual visit to a charity shop in 2012 got me this IWC 8531 for $10. The staff mustn't have known the value of the watch and I certainly didn't then but I did like the look of it and it started to work when I shook it but stopped shortly after. A service from a seasoned Watchmaker in my area proved successful (crown and stem and crystal replaced, not IWC). I wear it occasionally and enjoy it.2 points

-

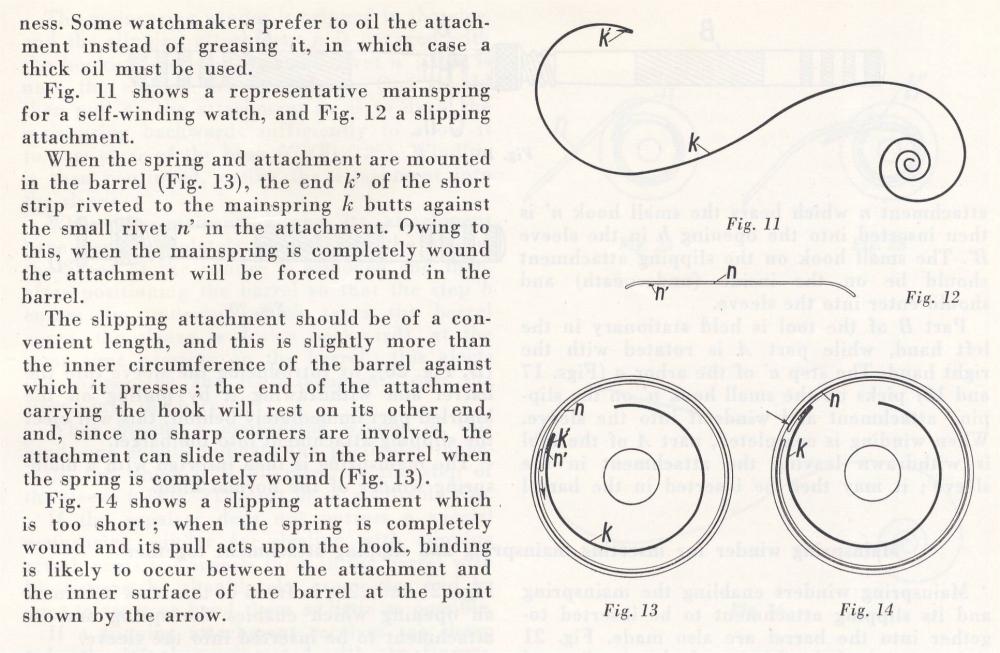

Somewhere in the discussion group in the past someone had a special set of the winders for the inside piece. That's because a lot of times it's much stiffer than the regular spring and getting it in is a pain. Then you still need your breaking grease on the outer barrel wall. Then once the inner pieces in that gives you something to hook the standard spring. Going to my images I knew I had something but turns out I have two images.2 points

-

This Suizo 1950s AS1361N 10 micron gold plated Automatic got an outing today. It is a gents watch, but is quite a diminutive piece (as was typical for the time). It is also very well engineered. The plating has a few wear marks, but other than that it is looking pretty good for its age. There is one minor discrepancy though. The dial states 25 jewels but the rotor says 21 jewels. Oh well, I guess nobody's perfect. It got a new crystal as the old one had resisted my best polishing efforts, but still wasn't up to scratch. I also treated it to a period correct 17mm dark green leather band from a job lot of 1950s or 1960s straps I picket up recently. Before you ask, no, I am not responsible for all of those scratches on the rotor, they were there long before I got my hands on it. Suizo is almost certainly a Achille Hirsch brand.2 points

-

Many brands made spaceman audacievse, Not all came with paint on the dial, some had stickers about half a mm thick on the dial plate. The ones with AS movement were Swiss but some were powered by ST96 and ST96 have been manufactured in India since seventies. The ones with no complication are highly likely to be manufactured in India. So best to ask for a picture of the movement and gurantee for a genuine dial with good feet. Cases come in several sizes, get the large or jumbo. Crowns on both square ones you show are genuine. They were and might still be the most sought after collectable piece. Rgds1 point

-

Screw uniformity and servicing considerations are always nice. I hate the movements that were designed to be assembled once with what I imagine are specialty jigs and such, then thrown away when they've worn out to the point of not keeping time. Just as bad as the movements that require special tools and other weird considerations.1 point

-

The keyword here is low cost watches. Depending upon when they made them or who made them a variety of cost-cutting measures. Like some watches really are Not meant to be serviced at all as they have no screws because screws and threading the holes cost money. Having a barrel Costs money if you can get by without one saves you money. Remember these are probably assembled by machinery machinery if you ever see a video of a watch going together everything will fit perfect as opposed to a struggling with trying to put one of these back together again. This is why often times instead of having separate plates over like the barrel in the gear train the watch might just have one entire plate covering everything. They made at a cost and corners or things had to be cut like barrel lids than just a whole bunch of other stuff.1 point

-

I've heard the rumors over the years of people buying interesting watches in the thrift store. One of my friends who his wife was working for goodwill learning In other words the job training said that the procedure was supposed to be to rotate the people in that department so nobody would get light fingers basically. But where she was working the boss put her friend there to yes you know where that's going. But it's always nice to hear that this is not an urban legend that it's really true that interesting and valuable things really do show up where you least expect them and they show up at good prices.1 point

-

No reason not to boast about a good find, it gives everyone else another reason to always be on the lookout. Its like treasure hunting, a great feeling when something good pops up. Lovely watch and that crown is a whopper.1 point

-

I'm afraid not but I do hope someone with more experience in identifying movements will be able to help you out. Anyway, you may still be needing a jewelling tool. Even if the jewel in the bridge is correctly seated it could be that you might need to adjust the depth of the jewel in the main plate (or bridge) to make it work. An affordable jewelling tool is a Chinese clone of Horia's jewelling tool. You can read about it here. Good luck!1 point

-

Don't know how common it is but I have definitely seen low cost watches with no barrel cap and was sure they where designed that way1 point

-

Well, the watch is finally running. I had to shift the hairspring quite a bit to get it in beat, it wouldn't start unless it was shaken. Interesting observation re beat, there is ~ 0.7 ms difference between dial up and dial down. I don't know what to make of that, maybe it's a timing machine artifact, different "noises" in each position. I'm sure more could be done to get this watch running better. After setting what I thought was a good total lock, I ended up having to open up the banking pins to get a decent swing out of the balance. It originally was sitting there jittering away nervously, worse than me Given the amount of wear on this watch, I'm afraid I could end up really chasing my tail trying to make improvements, so I'm going to leave it be. It should stay well within a minute a day when it's lying or hanging around, and I think that will make the owner happy. Onwards!1 point

-

I love the blue dial on this Westclox. The FE 140-1B was a joy to work on. All bridge screws, including the pallet bridge, and even the setting lever screws, were the same screws. Even the dial feet screws took the same size screwdriver as the bridge screws. I love that the calendar guard plate has a cutout for the date jumper spring so you can place the spring after first securing the guard plate. I wish every movement had that.1 point

-

Not so much an achievement, just a standard COA, but look at this movement, dial, and case combo! Elgin was, obviously, a mass producer of watches but this is their finest work, imo. From 1904, the fit and finish is as nice as any I’ve seen from anywhere. The pallet stones are even curved on top, reminiscent of Patek. Then the dial is an amazing “fancy” dial, too….gotta love it1 point

-

The interesting lessons you learn in life. When I was a student I polished my pivots because we're supposed to reduce friction. Then with my running watch over to the timing machine in the days of paper tape no digital amplitude. The paper tape machine every time it printed made a nice clicking sound you could hear it all across the room. Which means if you did something interesting like polished your pivots insanely round the watch would make interesting galloping sound on the timing machine and everyone would know what you did. Nobody said anything but. That I learned how pivots are supposed to be more flat and the problem went away. So one of those interesting lessons of reducing friction is good but not on the end of the pivots we have to have the equivalent of the same friction no matter what position the balance wheels in so the end of the pivot cannot be polished nice and round.1 point

-

Hi if you are just starting out best to use the finger cots and get used to working with them on, either practising of for real.1 point

-

I have a tool that moves the roller table in very precise increments for fine tuning the beat error. I only used it on one caliber I used to do for a small manufacturer, it's not terribly practical for everyday use. It has a table with a collet in the center that clamps on the roller table, then a finger clamp that holds the balance rim. The table turns around the collet, with index marks so you know how far you went. You can very easily turn the roller table a fraction of a degree, and then go back exactly the same if you want. For every day work, from the smallest ladies movements to marine chonometer, I set the balance with the cock on a bench block so the roller table is in a hole, balance on the block. Lift up the cock and move it over- not flipping it, just moving laterally, until I can see the slot in the hairspring collet, get in there and adjust (for tiny watches this is usually with an oiler, larger, a small screwdriver). Go back in the watch and check on the machine. If you have no idea which way to move, like when you are very close and the fork looks perfectly centered, you can check like this: let off all power, hold the balance rim, then nudge the center wheel so an escape tooth contact a pallet stone. See where it contacts. Rotate balance so an escape tooth can contact the other pallet stone, observe. This is with zero power on the watch so the balance really truly finds its neutral position. If, for example, a tooth hits the front part of the entry stone, and the last part of the exit stone, you can rotate the balance to see which way it needs to go (here the balance need to turn counter-clockwise from its rest state, so the hairspring needs to go clockwise).1 point

-

Welcome to the forum! It can be very inspiring to follow in the footsteps of a parent or ancestor. It sounds like you got to see a little more of your father through his eyes, as it were. My own great-grandfather was a tailor, and his father before him, going back to when most of us lived in München. And I found I had a bit of talent for that. On the side, I do a bit of costuming and tailoring; my clients mostly belong to the same Middle-ages reenactment group that I do, so my work is well known in that circle. But there are no clockmakers or watch repair people in my lineage. That was all me. When I was a little kid, I had an unsupervised moment with my mom's alarm clock and my dad's small screwdriver set. I managed to get it back together and working as before, so mom still doesn't know. Been tinkering with timepieces ever since. And more recently, I found this forum. These fine folks have been patiently elaborating on the proper ways to undertake this kind of work. I have learned far more than I started with. I believe you will too. Enjoy!1 point