Leaderboard

Popular Content

Showing content with the highest reputation on 12/16/22 in all areas

-

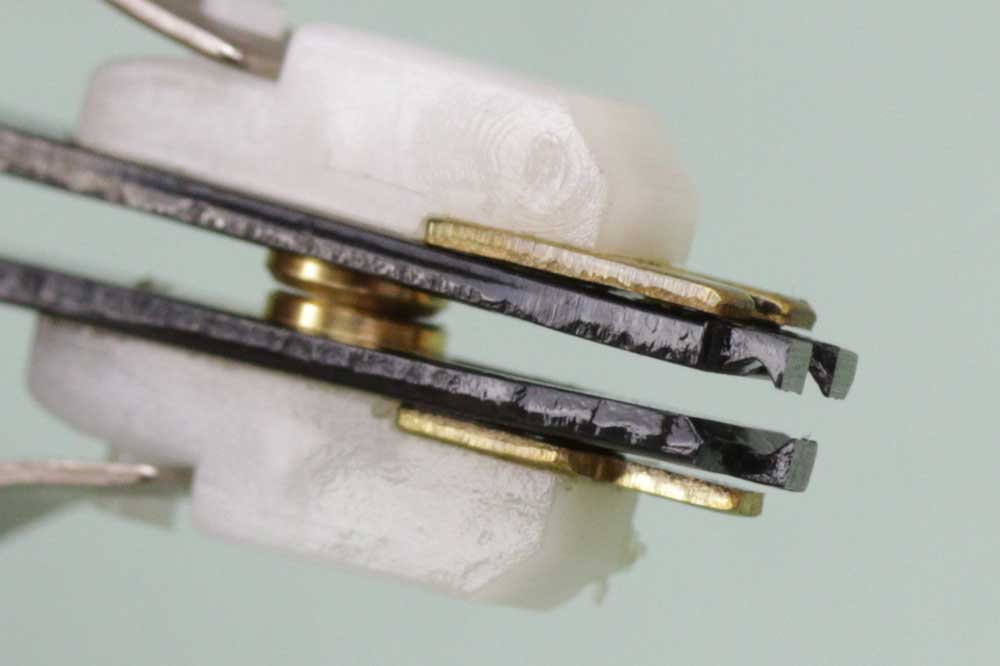

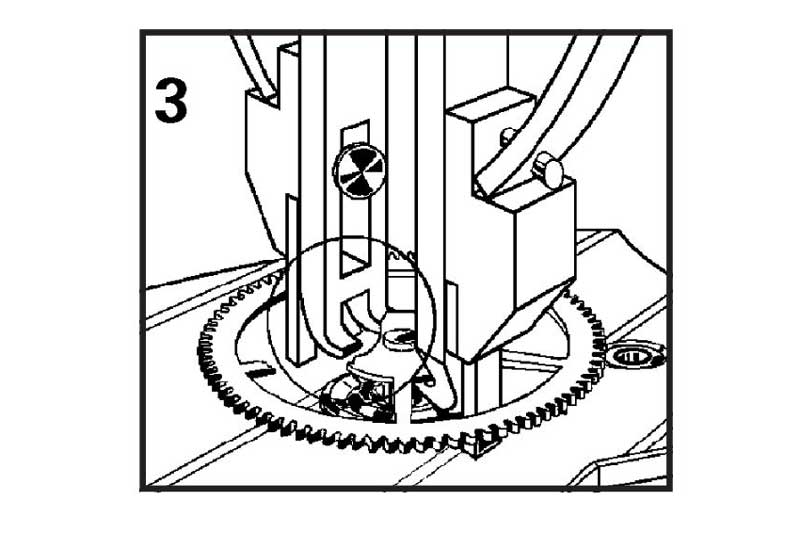

Hi Guys Got round to repairing one of my own clocks, The strike side spring had broken and it needed a clean, Managed to repair both. the spring end and the wheel which had three teeth broken off. After cutting out the broken teeth and making and fitting a blank piece . I had to make a cutting table for the lathe and using a dremmel cutting disc re cut the blank and shaped up by hand. I have tried the interaction with the pinnion and its ok so on to the rebuild. It is possible to do this type of repair without the use of cutting wheels and sophisticated rigs, just takes time an patience. Done barrels before, replacing broken teeth but this is a barrel ring gear which slots onto the barrel its self (two piece) so in effect its a bit easier to do. Although I dont post much of what I do on the forum I thought it might be interesting, Or may be not depends on your point of view.4 points

-

3 points

-

Not so much an achievement, just a standard COA, but look at this movement, dial, and case combo! Elgin was, obviously, a mass producer of watches but this is their finest work, imo. From 1904, the fit and finish is as nice as any I’ve seen from anywhere. The pallet stones are even curved on top, reminiscent of Patek. Then the dial is an amazing “fancy” dial, too….gotta love it3 points

-

To measure the hole you need to measure the pivot to measure the jewel a micrometer could work but the jewel must be absolutely straight when measured. This is the correct tool for the measurements of the old jewel and pivot. Jewels can be purchased from Cousins by size. To fit the new jewel you need a jeweling tool to set it to the correct height.2 points

-

Vostok 2409 Service Walkthrough Disassembly Pictures (Please sort by name in ascending order) Vostok 2409 Service Walkthrough Assembly Pictures (Please sort by name in ascending order) Being able to service the ETA calibre 2824-2 was a long-term goal and a dream when I started servicing and repairing watches some years ago. However, my first “calibre love” was the Vostok 2409; a reliable Soviet/Russian 17 jewels manual workhorse without any complications which has been around since 1970. It is still in production and found in Vostok’s Komandirskie series of watches, by some called the AK-47s of the watch world, together with its bigger brother the Vostok Amphibian dive watch. Modern-day Vostok Amphibians use the automatic Vostok 2415 (w/o date complication) and 2416 (with date complication) calibres, but the Amphibian that I’m servicing in this walkthrough, an Albatross Radio Room, popular among collectors, is from the 1980s and in those days the manual 2409, as well as its predecessor 2209, was commonly used in the Amphibians as well as the Komandirskies. While I was servicing this watch, I noticed that the crystal didn’t fit perfectly in the watch case. Being a serious dive watch originally designed for the Soviet navy this was, of course, unacceptable, so I replaced the crystal and video recorded the event in my “Bergeon No 5500 Crystal Press Review”. For me, the 2409 was a great movement to get started with as it probably is the most affordable movement on the planet, and spare parts are readily available and cost next to nothing. A lost or damaged part never spells financial disaster. Also, eBay offers an abundance of used Vostok watches in decent condition housing this movement for as little as $20 and sometimes less. A brand new Vostok 2409 (www.meranom.com) can be had for as little as $27. Be aware that, almost without exception, the eBay listings always state that these Vostok watches have been serviced, but in my experience they never are. Well, maybe dipped in a can of naphtha, left to dry and then injected with a bit of oil here and there. I’ve seen horrible examples! A somewhat tricky bit about the 2409 is to remove and replace the anti-shock springs. For this, I use a self-made tool made from peg wood. It’s shown in one of the assembly pictures together with a description of how I made it. A very similar tool is demonstrated in this video. Later, as I was working myself through Mark Lovick’s watchrepairlessons.com courses, I trained with the Unitas 6498 pocket watch movement which is the selected movement for the courses. In all honesty, from a learning point, the Unitas 6498 would have been an easier movement to get started with (especially the anti-shock springs), but the tinkering with the Vostok 2409 was a low-cost and fun way to get started and made me better prepared for the courses which answered a bunch of questions and was amazingly instructive. Eventually, I plan to publish a “Vostok 2414 Service Walkthrough”. The 2414 is identical to the 2409 but adds a very uncomplicated date complication. So, if you want a whole lot of fun for next to nothing when it comes to money, there is no other movement I would recommend before the Vostok 24XX movements, and the 2409 is a great starting point if you have a desire to begin tinkering with watches. Be warned though; tinkering may take over a substantial chunk of your life!1 point

-

What you're looking for is a Bergeon 30638-3, or it's equivalent from another brand. A normal presto will not fit, but this one has thinner feet that will fit inside the wheel. It is specifically designed to remove these wheels with an odd number of spokes (usually 5). I bought one, but have only used it twice. It's a single function tool, and overpriced, but it seemed to do the job safely.1 point

-

Hello and welcome to the forum, If you are wanting to learn The Horologic art may I point you in the direction of watchfix.com. Our Administrator Mark Lovick has an self paced on line leaning course to which you can enroll (cost) takes you from the beginning to advanced diagnostics and repair and is thorough.1 point

-

American watch companies are interesting with part numbers. So for instance Elgin has an 18 size balance staff numbered 857 that's a part number that's a exact part number. But the staff comes in four different versions and every single staff has a variation in size and that's not a pivots size variation every single staff is different in each of the four categories. Then every single one of those has pivots size variations. All with one exact part number which translates into how many different parts? No that's not a good assumption at all for one thing look at the balance wheel it usually has the serial number scribed on it which should agree with the serial number of the watch but that's not the problem. Yes this subject is come up before and I've explained this before but I'll explain it again. On modern watches or watches with flat hairsprings each hairspring is vibrated to the exact balance wheel it's on which is why hairsprings are never available separately it's a balance complete or nothing. On watches with an over coil hairspring to get the hairspring in the very specific shape it needs to be the easiest way to do that is to pre-make a hairsprings. That means the balance wheel has to be matched to the hairspring. Then the various strengths of the hairspring were determined by how heavy basically the balance wheel is. So if you have the right hairspring for that balance wheel than it should be the right strength it just won't match for timekeeping. Then timing washers probably aren't going to cut it you going to need timing screws which were available at one time. Then yes the watch is 18,000 beats per hour so you have to set the timing machine to that the problem is ill be way out of range and then the timing machine will be unhappy and not show the proper results. The amplitude on your display is unacceptable but it may be it's being influenced by the rate in the wrong setting such doing the wrong calculation so until you can get the rate close I'm going to assume the amplitude is probably not right on the machine very likely none of the rest of the numbers are going to be right You'll notice in the attached image what does it say about timing screws? It even tells you how to figure out which timing screw you need although just as a reminder make sure your balance wheel is round. Often times with handling a bimetallic balance wheels they get squeezed that will screw up timekeeping to a certain degree. But not as much as changing the hairspring you just need some timing screws. Then for Elgin part numbers just if you want to verify there is the link below yes it does look like that's the right hairspring now you just need to get some timing screws. http://www.elginwatchparts.com/1 point

-

I have a link to a website below. As you can see it's all about Bulova stuff but there's bonus things here. Is a nice military manual on basically learning watch repair you should download basically anything that looks interesting should be downloaded. Scroll down until you reach the section titled Joseph School of Watch Making. Then at the bottom of the list you to download the entire block.When you have the complete book downloaded you want to look at unit 3B it will tell you how to make a new stem. It even comments about sometimes you cannot obtain a new stem and it has to be made so this is where you find out how to do that. Along with a whole bunch of other useful information you may need someday in the future. https://www.mybulova.com/vintage-bulova-catalogs1 point

-

Eyup angrybear. Up and down the screen 20 times now to compare the 2 lol. Confirmed my intial gut feeling, the black dial to me is more 40's 50's classic and has a military feel about it. But then i am a sucker for the Dirty Dozen's. The extra addition of the 10 second numerals on the sub just gives it a bit more going on. The white dial is lovely but the black one is gorgeous, quality work1 point

-

American watch manufacturers offered replacement hairsprings in several "strengths". I'm pretty sure assortments were available back when the companies were still in business, which would be handy as there's really no way to know which strength you need without trying it out. Even with a good match it might be necessary to add timing washers or something to get things right on. Sets of timing washers usually give a rough idea of the rate change for a pair of washers for a certain size watch/balance, and for a given size you will usually see that there are 3 choices, 1min, 2min, 3min. In your case you might be able to fit 6 pairs of 3min washers (to opposing screws by pair, and spread over 6 pairs of screws if possible). That's a lot of timing washers, but it might be your only option.1 point

-

Yes, cylinder escapement. Hard to time on a lot of modern timing equipment but member praezis has a killer software that will pick up all sorts of escapements (and is Witschi level+ otherwise). Very important to have all power off before removing balance. Otherwise business as usual, lubricate escapement with 9415.1 point

-

Hi Bear the ever so slight changes do not detract from the overall quality of the watch but as Klassiker said to appreciate the difference one needs to see them side by side even then I would put them on the top class range. You are doing quality work Bear more power to your elbow I love them, the style is ageless.1 point

-

Haha that happens. I once lost the tiniest diashock spring known to mankind. I got fed up of looking after 20 mins, went downstairs for a pee, made a cuppa, took it upstairswith me. Sat down put my glasses back on, looked down and it was stuck on my jogging bottoms waving at me. Contact lens cases are a great idea, it came to me by accident. Went on holiday and ended up with someone else's toiletry bag in my case, in the bag was a contact lens case. Now there's an idea i thought, so bought 10 pair of cases for 3.50. Really useful and super cheap.1 point

-

In this case as it's a Seiko I would check with Cousins to see of a new pallet bridge is available, for a one off job it would a lot cheaper (under £20) than spending nearly £500 on the watchmakers micrometer and Jewelling tool. Or check with the usual used parts suppliers for a used part, Speedtimer in the Nederland's would be a good place to start.1 point

-

How to measure the jewel hole ? How would it be to use a smoothing broach inserted in the jewel hole, mark its depth and then measure its diameter at the marked point using a micrometer.1 point

-

Replacing jewels requires accurate measurements of the old jewel the jewel hole and its setting. To fit and replace you need the correct tools because without them failure is highly likely.. Tools required: a bench top micrometer and a jeweling tool.1 point

-

1 point

-

Something a little different today. This is a German Osco 400 (aka Dugena 1155) based "Ankra". The movement is a little quirky, with the ratchet on the dial side. Clearly its in need of a little TLC, but I'm hopeful it will spruce up very nicely. Maybe we wont see a genuine Dugena in the 404 club, but this is its pretty close cousin.1 point

-

Horolene clock cleaner is the one I used many years ago. I understand the one watchweasol mentioned is cheaper both will do the same thing. You mentioned cast brass if it is cast what ever you do do not use one of those ultrasonic cleaners as it can and will cause stress fractures in the brass. What type of clock movement is it?1 point

-

1 point

-

1 point

-

Those movements are very interesting, fun, and educational to get started with. Good luck! BTW, you might find this service walkthrough useful.1 point