Leaderboard

Popular Content

Showing content with the highest reputation on 12/14/22 in all areas

-

Not so much an achievement, just a standard COA, but look at this movement, dial, and case combo! Elgin was, obviously, a mass producer of watches but this is their finest work, imo. From 1904, the fit and finish is as nice as any I’ve seen from anywhere. The pallet stones are even curved on top, reminiscent of Patek. Then the dial is an amazing “fancy” dial, too….gotta love it1 point

-

The interesting lessons you learn in life. When I was a student I polished my pivots because we're supposed to reduce friction. Then with my running watch over to the timing machine in the days of paper tape no digital amplitude. The paper tape machine every time it printed made a nice clicking sound you could hear it all across the room. Which means if you did something interesting like polished your pivots insanely round the watch would make interesting galloping sound on the timing machine and everyone would know what you did. Nobody said anything but. That I learned how pivots are supposed to be more flat and the problem went away. So one of those interesting lessons of reducing friction is good but not on the end of the pivots we have to have the equivalent of the same friction no matter what position the balance wheels in so the end of the pivot cannot be polished nice and round.1 point

-

How is the vertical amplitude, in good relation to horizontal? Then too strong spring or gears running more easy than expected. But sometimes the balance pivot ends were polished ridiculously round. That will give high amplitude horizontal, but shows poor amplitude vertical. Frank1 point

-

Do these jewels have cap jewels associated with them? I have a feeling that where cap jewels are used the hole jewels are fitted with the oil sink on the opposite side to the cap jewel. The cap jewel then controls the end shake and keeps everything lined up.1 point

-

1 point

-

Anybody read this? I read a very short review--sounds interesting. https://www.amazon.com/Your-Brain-Time-Machine-Neuroscience/dp/0393355608/ref=tmm_pap_swatch_0?_encoding=UTF8&qid=1670981435&sr=8-11 point

-

I think you're going to find that there's a heck of a lot of force on a mainspring and the epoxy will fail. At one time one of early automatic watches the outer part actually was a separate part. Then the mainspring would attach to the outer part and this is where someone kinda tried to simulate. But it would be much more appropriate to find a new mainspring. Just in case you don't have it I've attached the parts list Seiko 7019A.pdf1 point

-

There is no reason why not but it’s not the correct way. The correct way is a new spring, the point at which the spring is folded will always be a weak point and may break again, requiring you to dismantle the watch and fit new. Best to do it now and save a little pain later.1 point

-

There were many other problems along the way. I had problems with the balance jewels, the hairspring was all sticky, then I kept having issues with the watch stopping when I put the face on. Turns out there's a friction ring that holds the date ring in place, and it was slightly interfering with the dial feet, causing the dial to put pressure on the hour wheel, stopping the movement. Drove me bananas for days tracking that down. I learned a lot, and I think I'm a better repairer for it, though. And I've got a lovely Christmas gift for a young man to show for it. I'm smitten by the pinstriped dial, and the new crystal really makes it pop.1 point

-

As you said, I was given lots of interesting info on it. Here is the link to the thread....https://mb.nawcc.org/threads/help-id-e-howard-co-boston-pocket-watch.192951/1 point

-

Hi It looks as if at some point the bridle broke away from the spring and the repair was to fold the end of the spring and slip the bridle into the fold. This would provide some friction to hold the spring but only as a temporary fix whilst awaiting the correct spring. not a permanent fix/1 point

-

Yessir, here's the specific movement. It's a late 2014 model, in line with being in a 2015 watch. This is the updated version so technically the ratchet wheel issue should've been resolved already. And the offending rathcet wheel. New one on the left, shewed up one on the right Just for the sake of clarity, I don't want people to think I dislike the Sellita movements - quite the opposite in fact. Like with any product there are some potential issues to be aware of so me carrying on about it is to merely create awareness of the issue. Sellita parts are much cheaper (and more accessible) than the ETA counterparts so in principle I'd support Sellita if given the choice. They're certainly not some mickey mouse company.1 point

-

it is not a Rumour that Sellita modified the Weels, it is documented by Sellita look here https://www.google.ch/url?q=https://www.sellita.ch/scripts/calibres/images/IS%2005_Evolution%20calibre%20SW200%20vers%20SW200-1.pdf&sa=U&ved=2ahUKEwig44XUqfX7AhVP4qQKHQw5DOwQFnoECAsQAg&usg=AOvVaw0QDdoNfkxEmBq3gOVDEgir hope this helps a bit, i like Facts..... regards, Ernst1 point

-

I haven't noticed any difference in cleaning results between the two. I was always happy with the Pearl when it worked but when it didn't the seller refused to provide any help even though there was a "warranty". Having a business that actually stands behind their product was the reason I decided to get the SE. What I do like about the Solvex SE compared to the Pearl is that liquid doesn't splash all over like it did on my Pearl. The rheostat works from 0 through 100%, and it is much easier when moving the basket between jars.1 point

-

Hi if you are just starting out best to use the finger cots and get used to working with them on, either practising of for real.1 point

-

Hi Mike Have a look at this link http://www.abbeyclock.com/buk.html it has animated descriptions of escapements in action.1 point

-

Hi fellas, I'm pretty sure you've both read this but it will take some mystery out of things. I know it's a chore without accompanying pics but if you do those checks you won't be bending stuff willy-nilly. Just had a "chronometer" (in name only haha) pocket watch in with both pins bent the same direction, did my checks and the escapement was . Why they were bent I don't know, but I would have spent some time un-doing had I just straightened them.1 point

-

I think the rivet holding the hand to the tube was loose. The hand would have come off regardless of the tool used. This hand remover pushes the pivot out of the tube, reducing the risk of the pivot breaking off or bending. If the hole in the chrono hand is not enlarged, it might be possible to refit the hand and expand back the rivet to hold it. Watch this video on how a hand tube is made. I just thought of something... not all hand tubes have a hole on top. If you use a pusher like this on a tube with no hole or use a pin that is bigger than the hole, you'll end up pushing the tube out of the hand.1 point

-

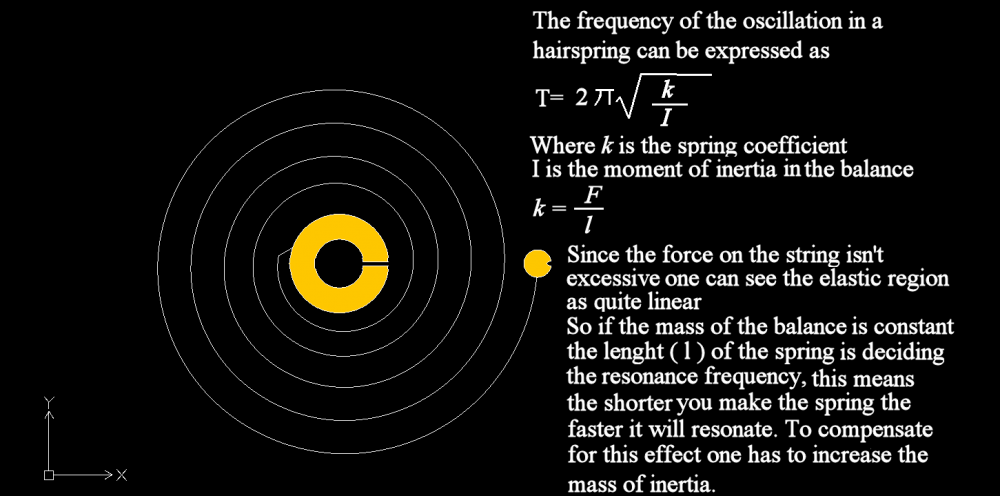

Well, everything is simple if you know the theory behind it, just like @nickelsilver said there are two options to go with, it is either playing around with the length of the spring or the mass of the balance. In nickelsilvers example he solved it by drilling away mass from the balance, wouldn't say that is what a novice would be able to do without proper tools. Adjusting the length of a hairspring when one never done it before, well if you have a good hand to eye motoric it might work. I wait with anticipation on the tutorial. Meanwhile I can contribute with a small illustration of the theory I think is in play here ?1 point

-

In regards to finding replacement parts in the EU, I have a very good experience with Ernst Westphall(watchparts24.de) and Rudofl Flume( Flume.de)1 point

-

Grab the arbor with a pinvice or barrel arbor holder (really just a glorified pinvice) and turn clockwise while keeping firm pressure against the spring. It should open up and take the arbor.1 point

-

Use that page a lot . Almost every day . Not always right but 90% of the time it helps finding parts . I looked for a arbor for a Omega 601 pallet fork. Jules said a Zodiac 72 arbor would work . but it's not the same . Had one i tried .1 point

-

I often observe the balance wheel oscillating without the pallets to get an idea of freedom of movement. You could try the same and compare vertical with horizontal. Helps to take the escapement out of the equation.1 point