Leaderboard

Popular Content

Showing content with the highest reputation on 12/09/22 in all areas

-

Yes we've had lengthy discussions were newbies feel unhappy which is why we actually have a safe zone for newbies to ask questions. But sometimes people won't even look at the newbies questions for fear of somehow upsetting a newbie. Supposedly at least the person who really wanted the newbie section was that newbies could work together share their ideas pool their resources and not have to deal with the evil experience people on the group. The problem is that the newbies don't have experience or knowledge to answer their own questions. Then unfortunately a lot of newbie questions can be answered with a section of standard answers. But apparently newbies don't want that they want to have an individual answer for the same question that's been asked 50 times in the last month although I don't think I've ever seen that here. A lot of times newbies get very demanding on how the watch world works and it's not actually grasp how it works to the settled Down and then start to behave appropriately for the discussion group. Yes contrary to popular belief learning watch repair is not easy and everybody gets frustrated. Bless everyone has parts issues I have watches currently on the bench or actually it's a small car clock needs parts no idea where were guy get them so it's going to sit there for a while. With angry customer calling from time to time wanting to know where the status of the clock is now there is something the hobbyists shouldn't have is angry customers bothering them. The problem with Seiko is is it an overseas Seiko or US Seiko? Then there's also the possibility that maybe the material houses don't work with Seiko.Then of course there is the other problem material houses are run by people just like us well hopefully knowledgeable people in the material business but not necessarily. Then they need numbers the same as we do so yes conceivably they're all using the same database which is what the problem is. So they don't have Seiko access their probably accessing the same thing we are online Then I would be curious would you give me the wrong numbers please and are we still waiting for correct number for your case? What hostile watchmakers? One of my friends Doug learning watch repair on his own I pointed out that we have a school yes Seattle has two schools we have a professional school and a school for hobbyists to learn watch repair in a friendly safe environment. I'll give you a link below and know don't even think of emailing and asking about online courses they don't do the. Not that people don't keep emailing and then I send them to Mark's course that is if I think they're serious and not pulling a scam because most of them are trying to scam in some way or another now back to Doug one day at a nawcc meeting He was explaining that is he was learning watch repair whatever he was looking at he went downtown and asked the question and I resisted laughing hysterically because I knew what the outcome would be. So what was his question he walked into the furnace watchmaker shop explained that he taught himself watch repair he offered them money if they would evaluate what he did and of course they all through them out. No that's not true of everybody if you walk into where I work and ask Sam's happy to sell you a practice movement and talk to you so it's not 100% but a lot of the old-time watchmakers are well very peculiar people. Amusingly that's something they try not to talk about at the school teaching professional watchmakers locally. Dave the instructor comments it basically well we can't compete with Microsoft. With so many tech companies like Microsoft that starting pay is $1 trillion an hour or whatever it is watch repair just can't compete. So yes the pay is a definite problem but let's look at this a little bit differently what you think it should cost to get a watch serviced? Let's look at the Seiko in this discussion is anyone know how long it would take the taken apart clean it lubricate it put it back together case it up add in handling the paperwork because you're doing a job for customer you have to some paperwork possibly some billing how much time you think is spent to service the watch? How much an hour would you like to make look at your current pay and if you're running a business you have to charge more because you can't just collect your pay you have to pay for all that equipment you have the cleaning machine the timing machine etc. Then unless you're working retail we typically get the most money if your wholesale well usually that's 50% but not always. So in other words if you took a watch into a jewelry store and it cost you $400 to get your watch serviced and you felt ripped off. The watchmaker only got $200 Of that. The worst-case example what is working downtown was think I can't quite remember they marked up the wholesale it wasn't the typical twice it might have been four times I think that's what it was and in the cost of the repair was the same price at the person paid for the watch brand-new from their buddy at the wholesale house which was selling Seiko watches. And you know whose fault that was that was the greedy **BLEEP** watchmaker who nearly lost her Seiko service account. Yes in the early days independent watchmakers basically ran service center is for the various companies were now they have their own independent shops You should have been at the Christmas party I was at last week a nawcc local chapter Christmas party that had the various president of marketing for a chain of local jewelry stores. Talked about all the watch brands they have the trends and then I got to the end where they talked about the problem. A huge problem that she perceived and they're going to give out more scholarships now to encourage people to get in the watch repair. Not that they're already not trying to read the try to set up some of their own teaching I think in association with the school. Basically they're running scared of the lack of watchmakers means the watch makers are going to cut back even more as a guess. So I think she had a fantasy thought and their thought was more people servicing then hopefully more parts perhaps but she didn't ask you say that. So they want to take an active role in making sure there are enough watchmakers because I'm pretty sure there service center makes a lot of money she was giving numbers and they service hell of a lot of Rolex watches and if they couldn't get Rolex spare parts that would be a huge impact to the business. Unfortunately I have to wonder if they talk to the Swiss about these plans because I think the Swiss one to illuminate everybody who repairs watches. I don't think they care whether a hobbyist or a professional. It's why Rolex has a service center in Texas filled with unskilled labor that just does one little task. Like one person will disassemble watch and it goes in the cleaning machine another person will reassemble another person will lubricate and only if it fails some quality control what go to something that resembles a real watchmaker. Quite a savings not to have to pay skilled people or distribute spare parts all over the place. Not sure this quite compares for instance if you go down to your local auto shop will they let you hang around in the shop? And yes I know you hate this example let's go to the hospital and hang around in the operating room to get a feel for becoming a doctor. A lot of the hobby and artist spaces are well-liked makers spaces they still exist out there yes they encourage people to come and visit but they're not a professional business trying to run and make money. It's kinda hard to do watch work and talk to newbies at the same time. Well it's hard to talk to anybody when you're doing watch work and then you get yelled at by Your boss For talking too damn much but I'm the skip over how I know about that one. Now I give you a quest reach out to all those people who want to know if you do watch work and ask them how much they would pay you to do the watch work? In the early days I remember the jewelry stores were damn cheap cheaper the better. So basically the only way wholesale watch shops can function is out of people's houses preferably in the middle of nowhere where rent costs nothing. Think about it this way you're a collector of watches you have hundreds of them occasionally need to be serviced and you spent so darn much money on those expensive watches you really want to pay somebody to service them? After all you get the oil changed in your car for how much shouldn't to watch repair costs something similar?. Oh and the case you think I'm joking about this is another discussion group out there of collectors who think that? Will it used to be they thought of pocket watch repair I think was between 50 and $100 and a while back somebody was recommended and I think he was like 125 for pocket watch repair and they said he was expensive. So yes watch collectors are really cheap and don't want to pay watchmakers. So it's a really complicated situation of it just complicated and there's going to be no easy solutions Or answers and the parts availability is never going to change. Especially if you understand how parts come into existence anyway and how their distributed. Yes hobby schools really exist but unfortunately you have to be within driving distance of Seattle. http://www.norwestschoolofhorology.com/ Oh and is not just hobby school we have an Association it once was in AWCI chapter but we got annoyed with them and broke free. So meetings that are open to anybody. If you have an interest in watches and clocks and repair and you're within driving distance. http://www.norwestschoolofhorology.com/wwca/index.html4 points

-

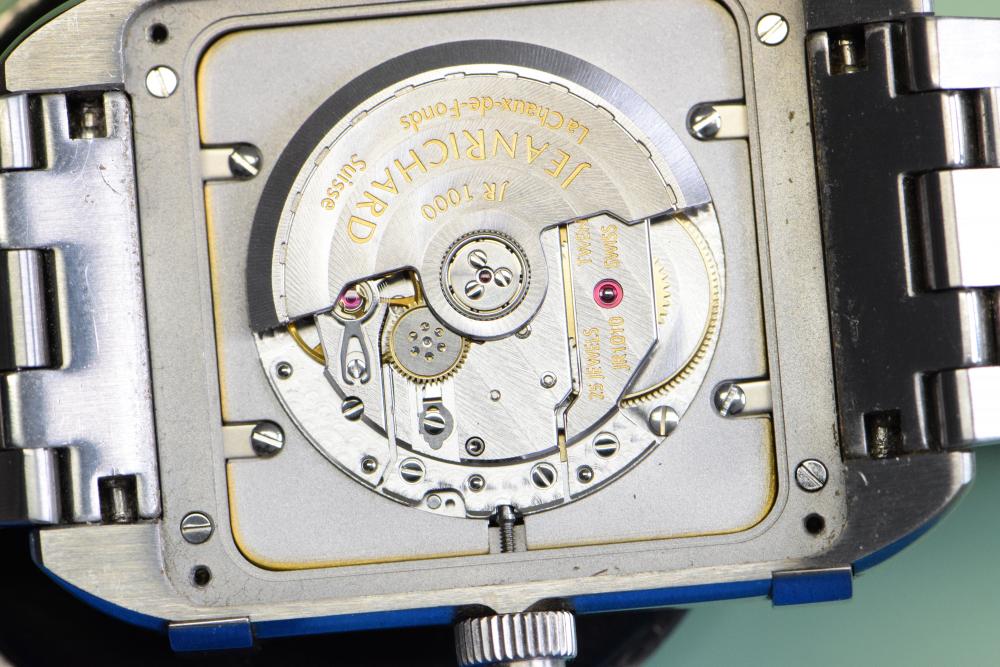

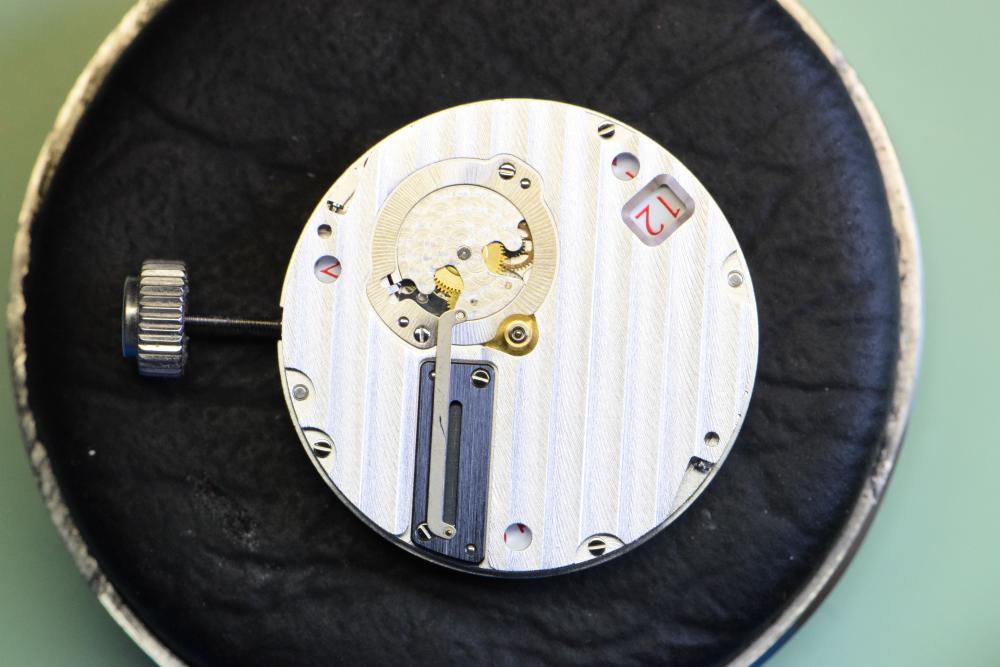

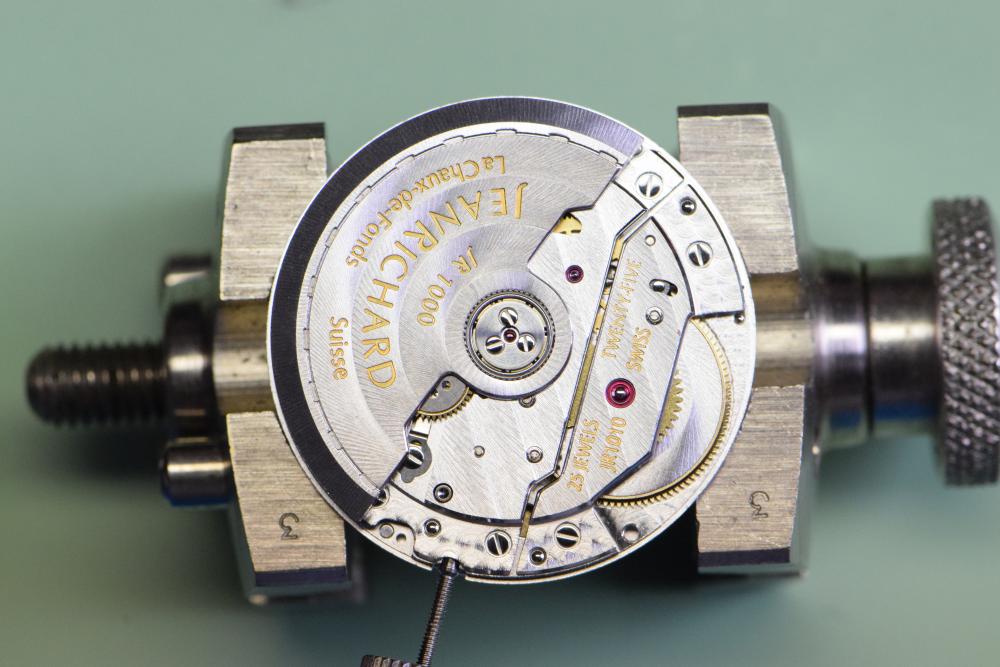

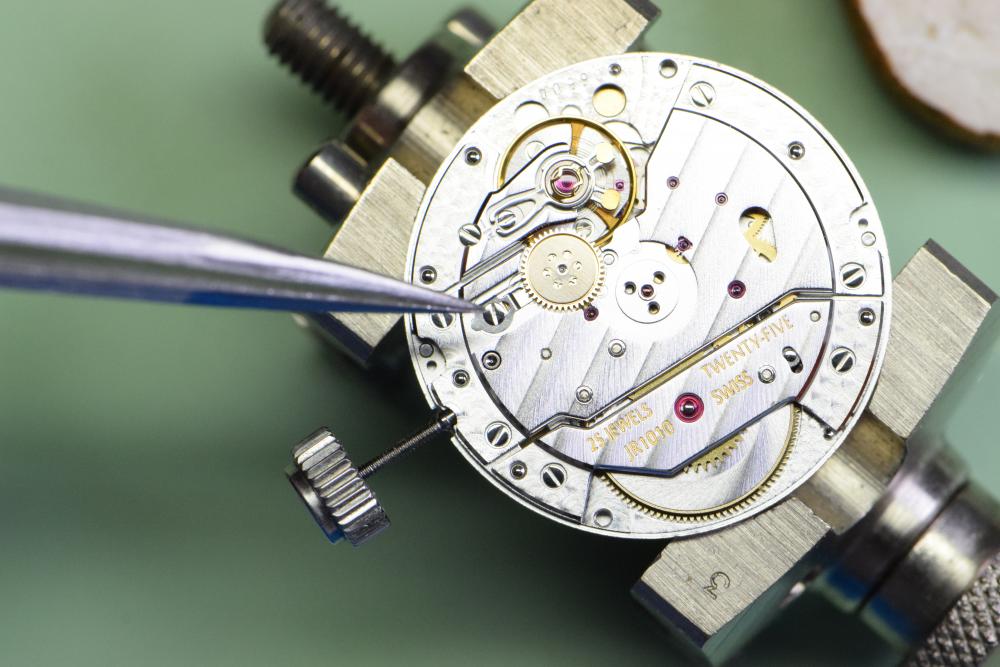

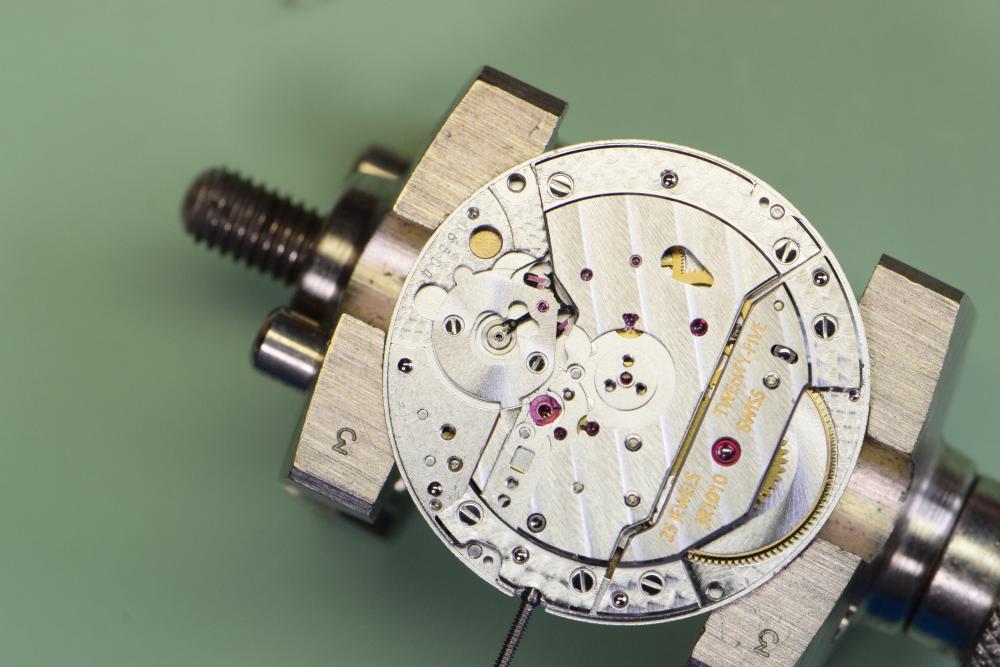

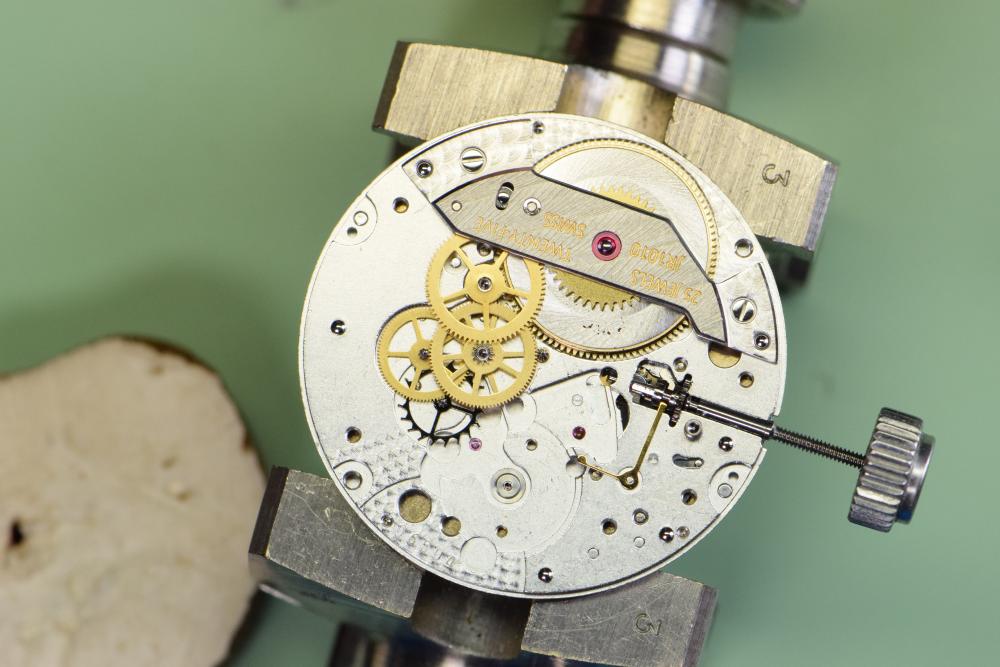

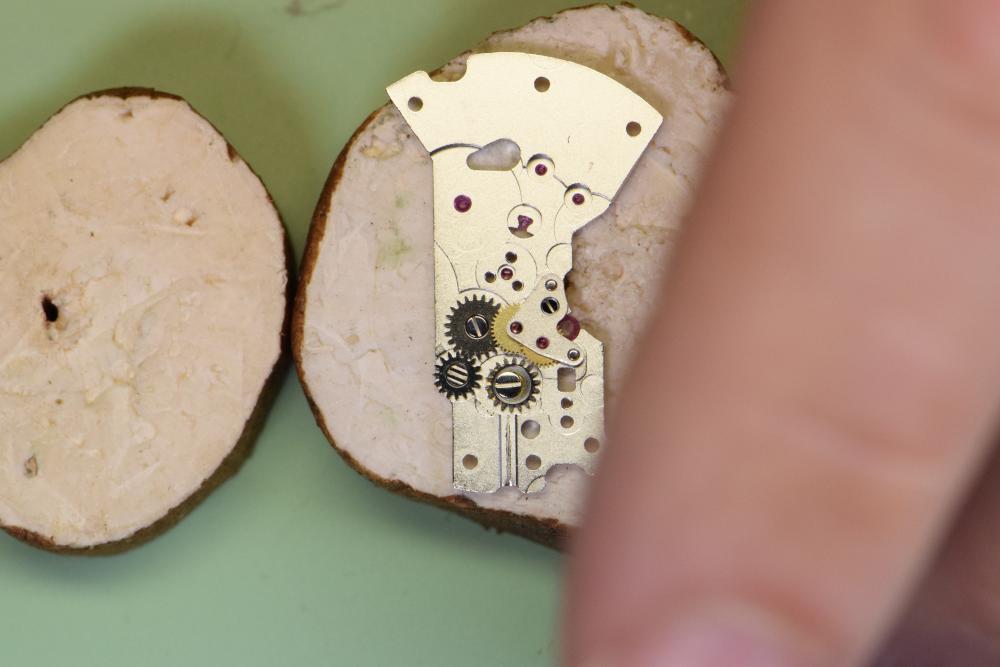

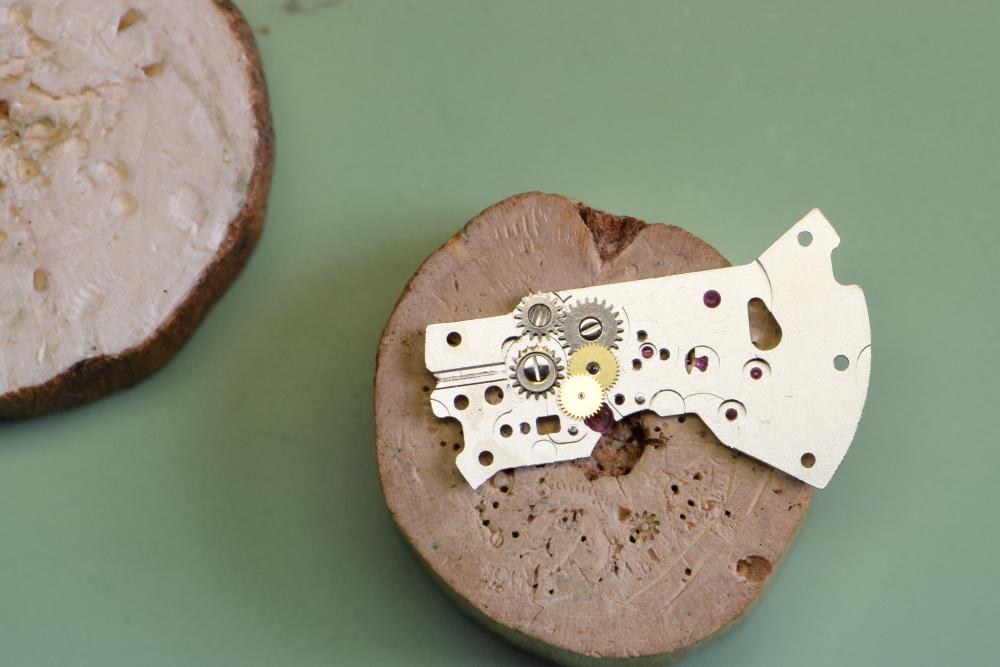

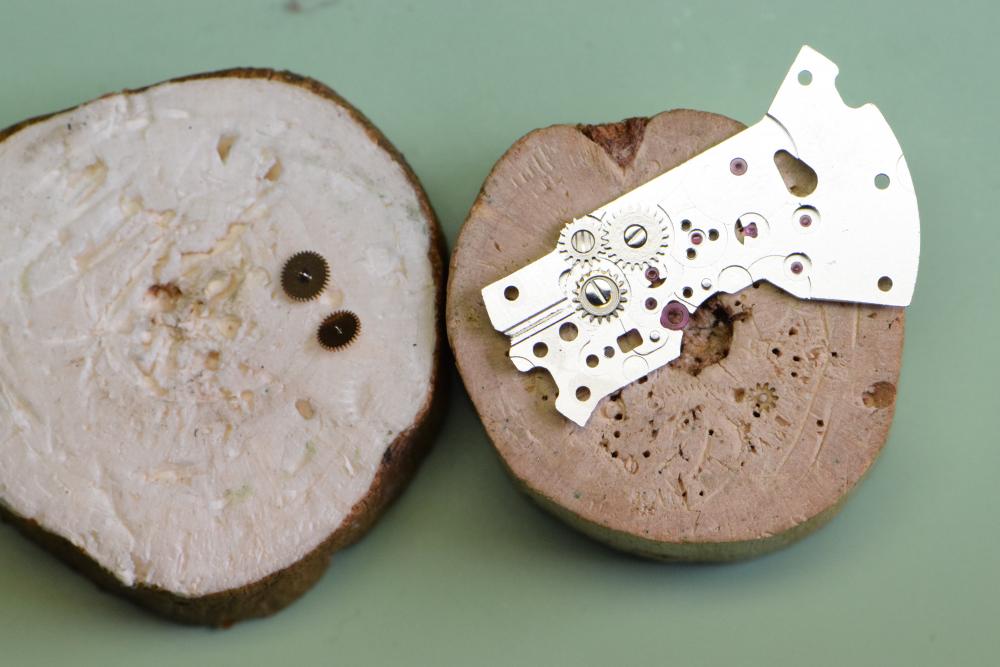

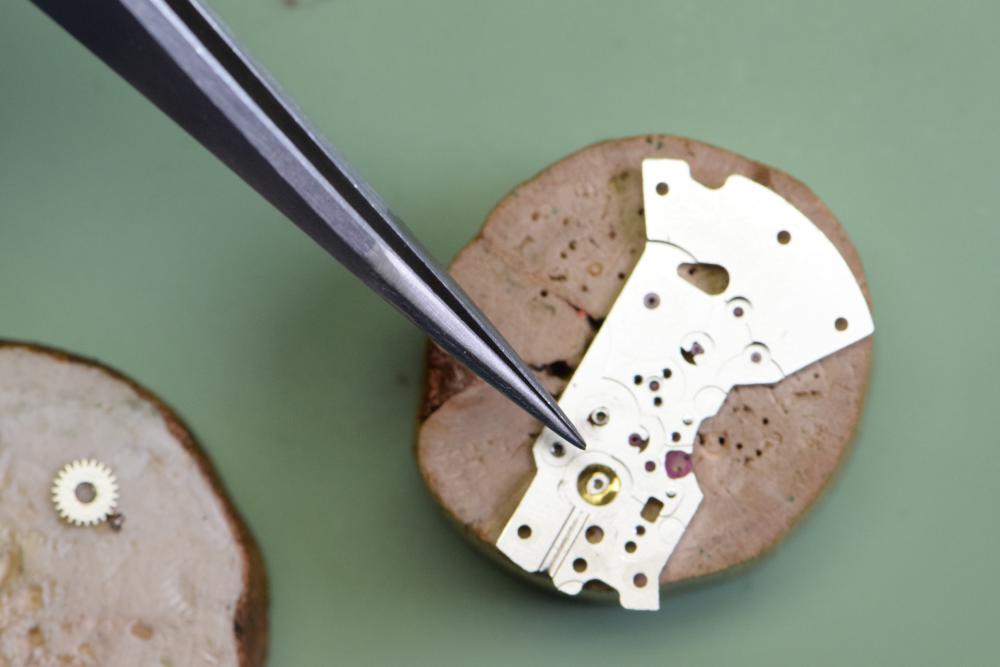

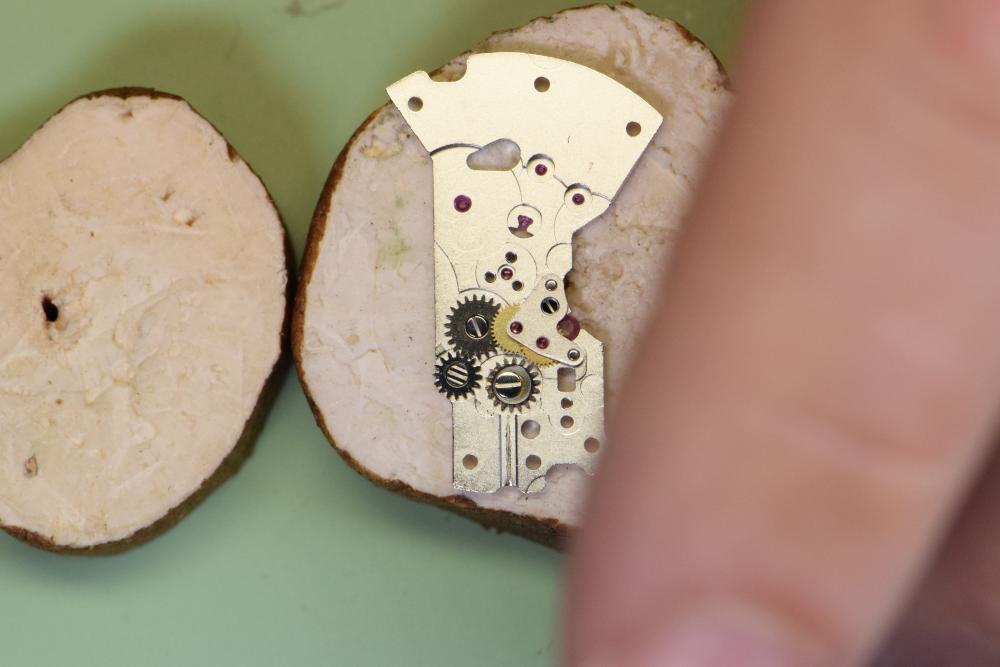

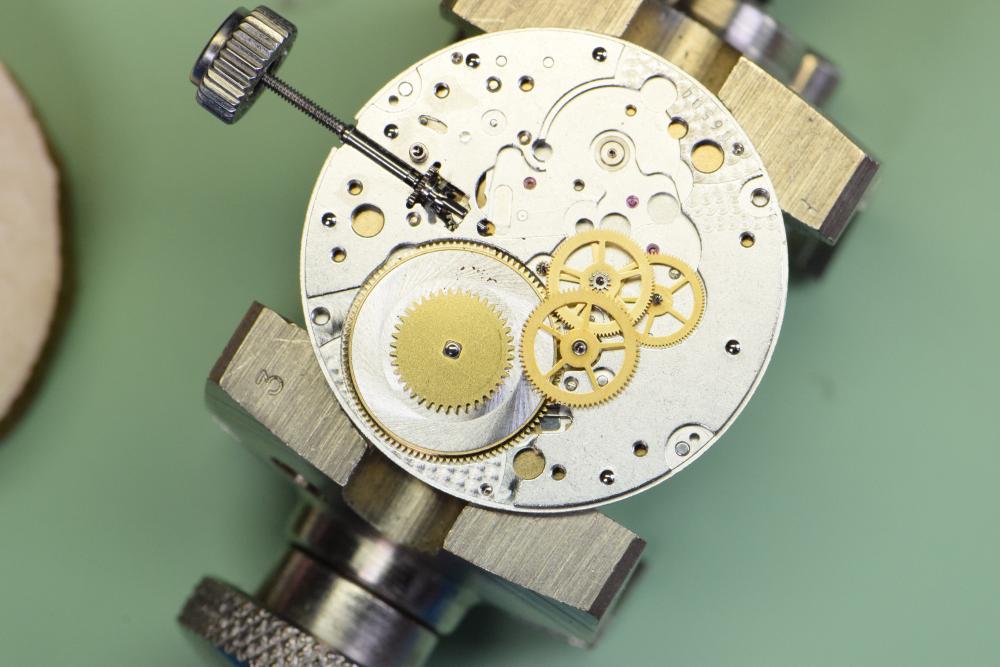

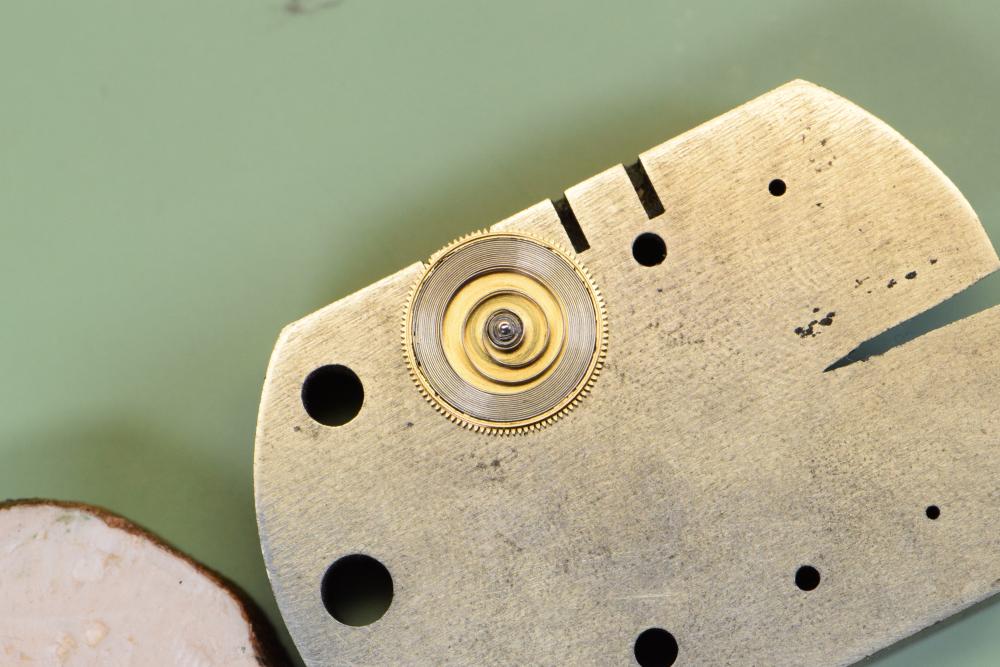

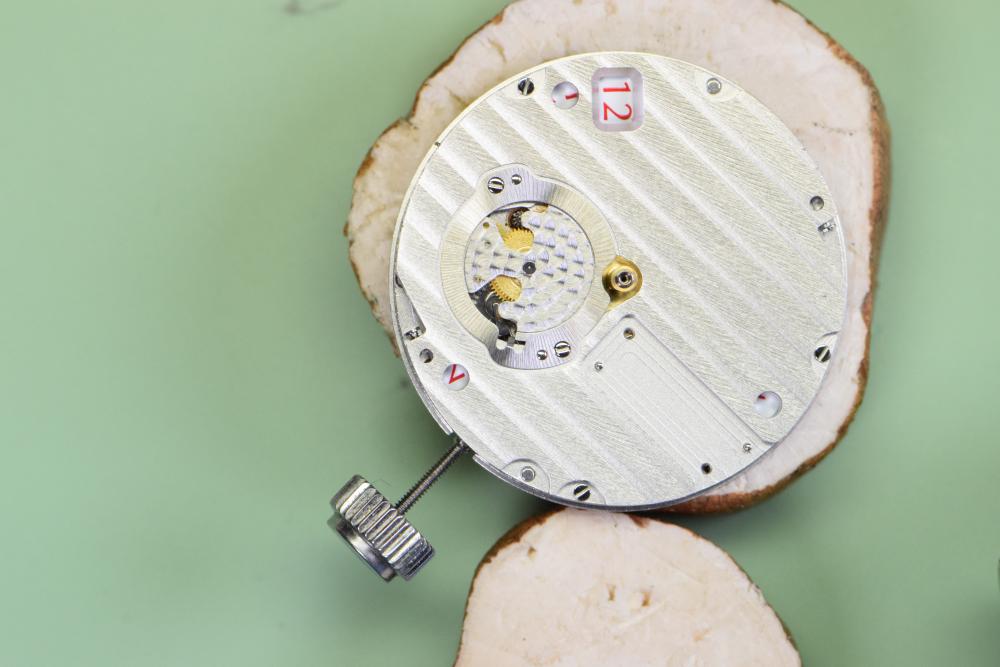

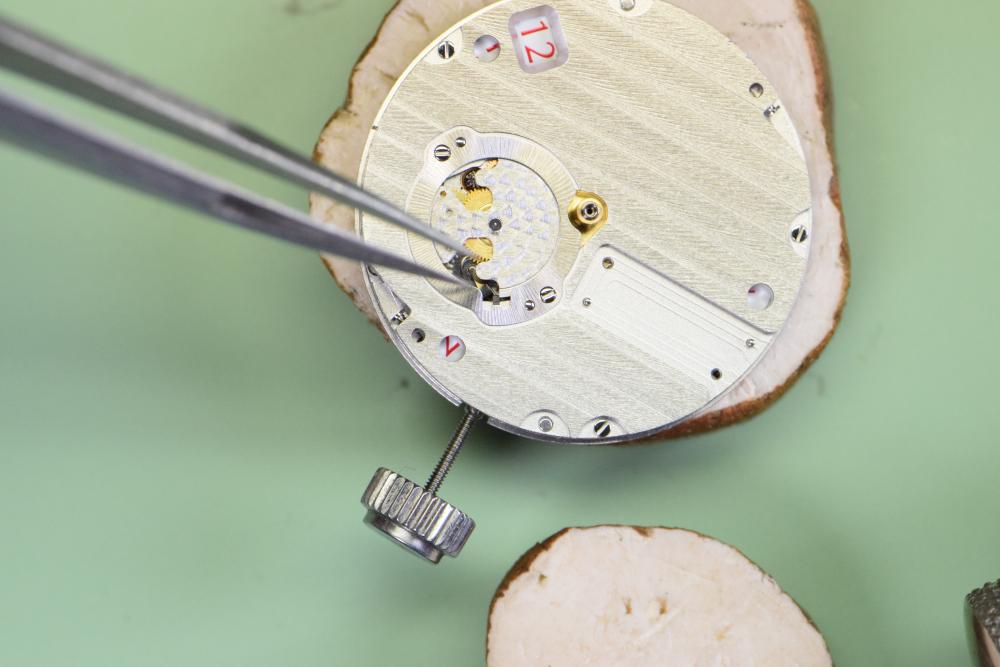

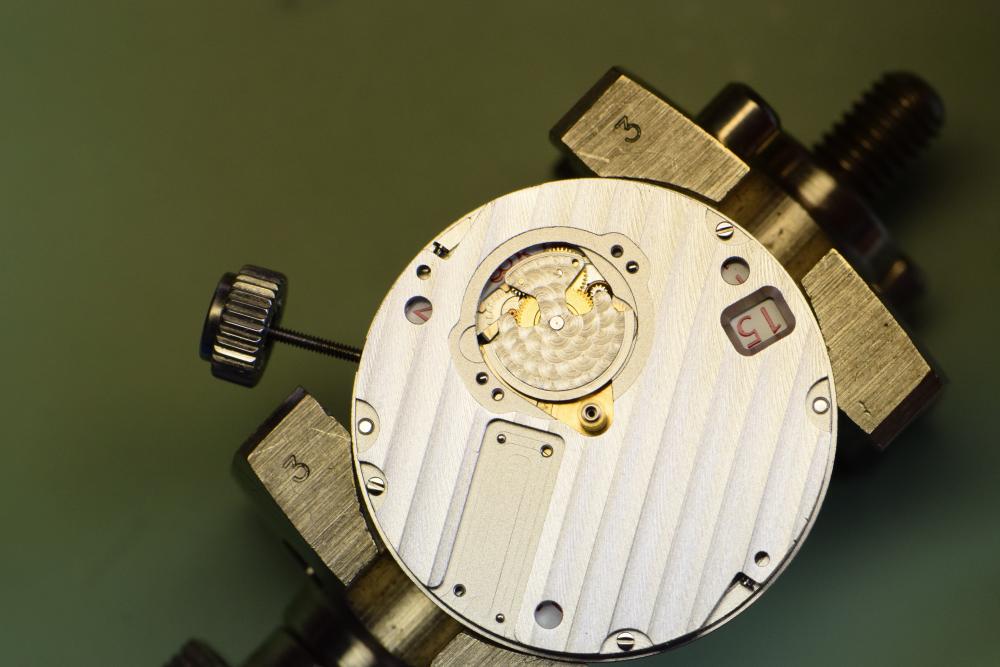

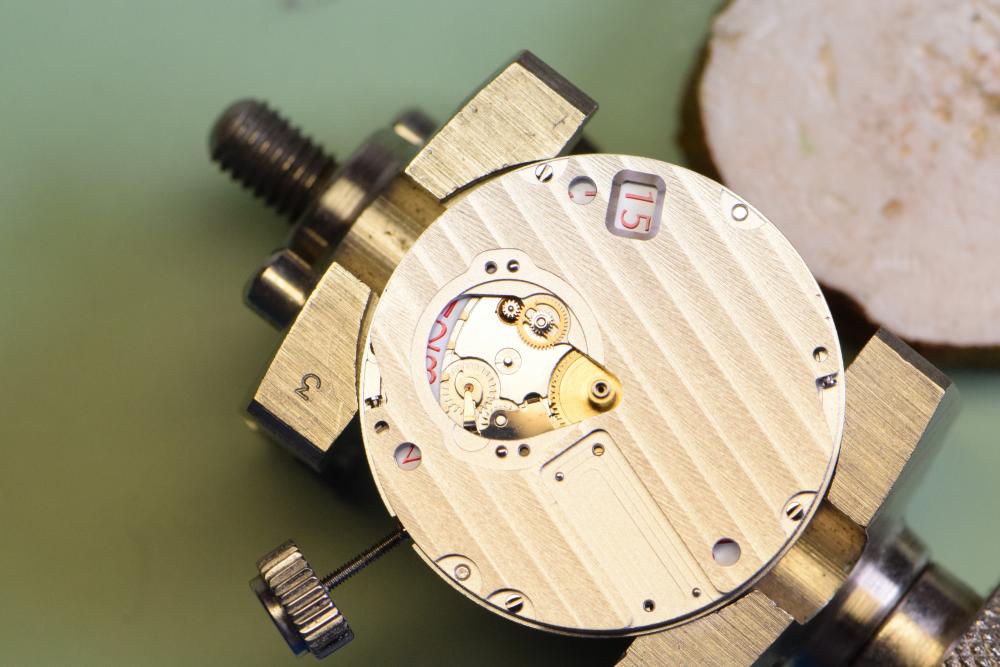

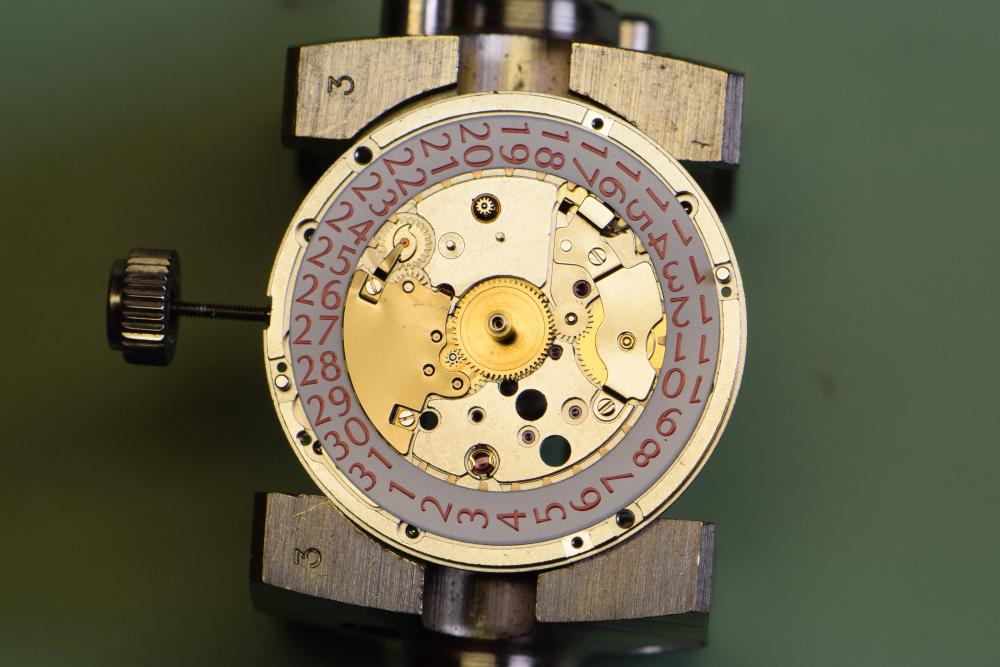

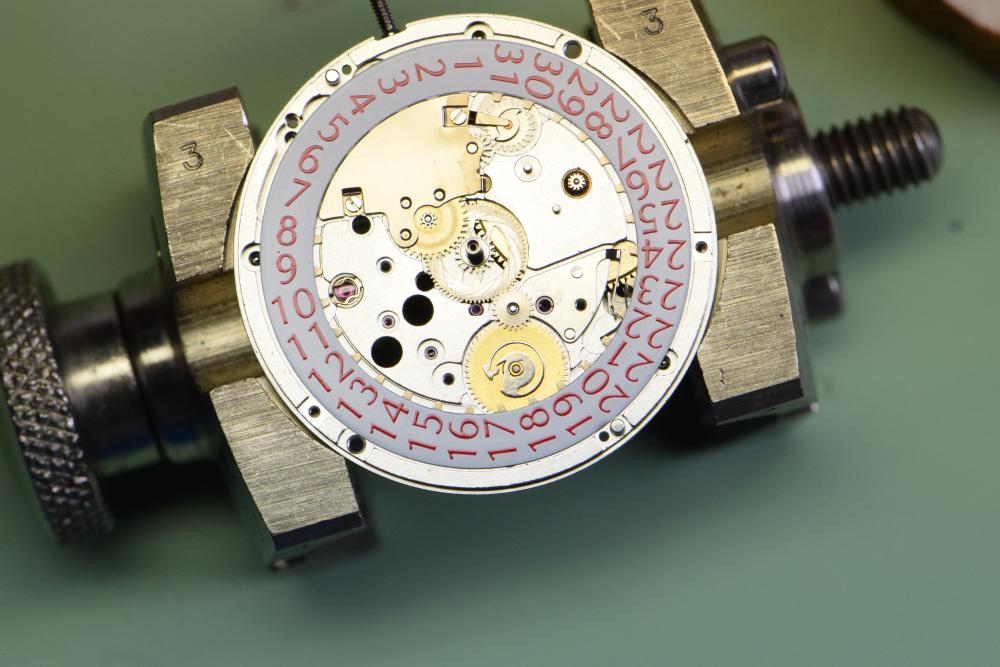

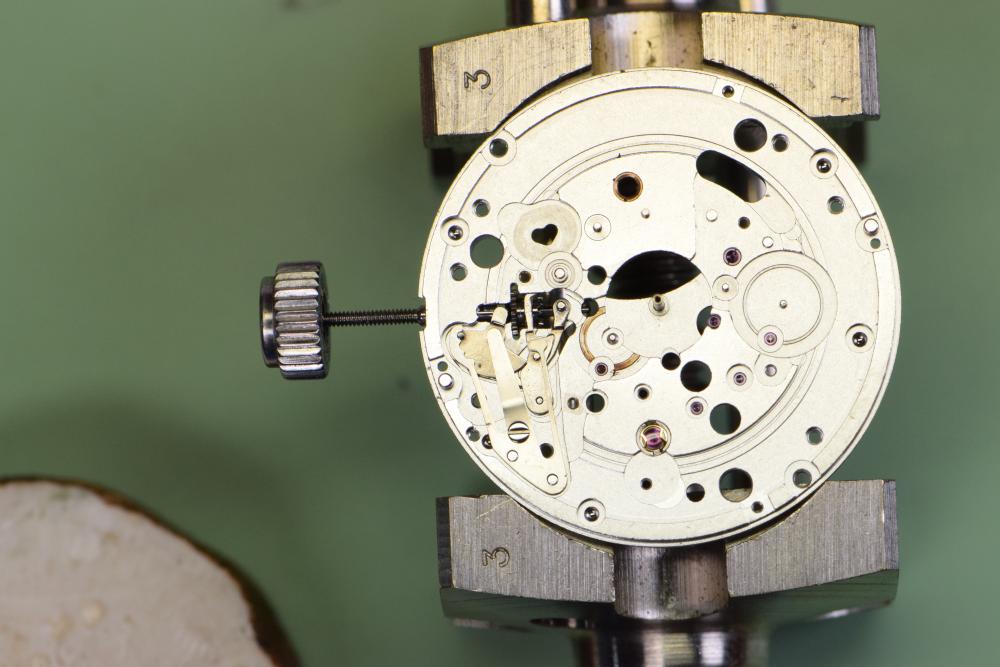

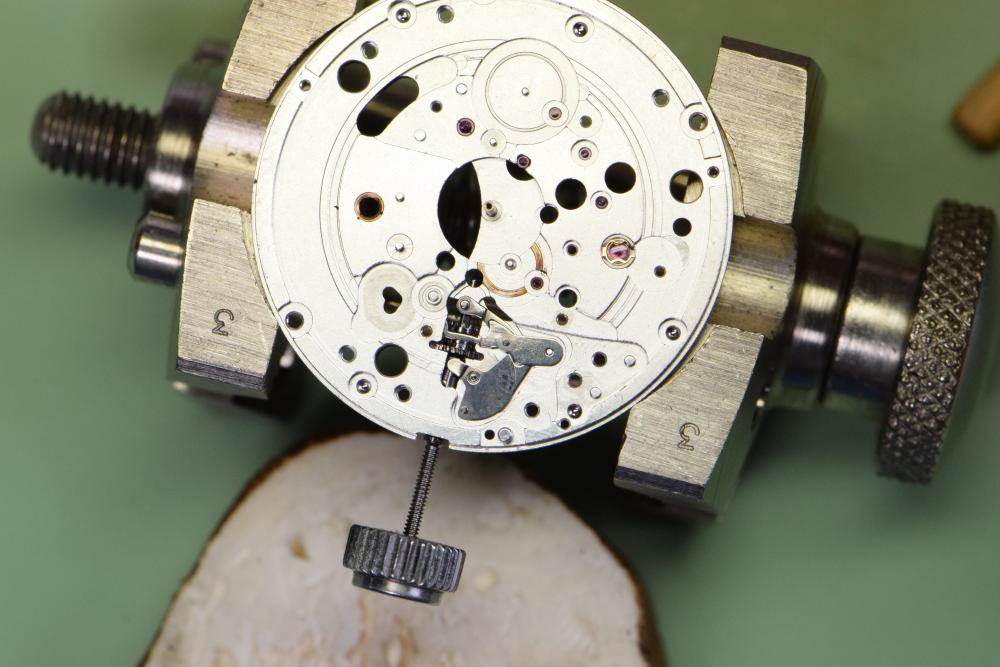

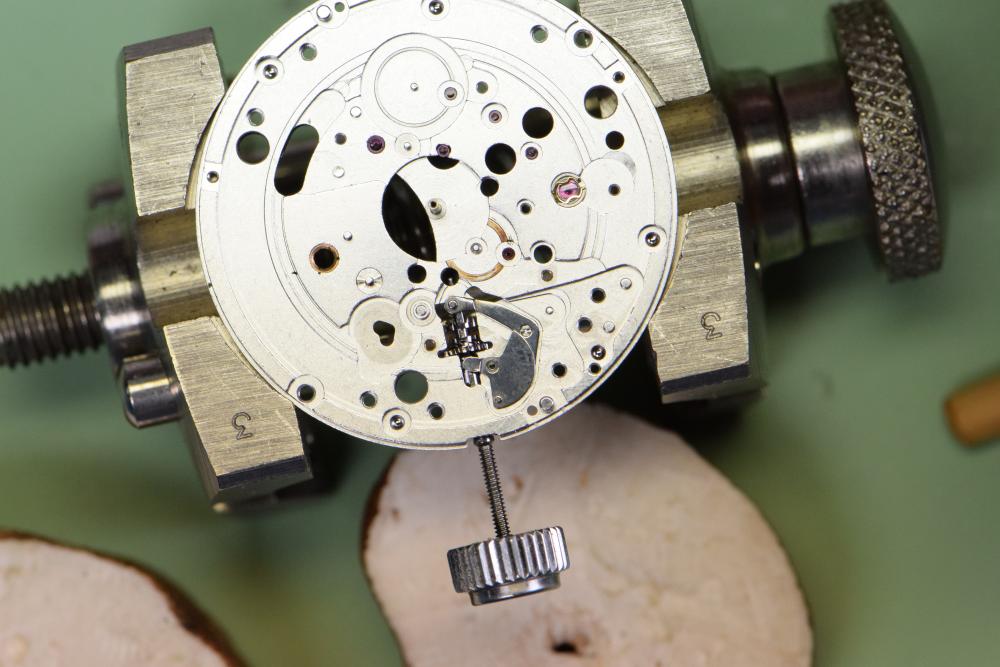

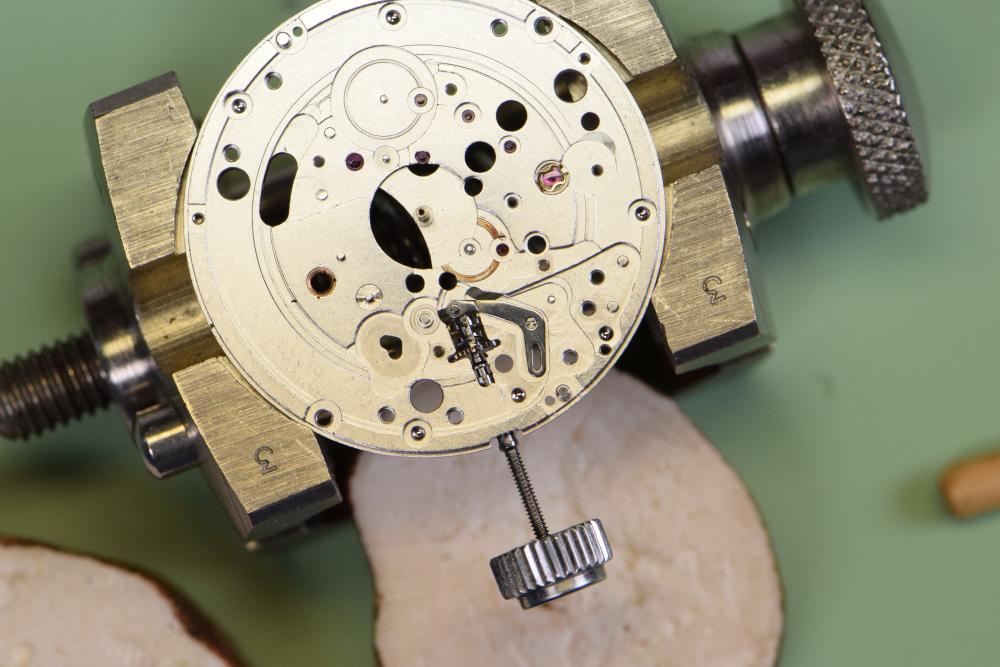

Hi - I recently serviced a JeanRichard JR1000. I was unable to find any technical documentation in the usual locations, so I had to wing it. In the end, there were no real surprises, except the reassembly of the power reserve mechanism was a but tricky. I invented my own procedure for this which I will explain later. This watch is a limited edition - #13 of 50 produced. On arrival the watch would not run for more than a few seconds. After removing the back, you can see here that the movement is secured with 4 case clips. The screws on the outer perimeter seem to secure the crystal/bezel to the case proper. That said, after removing them I was unable to separate the case. I decided to leave it be instead of risking damage. Once I removed the case screws and clips, the movement and its retainer were easily removed. Next step was to remove the hands in the normal fashion. Removing the 2 screws indicated by tweezers below freed the movement from the substantial retainer. This assembly really holds the movement VERY securely in place. Removing the dial is done in the normal fashion - 2 screws on the side of the movement (not shown). Once removed you can see the power reserve mechanism along with connecting lever that couples the mechanism with the power reserve indicator hand. I removed the plastic "track" that the indicator lever travels in by removing the 2 small screws and lifting up. Not pictured below, the lever is also easily removed from the plastic traveler. There is another component that the lever attaches to on the underside. Make sure you pay attention to the orientation of this component when removing - it is asymmetric. I failed to do this, but it's pretty simple to deduce the correct orientation on assembly. Also - remove the thin plastic (teflon?) sheet that I assume is a friction reducer. The rotor is removed by removing the 3 small retaining screws. Next up is the reversing wheel - part of the automatic mechanism. Remove the screw indicated below, slide the retaining clip out and then remove the wheel. Here's the underside of the reversing wheel. On reassembly on treated with Lubeta V105. Remove the balance and pallets - normal procedure - obviously after letting down the power in the mainspring! After removal, I put a slight wind on the mainspring, but no power was transmitted to the train - so clearly there is something very wrong here! That said, I don't see anything obvious in terms of broken teeth, loose parts, etc. Remove the train bridge and then remove the balance hack (pointed to by tweezers) There's a bit of disassembly to do on the reverse side of the train bridge. Start by removing the single blue screw and the small bridge that it secures. Remove the 2 small brass gears. And the remaining components. Note the dial washer that sits beneath one of the gears. Remove the escape wheel and the barrel bridge. The click and clickspring are on the reverse side of the barrel bridge. They should be removed (no pic) Remove the train gears and the center seconds pinion. And at this point I see the issue with the movement. The barrel is frozen in place. The lower bearing seems to have some material, like gunk, that has seized up and is restricting its movement. I had to use a bit of force to dislodge the barrel from the main plate. I didn't see any notable permanent damage - just a large deposit of dirt and grease. After wrestling the barrel from the main plate, remove the arbor and spring. Note the arbor has a small independently rotating section on it as well. You can see it as brass on in the pic below. So far so good - let's flip the movement over and focus on the dial side. This power reserve mechanism requires some exploration. I am using the tweezers below to point out the orientation that the mechanism is in when there is no power in the mainspring. Note that I actually took this pic before disassembling the other side of the watch - while the barrel and train were still in the watch. Remove the 2 small screws and the retaining plate. Lift the mechanism as a unit out of the watch. You need to wiggle it a bit to get it out. The reason for this will be apparent soon. The small gear remaining below actually fits between 2 of the gears in the mechanism removed above. The reverse of the reserve mechanism. Nothing to disassemble here - I just cleaned it as a unit. Remove the 3 screws and the calendar plate. Remove the hour wheel and the two date maintaining plates, followed by the date ring. Remove the minute wheel, intermediate gears and the date change gear. We also remove the date jumper and the small date setting gear that is held in place by the jumper. Remove the cannon pinion and its attached gear along with the date advancement gear. We now have just the keyless work remaining! Next up is the setting lever spring Next remove the yoke Now the setting lever and the remaining lever. Finally the winding pinion and the sliding pinion. And that's the full disassembly of this very nice movement. I mentioned earlier that I needed to be a bit creative reassembling the reserve mechanism. Since the reserve mechanism is replaced after the calendar plate is installed, the jewels on the dial side must already be lubricated (since they will be hidden by the calendar plate). So this implies that the barrel and wheel train are already installed. Problem is that with the barrel installed it is very difficult to get the reserve mechanism seated correctly. I ended up doing the following: 1. Reassemble the wheel train and barrel. 2. Lubricate all dial side jewels and bearings 3. Install the calendar mechanism 4. Remove the barrel and train of wheels. Note that the issue is really the barrel, but you cannot remove the barrel without also removing the train 5. Now it is trivial to install the reserve mechanism and orient it as mentioned at the time it was disassembled 6. Taking care not to allow the reserve mechanism to rotate (and become misaligned), reinstall the train and barrel And that's all there is to it! Hopefully someone finds this useful. At the end of the day, the watch now runs perfectly after a good cleaning and lubrication. Stu...4 points

-

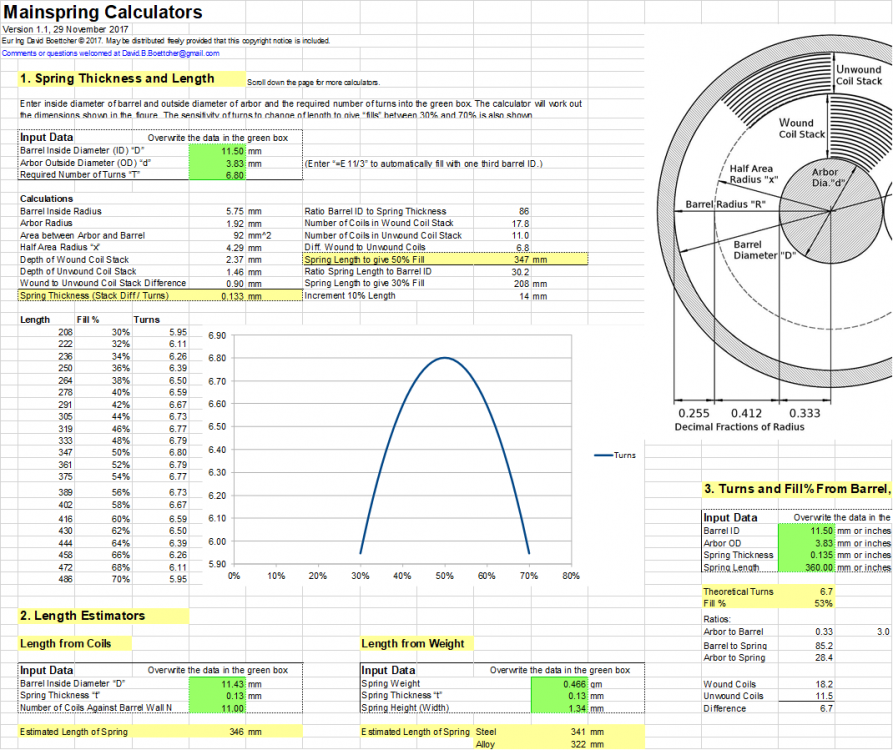

I've used a mainspring calculator which in an excel spreadsheet. I'll see if I can post it. Which I can't, but it looks like this... If anyone wants this, I can put it in the cloud and give you a link to download it. It's really useful and got me out of a few scrapes not knowing the spring size, as one wasn't present. The last one I used this with was a 100 year old trench watch which I calculated the spring from the arbor and barrel dimensions and got 290 to 300 degrees out of it. What a result! So, this does work well. I find coming down half to one strength when converting from blue steel to alloy mainspring helps from experience. It certainly isn't a direct swap size for size.4 points

-

2 points

-

It used to be that Seiko Australia (Oceania) would let you look up parts on their website, even though they didn't sell to the general public. Not any more, though. I don't know why they changed this. Now they only have instructions and battery information, and a list of wholesalers in Australia. At least Seiko still supplies parts, but they do the typical distribution dance, Manufacturer -> Wholesaler -> Retailer -> End User / Hobbyist. And, believe it or not, this field is much friendlier to hobbyists than it was seven or eight years ago. For instance, Jules Borel only sold to businesses, they would not sell to individuals, and they would not let me have an account. Eventually they changed, and started "retail" sales. Lots of folks had to find a friendly soul that had a parts account and ask them to help out. Really, watchmaking as a hobby is a relatively new thing, and the only part of it that is maturing is the "modding" community. Seiko modding has come a long way in the last five years, with places like Crystal Times providing interesting parts to people who want to trick out their watch. I think that there are still a lot of people who don't think of watch repair or watchmaking as something that can be done at a hobby level. This comes from the belief that the skills needed really require formal training, and that most people who try this own their own are going to destroy a watch or two and then move on. I read a rant not long ago from someone who was incensed at incompetent hands screwing up antique pocket watches, he was really upset. He thought if these watches had been left to those who knew what they were doing, they would still be running. Now they are gone. I would have loved to have had formal training, but that was just not in the cards. I had to try to self train. After eight years or so, I think I've made some progress, but I still think of myself as a "hack". I'm glad that I was able to start out at a hobbyist level, and that it was at least possible to do so, if not easy. You know, I think I once compared Mark to Bob Ross (in a complementary way), but Bob Ross and his business partners were able to partner with a manufacturer that could create all of the materials and supplies necessary to back up his particular style of painting instruction. We've got the videos, but the rest? Not so much. Cheers!2 points

-

@VWatchie youtube channel “it’s about time” good video on these little buggers. Tom2 points

-

The Seiko code for the gasket you're looking for is 86622310 (according to Boley.de). Cousins has it in stock (8.15 pounds plus taxes and delivery), I don't know about other suppliers.2 points

-

That may or may not be true because every time I look on this group people are typically ordering from cousins even in the US. The problem is material houses can do a nice job of hiding. I remember when I was in school I was looking in the phone book yes it was that long ago and the material houses weren't really listed anywhere there are listed by name. I think I asked somebody once and basically they felt you either knew they existed or you didn't know and they didn't want to do business with you. asically had to be in the trade and if you run a trade he would somehow know they existed and if you didn't swell too bad. Then of course a lot of the US material houses if you go and read the fine print they will say reach out to us if you have a part problem Unfortunately it's not a bezel gasket it's a shame we didn't need a crystal gasket too bad. Look at this link what does it say about ordering a gasket The second entry and says use this stock number it give us the case number and they'll look it up for you that's why things aren't online because they don't have it online you have to give them the information then they'll look it up. https://www.ofrei.com/page1744.html Oh and while you're on this webpage if you go to the bottom of the page notice what it says for stuff not listed on the website they give you a telephone number. Now if you want to be a good person when you call up make sure you have all the information of exactly what you need because material houses do not like you to waste their time. Plus it doesn't matter whether you're a hobbyist or professional the last time I saw Debbie she was complaining about somebody in the trade who kept ordering the same part claiming it was the wrong part confusion on the purchasers part irritating the material house. Definitely not good to irritate your material house. Then there are not the only sites I'm looking at another US site looking at their fact section and it says have a parts request telephone or send a fax. Yes material houses still have fax machines at least some of them do. So basically if you really want to part you have to do some work and not just assumed that it's on line. The real fun is if you have a physical material house you can go to. That's where like in this particular case you'd walk in with your case and set on the counter and say I need a and then it go and look up for you. Yes the good old days of physical material houses and they still exist there out there just have to go looking for them. Unfortunately quite a few are gone2 points

-

I think this Debbie is definitely worth knowing, so Colin if you are paying attention, see if you can get her phone number pass it on to me and i will charm the pants off her ahem er i mean parts of her that you need. My mission please2 points

-

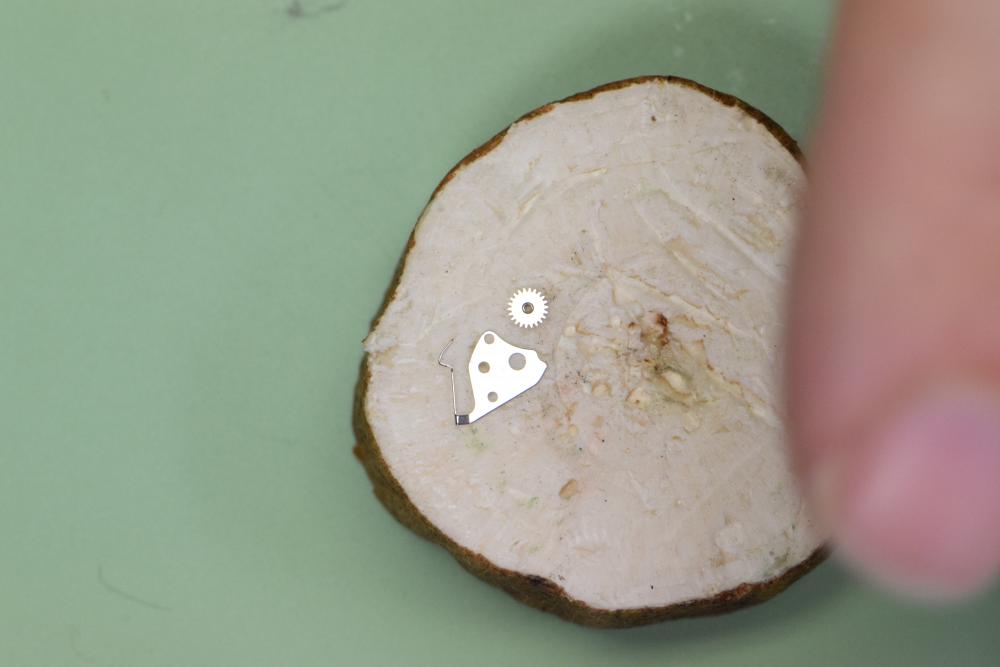

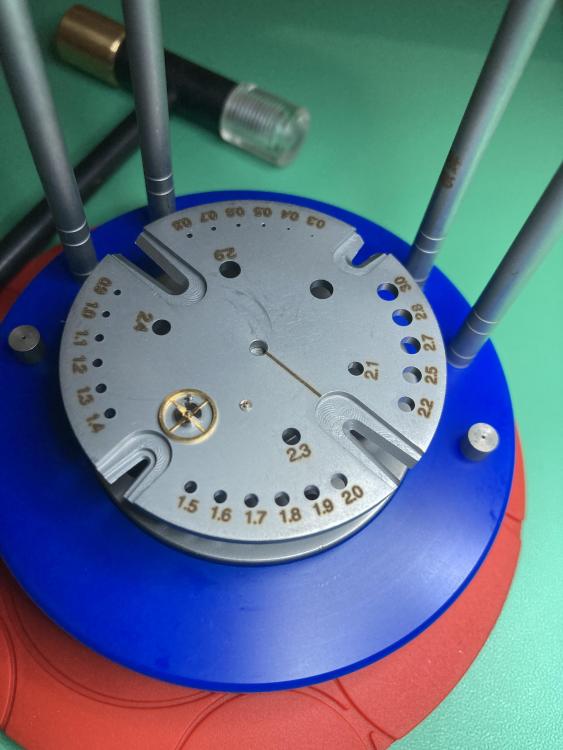

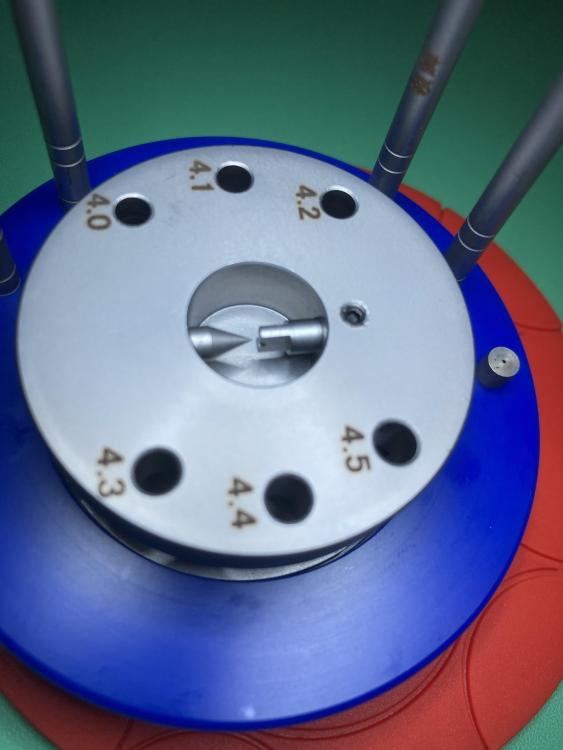

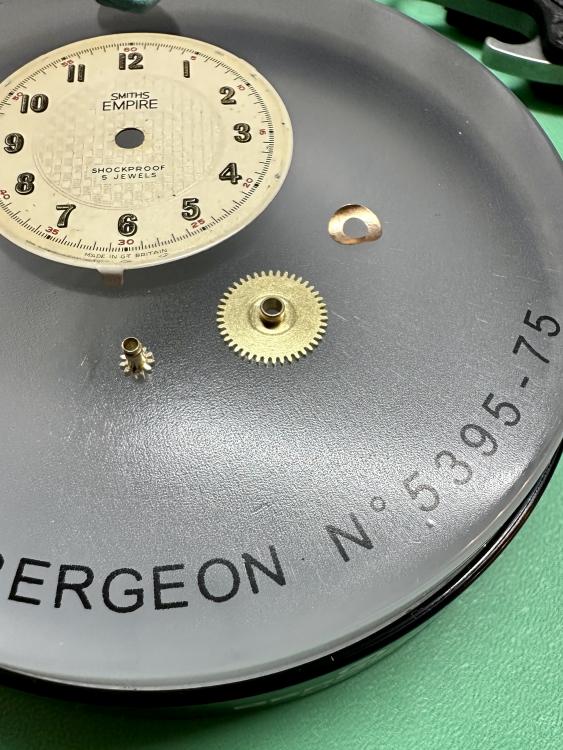

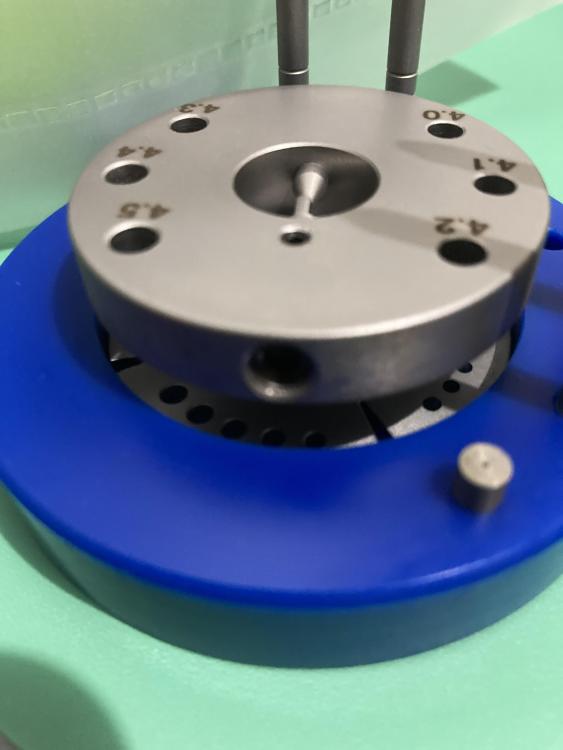

Finally got it today. Just removed the roller table from the balance staff of a Seiko 1104a using the platax type notches and the smallest of the 4 stakes (0.15). Took the balance staff off the collet and wheel using the same stake and one of the platform holes. Build quality is good IMHO. Trying to figure out what this is used for :2 points

-

1 point

-

First, let me say that putting the battery in upside down is almost certainly not going to get the watch to run backwards. The reason I say that is that the watch relies on a CMOS IC that requires the correct voltage to operate. The IC contains an oscillator circuit, and a binary counter to divide the 32768Hz down to 1 Hz, and a driver transistor to drive the coil with the pulses from the output of the counter. If you put the battery in upside down, the most likely scenario is that the watch will simply not operate (and the battery will probably drain quite rapidly due to a reverse polarity protection circuit in the IC). The worst case scenario is that if you put the battery in back to front, the IC will fry. So the fact that it is going backwards is more likely to be a mechanical issue, or the rotor has somehow been subject to some very strong magnetic field (a neodymium magnet perhaps) and is now magnetised backwards. This *might* work, but typically the rotors have more than one set of poles, so I would be surprised if a strong magnetic field didn't simply kill it. I guess if it reversed one set of poles, it might take two steps backward for every one step forwards or something like that. Given the cost of a replacement module, that would probably be the easiest fix, but I am genuinely curious to see if my theory is correct. I do have a job lot of Ronda movements, so I may pull one of those apart and see if I can re-create the effect.1 point

-

I'm sure we dont have that here Col, not intentionally anyway. But i do see it as a way of learning having to search something out for yourself. Obviously there are times when you are completely stuck and the problem you've been having is a prime example. Really frustrating and even more so when its starting to waste money. I guess there is not always a simple answer and things that even the pros are not sure about.1 point

-

Haha, yes, perhaps. I have my hands full with two Empires. The one in this post should be fine once the new spring arrives. The other is a second sweep and non runner. Of course someone thought a quart of oil would do the trick. I spent most of today cleaning it up but there was nothing obvious for why it wasn't running. The balance is free and the mainspring is steel but lovely. I'm a bit worried as some of the pivot holes look oval but will have to do some test fitting to see what's what... Oh, here's a pic of the W10 for you. The dial looks great- I believe the mess is all on the crystal...1 point

-

@Birbdad which watch repair groups have you visited that were hostile? I’ve found most places I visit, especially here, to be very helpful. That being said, many new comers in many hobbies do tend to ask similar questions all the time and being told to ‘go and search’ is because those questions have been asked before, or has been explained in great detail already by someone more competent. Unfortunately many times there’s no quick answer to a seemingly simple question when it comes to this hobby I for one recommend doing Mark’s course to anyone looking to enter the hobby. But if you don’t want to commit financially yet, go and check out Alex Hamilton’s videos. And more give I trust you would!1 point

-

After movement assembly using the old (cleaned) reverser the manual winding felt extremely stiff. I tried using a PTFE dry lube. Might have been a bad idea. After installing the new reverser all was perfect.1 point

-

1 point

-

Maybe thats were we all come in John. If you and a few other pros here teach us all well enough we can fill that shortfall. Good idea yes/no ? We cant let the likes of swatch take over the world. The idea is still in my brain FRIENDS of the FORUM SOCIÈTE. I need to see that FFS 20 foot sign wrote on the side of a building before i die. Hopefully it comes together for you Col veeery frustrating by the sound of it, i may just stick to repairing swiss after all.1 point

-

The beech is noticeably harder than the hornbeam and is available in a 2.0 diameter size. I used a piece of the beech for the diafix tool. I’ve done the diafix in my scrap practice bridges with just two #5 tweezers. Works just some of the time. Need more practice but the frustration and cursing that accompany diafix and tweezers (and lost jewels and springs) is a deterrent. The notched pegwood is just so much easier IMHO. Takes most of the sweating and frustration away.1 point

-

Thanks for the links! The springs for the balance are generally not that troublesome because they are quite a bit larger than the springs for the escape wheel and the 3rd wheel. I made a similar tool as Alex, for the escape wheel and 3rd wheel, but the problem is that the peg wood disintegrates when the size of the peg wood becomes this minuscule. There are two types of peg wood from Bergeon, beech and hornbeam, and as I understand it, beech is a slightly harder wood than hornbeam. It could be that I only have hornbeam and really need beech. I'll have to look into it. I'm still waiting for someone to demonstrate how to handle those super tiny springs in a safe and easy way, but I fear that the only way is by using two fine tweezers and a lot of practice as Mark is doing in this video at 13:25.1 point

-

Hehe, i know what am i like. Morning Gert, its - 3 here in Yorkshire and I'm outside ripping fascia boards off a church. Again what am i like ?1 point

-

At 20 minutes in he makes a pegwood tool for the rectangular diashock/diafix springs. Makes the process a lot less fiddly. Still a PITA but much less chance of something pinging off and no five/ten/fifteen minutes of multiple attempts to get the spring tab into the slot. The flexibility and softness of the pegwood really helps here. In the video after this one, he demonstrates his method of working on the older style diafix.1 point

-

As I remember it, my 7s36B had the rectangular type and those dust-sized springs really made me sweat. I eventually got them into place but I also deformed one of them in the process. Before the Seiko, I had overhauled an Orient calibre 46E40 which is very similar to the Seiko 7s36B but using the diafix springs instead. As I remember it the diafix springs were fiddly too but not as fiddly as the rectangular Seiko springs. (My service walkthrough of the Orient 46E40 here). I would really like to see that! Can you provide some photos or a link?1 point

-

Surprisingly well for such delicate parts, the lack of a stake holder as you noted, and it being the first time I tried doing something like this. No apparent damage when I inspected them under the microscope. That staff has a rusted and broken pivot on the roller end but the other end was fine and survived the stake application. The underside bits do screw in and out. The notched anvil can be rotated if the small 1.5 hex grub screw in the base surface is first loosened. It can then be advanced/retracted by turning a larger 3.0 hex grub on the side. The spike is advanced/retracted using the slotted screw on its side. Here you can see the hex grub screws for the notched anvil. Will insert a cannon pinion and see how it goes. That does appear to be the most likely use of these bits.1 point

-

One of the problems and watch repair is inventory control basically. The material house I conveniently I've not mentioned by name I once worked there. I learned how to cut glass crystals. That meant I got to talk to Bob because it was his material house. When I first met him he was working for one of the other material houses I just can't remember which one Seattle used to have more than two that we have now and they used to be much much bigger. One of them largely occupied one of the buildings downtown but they also supplied the jewelry trade and had a heckuva lot inventory and has been around for almost 100 years. So after working for a variety of material houses he branched out on his own with the crystal cutting business. Recognizing the need for custom crystals. Then from there started his own material house. Which is now owned and run by his daughter. So in my conversations one of the problems with watch material is there is a whole bunch of different systems to inventory the parts. So basically each material house ended up with possibly their own or a different system. heard a story that one of the bigger material houses back East when it acquired other material houses it would put that material house in the warehouse but keep everything separate. Even though we might get excited about the cost of a watch part there isn't enough money and watch parts to integrate all the parts together. Then of course with all these separate sub material houses in the warehouse if you need a part somebody's going to have to go search for it is not going to build a search on line Oh and then of course there is the other problem with watch repair the number of customers purchasing from the material house shrinking. It's why the material houses used to all be located downtown because typically that's where all the watch repair shops were. They're all located within a block or two of a very specific location. I even remember one watch shop when Debbie moved her location to another building he moved his shop so he could be next to her because then he didn't have to carry any inventory at all P needs a battery ideas ran over got about. But all those old-time watchmakers are retiring nobody's taking their places anymore the schools are not generating enough students. I notice is available on eBay as usually always have to check your pricing because it's always cheapest on eBay cousins is cheaper https://www.ebay.com/itm/194600006517 Then there's the other strange problem. I was looking at the case number I saw another case number like associate with the crystal 7S36-03J0. Which does show up on the Jules Borel Listing but it doesn't list anything other than just a few parts. https://boley.de/en/case-parts/seiko/37284.7s36-03h0?q=7S36-03h0&p=0&s=101 point

-

It sounds as though you and even enthusiasts have much better access to parts than we have here in the Uk John. We do have Gleaves which has been around for a long time and as far as i know are quite accommodating to us hobbyists. Washington state hmm, i have a cousin that married a lovely American girl, they live in Washington state. I must visit some day.1 point

-

It wouldn't do you any good. Yes I know you would like her phone number because she purchases directly from Seiko she has a Seiko account. Although technically where I work we have a Seiko account I just don't have access to the Seiko database the last time I asked one of the wraps they said easy just login but nobody will give me the login information apparently I don't have any need to look up Seiko parts. Now one of the other problems you run into with material houses are they will typically but not always only do business with people in the trade. Some of this is done for tax reasons. In other words if you purchase as the final user like I purchase a gala cleaning fluid I have to pay sales tax. If it's a watch parts that goes into a watch then whoever charges the customer clicks the sales tax and the material house does not collect it but they have to have paperwork to show that you have the proper business license to do that sort of thing. So basically in her case she will deal with wholesale only for watch parts but would sell you tools but I think typically she only deals with people in the state of Washington. Although I did ask nicely once and she did in order for somebody out of country who had his items shipped to the state of Oregon which doesn't collect sales tax and then it was shipped to his location Then I suspect that even in the United Kingdom there have to be other material houses out there the problem is it comes back to as to whether or not they want to deal with nonprofessional people. Like I know the other material house we haven't towns enough she'll deal with anybody that walks through the door way out as long as are interested in watch stuff. Then a note regarding? Okay because I was curious I've never actually done a case search here. So if you read the fine print it tells you how to do a case search. But there's a problem so once you grasp what the problem is you need the only do a partial case search and then you'll get the problem http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK+CS%237s36-03&submit=Search So you'll notice when you do the partial search we do get a few case numbers just not the right extension part at the end that means it's not listed. It either means that super new and they haven't updated a database or there is the other itsy-bitsy problem would say,. Seiko and other watch distributors have marketing regions so if you buy a Seiko out of the USA it may not actually have any casing parts and all available in the US because it's not supposed to be in the US. Oh and then there's the other tiny problem also in the early days before everyone was online for the material house that Debbie owns I worked for her father plus occasionally did tasks like wrote a program to access the Seiko database. At that time the Seiko database was a really big file that had to be imported into a database program. Whenever I did that very long time ago casing parts there over 50,000 casing parts in the database. Bob was upset because each year they would drop old numbers in favor of the new numbers so this is the other problem of casing parts there are literally a hell of a lot of them. So when you're unhappy that you can't get some casing part it's because there are so darn many different casing parts Okay I have improved my reading skills it's not a back gasket. Then no I don't always read the title I usually read the text of not in the text I don't always read the title so I can see okay in the title you want a Bezel gasket which I assume is not the same as a crystal gasket?1 point

-

1 point

-

Okay I know I'm being nitpicky here but which gasket? Back, crown, crystal probably not the crown So do I get To flip a coin for which one crystal or back? Then it would be nice to have a picture of the case and you have a picture of the old gasket? One of the problems with asking the pros are we have resources that you don't. For instance I've pointed this out in the past but nobody seems to pay attention not all material houses are on line. Then even the online material houses do not necessarily list everything they have 100%. Cousins is probably the example of everything they have is 100% online because when you look at their history they went down that path a long time ago. But a lot of the material houses in the US and probably all over the world still physically exist and not everything is online or even online at all. So for instance If I need something for work I typically Would email Debbie as her material house is not online. Or I can just telephone her and ask her and she'll look it up for me. Then because where I work is doing so much business she will mail at least once or twice a week or occasionally somebody will go downtown and pick up something of the Apsley have to have a right now. So this is the problem with asking the pros we have resources if you do not. By the way where on the planet are you located?1 point

-

How do you think the roller and staff removal went ? Can you see any extra damage to the roller or balance wheel ? The only downside i can to this at the moment is not having a stake holder to keep things perpendicular. The underside looks a little like its for tighening a cannon pinion, do they screw in and out ? Ah no extra accessories held in the a grub screw, maybe the notched anvil fits into the base, i wonder does the pin fit into one of the stakes ?1 point

-

One way, would be to wind the watch in dial down position and see if the rotor spins, then see if the rotor spins when the watch is turned towards a vertical position. If the rotor does 'helicopter' this might indicate the reverser(s) being shot or just gunked up, so you would do the same test when clean. If I receive a watch that hasn't been serviced in over 10 years, then the rotor bearing and reverser(s) will get replaced as standard, as they can't put up with working with no lubrication. If they are not completely shot after wearing for 10 years, then they will be in the near future. Another way would be to turn the auto module upside down and with the rotor attached, turn the ratchet driving wheel with a thin brass wire and see if the reverser(s) slip easily without much pressure being put on the driving wheel or the wire bending, indicating too much pressure is needed to make the reverser(s) slip. This emulates the movement being hand wound, thus the reverser(s) slipping. I know the service manual says to replace the reverser wheels, but they will wash and Lubeta V105 just fine, as long as there is not too much wear.1 point

-

That's a very interesting, and much cheaper, idea! Here's one that goes from 35-70°C for $40 https://www.amazon.com/dp/B09X29YPGZ1 point

-

When you rock up at someone’s gate and that comes to meet you, you kinda feel the owners are telling you to f.off1 point

-

We can remove the balance- cock assembly safer than the bearded guy. Do not remove the cock screw, just loosen it enough to loosen the cock, once you have partially unpinned the locating pins, proceed with removing the cock screw. With this approach you have the cock secured on the mainplate by the cock screw( not fully unscrewed, not removed) , preventing cock from falling off as you are unpinning it. Better safe than to look pro.1 point