Leaderboard

Popular Content

Showing content with the highest reputation on 12/05/22 in all areas

-

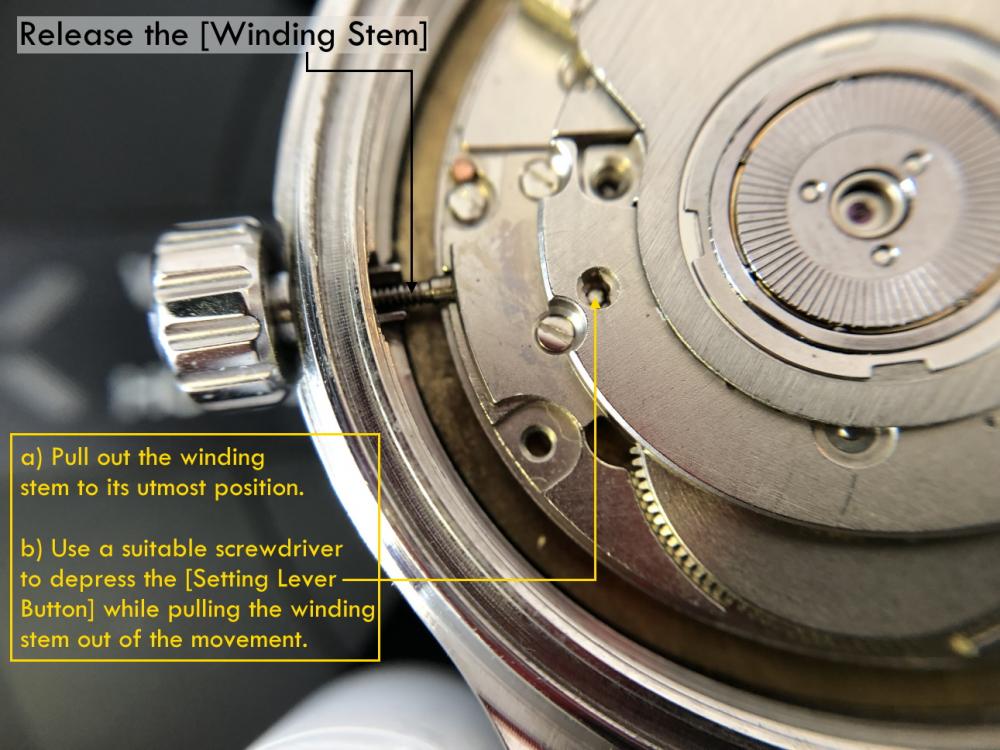

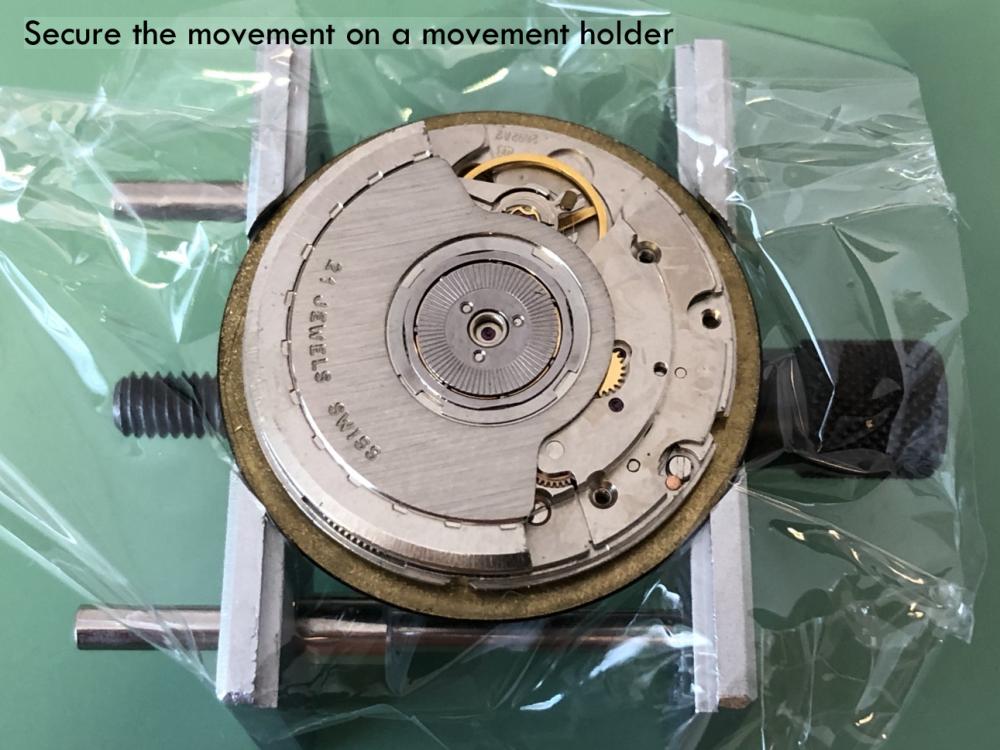

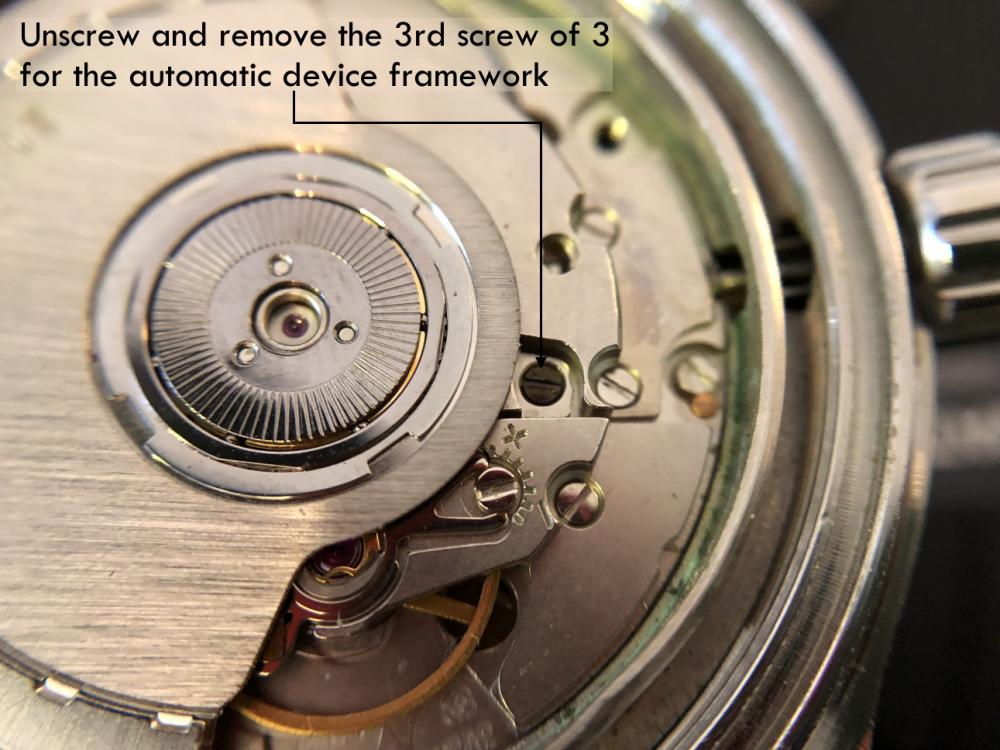

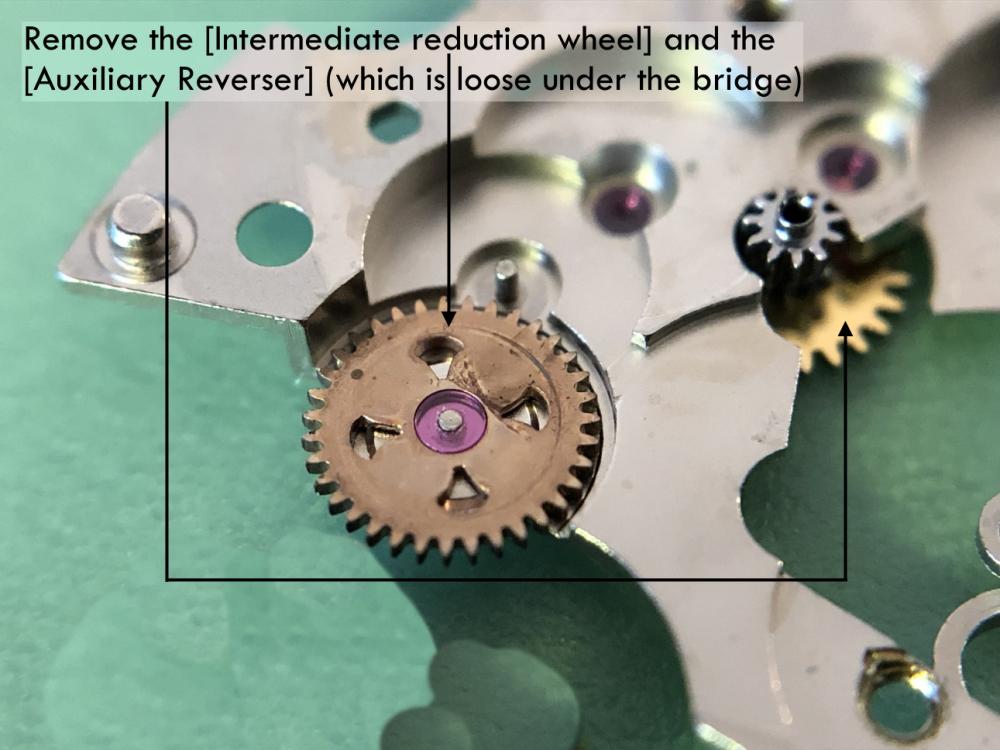

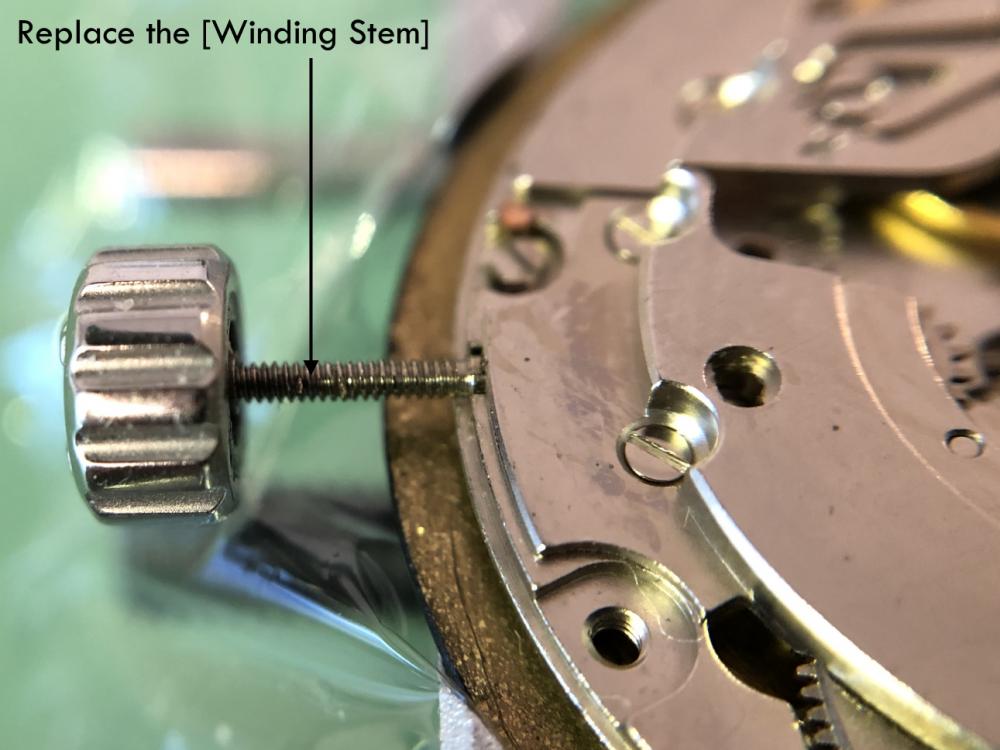

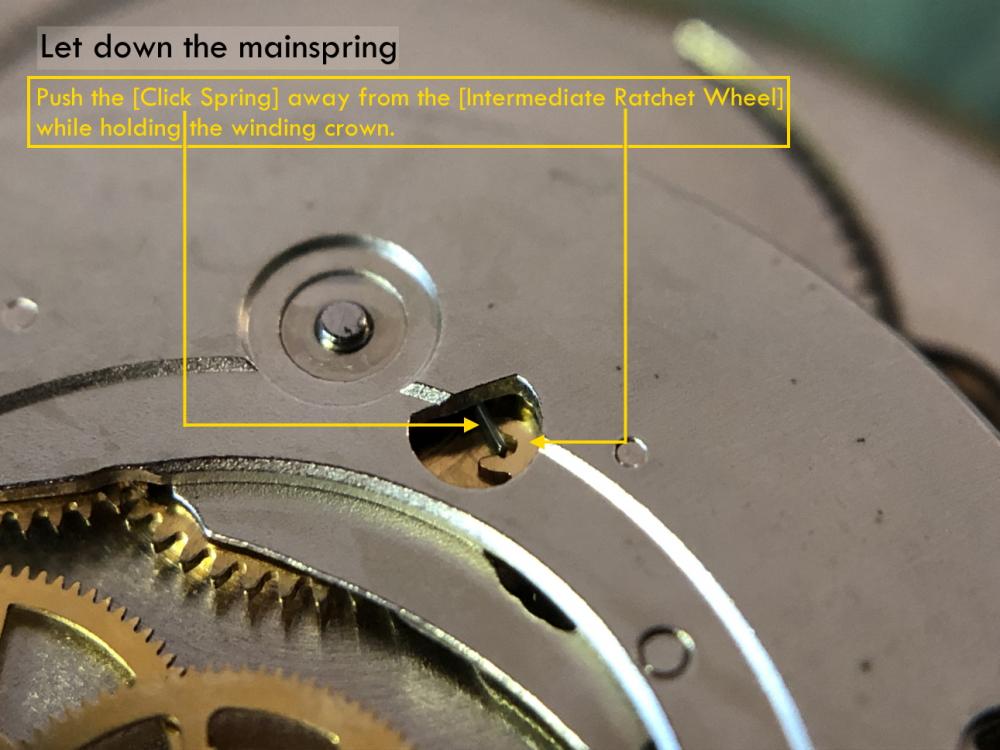

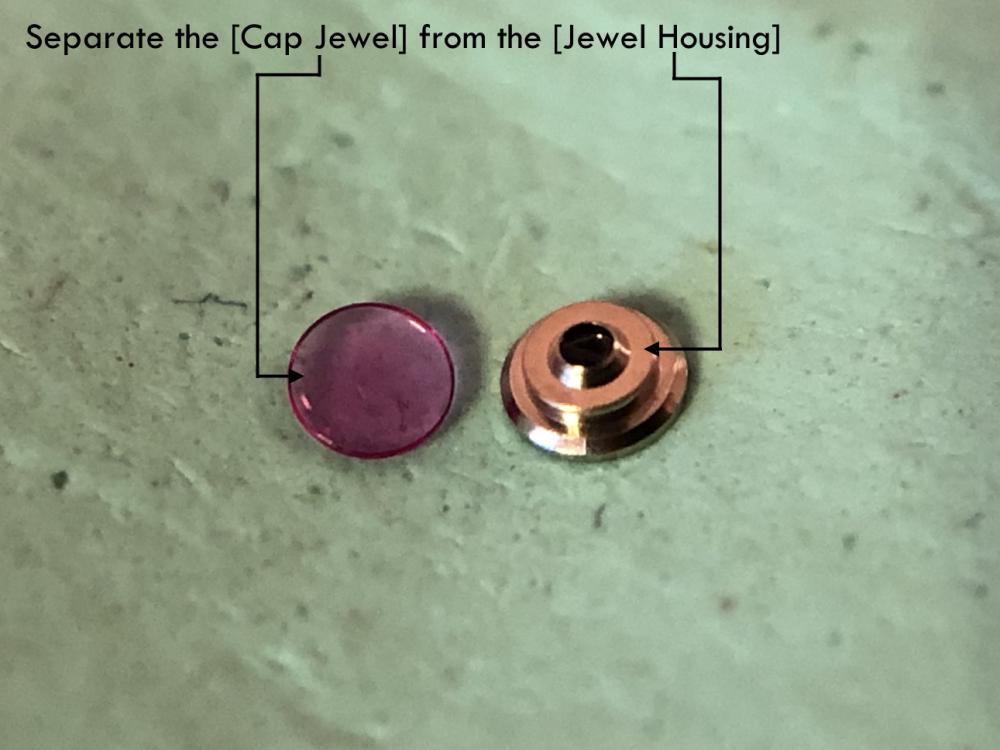

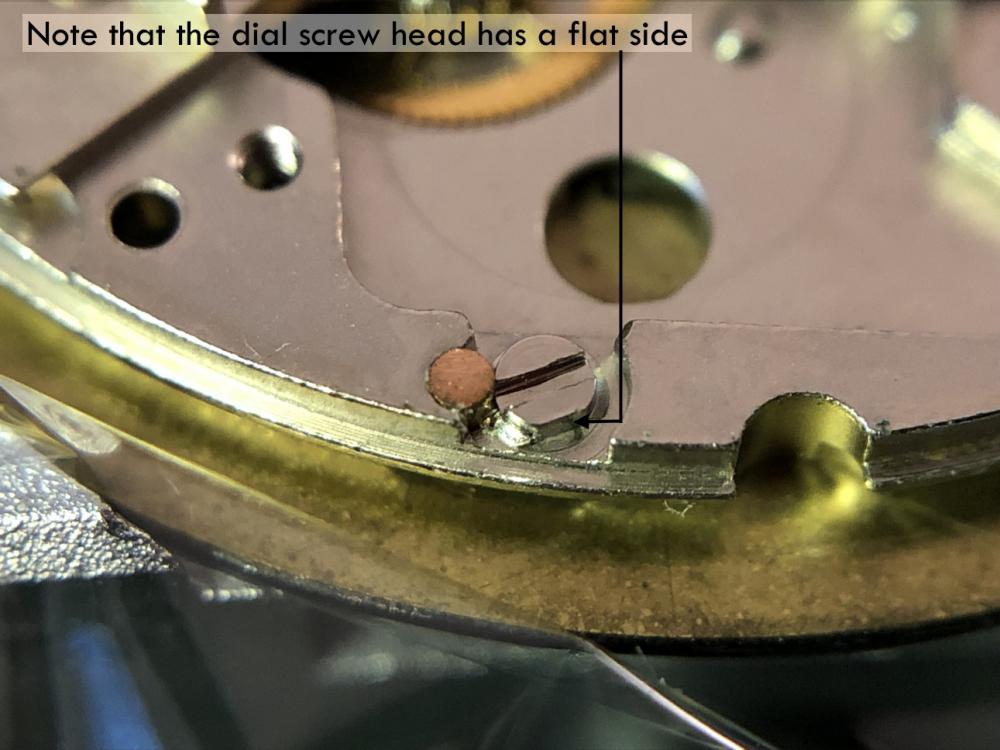

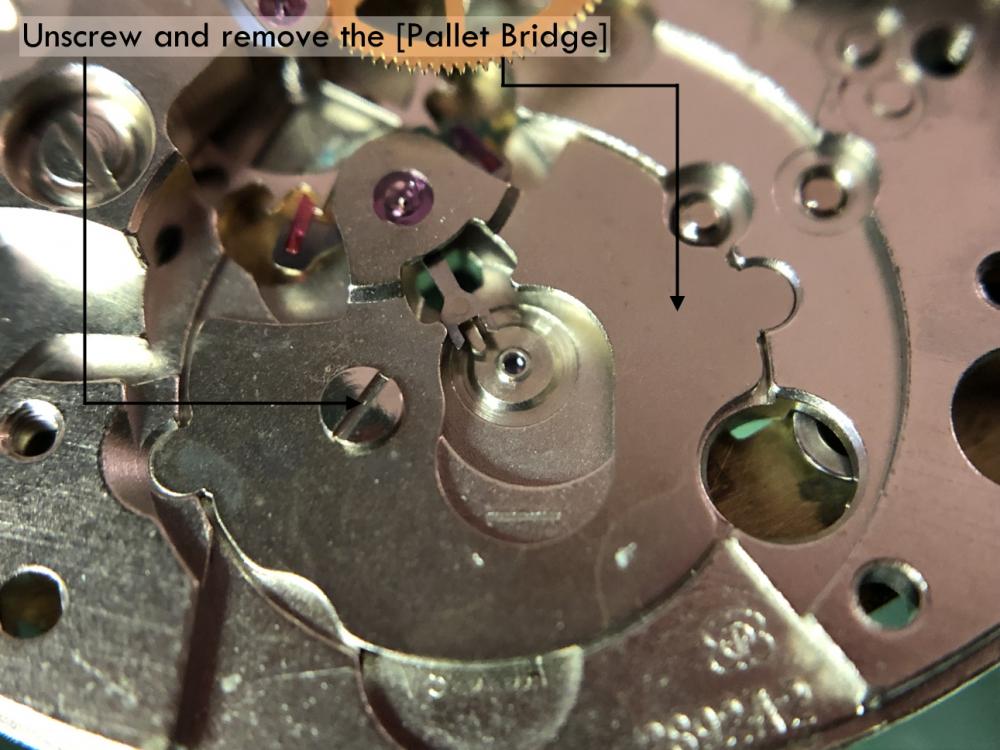

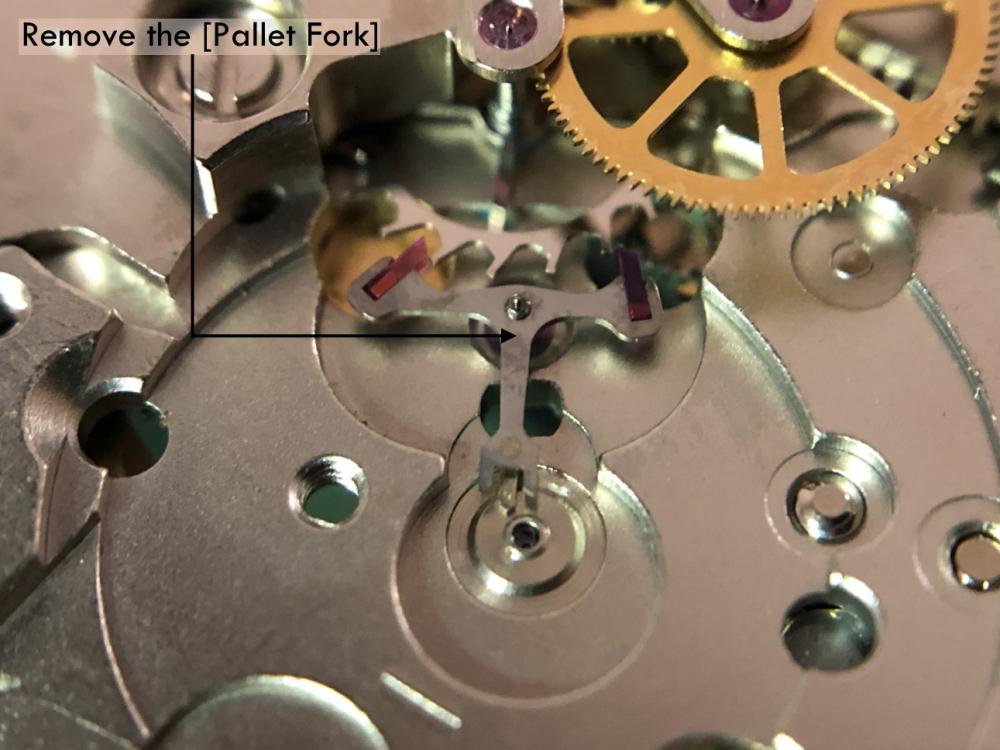

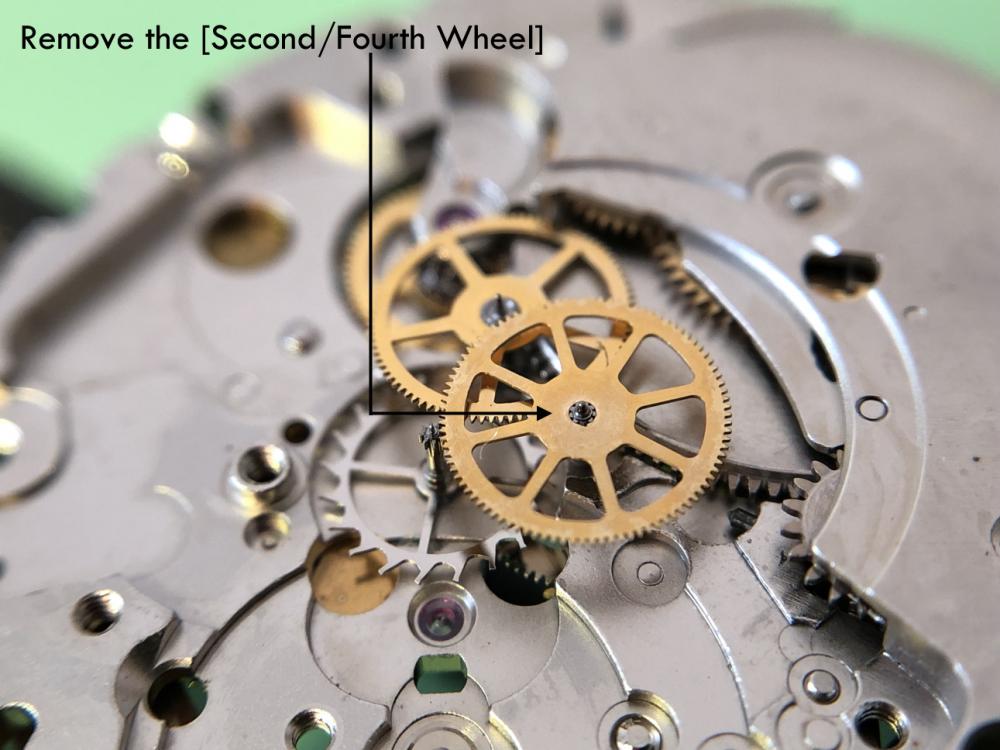

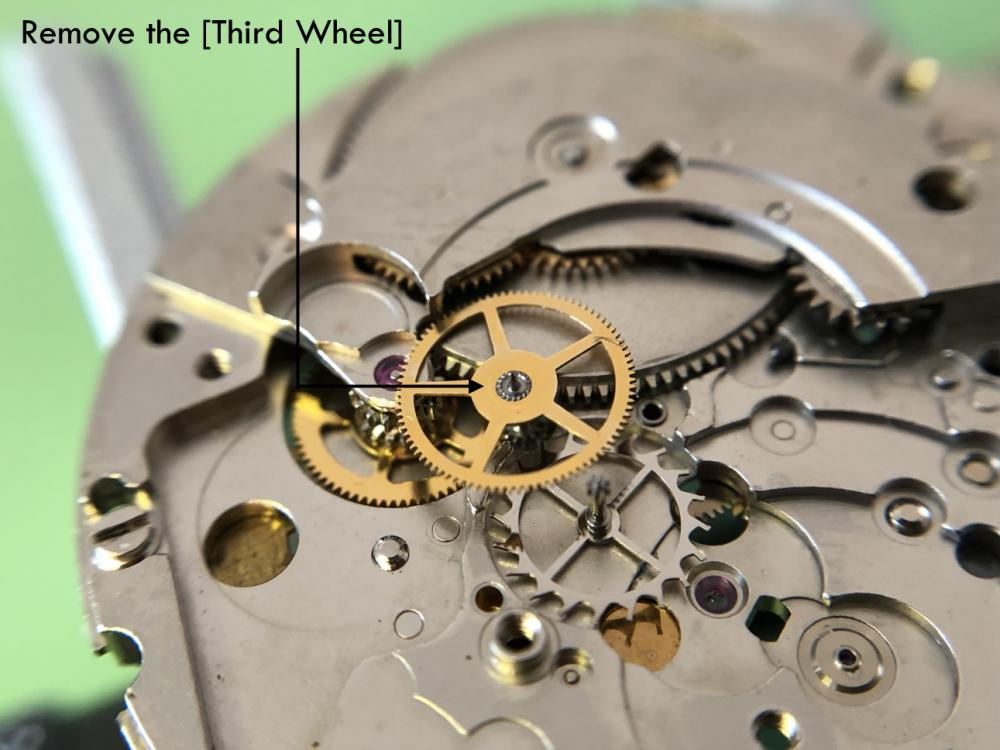

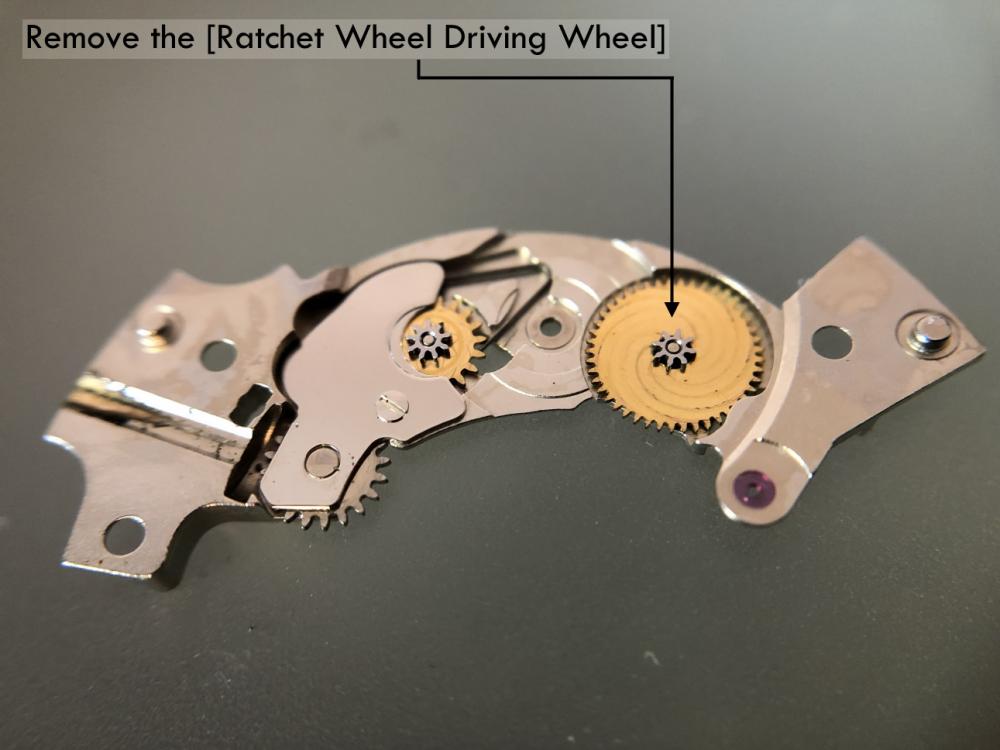

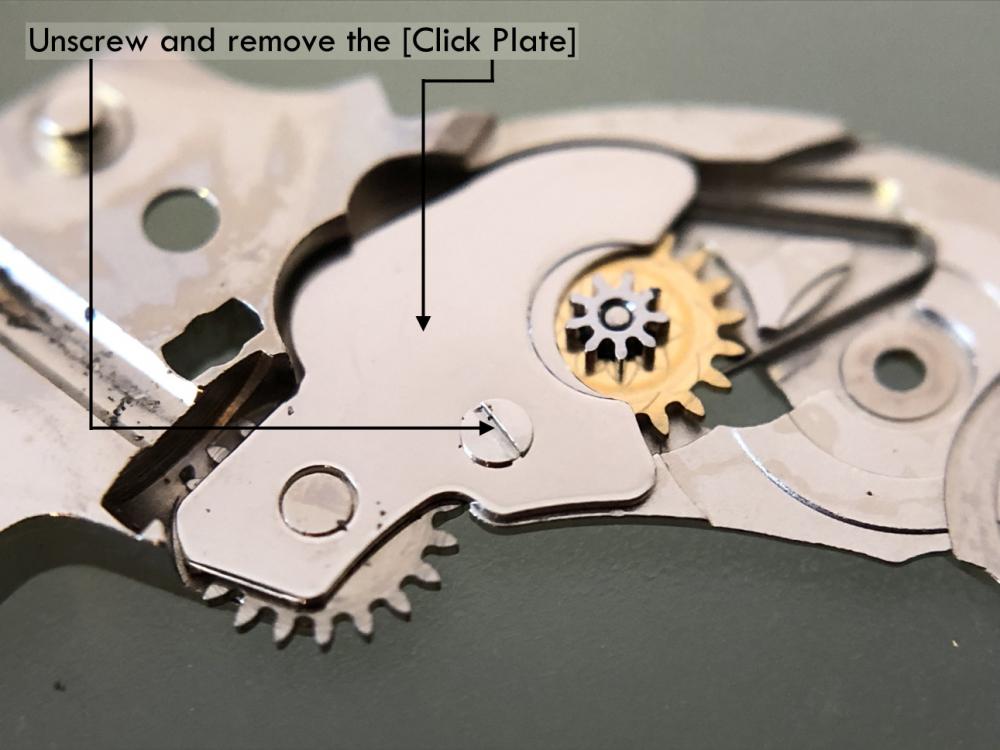

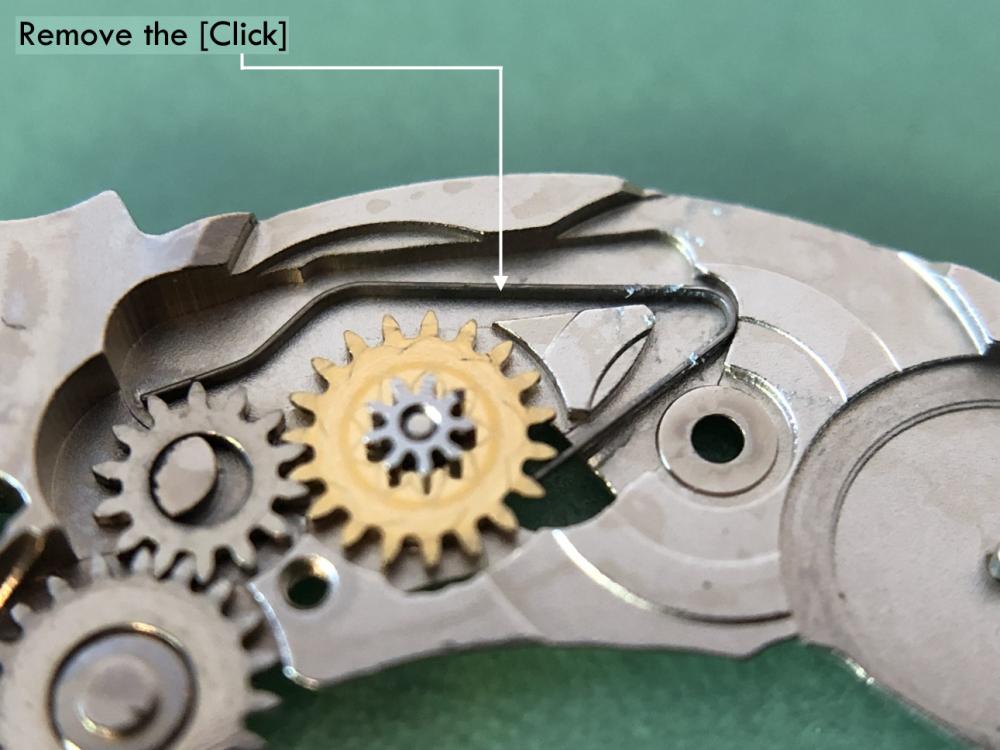

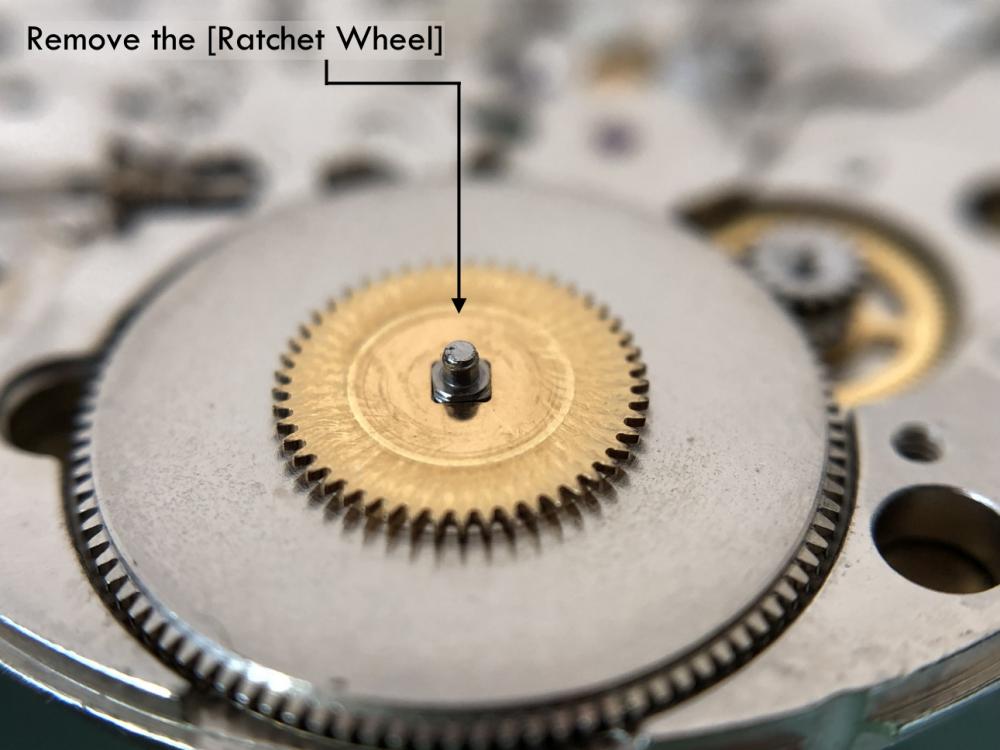

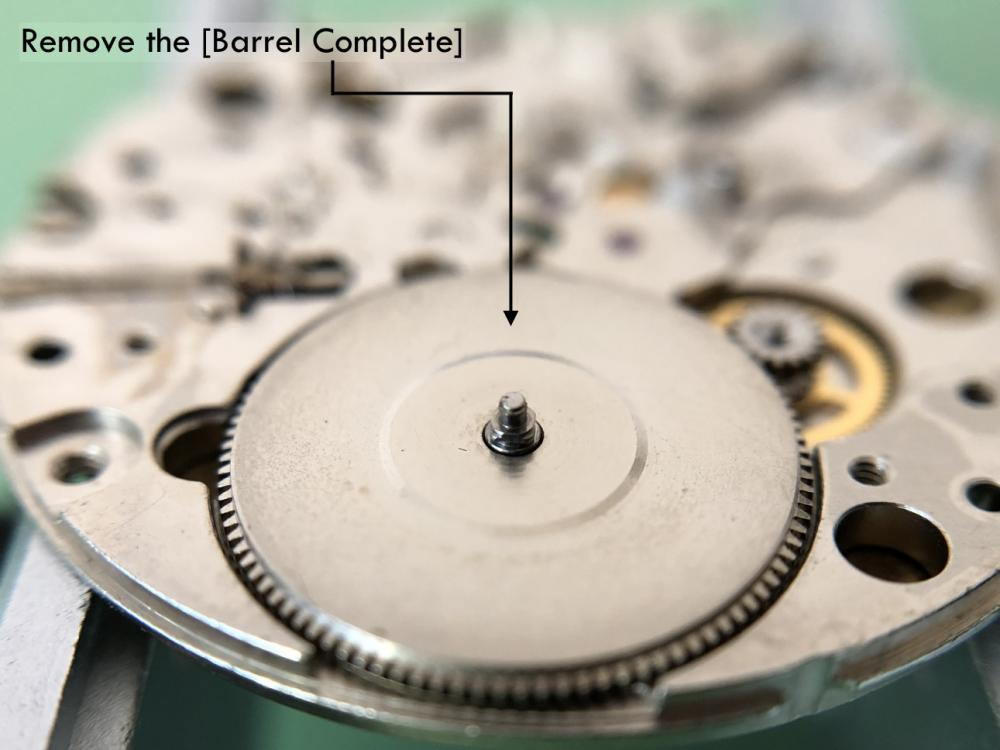

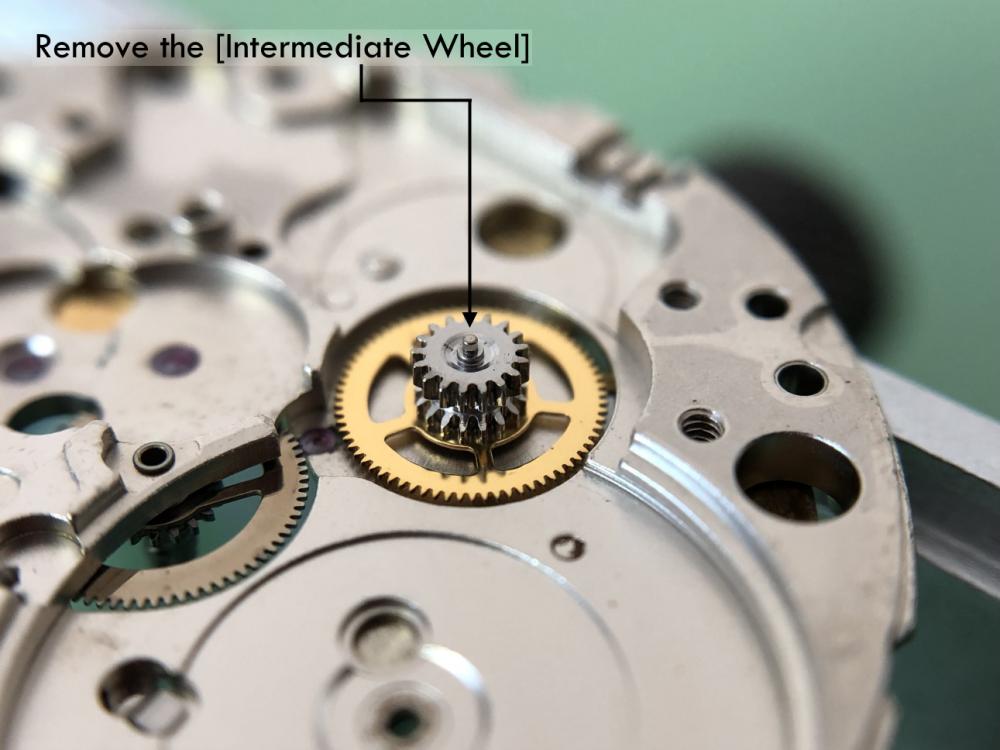

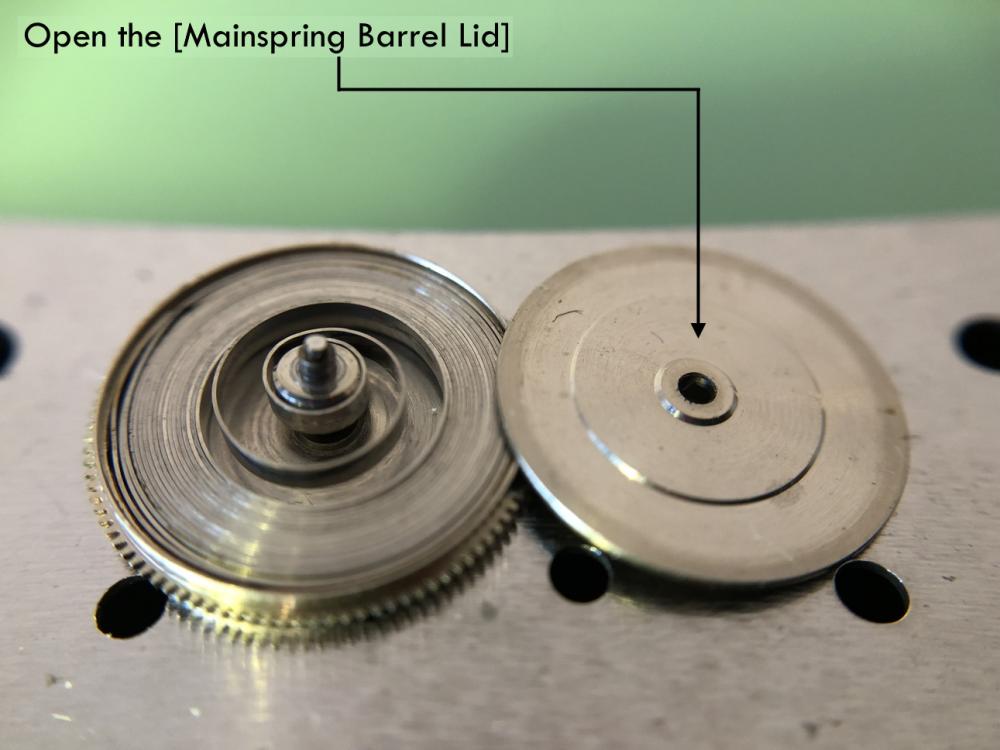

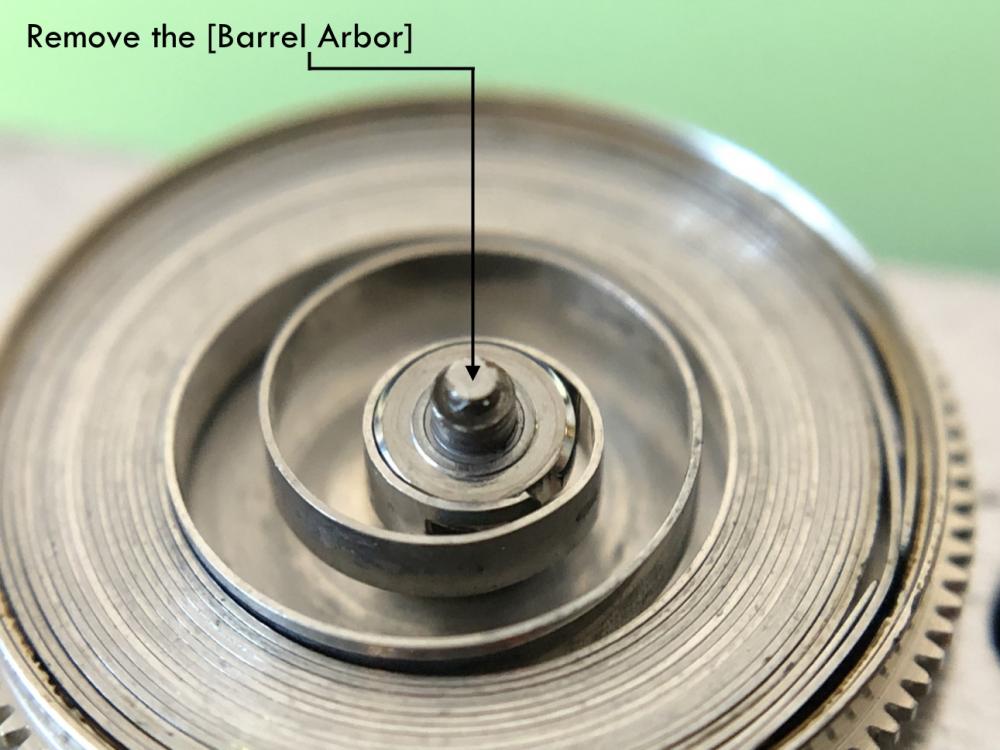

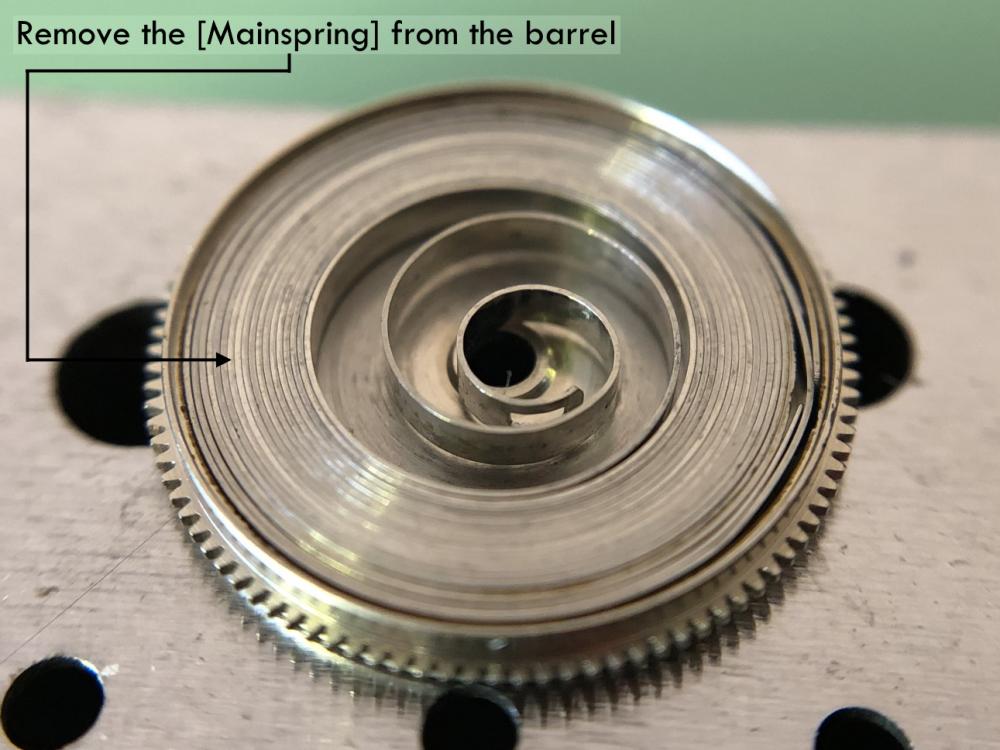

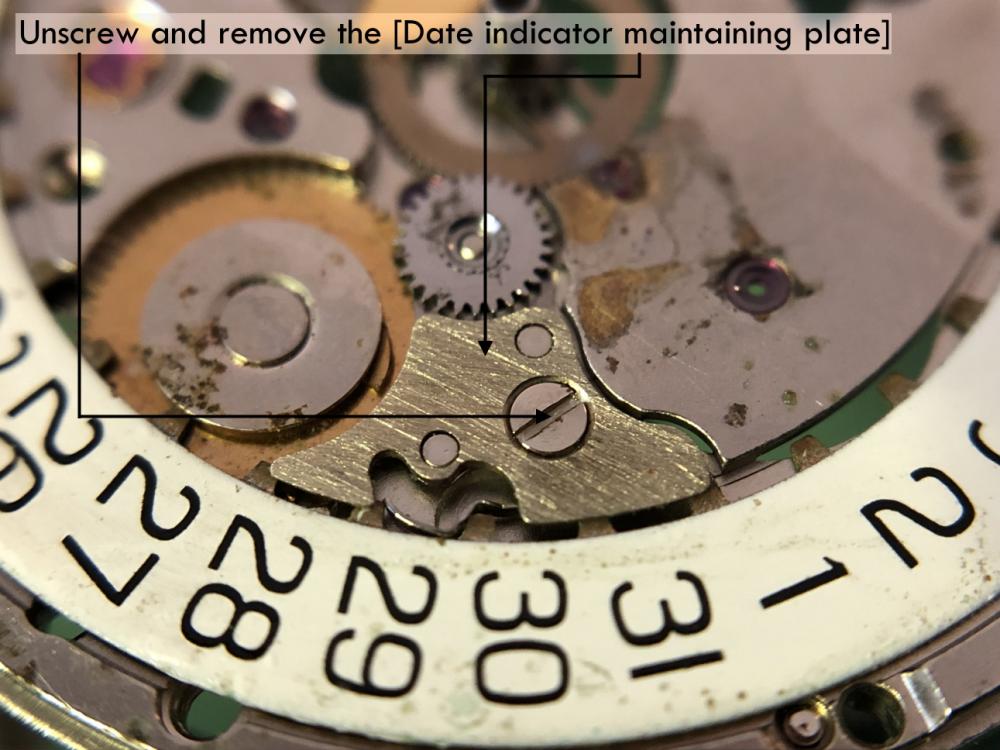

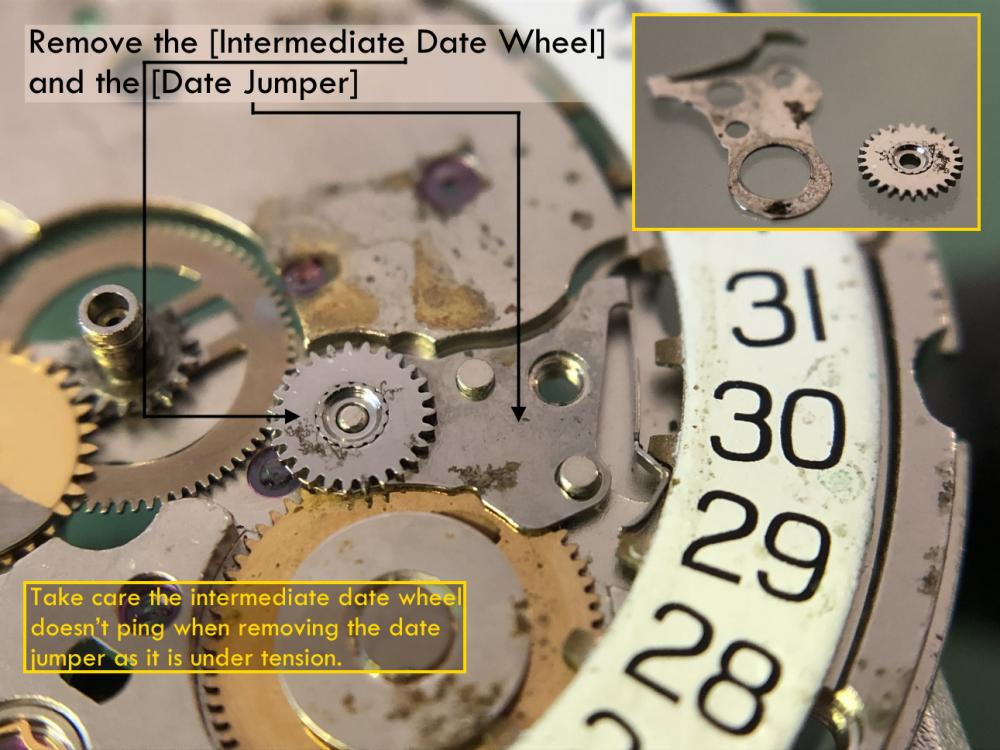

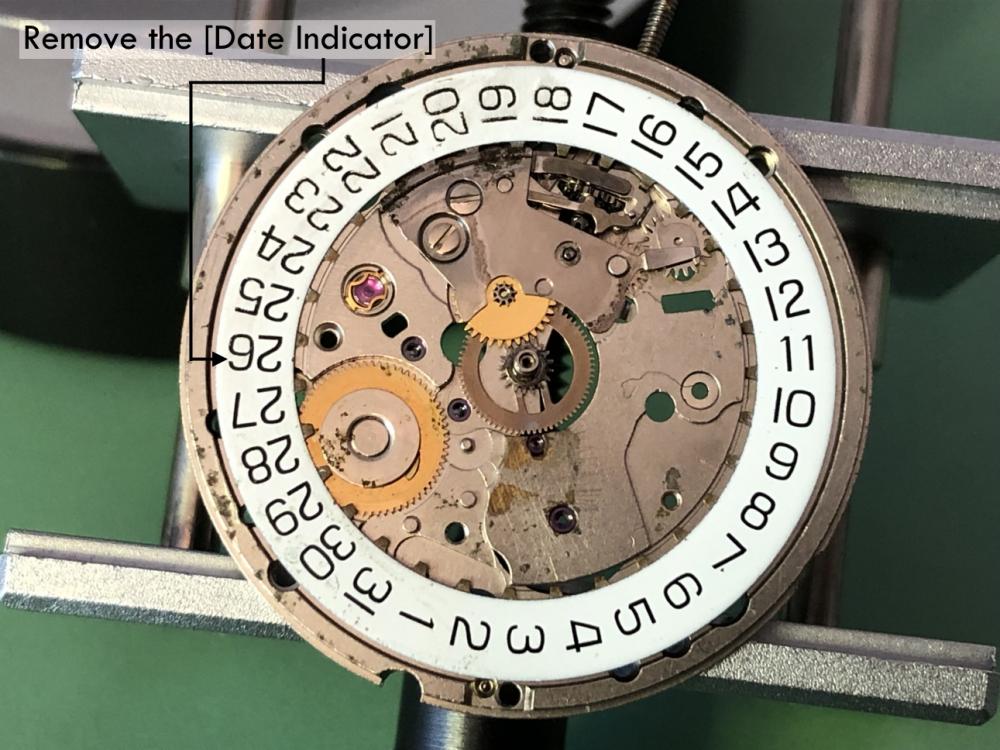

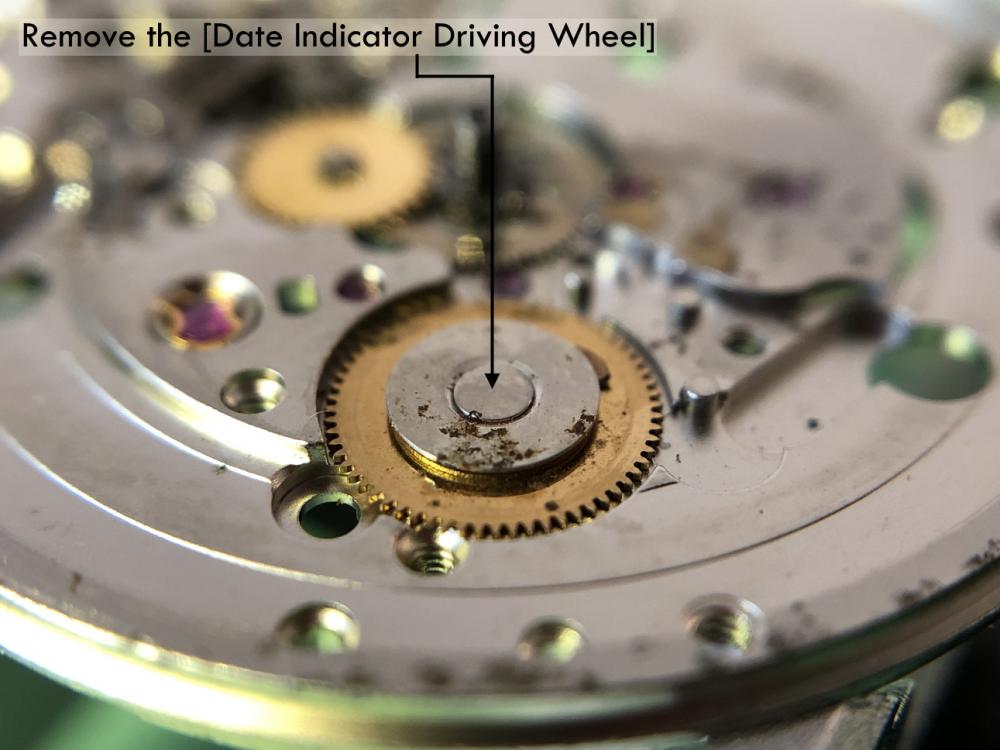

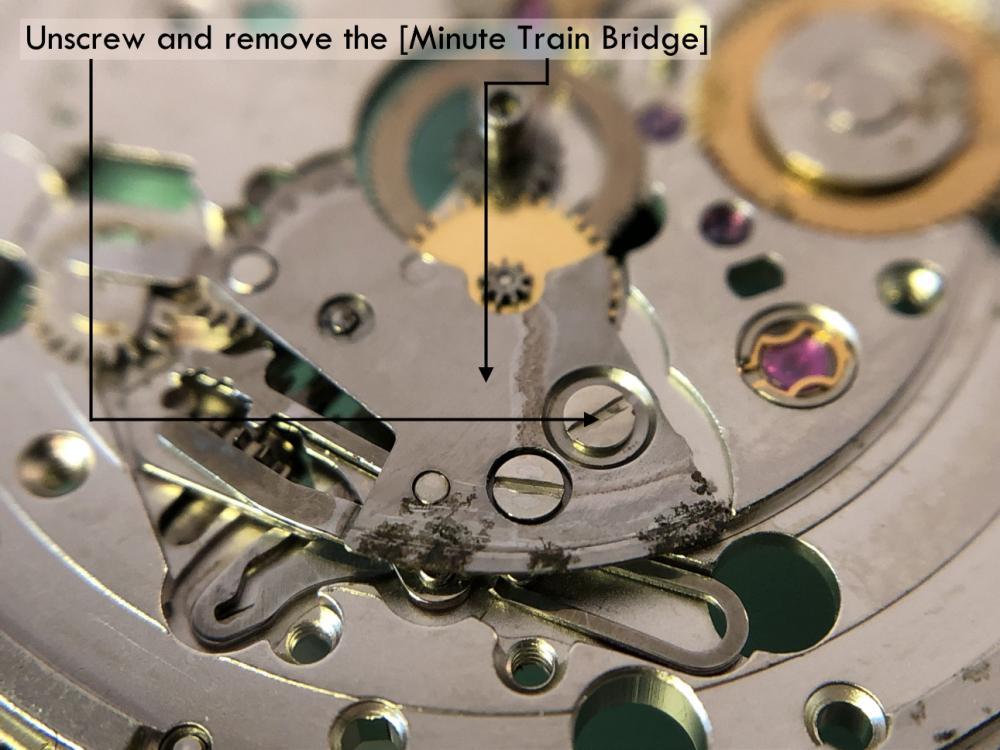

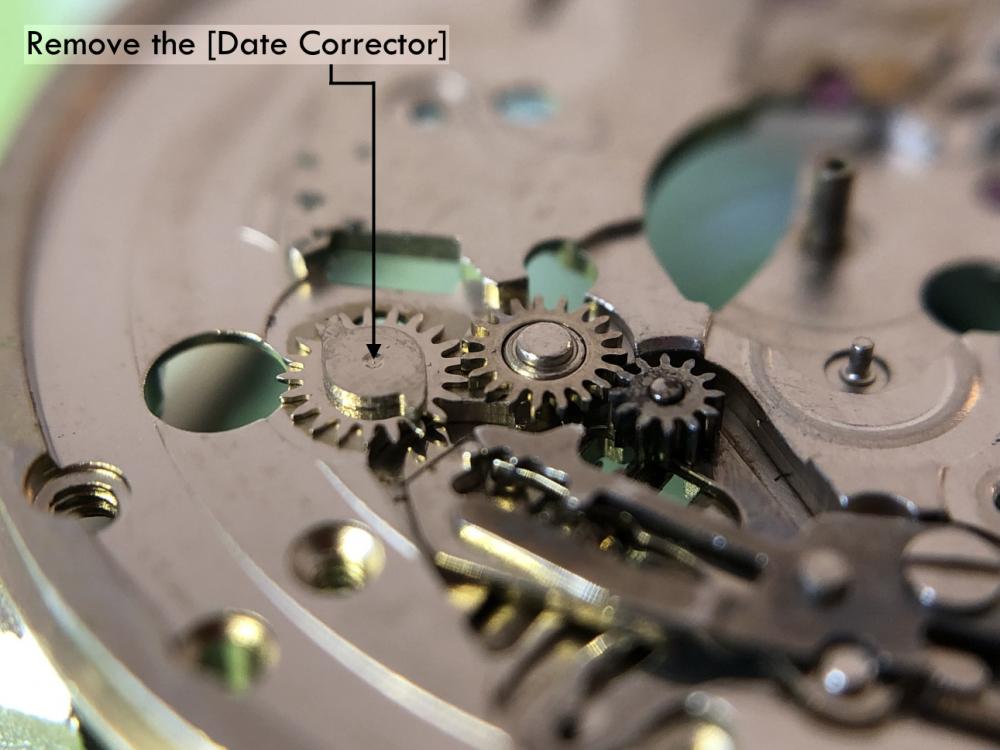

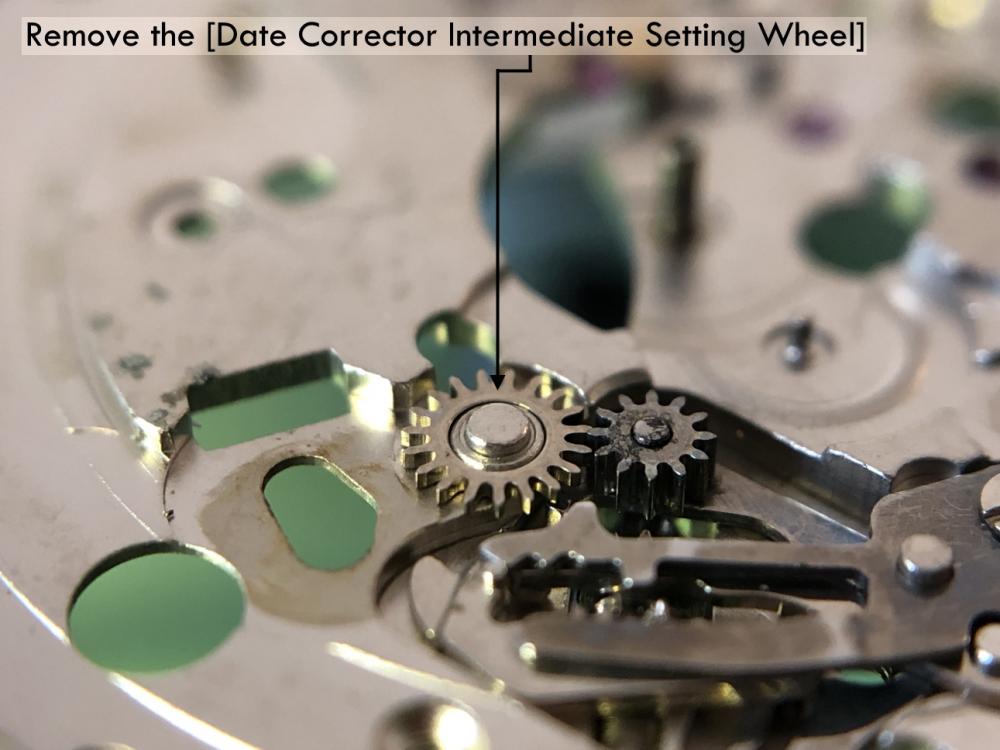

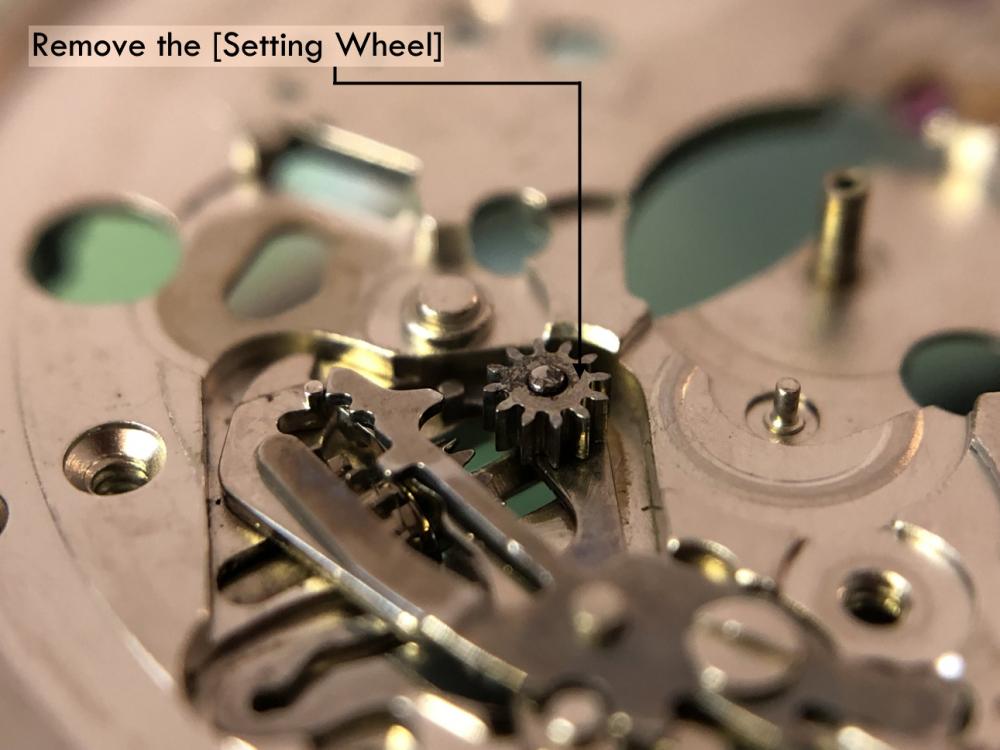

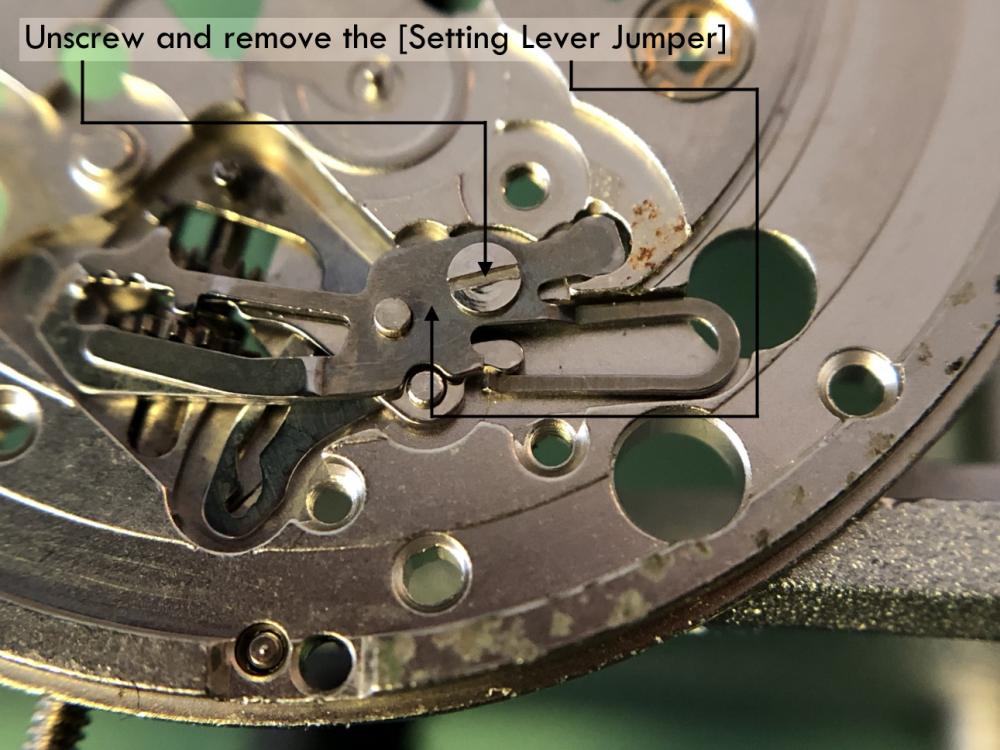

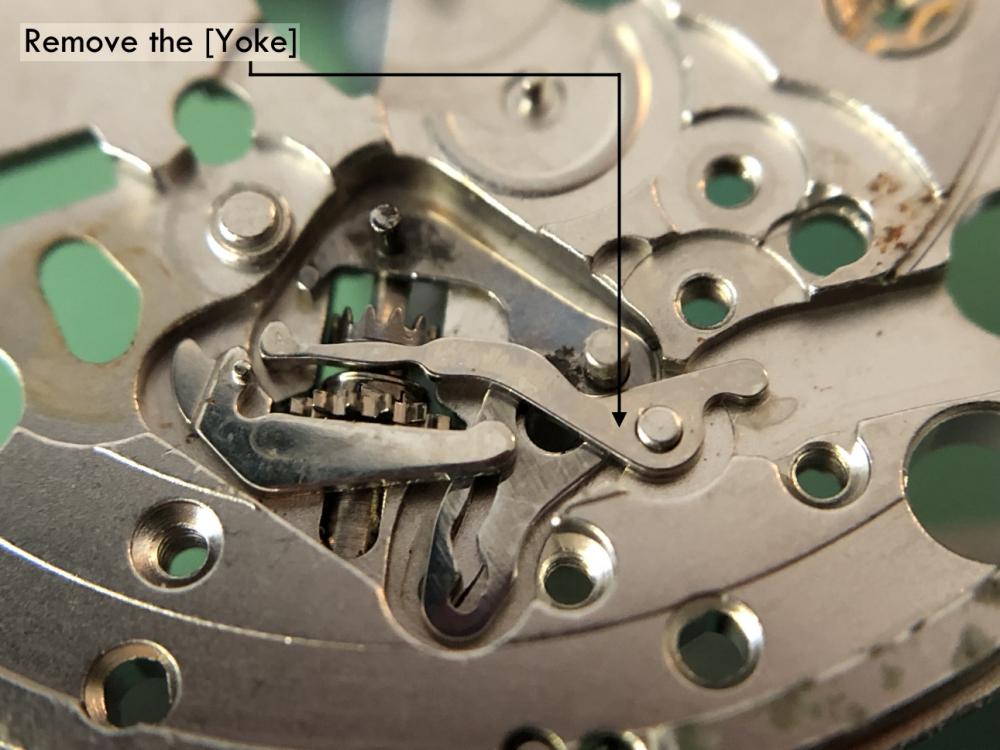

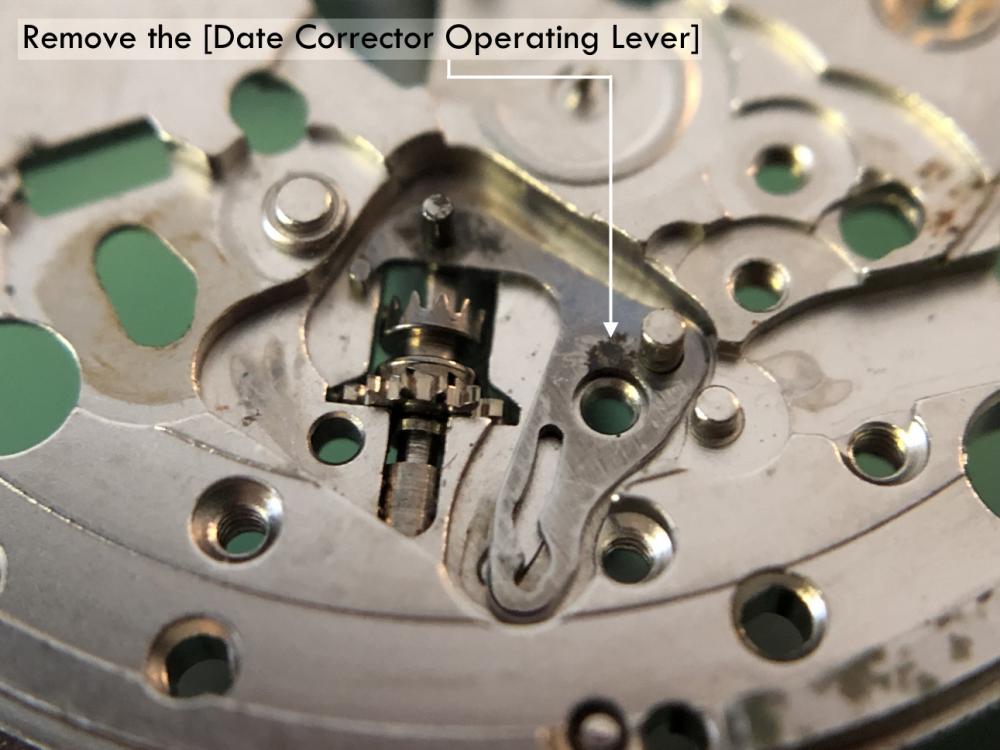

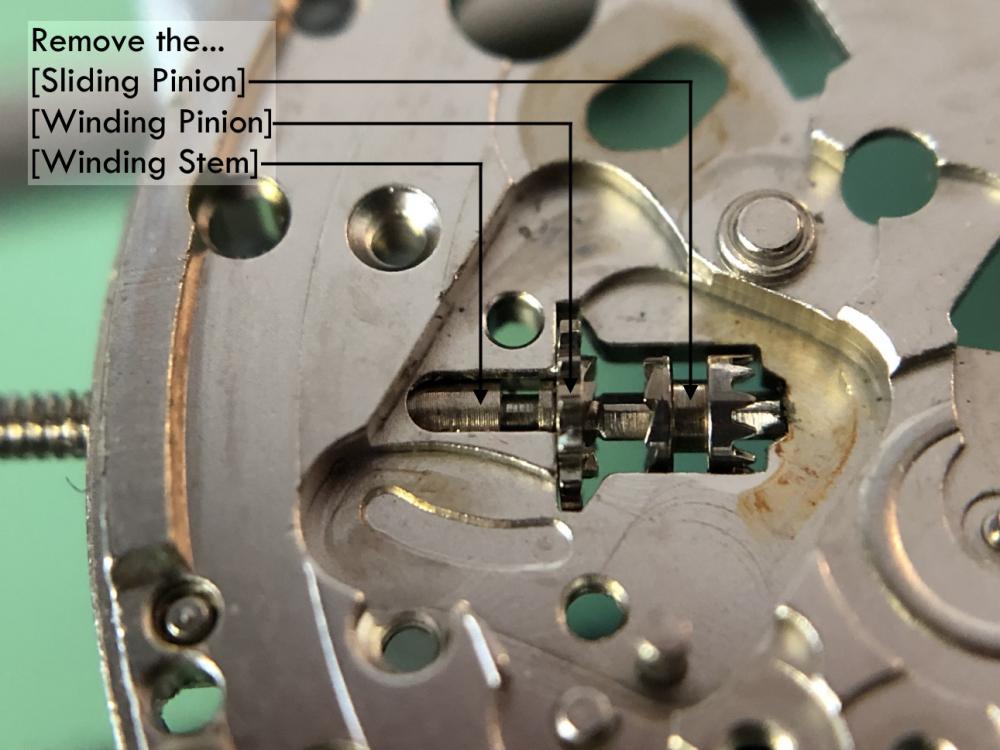

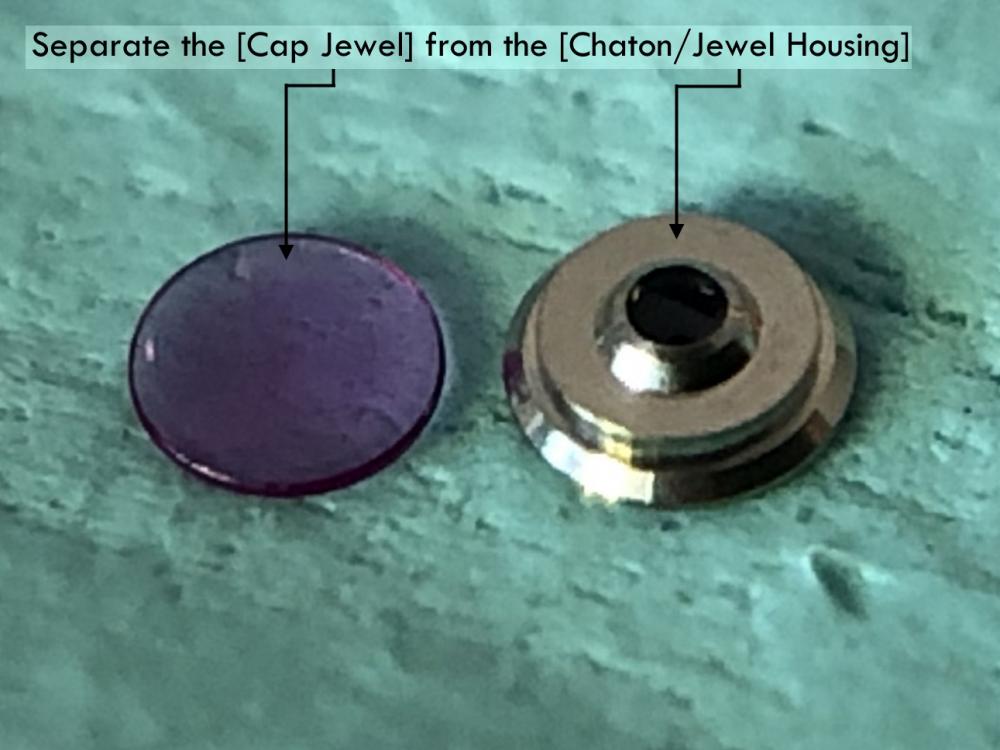

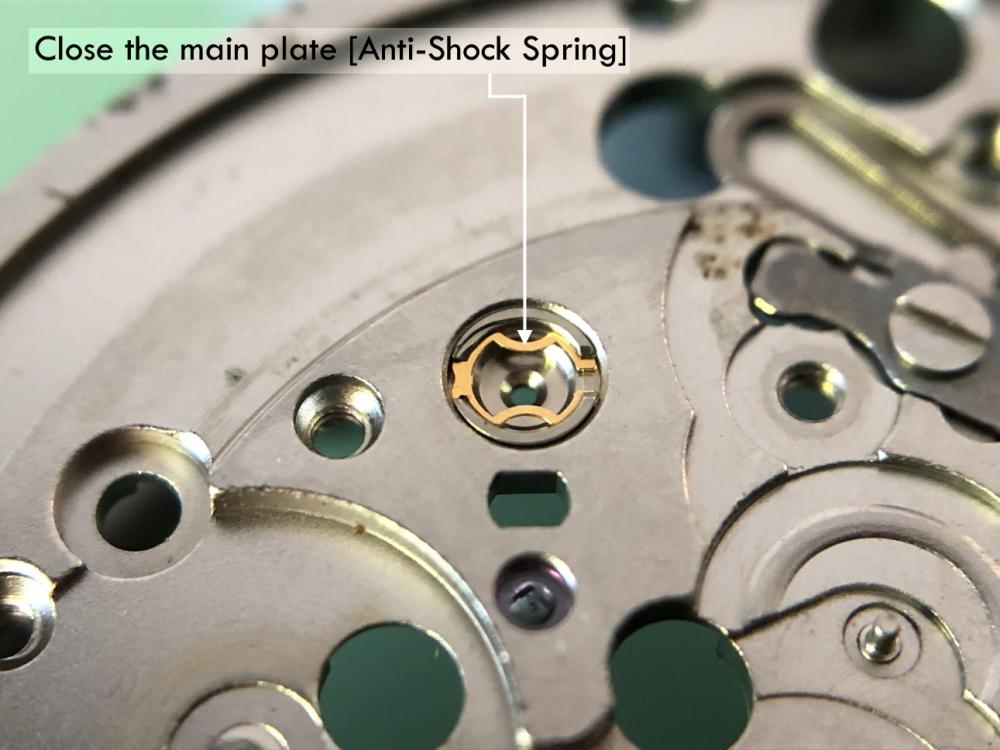

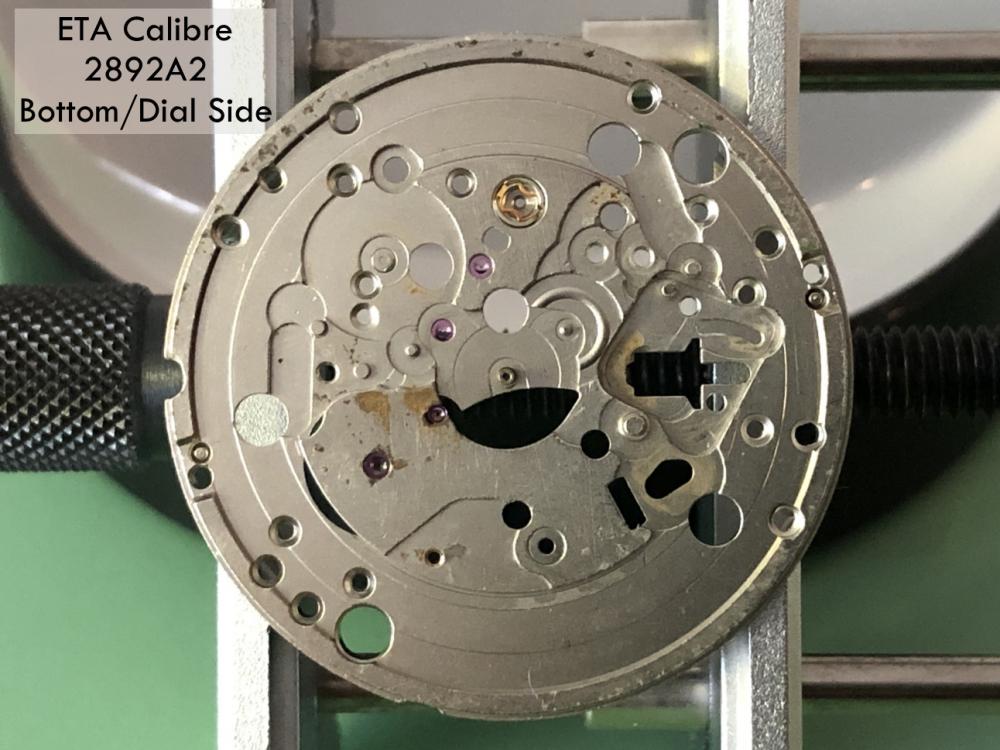

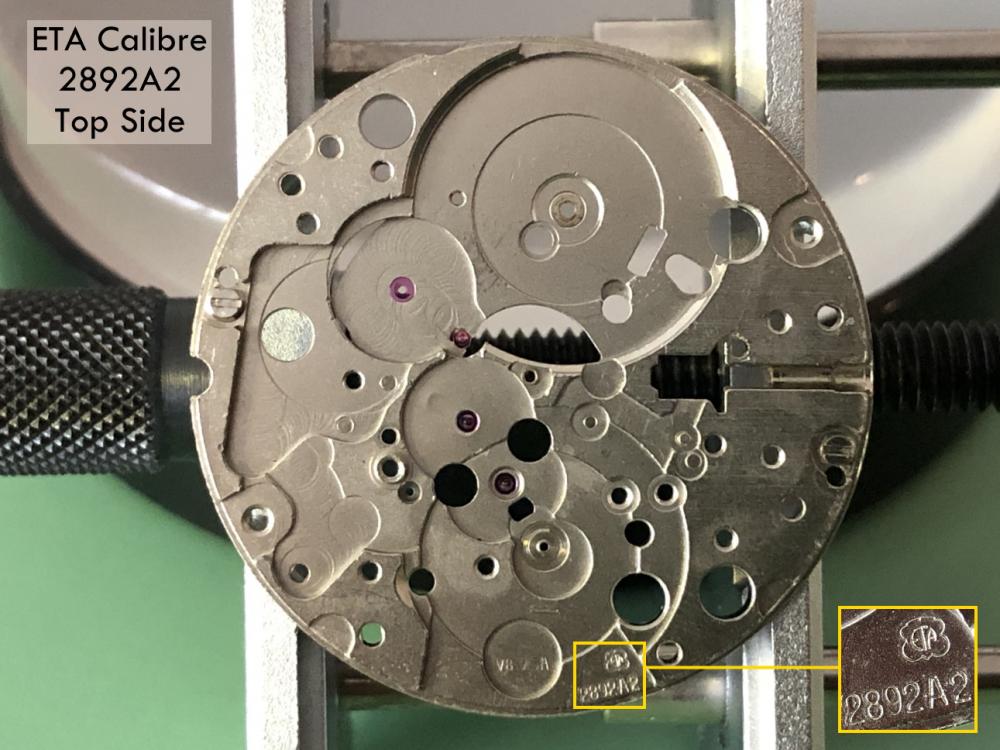

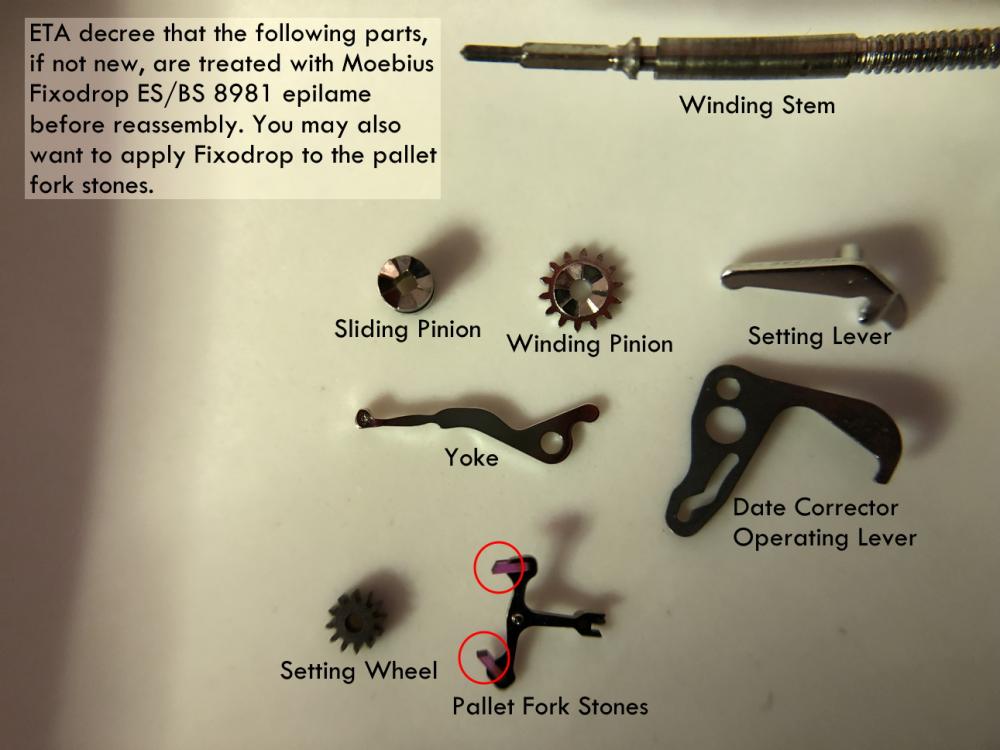

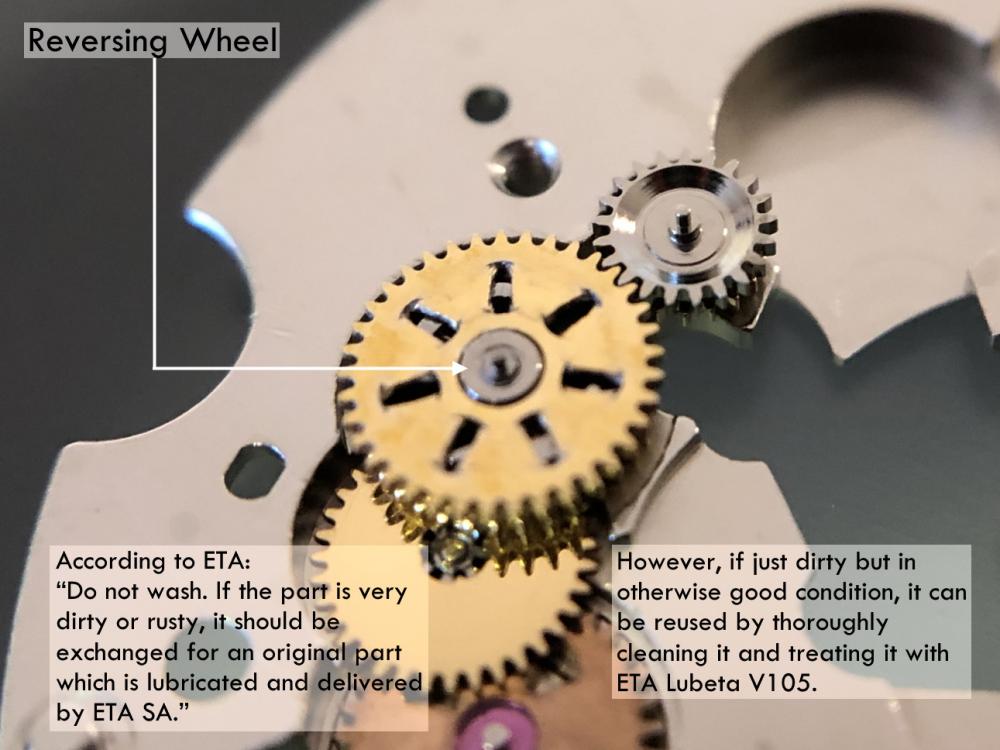

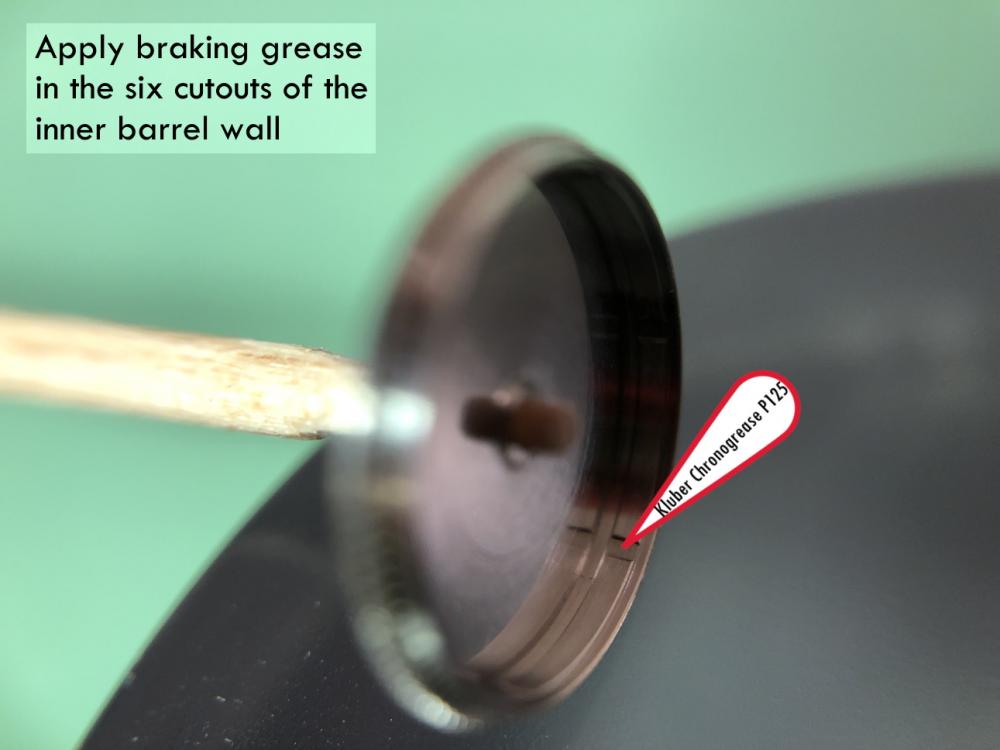

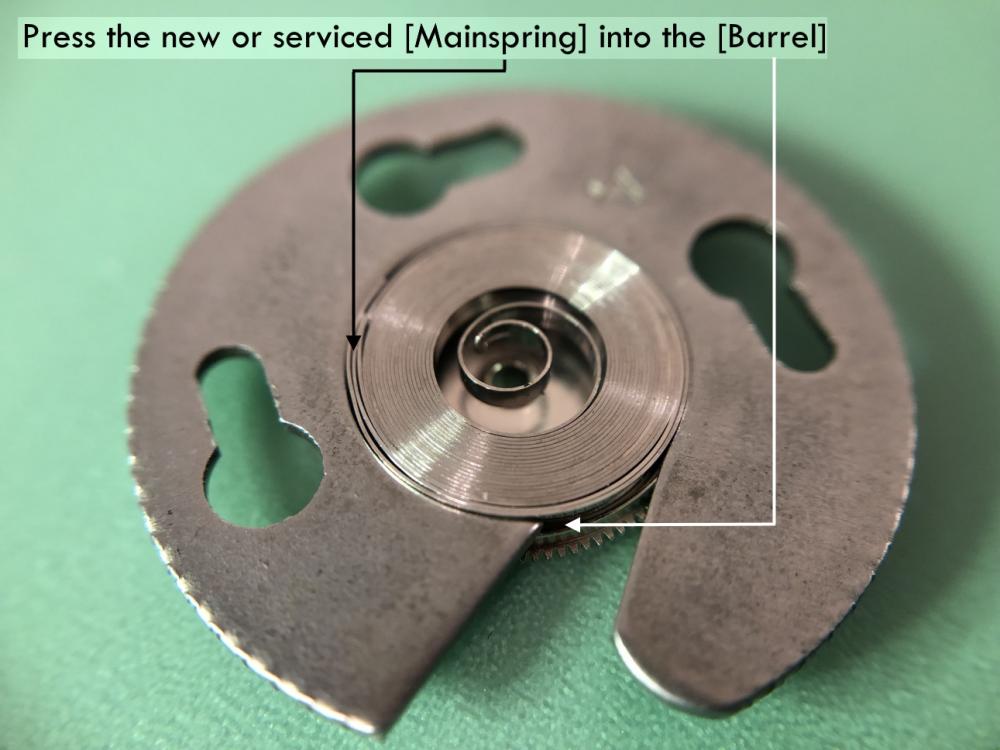

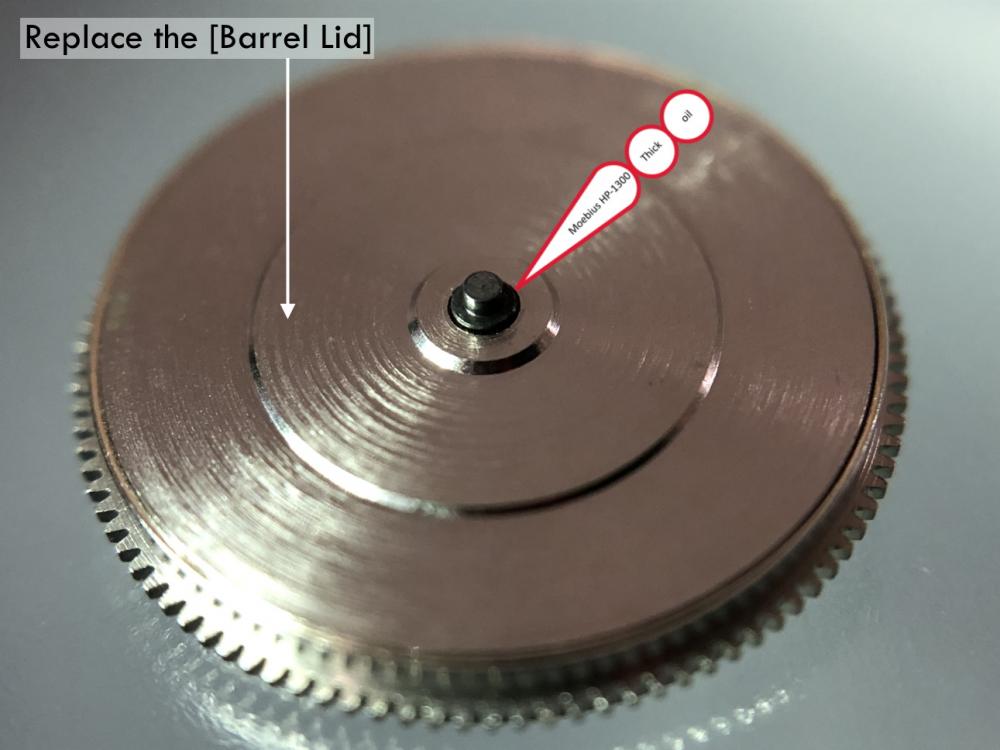

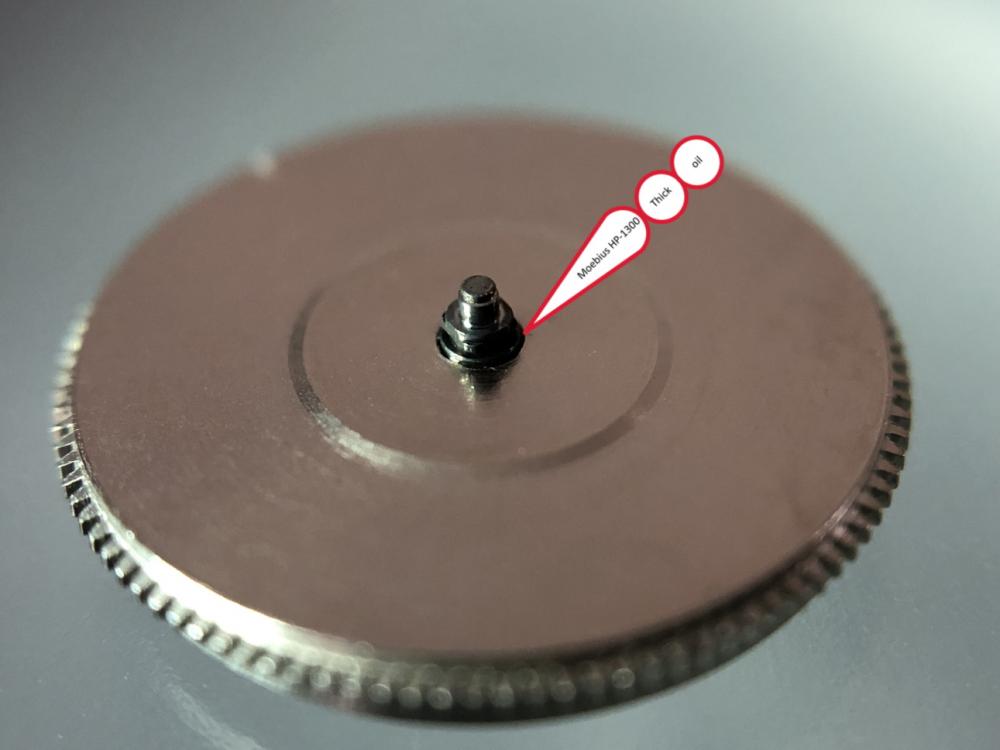

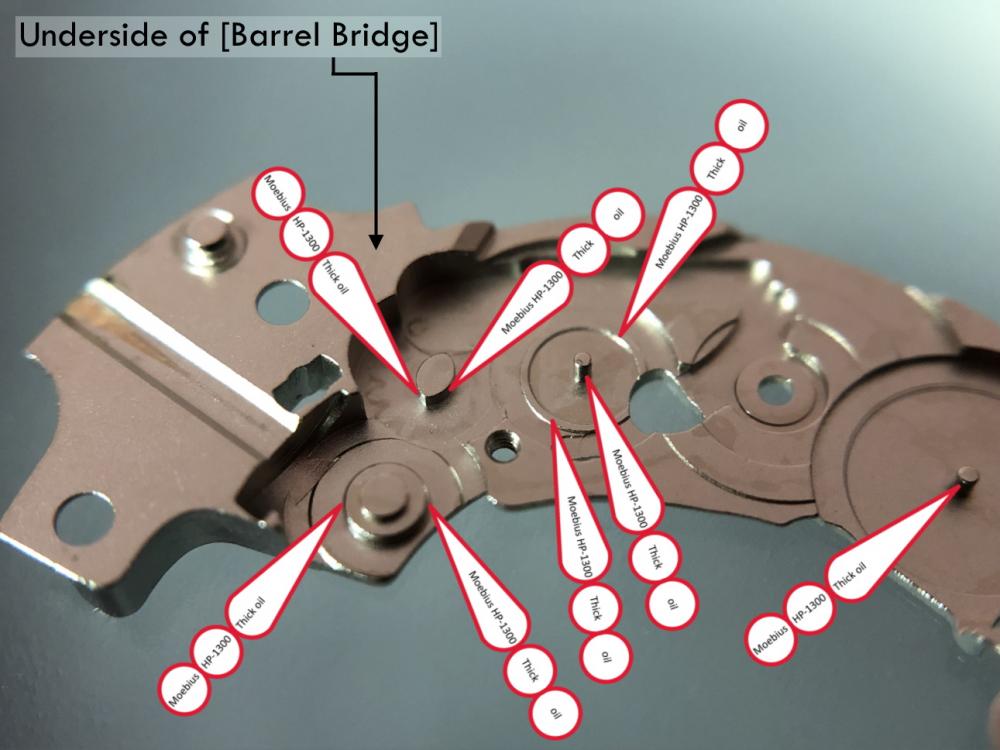

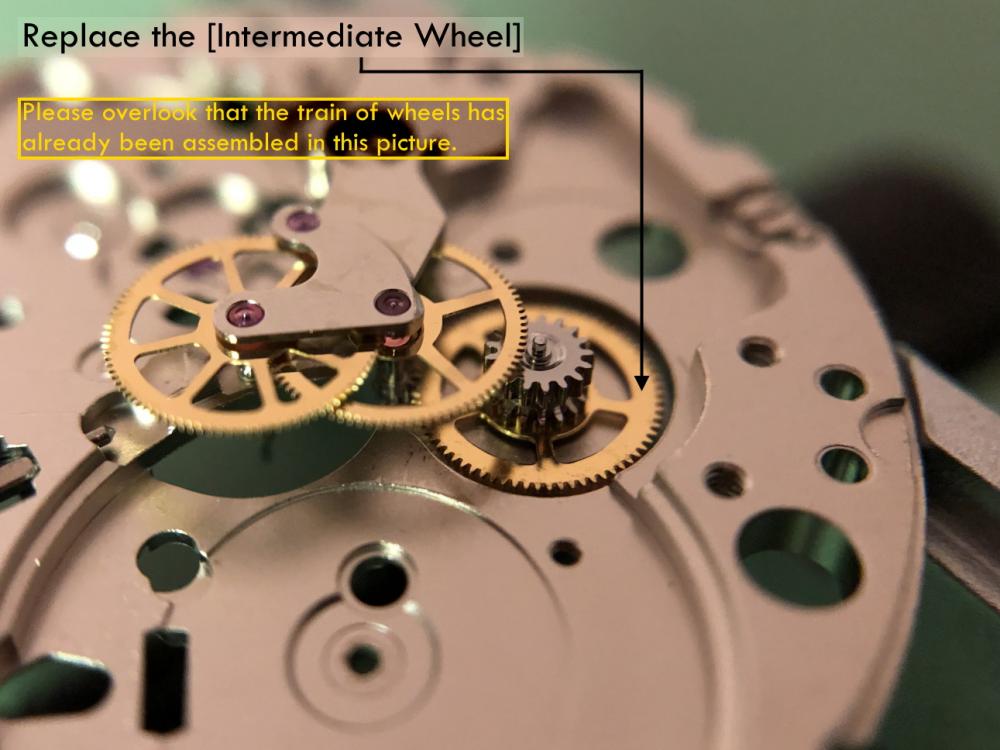

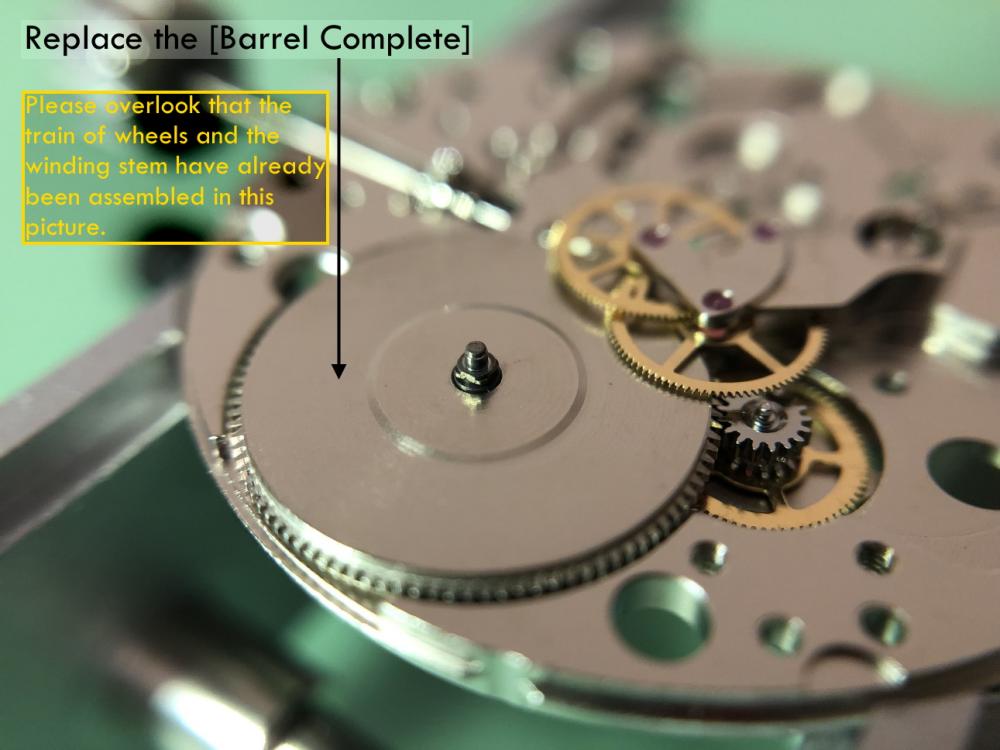

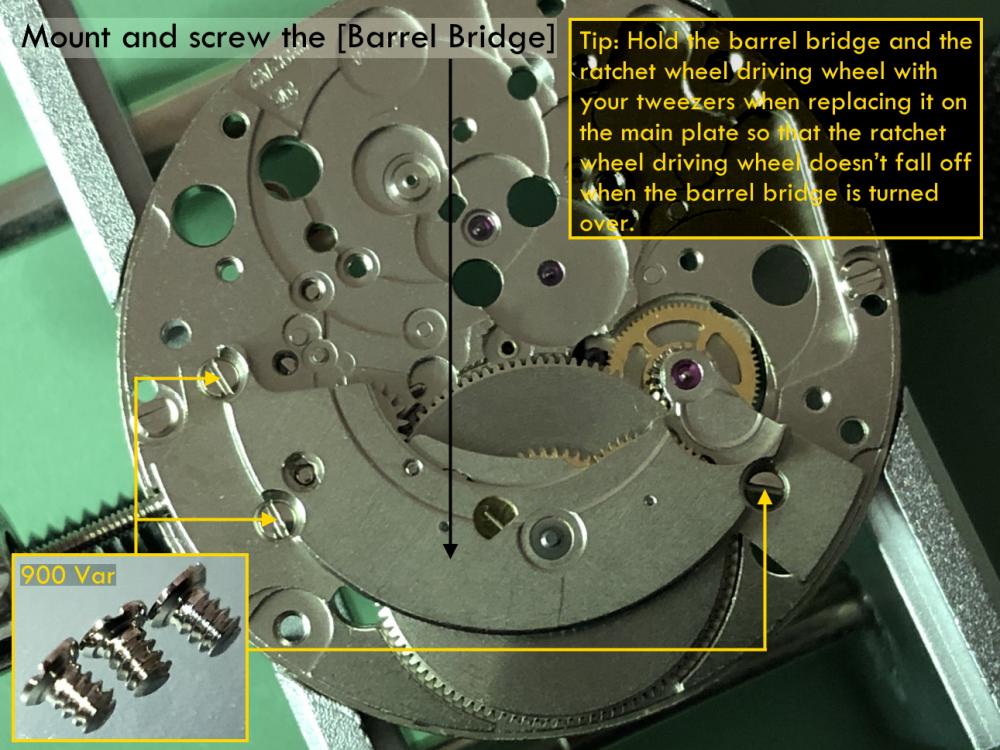

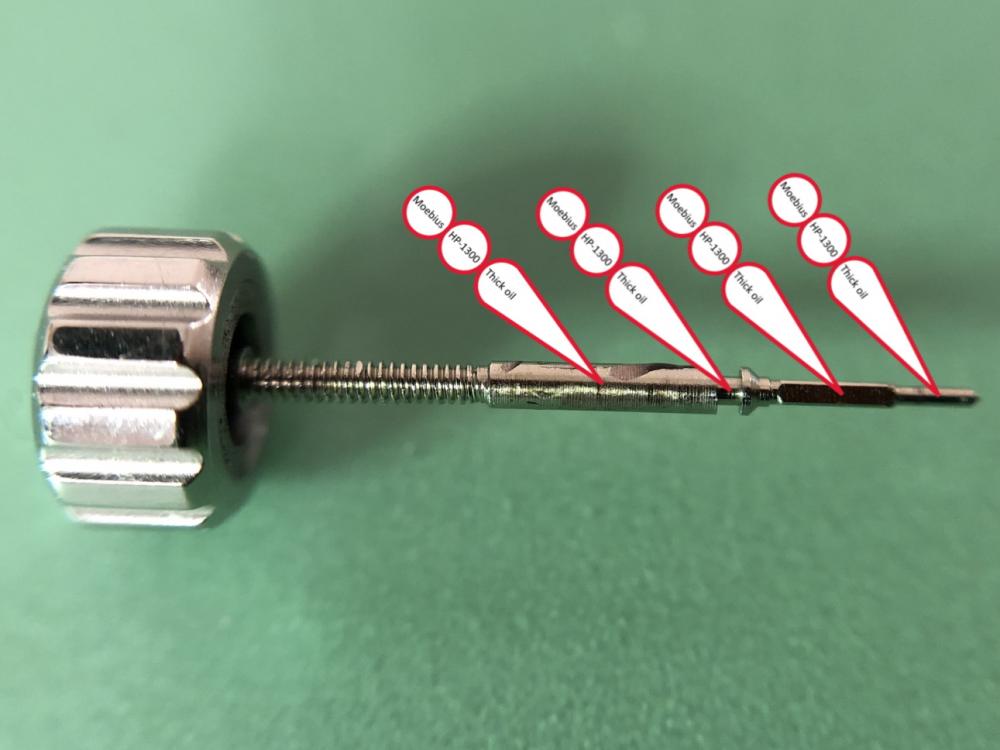

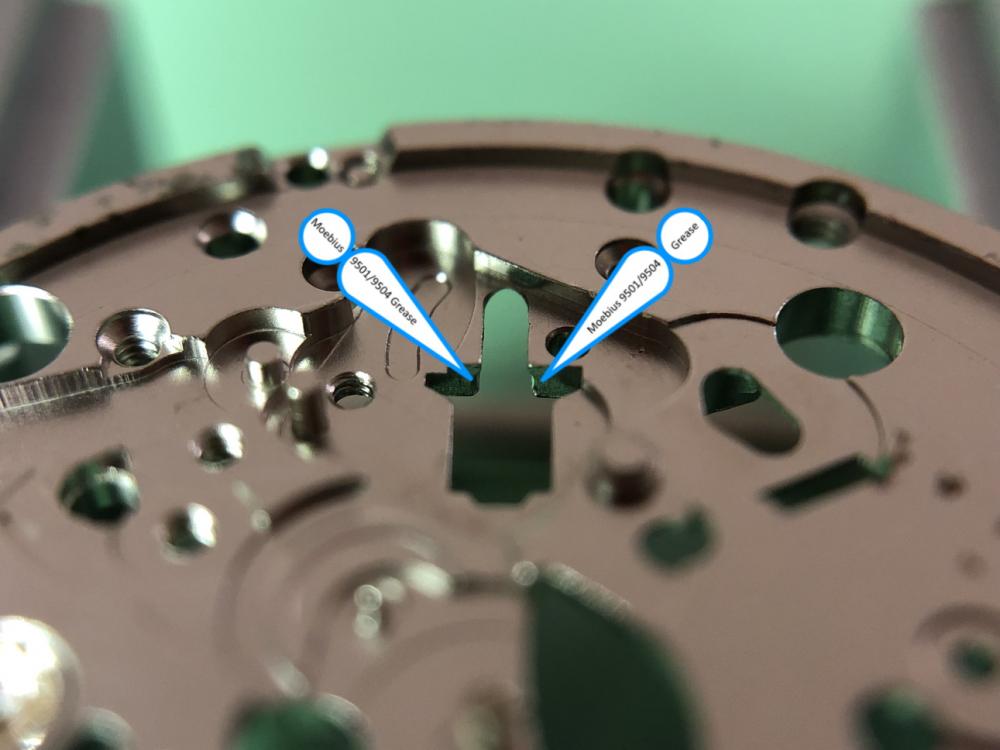

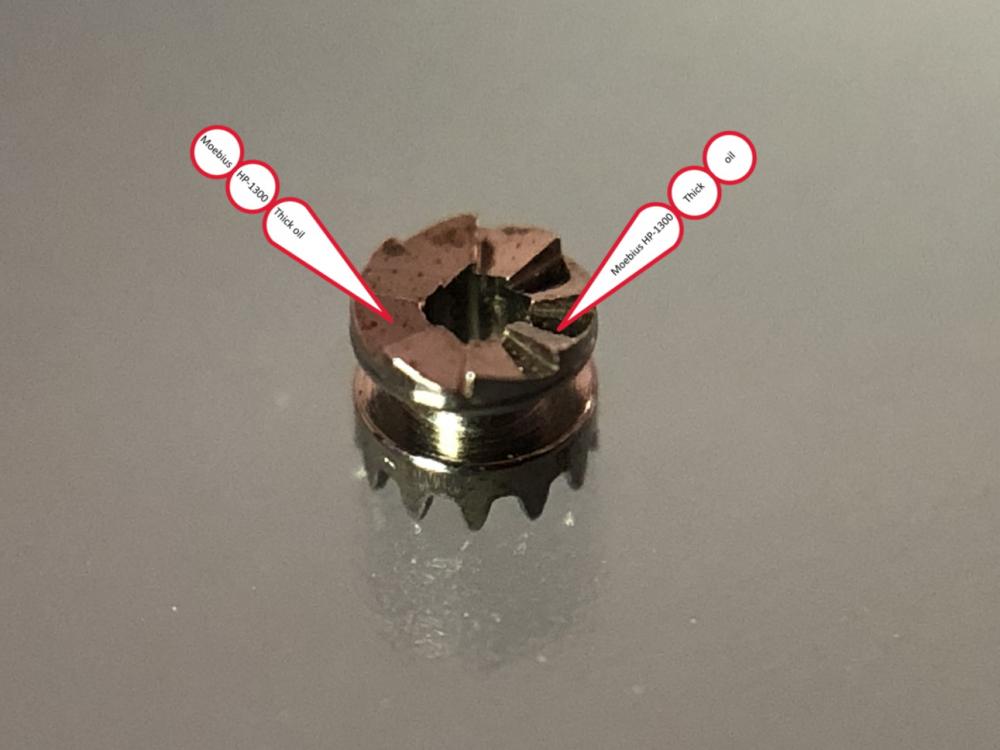

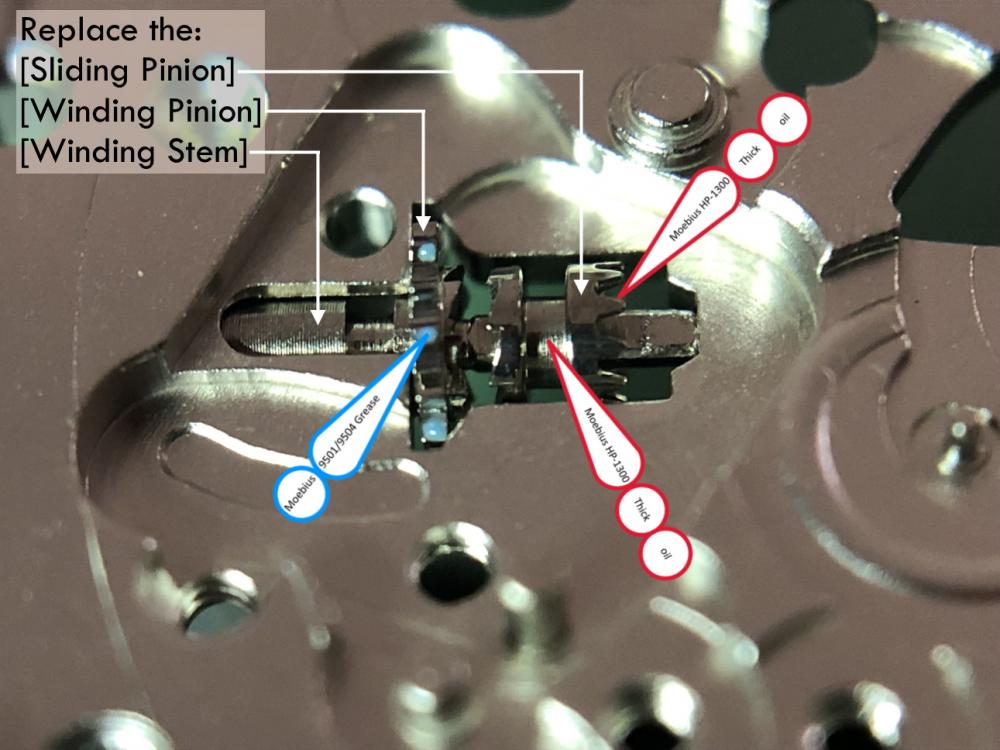

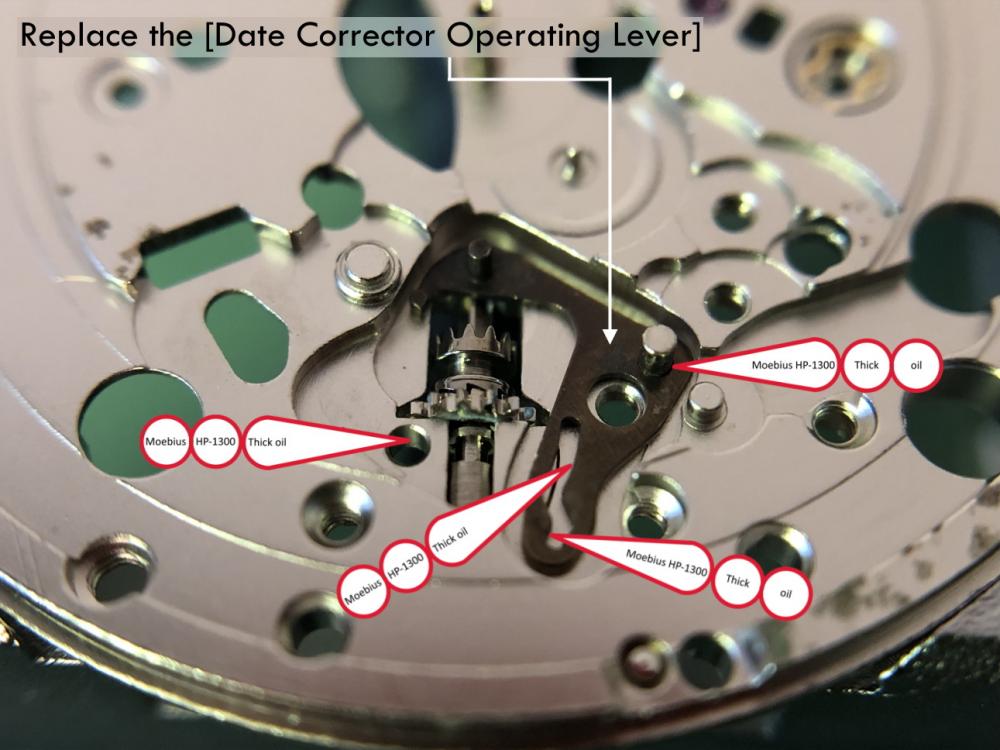

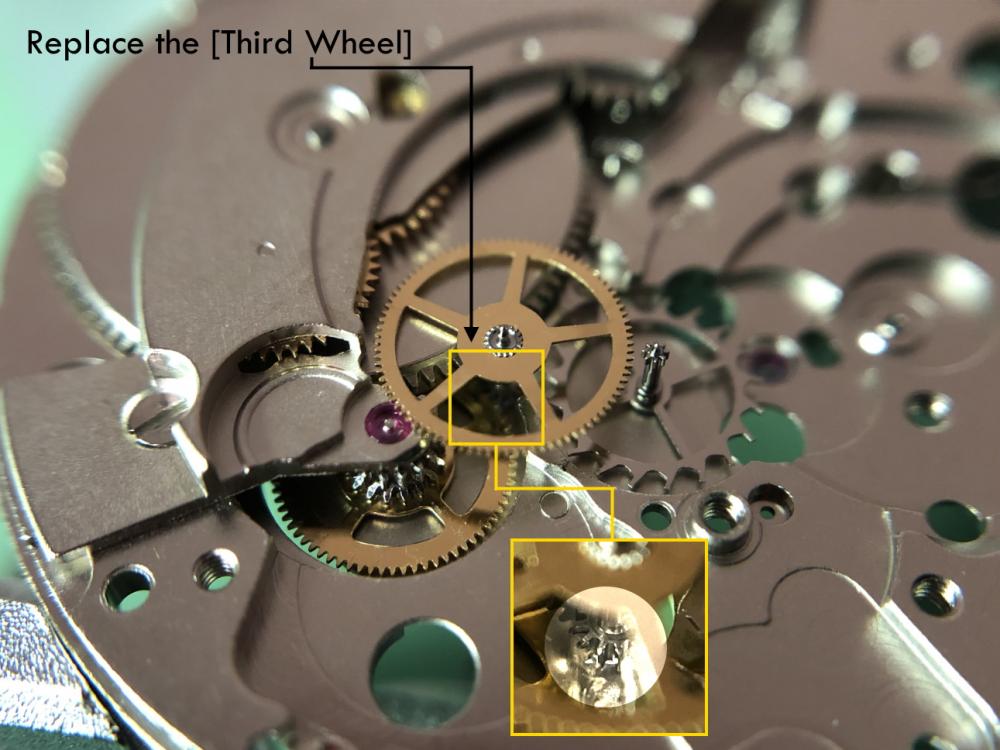

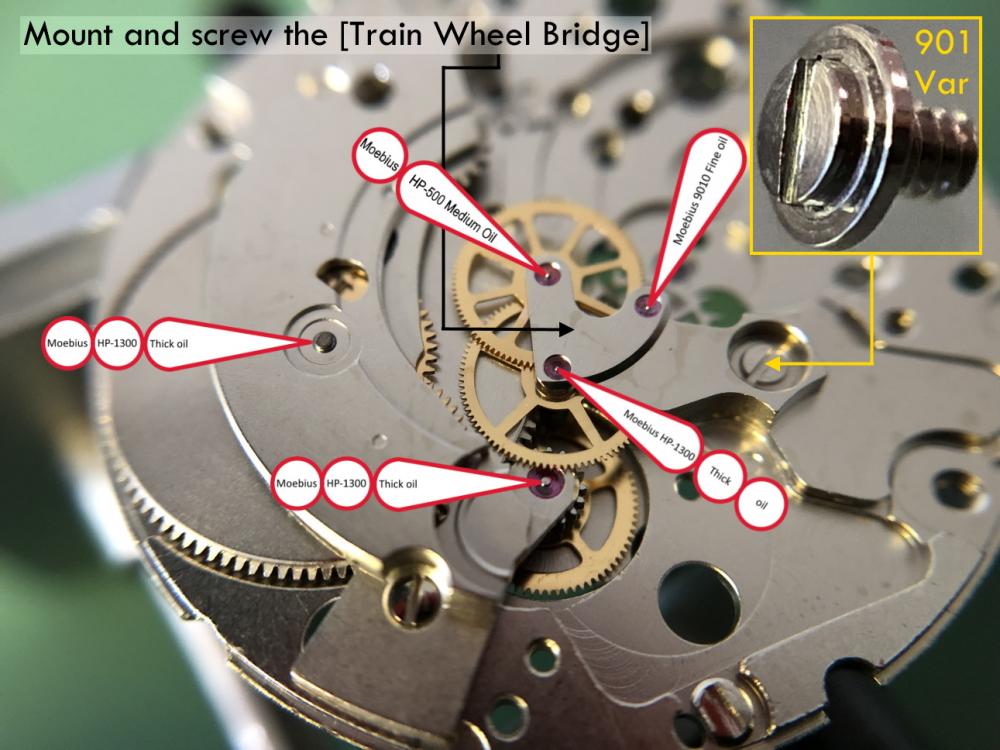

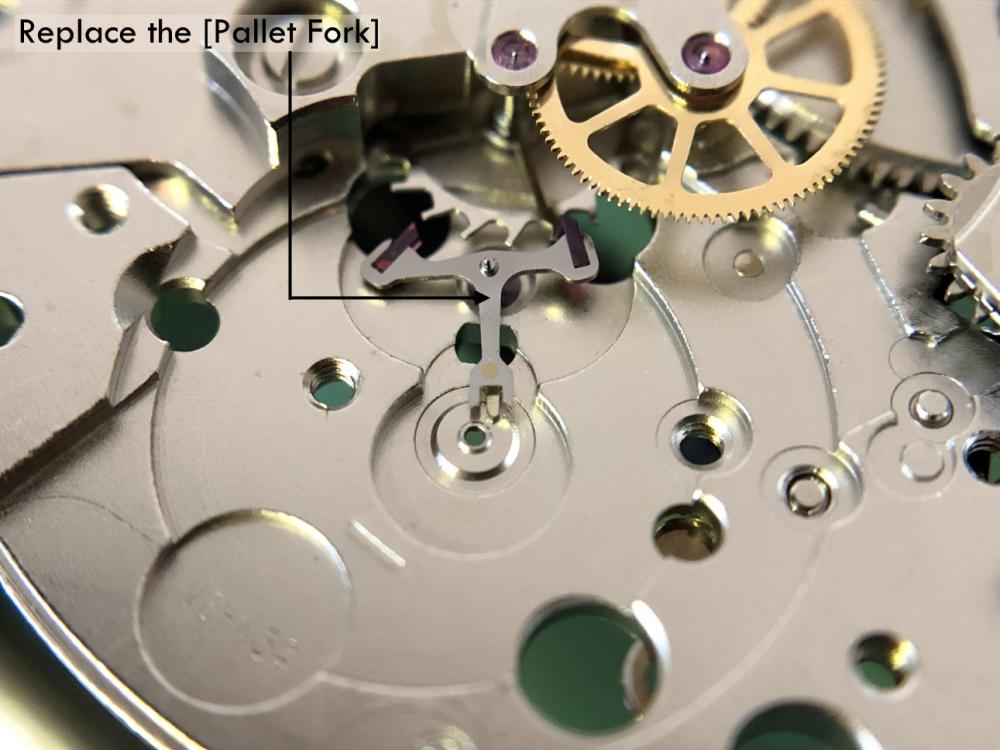

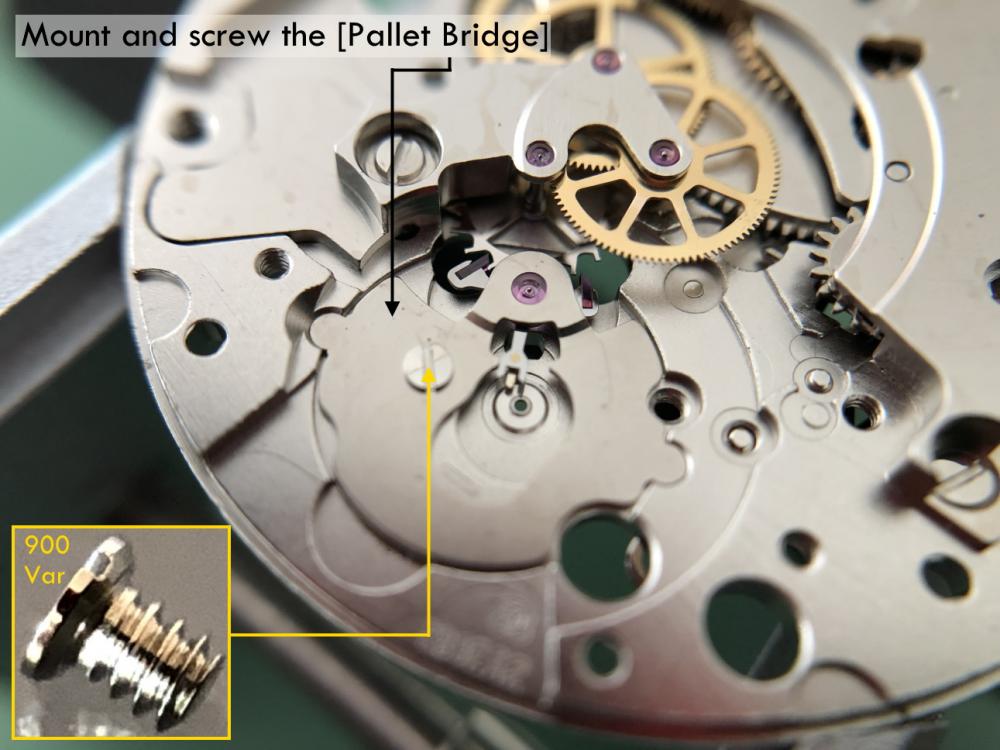

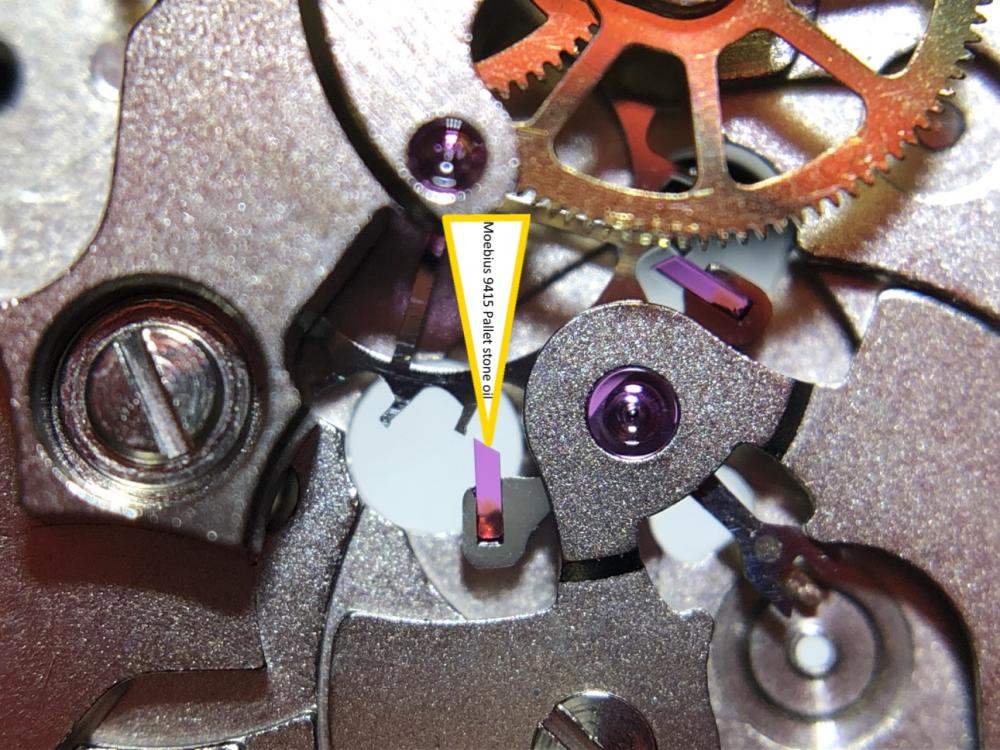

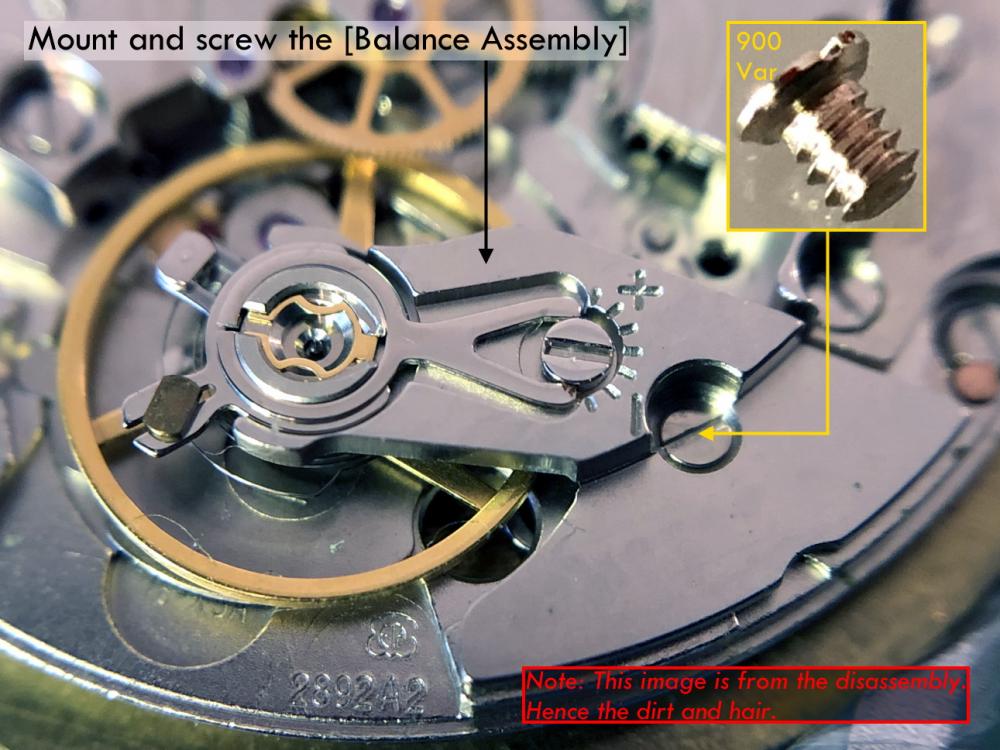

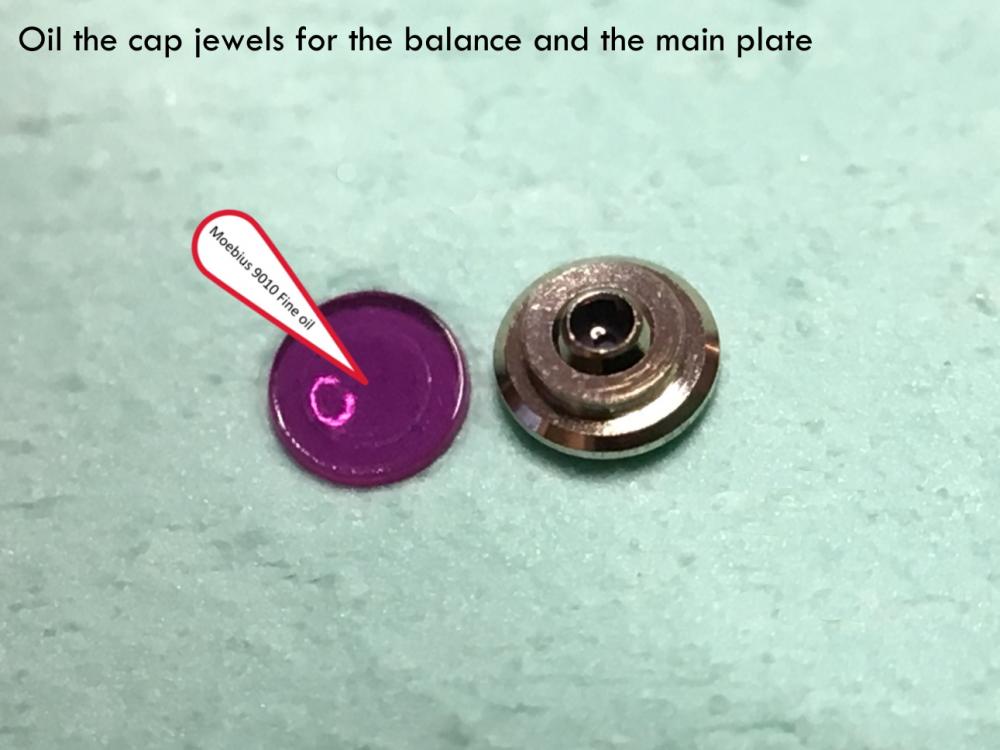

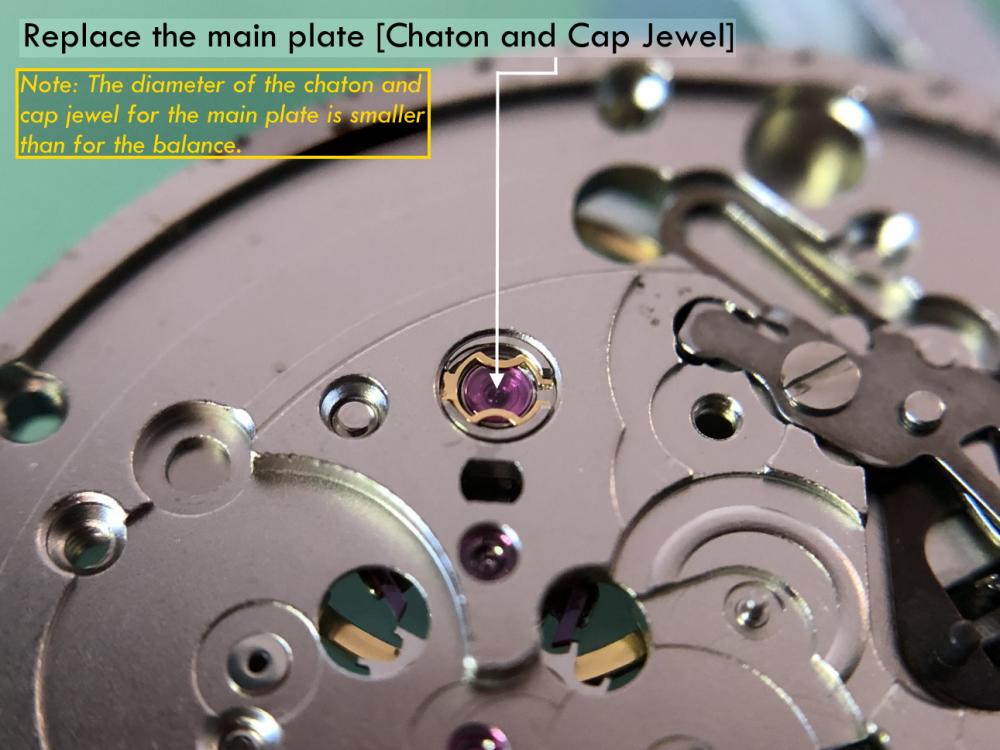

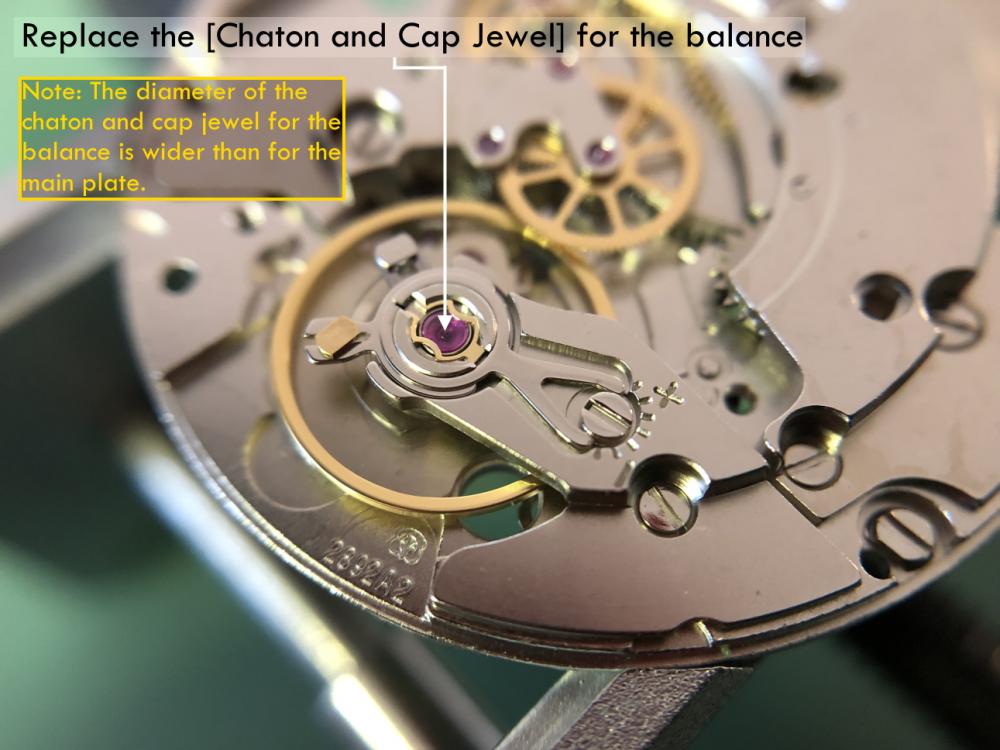

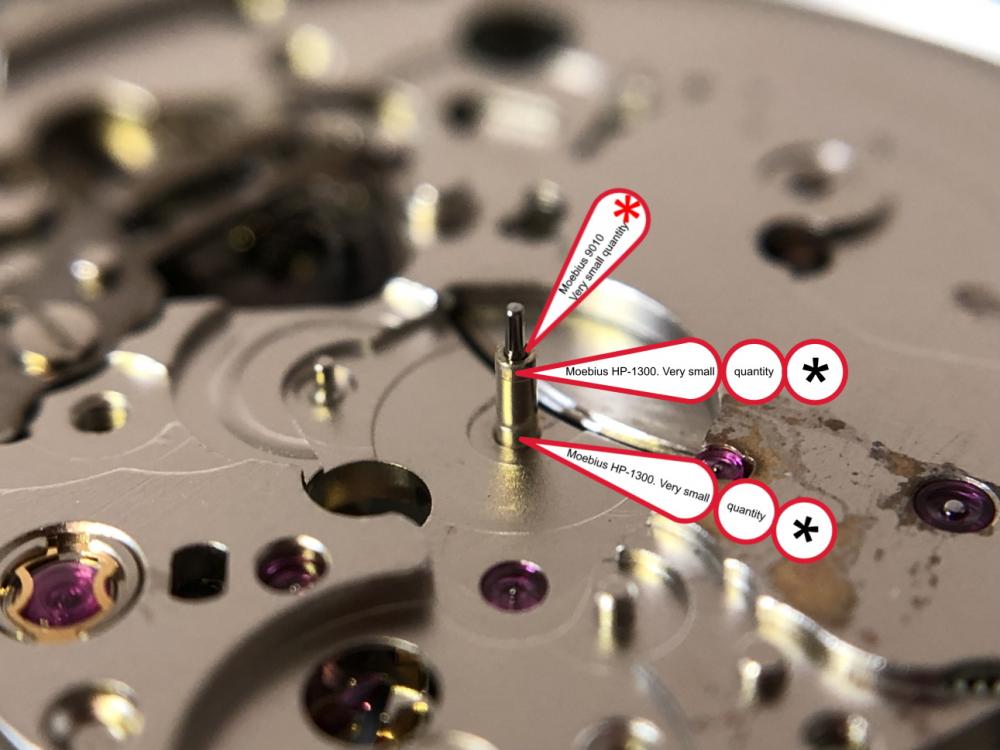

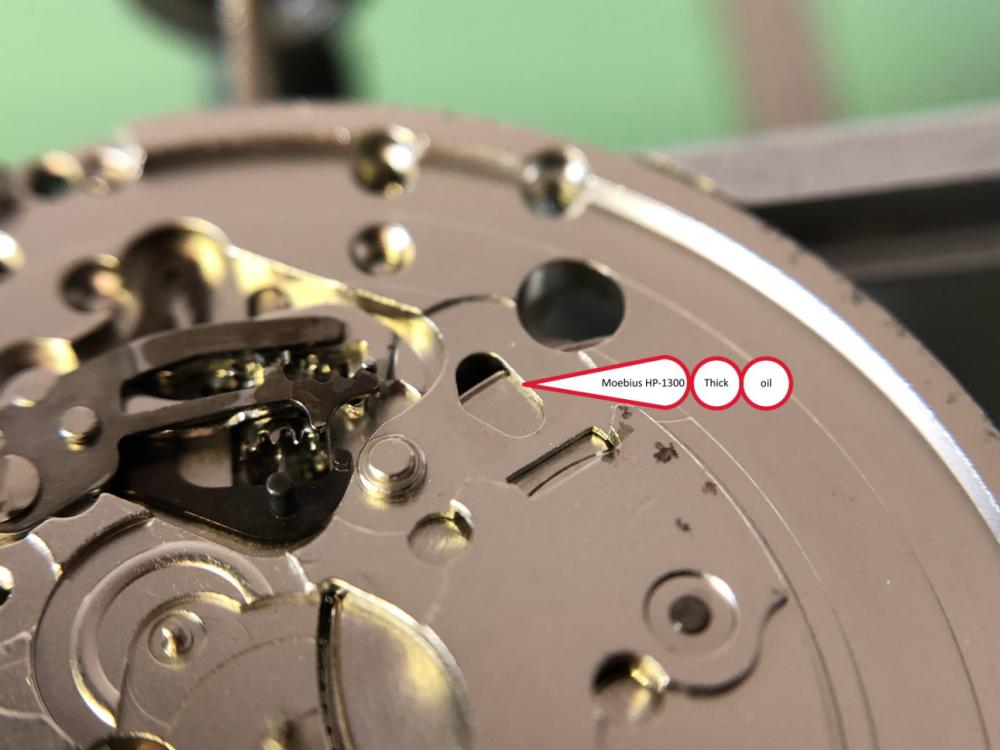

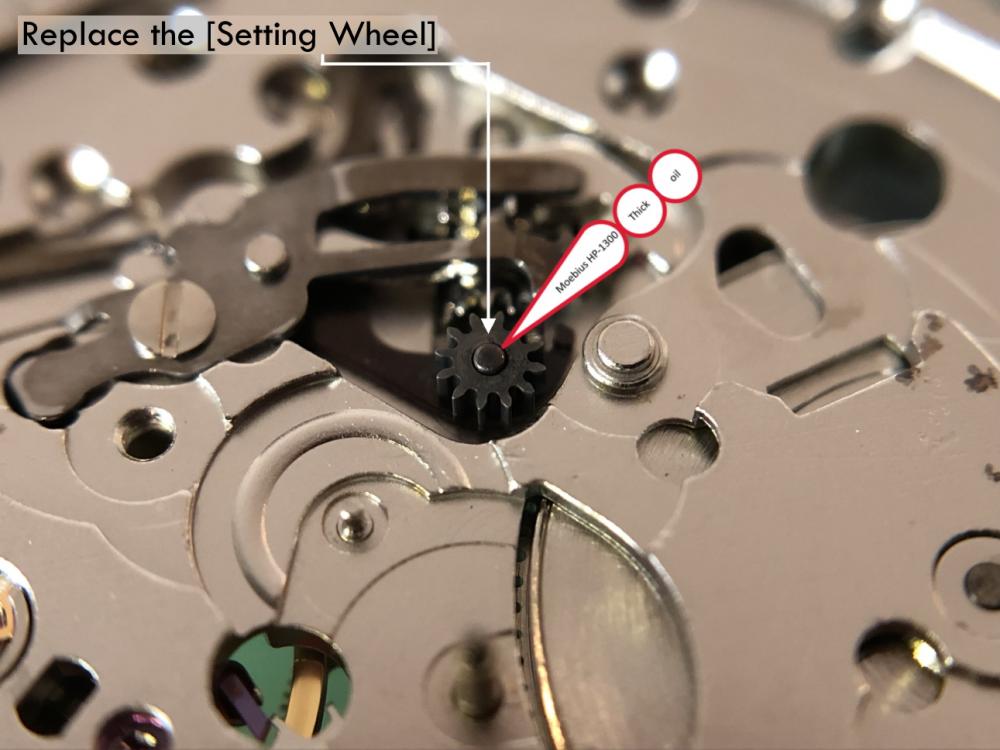

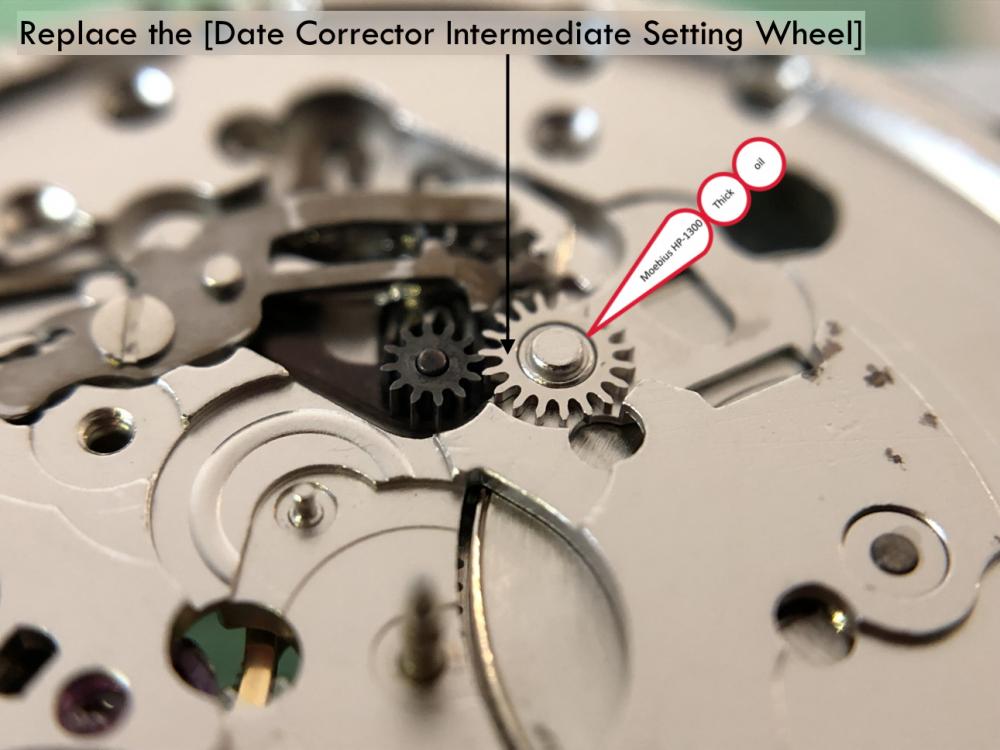

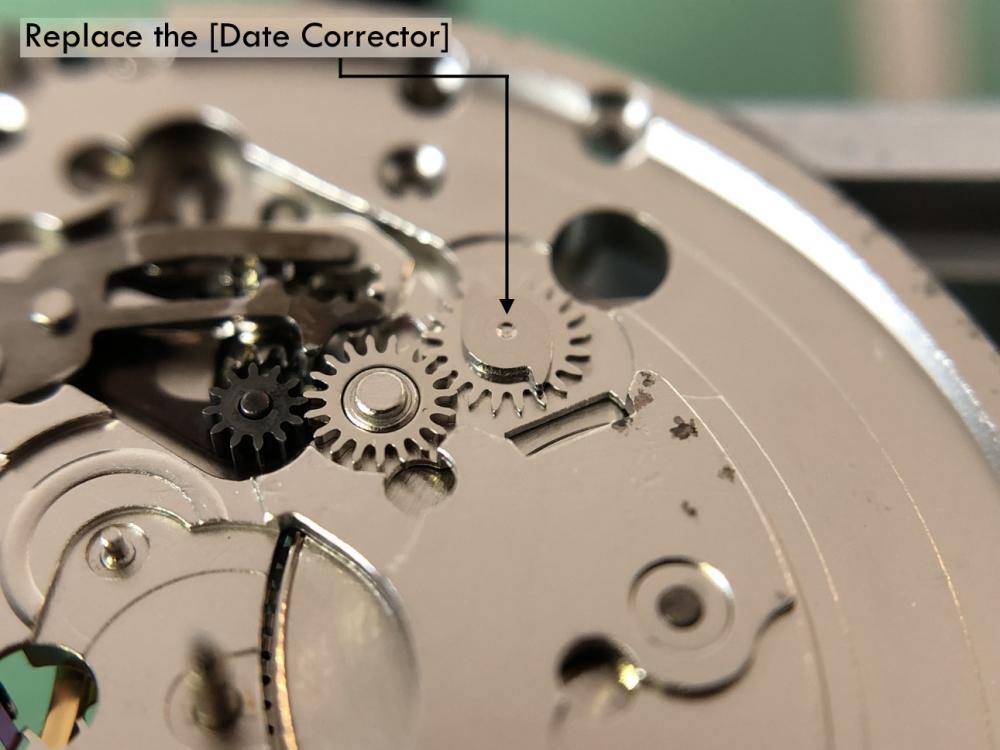

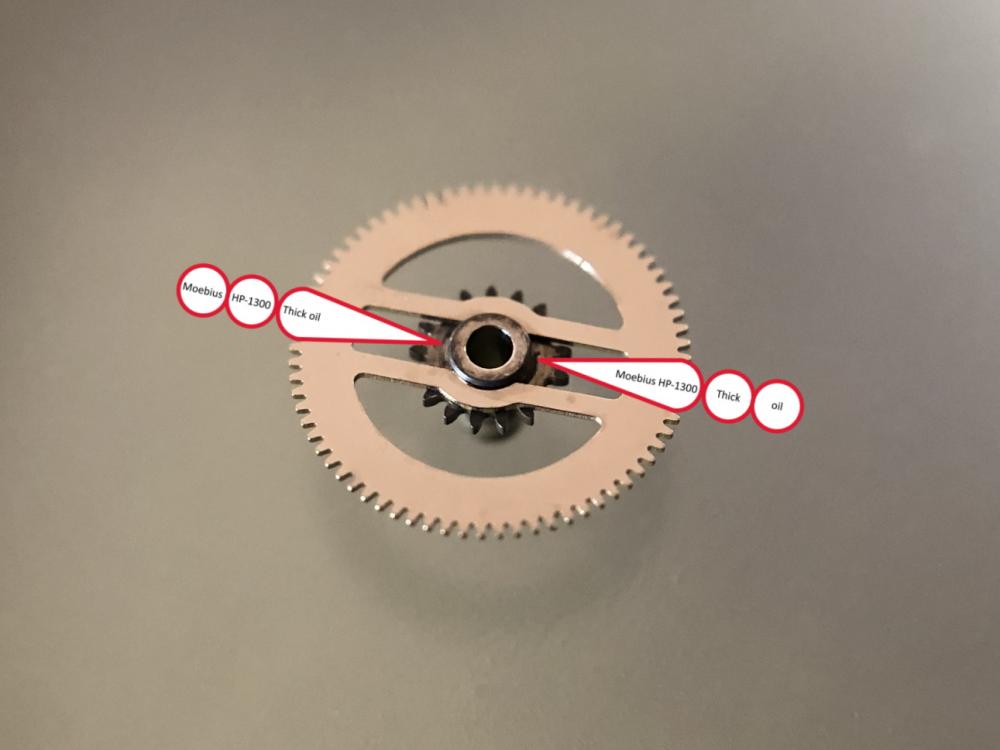

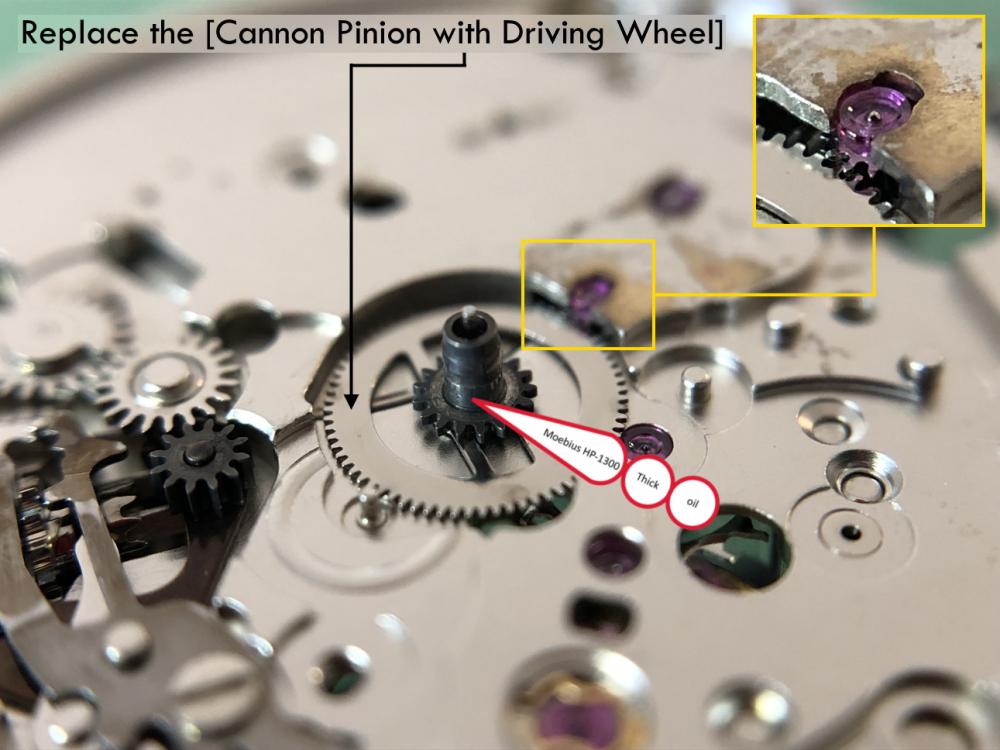

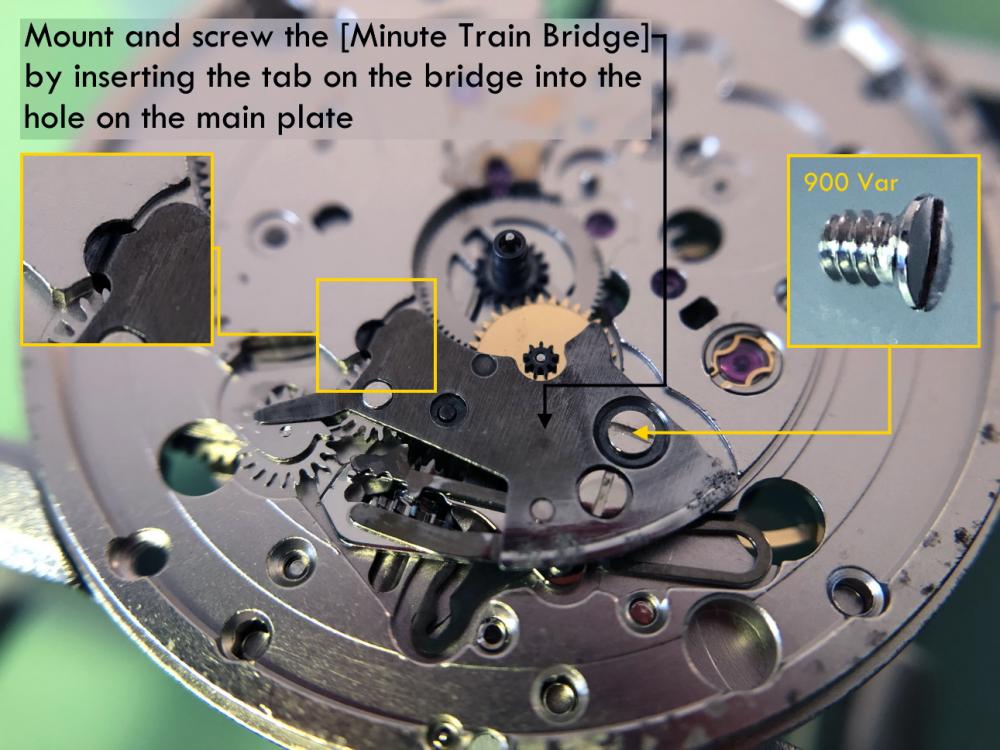

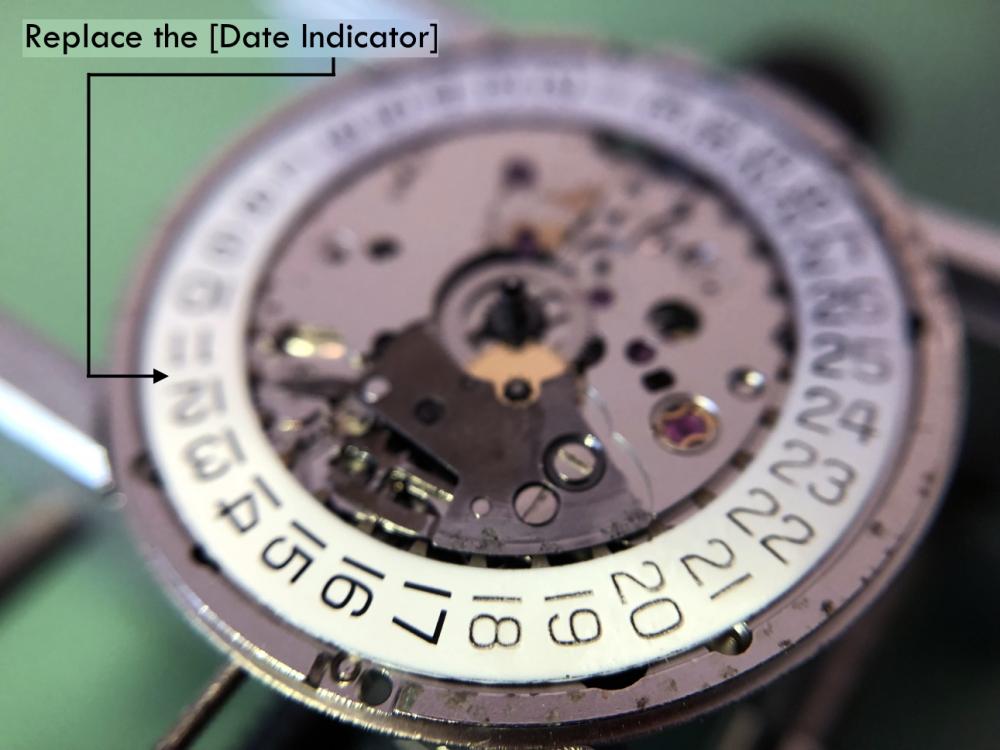

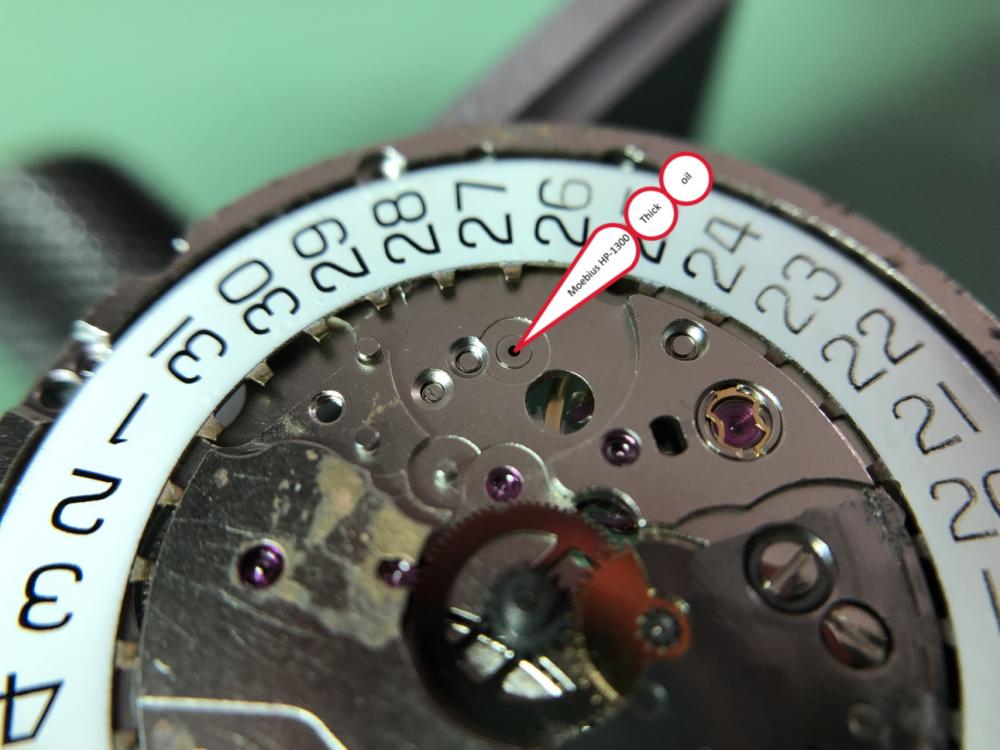

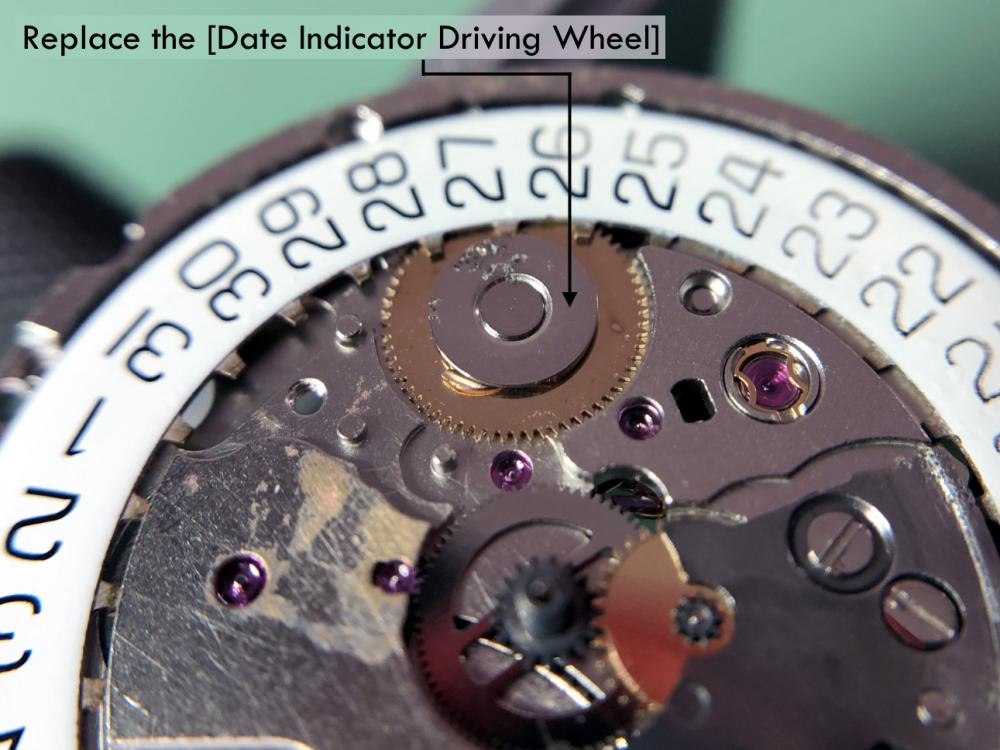

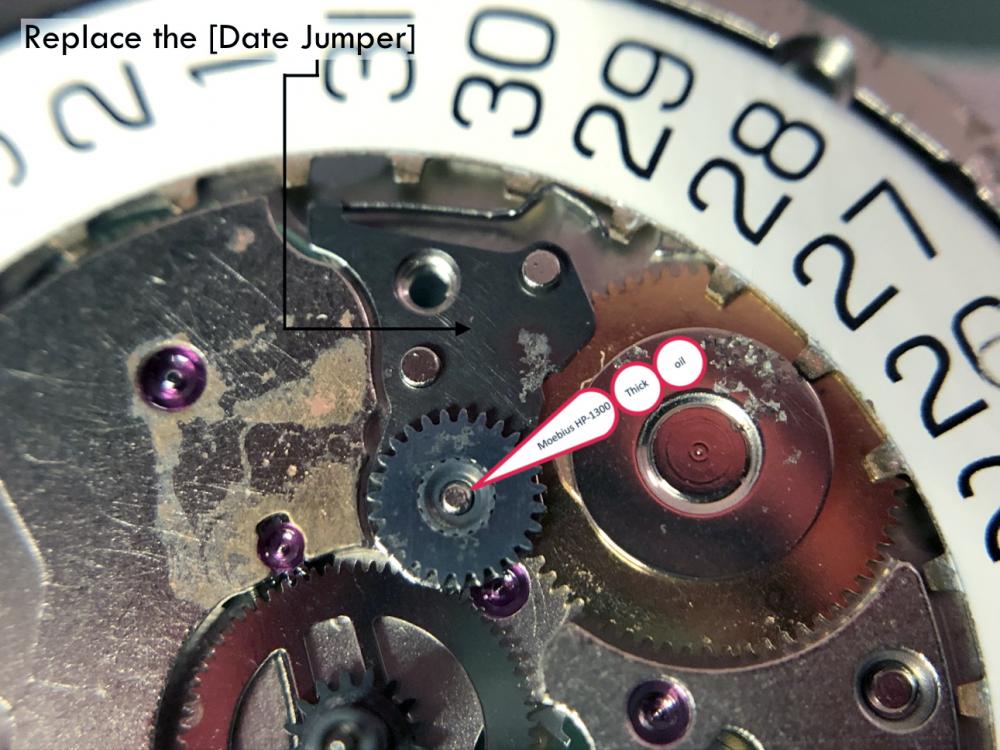

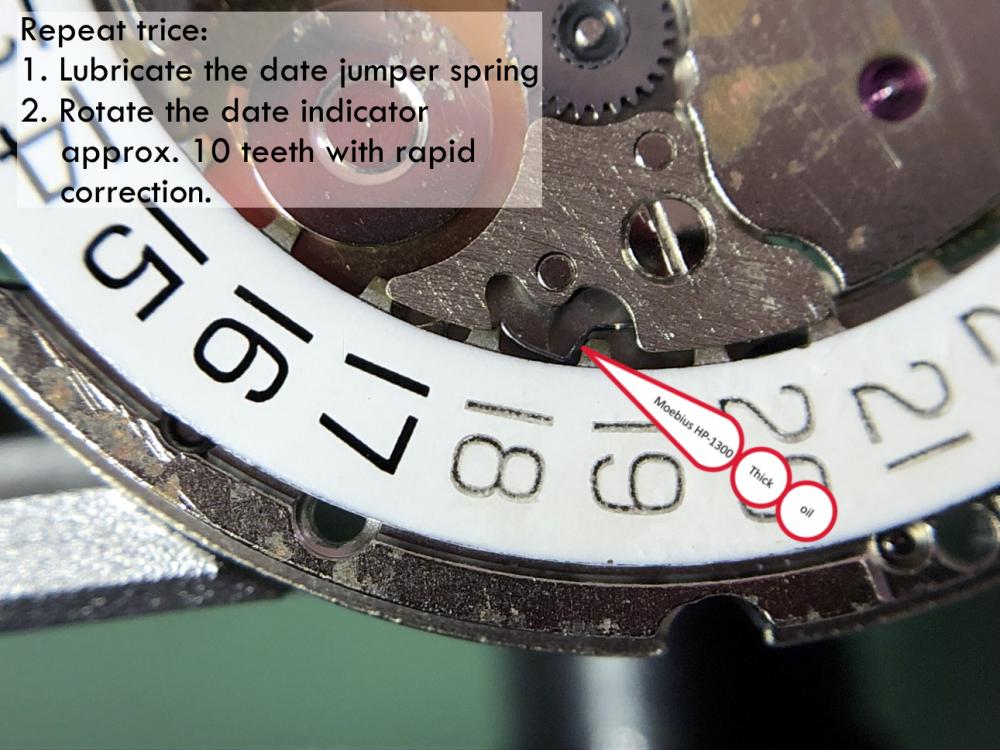

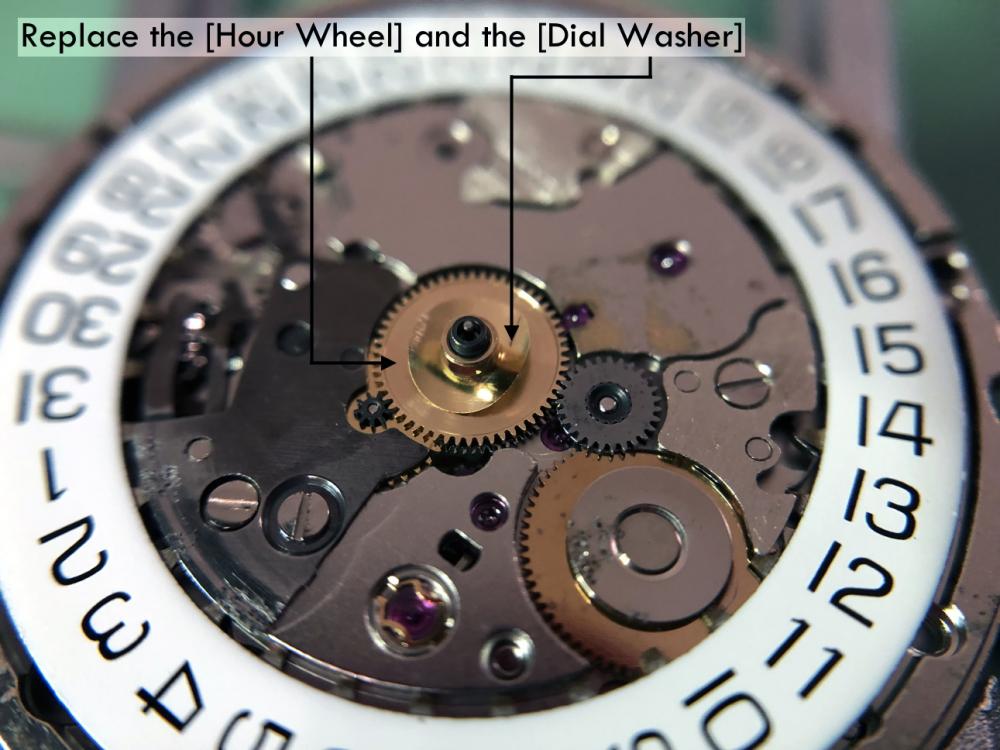

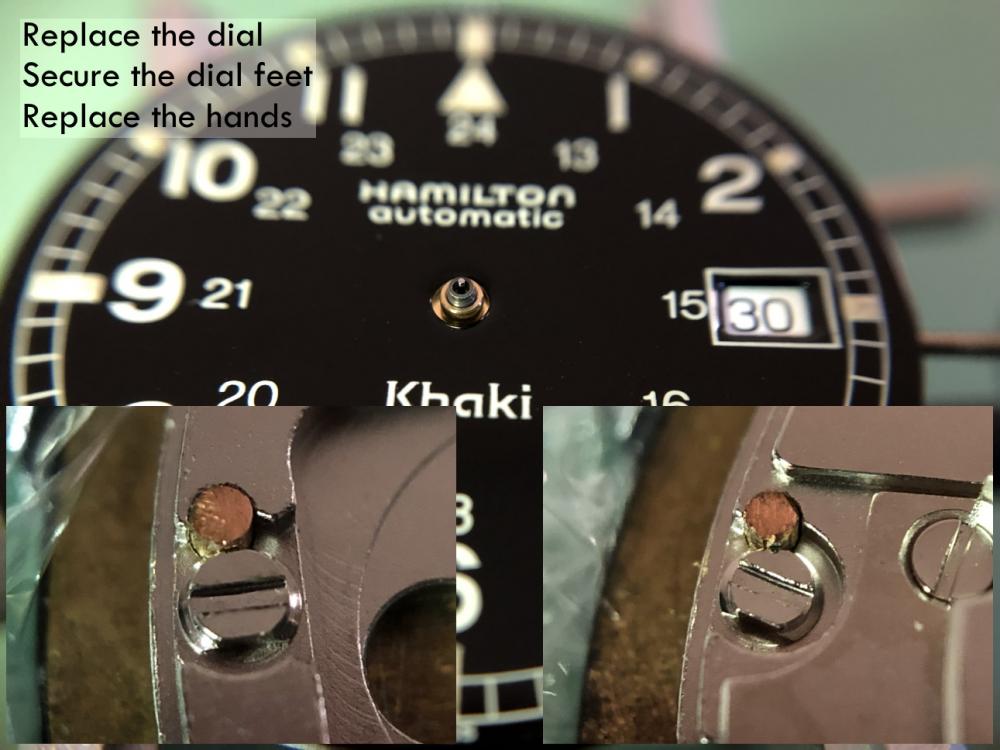

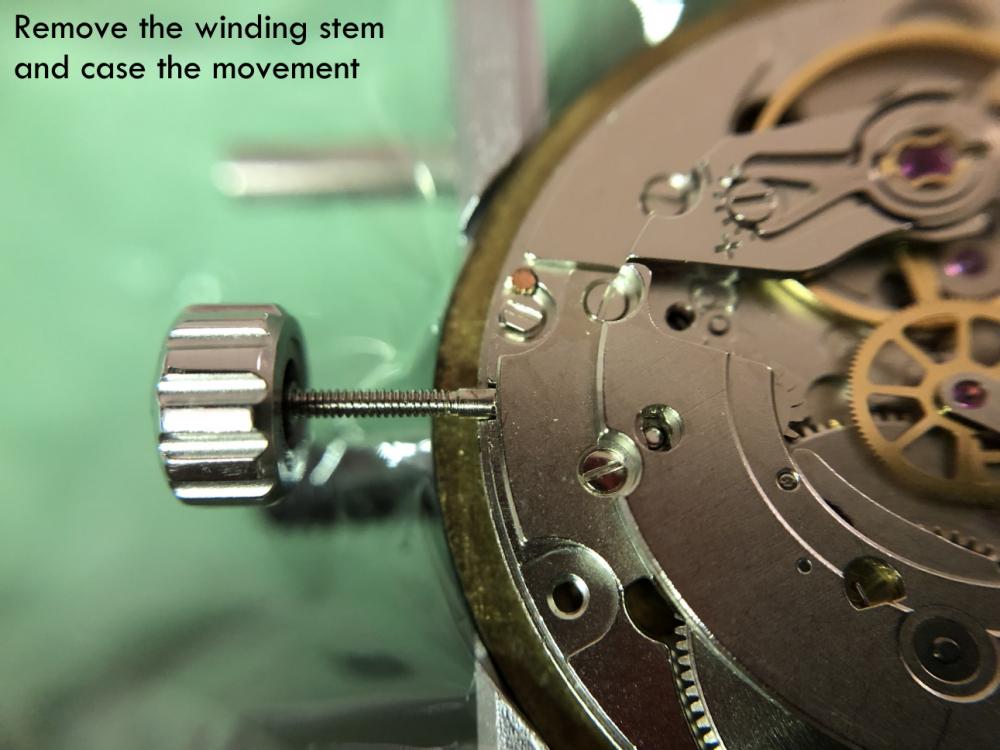

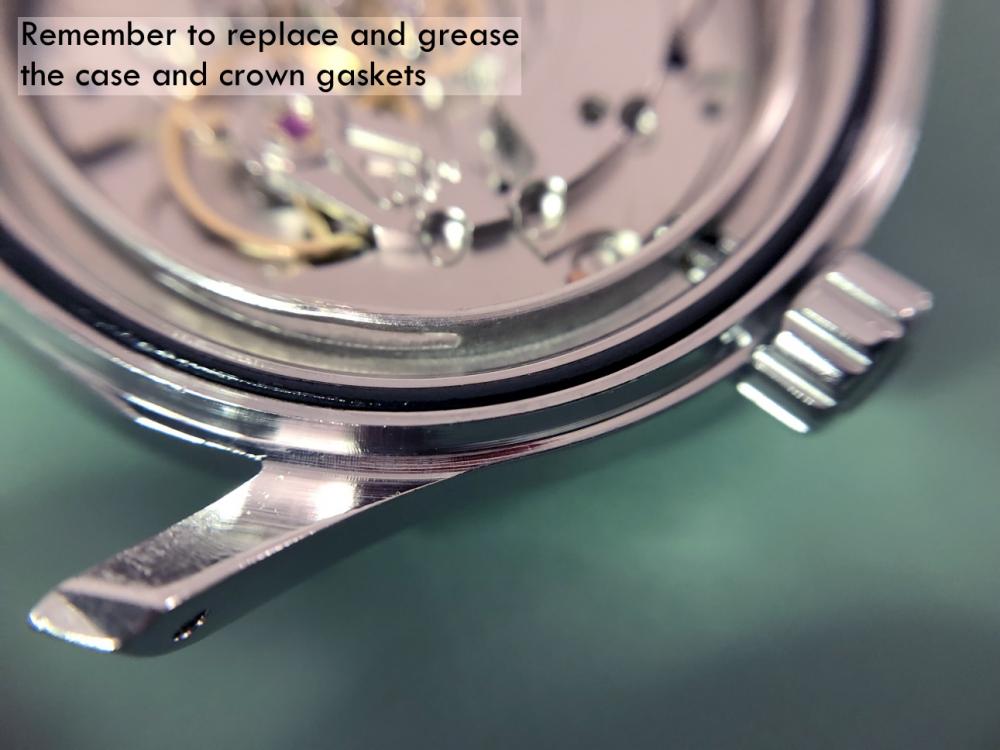

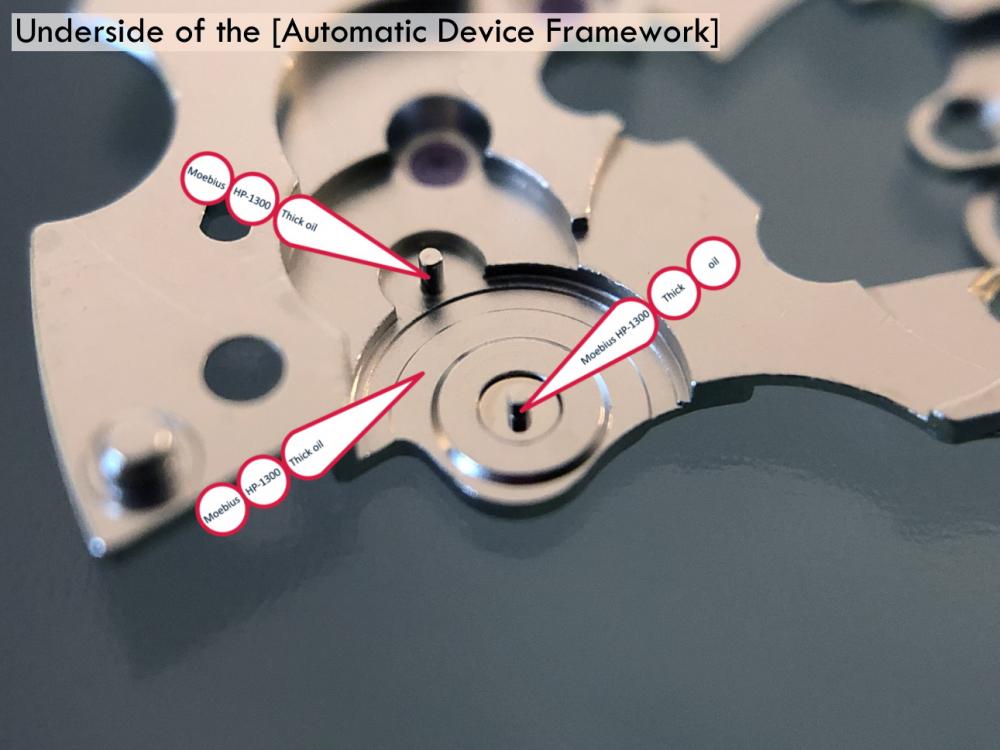

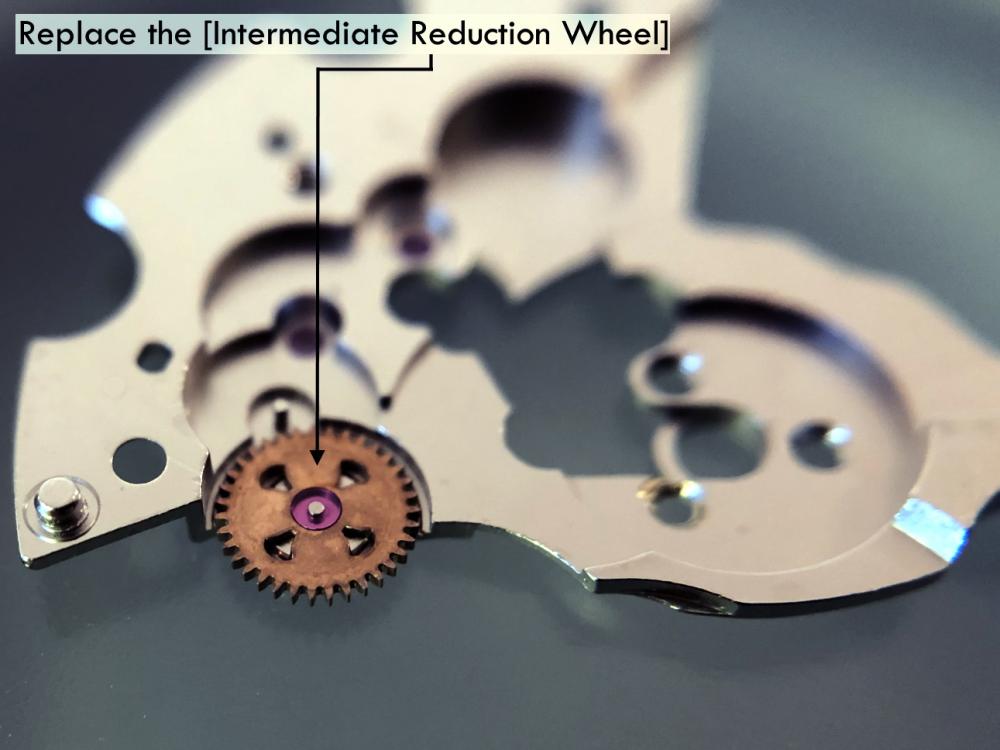

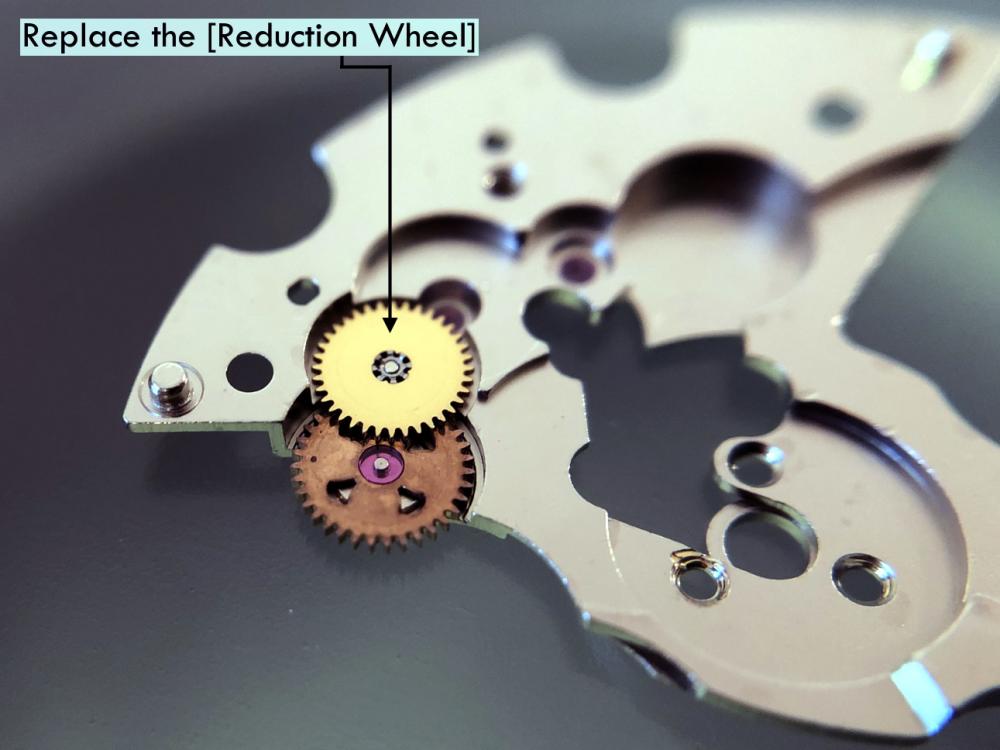

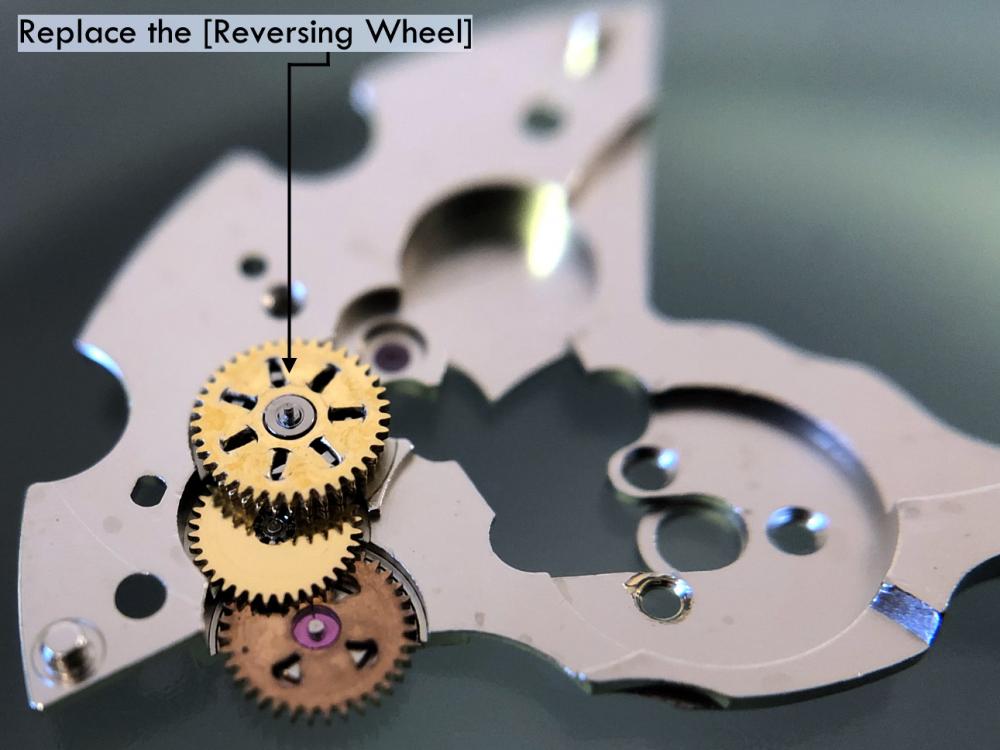

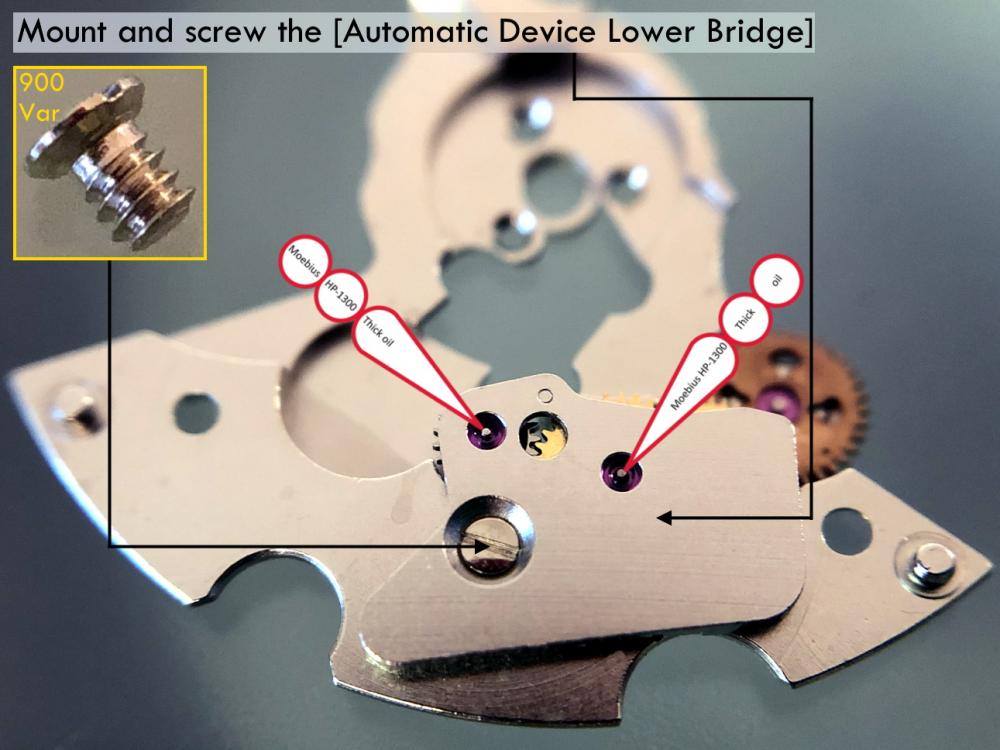

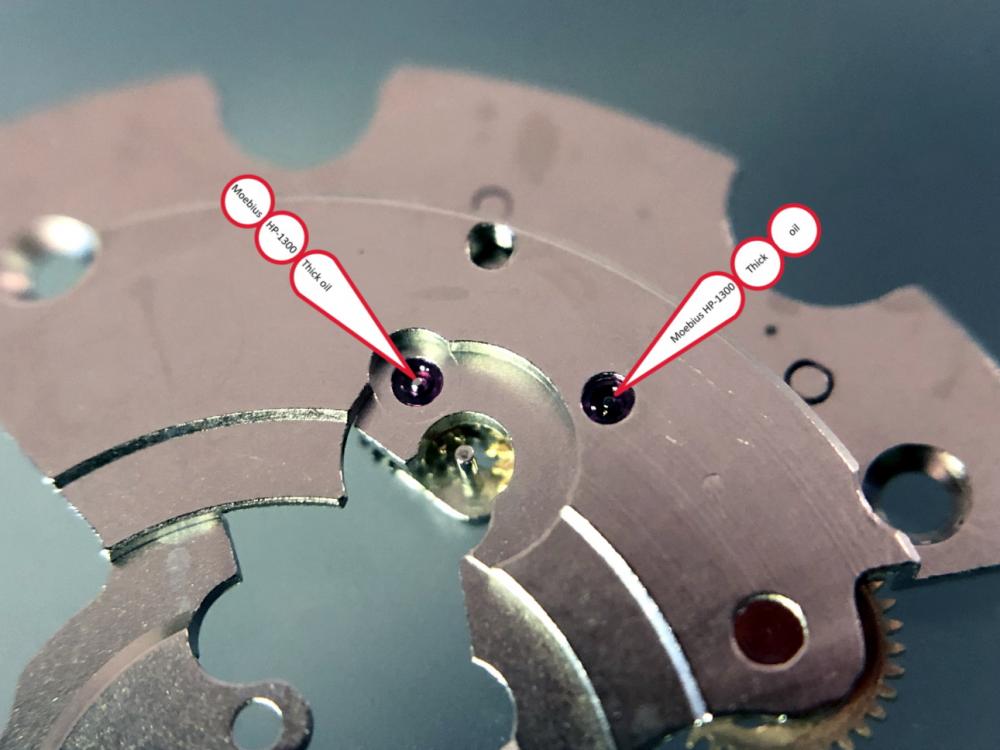

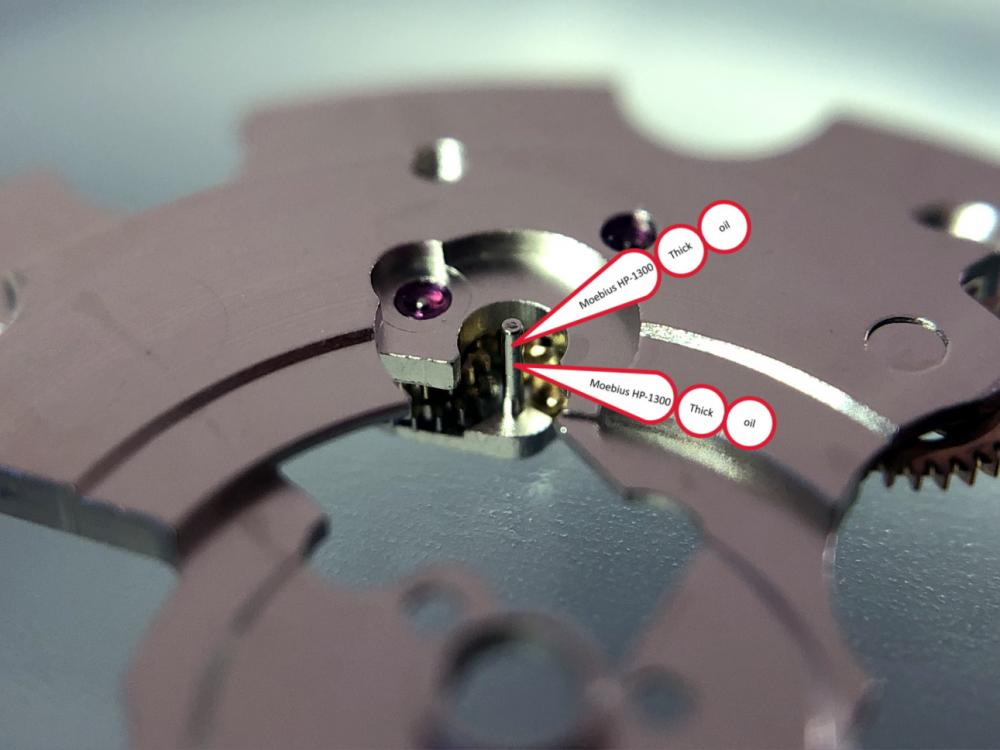

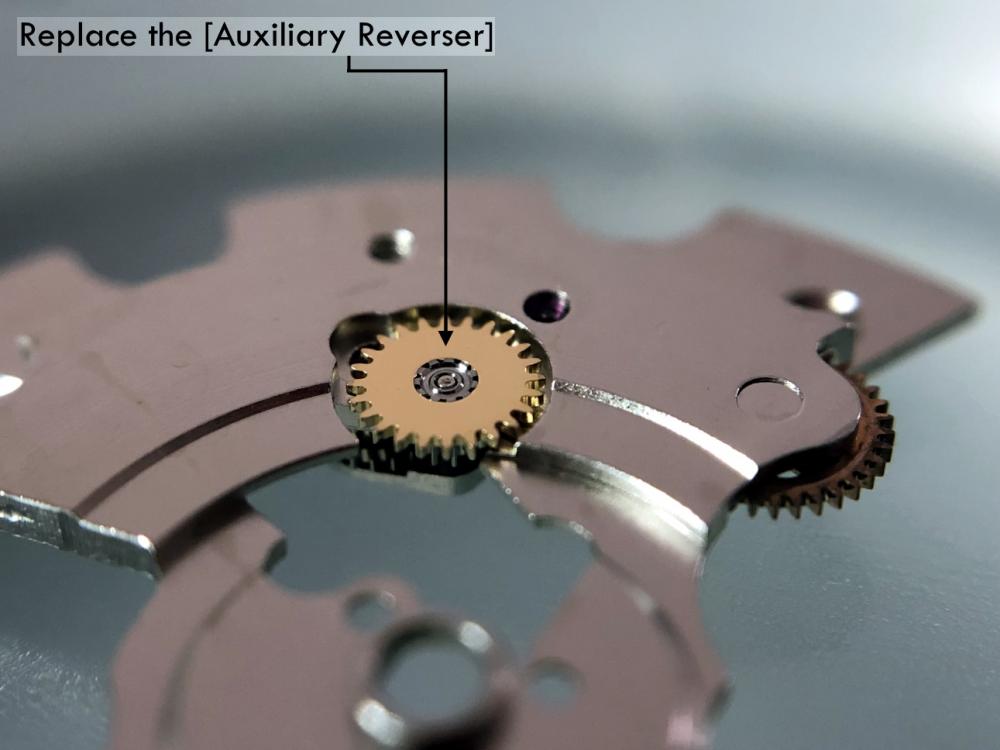

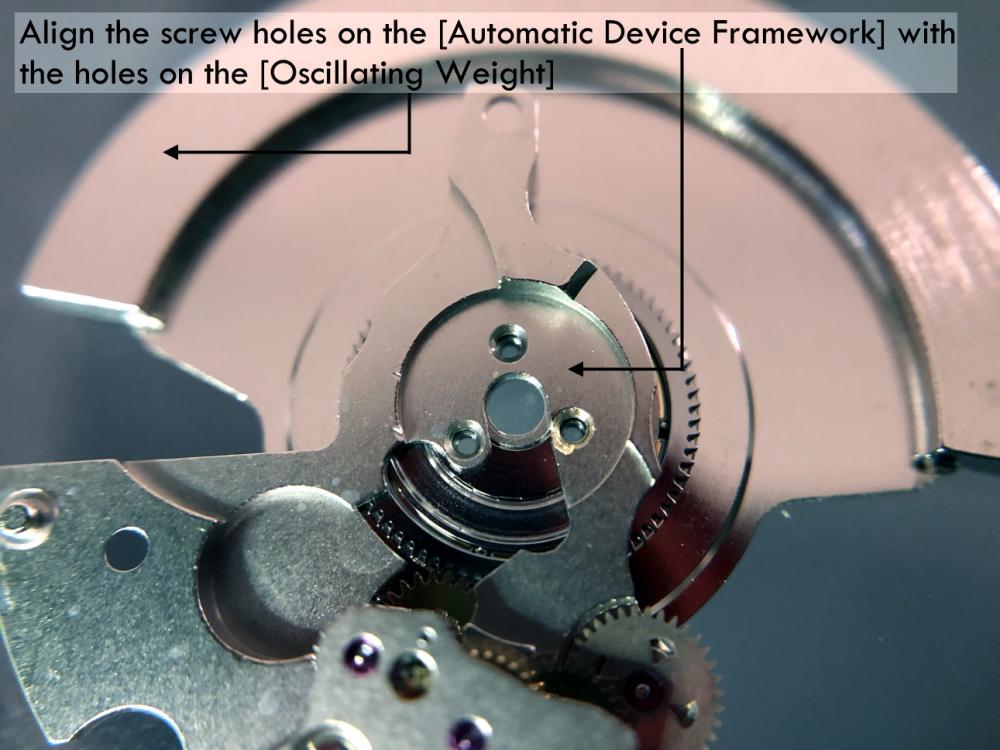

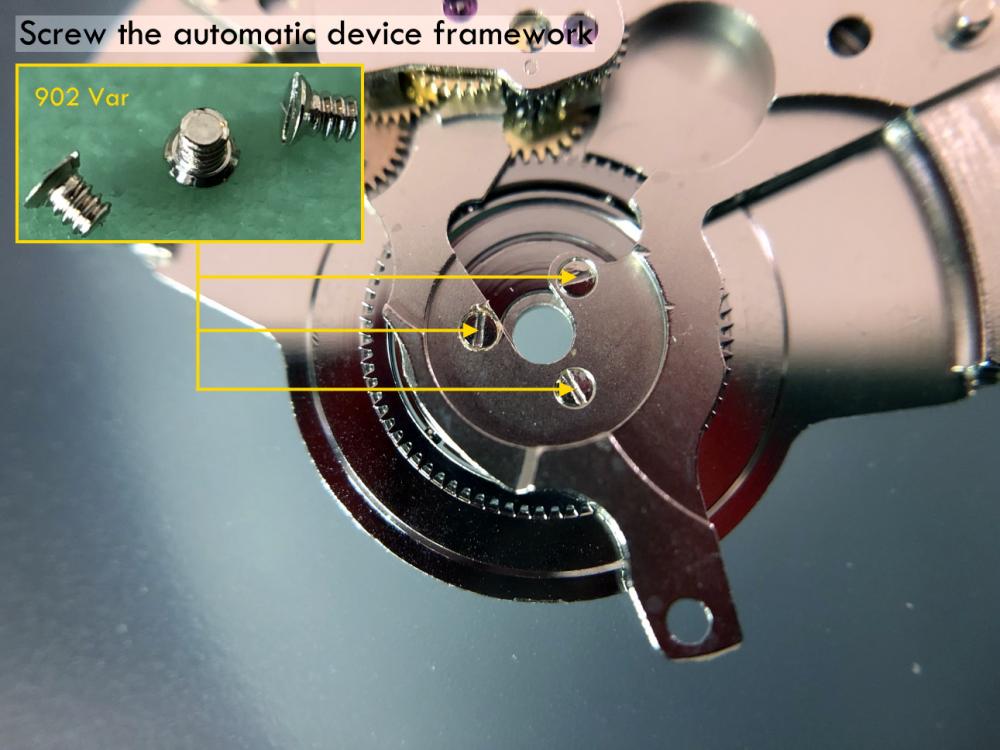

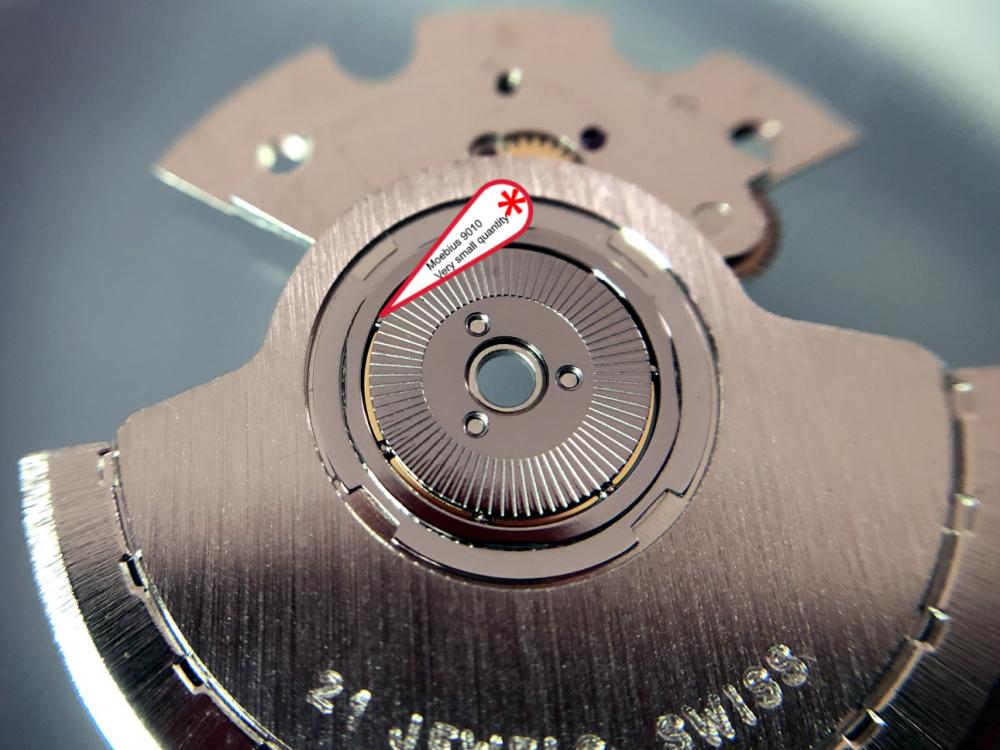

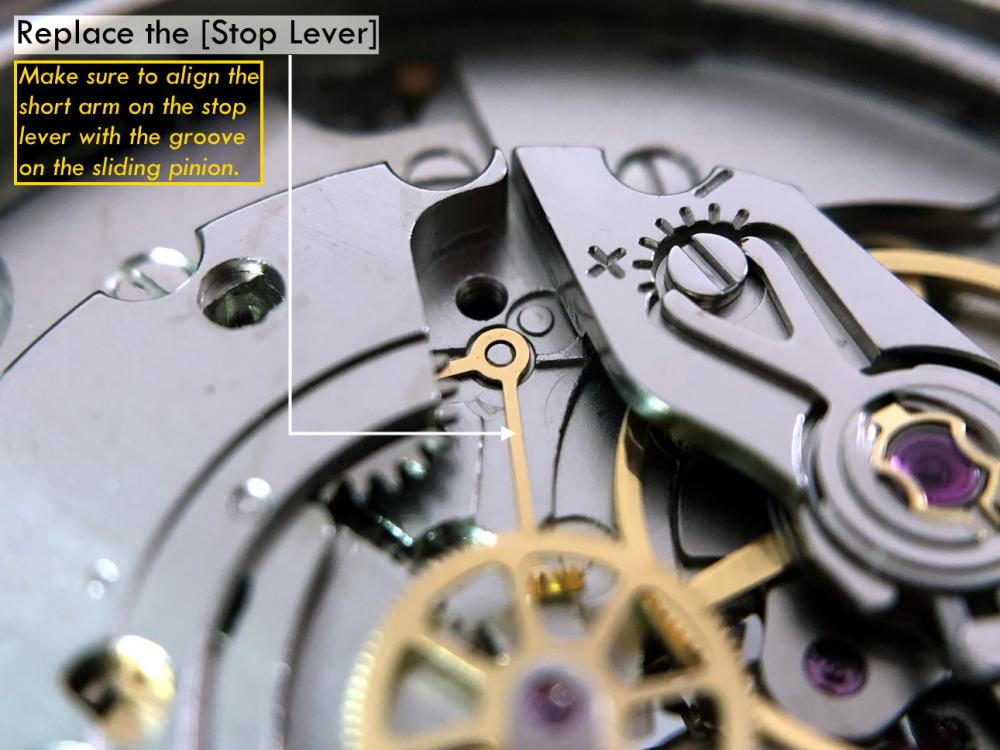

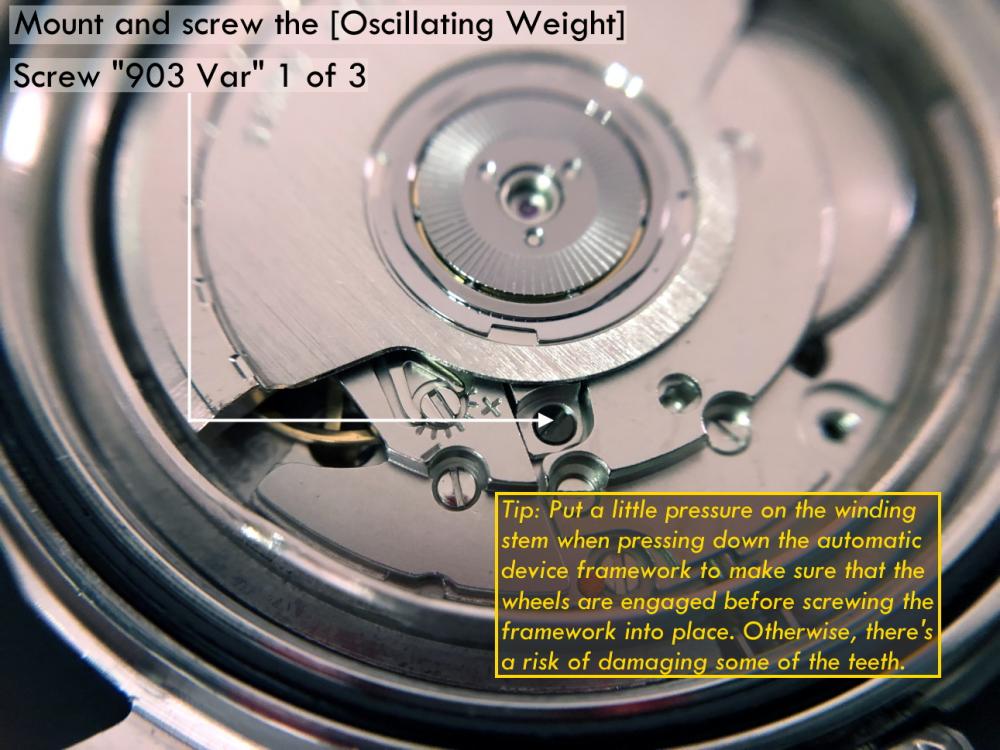

It is my impression that ETA's calibre 2892-A2 is usually found in more expensive watches and in luxury watches where oftentimes the movement has been modified. Mechanically, I don't think the 2892-A2 is superior to ETA’s classic 2824-2. Both movements have the same diameter (11 ½´´´ Ø 25.60 mm), the same frequency (28’800 A/h), and the same date complication. The decisive difference is the thickness where the 2892-A2 is one-millimetre thinner (3.6mm). That, combined with being a reliable and well-functioning movement, has made it popular for additional complications and alterations such as moon phase, power reserve display, co-axial escapement, chronograph modules from Dubois Depraz, and so on. The Swiss Sellita Calibre SW300-1 is, as far as I understand, an excellent clone of the 2892-A2. There is also a Chinese clone, the Seagull Calibre ST1812 (reviewed by @Markin the video “Chinese eta 2892-A2 Clone - Service and Review - Seagull ST1812”), and possibly others. Mark has made a playlist of videos that excellently demonstrate how to service the ETA 2892-A2 movement. The playlist is named: "Omega 2500 Co-Axial Stripdown and Service (ETA 2892-A2)" I recommend Mark’s playlist for several reasons. Among other things, he shows how to mount the barrel bridge safely and how to hold the minute train bridge with your tweezers to easily get it into place on the main plate (which I found a bit fiddly). In addition, he shows and compares the parts that are all too easy to mix up. One thing that is not shown in Mark's service video is that the Incabloc setting (chaton and cap jewel) for the balance and the main plate have different diameters. The main plate Incabloc setting diameter is smaller than that of the balance. The reason this is not shown in the video is probably that Mark removes, cleans, and lubricates the Incabloc settings one at a time after he reassembles the balance, so he wouldn’t notice. Anyway, don't mix up the two sets! Something that I appreciate about Mark's videos in general and that sets him apart from basically all other watch repairers on YouTube is that he doesn't continuously babble in his videos but mainly talks to make clarifications. I enjoy those segments of silence where I can just focus on the work being done. When I started my service, I decided to follow Mark's disassembly which worked perfectly. But for the assembly, I made up my mind to follow ETA's technical documentation to the letter. It turned out to be a mistake. In ETA's documentation, the assembly of the movement begins with the keyless works, then the train of wheels and then the barrel bridge. The crucial problem with this arrangement is that it is physically impossible to mount the barrel bridge if the train of wheels is already mounted. It is also very fiddly and difficult to baste the end of the winding stem into the winding pinion hole because the hole for the winding stem in the main plate is both open and tapered and therefore does not hold the winding stem. Mark takes a considerably more hands-on approach. He begins the assembly with the barrel bridge. He then mounts the keyless works whose constituent parts (the winding stem, the winding pinion, and the sliding pinion) are supported by the underside of the barrel bridge, making it considerably easier to get the keyless works in place. After I revised my strategy, this service walkthrough now follows Mark’s approach. It surprises me, but it seems like no watchmaker has proofread ETA's technical documentation. Alternatively, ETA follows an established practice and expects those using the documentation to understand that the assembly order in the document is not significant. I am also somewhat sceptical of ETA's recommendations regarding lubrication. Where we traditionally use grease, for example in the keyless works, ETA chooses mainly oil (HP-1300). I guess that ETA treats all parts of the movement with epilame (Fixodrop) and that oil may then be a better alternative. For better or for worse, my service walkthrough follows ETA's lubrication recommendations. As usual, I would like to remind those of you with no previous experience in watch servicing that this service walkthrough should not be seen as a tutorial on how to service a watch movement. A lot of tools, consumables, training and know-how are required to succeed. Fortunately, there are several excellent resources and watchmaking schools online. When looking through the pictures you’ll see that a few screws and plates are either marred or have pits and grooves in them. None of this is my doing but is either the result of rust (that I removed) or the doings of a less scrupulous repairer than myself. Finally, someone may ask, “Why to bother to do a service walkthrough with pictures when there is such an excellent video?" The main answer to the question is that I find it interesting and fun, and I see it as a complement to Mark's service video. Using this walkthrough, you can quickly scroll through the pictures to read what the different parts are called and where and in what order they should go, what the screws to be used look like, and to read ETA's lubrication recommendations. So, I hope you’ll find this ETA 2892-A2 service walkthrough useful, now or in the future. *** ETA Calibre 2892-A2 Disassembly *** ' *** ETA Calibre 2892-A2 Assembly ***6 points

-

2 points

-

Those look pretty good. I have some old Dumonts here, and really like Lindstrom (from your neck of the woods). But even good quality nail clippers can work, straight face is nicer than curved. I also like to grease the inside of the CP. I don't want the grease contaminating the oiling of the center wheel!2 points

-

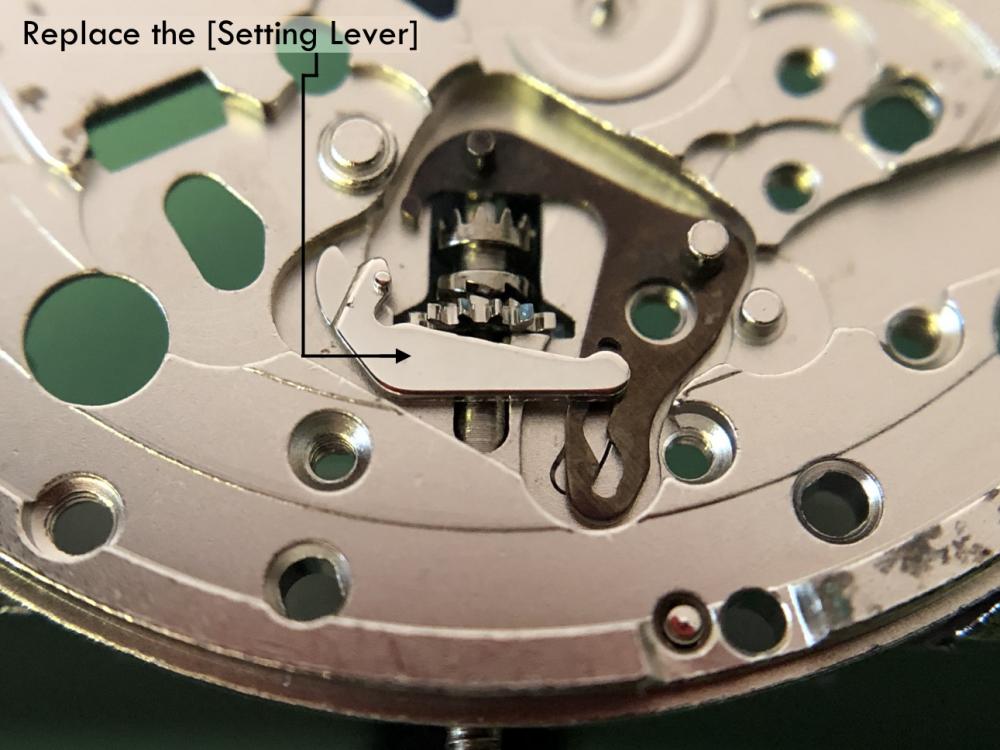

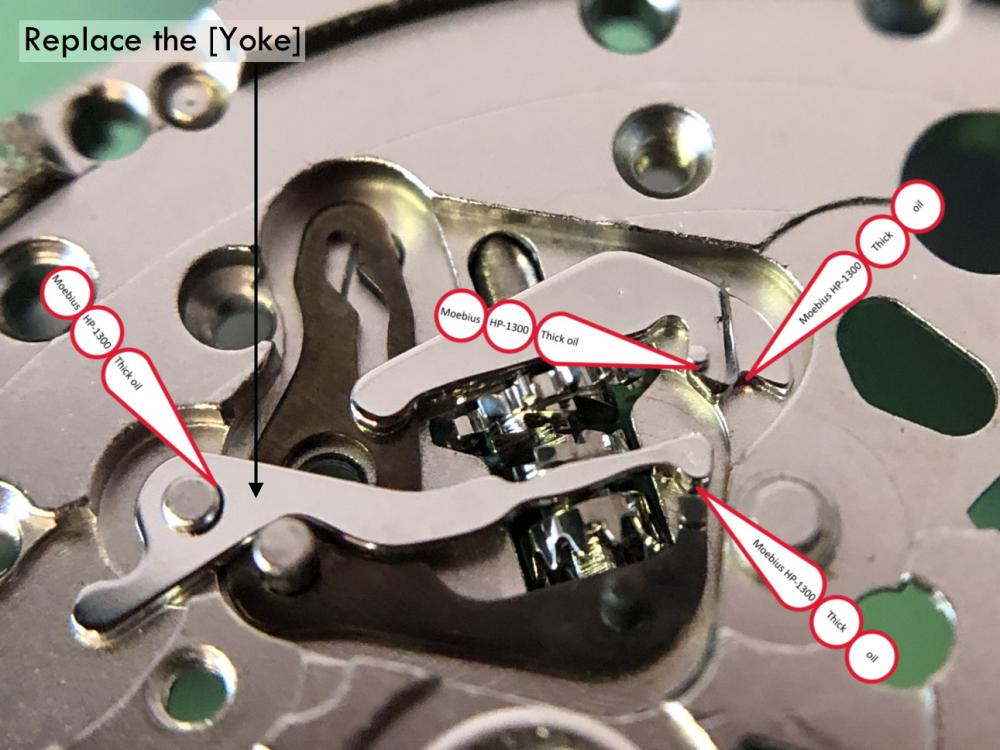

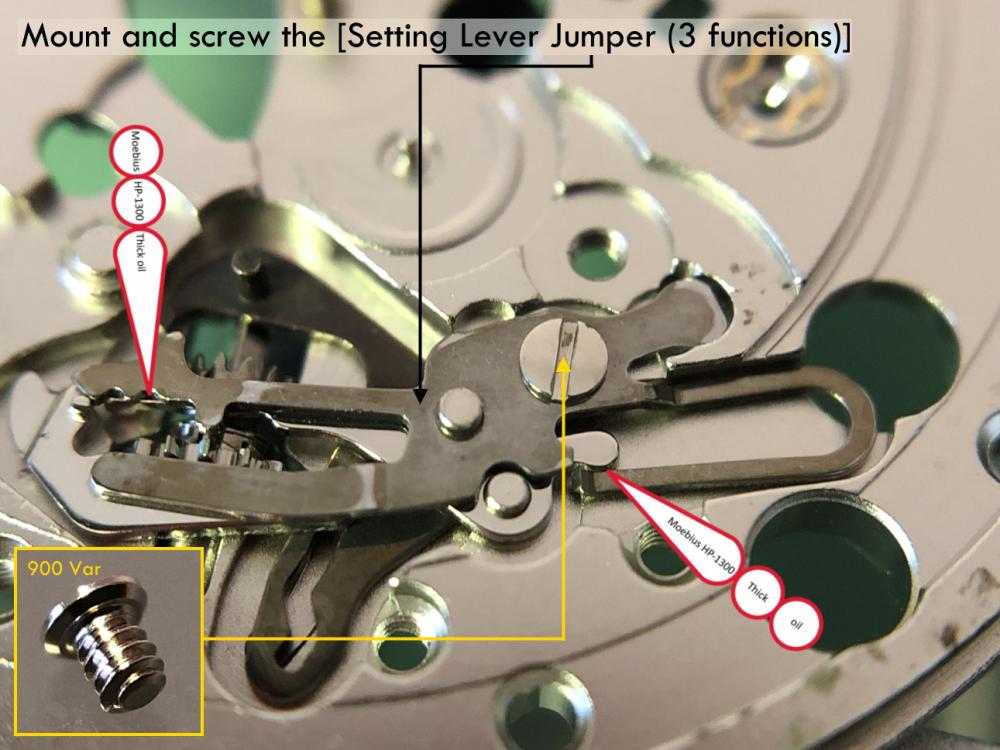

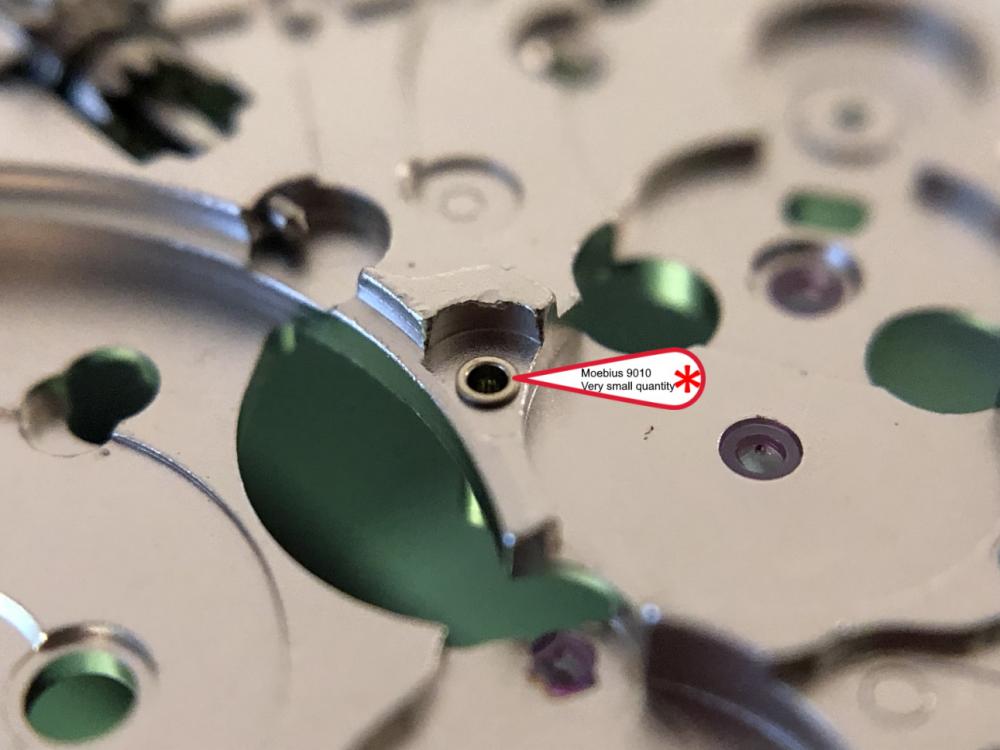

Second Seiko service! The keyless works were messed up. It showed up with a busted stem. The new stem would not insert, so I knew something was wrong. The setting lever jumper was bent upward and disengaged. Other than the dealing with diashock and kif, it was a pretty uneventful service of the movement. Well...it did take me close to an hour to service the mainspring. I realize now that I had the teeth on my winder closed too much, so as I got close to the end, it was binding. Lesson learned. I was having trouble getting the stem in. First time, I knocked the setting lever jumper off track. I took it off and did another bend' Had an issue with the casing but it was my own fault--not paying attention. Trimmed down the stem and installed a new crown. Seems to be working fine. This watch has been worked on before...perhaps several times. That second hand does not look genuine...maybe replaced during a previous service? Dunno.1 point

-

A close up vid of the oscilator when running be great, show the coil from top view looking streight down and a side view of the coil when running. Running this fast is somewhat unusual though, we,ll work with you every step of the way. Rgds1 point

-

I did my first Diashocktoday. Hmmm...not so much fun. Same watch used Kif trior...also not fun. I have done some MT Antichoc...really really not fun. I nominate the inventor of the incabloc for sainthood--yeah...Saint Incabloc From all these, MT Antichoc is at the top of my hate list.1 point

-

Very nice @VWatchie, thank you for documenting this. I'm in agreement with many of your points on the latest 2016 assembly sheet from ETA. First time I did one I also tried to follow it to the letter. I agree it's just dumb to fit the train before the barrel bridge. ETA even went so far to chamfer the end of the barrel bridge that you're supposed to finagle under the previously fitted train wheel. It's retarded. Also, using HP 1300 on the keyless works also leaves me baffled. I've serviced a lot of recent ETA movements (2005-2010) and there's heaps of oil around the keyless works (and I can confirm I've been the first in there). I understand that they want the winding action to be light and smooth but at the expense of flinging oil all over the show. And no, Epilame won't magically prevent oil from flinging off the clutch with enthusiastic winding. So I'm sticking to using grease in the keyless works. Another little gotcha is the orientation of the intermediate reduction wheel on the automatic bridge. It's pretty easy to put it upside down and for the keyless works to lock up once the automatic bridge is fastened. And then some idiot goes and forces the winding works, breaking the ratchet wheel. Not my finest moment. I also note that both ETA and Sellita insist on replacing reverser wheels during service (correction, if you were to wash them, you should replace them). These are still perfectly functioning parts and at 16GBP each they start adding up. So I do wash them but leave them in Lubeta V105 for a bit and re-use them. If they're physically worn then I'll replace them, but this is only an issue on older movements from the 90's that have really worked hard. What I do end up replacing frequently are the rotor bearings as these work pretty hard trying to keep a heavy rotor in place - that slight bit of 9010 you lubricate the balls with evaporates between services (we all know how thin 9010 is)1 point

-

Well done in getting it apart. What you mentioned is quite common.1 point

-

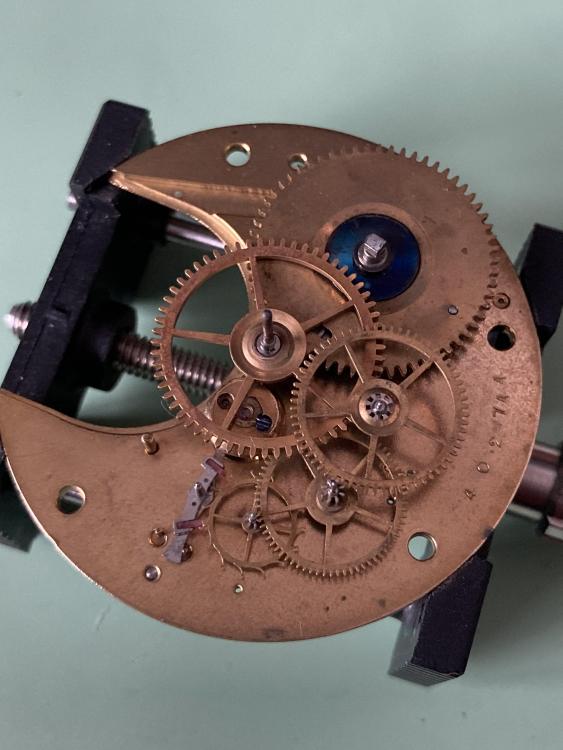

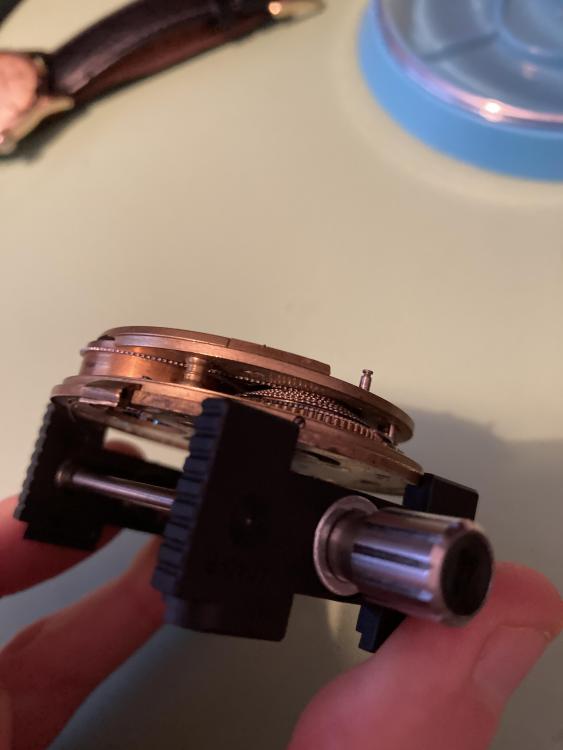

So, I took the movement apart over the weekend and it is indeed an unusual fusee, showing some Swiss influences in the design of the escapement (there are even pallet inspection holes in the pillar plate). Note the channel cut into the back plate to allow the fusee chain to pass through. To my eyes, it was an attempt to make fusee watches (to meet whatever demand remained at the time) using machinery and to make the construction as straightforward as possible. The style of movement looks like an Erhardt (Birmingham) or Lancashire Watch Co. I doubt many were made!1 point

-

I believe this is true for the 2892-A2 as well. Yes, Googling I found this: "The ETA 2892. A2 exhibits three grades: Elaborated, Top and Chronometer".1 point

-

I use the "pointy thing" in the staking set, which is used to align the holes. It has a nice sharp tip. I put a bit of brass, or a broach in the pinion to prevent crushing, then a very light tap with the hammer1 point

-

That does work, ive tried it and tested the cannon pinion's position on a smoothing broach. A before and after with and without an insert in the cannon pinion. Without an insert it tends to crush the tube, with an insert the indent is more localised to one small area. I do have a specific tool that has an anvil to tap into the cannon pinion which does a better job.1 point

-

I did make the mistake once of increasing the friction to much with a cannon pinion.. Lesson learnt never adjust the friction of a cannon pinion without total control. I now use my sietz jeweling tool that has a stump specifically for this task. There are other tools such as the Bergeon 4733. To reduce the friction a small smoothing broach would be the best way.1 point

-

Thank you so much gbyleveldt for your advice and information. I checked from Cousins, the ID2.2mm one says for Crown 5.5mm which I think may not be right for crown 5.25mm. I think I will go for C8623 although its 6.9mm long which is for screw down crown as per Cousins. Thanks you.1 point

-

I'm checking on an SEL I have stripped here. The crown is 5.25 mm with what looks like either a 2.1 or 2.2 threaded inner tube, Cousins part number looks like C8612 For the tube, It's 2.6 OD and 7mm long. I can't be sure if it's ID is 2.1 or 2.2mm as that's the threaded part. I'm leaning towards 2.1mm so Cousins part number should be C8623. I would suggest you buy a 2.1 and 2.2 ID tube to be safe.1 point

-

Most people on this forum are far more qualified than I am, but if I were to hazard a guess, I'd think there is something off in your automatic winding works. Something in there is not working correctly, and holding your ratchet wheel in place, not allowing it to move. You have one of the wheels off in some sort, or bent teeth, etc., thus not allowing free movement between the parts. Something in the automatic works is off.1 point

-

Yeah, but this on is a keeper. I'll put a good strap on it. I actually have a few watches with those inexpensive Cousins straps that I wear regularly. I really don't mind them at all.1 point

-

Could be that the back doesn't belong and someone just glued it. Have you tried heat, if you have a soldering gun.1 point

-

I've given this some thought today, and I believe it's more to do with the extra overall height you would need. To cover the open end of the cannon pinion, the minute hand would need a collar or tube on the underside, with a thickness of at least that of the hand itself. The space between the hour and minute hands would increase accordingly.1 point

-

A WRT member posted picture of one he made, Inspired by Bergeon tool 4733. Rgds1 point

-

Some cheaper old watches have garnet pallet jewels. Garnet sits between 6.5 and 7.5 on the Mohs scale, where ruby is 9 (diamond is 10). I wonder if that's what you have there? Ruby pallet stones can wear, but you don't see it that often. Garnet is way more "crumbly" too. When pushing in pallet stones brass or nickel tweezers are good, and I usually do the final pushing with pegwood. It's very easy to chip them. When adjusting, to come out I use a broken oiler with the tip stoned to a screwdriver shape, get in the back of the slot and twist (on a heater). To go in it's pegwood.1 point

-

I think someone mentioned using nail clippers1 point

-

Just to make sure. As far as I can reason, the only time it makes sense to test the cannon pinion friction is after service. In my experience, friction usually diminishes after service. That is when the cannon pinion has been thoroughly cleaned and lubricated. BTW, I always lubricate the inside of the cannon pinion rather than the centre wheel arbor. It feels like it eliminates some of the risks of getting the grease where it's not supposed to be. It feels sort of embarrassing having to ask, but what does "a pair of fine cutting pliers" look like? Perhaps something like the picture above (link in the picture)? Any specific recommendations or advice?1 point

-

Hello again to all at the forum. It has been almost 12 months since I started. Never having looked at a watch apart from telling the time on my wrist. Where am I? Well, I now consider myself a fully fledge watch hobbyist. I now partially emulate many of those illustrious YouTube personalities who restore watches. I can remove a movement form a case, disassemble a movement. Clean the components using peg wood and liquid, lighter fluid and IPA. I can even remove and clean jewels. Clean and replace mainsprings. Not yet able to repair balance hairsprings, But I am working on it. Microscope for Christmas from my bride. Can't wait for the 25th. All this I can do without leaving a scratch on the surface. Hardly a 'ping' in evidence either. Case repair. Unfortunately, not for me. Just a general clean using and ultrasonic machine. I've limited myself to a few movements. ETA 2789 and 2789-1. Seiko, 6309, 6319, 7009 and 7S26. Citizen Miyota 8200a and my favourite Sekonda 2428 and 2427. All of which I can disassemble and assemble with ease. Happy Bunny. I still have year to go before I attempt my own lifetime watch. A Breitling Top Time, with a Valjoux 7730. A special thank you to all you members who have encourage me during this time in our world's dark history. I have learned from you all. Perserverance and practice. YouTube has been a great help. Initially it was hard, not really understanding much. Mark's course was a great. Learned so much and still learning. Other's now help as much as I can assimilate to a higher degree. My bride has just called to coffee. So, tools way. Regards Ross1 point

-

A canon pinion that can be installed on the watch is likely not to be overly tight or it wouldn't have got on the center arbour. I add a bit of oil ( not grease) and turn the minute wheel with the crown, it often turns which indicates its not overly tight , keep turning to reduce friction. you then remove clean the parts involved, grease and instal. Try it, you have more success than you think. I haven't tried this on watches with chrono complication, too sensative to extra friction I imagine. Rgds Though I haven' 't studied Arabic, I think I understand some of OP's words. کیف how یمکن possible المدفع tube لتقلیل reduce الاحتکاک friction Not bad ha.1 point

-

Anything with an ETA 2824 - they're still being made by the millions and you can actually buy parts for it. In fact, in some cases, parts for Sellita SW200's will also work in it, plus it's cheaper. They're actually simpler to work on than the 7S26's you've been messing with.1 point

-

I would remove the balance and put it to one side, no point in damaging it. Remove the Geneva stop-work. I expect you will need to put the movement back in its case for the winding to work. You will most likely need to loosen the screw that hols the click just a tiny bit, when you wind hold on to the button you need to let it slip a little when you move the click away from the wheel letting it down until all the power is off. What ever you do you must never twist the chain. If you need help in how to put it all back just ask these watches with a fusee can be little buggers if its your first one. No name listed in any of my books. I would say middle to late 19001 point

-

Certainly! It’s a large movement, and the rather dull plating and basic decoration on the balance cock makes me think this dates from the 1890s to 1914 when these would have seemed a bit old-hat. So, the cynic in me thinks the stopwork was perhaps less costly to make and more reliable than the traditional stop-iron and spring. That said, there is always something new to learn about these watches.1 point

-

first step in timing machine interpretation troubleshooting is to troubleshoot the timing machine. The most important aspect of whatever you using whether it's an actual timing machine like the Chinese 1000 or the 1900 or in this case a software for the PC or a phone App the absolute most important thing is that you get a good clean signal. While the ticking sound of a watch is an audio frequency range the timing machines themselves the pickup is actually picking up the vibration of the ticking not the audio. Most things that are not timing machines have microphones that pick up audio sounds that are not actually designed for timing machine use. So whatever you use has to pick up the signal correctly or we will have a problem. then yes you really do have to understand all of this if you would like to interpret the results of your timing whatever. Because until we get a timing machine with artificial intelligence that will just tell you what the problem is you do have to understand. Otherwise as I said you will have a problem and I will explain farther down what the problem is. then we have a really nice video wasn't specifically designed for the purpose that I like the use it for it was designed this show us how wonderful their new escapement is but in order to show you how wonderful it is they have to show you the lever escapement which works beautiful for us. then the video shows everything is being absolutely perfect which works well for learning point of view unfortunately a real life the waveform isn't always as perfect as this but it is really nice for training purposes. So skip ahead to about one minute and two seconds we get to the lever escapement . You can see is the balance wheel is rotating the roller jewel is crashing into the fork and generates sound number one. the absolutely most quiet sound of the ticking and its key to everything if your timing whatever is going to work. then for the middle signals number two and three no notice they overlap to certain degree. Then in most drawings of the escapement oscilloscope they will overlap these to one signal so typically LC three signals one reality we notice five because the overlap. now we get to the next most important to locking sound which is number four finally crashing into the banking pin. These two of course overlap to certain degree. ideally should watch the video more than once there might be a test later on. https://youtu.be/g5c5RK4WFV8 then I've attached a whole bunch a images and a PDF while we continue our education into interpreting timing machine results. from the witschi PDF two separate images where of course the waveforms are consolidated to three each rather than five and they show the importance of two of them. The roller jewel sound is number one key to everything. Then if you want have amplitude you need the fourth sound and you can measure amplitude looks pretty simple. the notice in all of this so far we've been using the oscilloscope to look at things and unfortunately on most timing machines you don't get around oscilloscope. Although on most timing machines you don't typically need on oscilloscope because typically they pick up the signals correctly and typically will show you the correct results. Fortunately on our application for the PC in this discussion it has an oscilloscope and let's see what we can learn from that first I went online and found another image somebody else's and notice on the oscilloscope I circled it looks pretty darn perfect. We see three clear signals and nothing in between absolute quietness. This is ideally what were looking for. now we can see aware having our oscilloscope for your timing machine is really important let's snipped out an image for up above and compare with everything we've learned. We know that ideally background noise should be nonexistent and we see a lot of background noise if that is of high enough level the timing software might think it's a valid signal or? In other words it might interpret it as a problem in the watch something making noise that shouldn't be making noise and of course it could show up as random dots on the screen. Then the number one key signal doesn't appear to be super clear to me if it's not clear to software then your rate is going to be all over the place especially if it varies a little each time in other words you can't consistently trigger off something that it has to trigger off of. Of course if the rate is wrong because it doesn't get a nice signal amplitude will be wrong and basically everything will be wrong all because of a signal that's not quite correct then mentioned there was a problem of what if we do not get a clean signal? It may be we don't get a clean signal because the watch is having issues and running really poorly or we may not get a good clean signal if you're just not picking up the ticking sound correctly. The problem becomes where is the problem is if the inability to pick up the signal correctly or is the watch itself having a problem. We've done this a couple of times with people with phone apps where the problem was really in the app and the microphone that wasn't designed to pick up ticking of watch sounds. As the image I found online shows the software can work it just has to have a proper pickup that gets the correct signals otherwise we can end up with a situation like this of is that the watch having a problem or is it the software having a problem? Witschi Training Course.pdf1 point