Leaderboard

Popular Content

Showing content with the highest reputation on 11/29/22 in all areas

-

I was cleaning a watch today. Had already done the clean stage and had started the rinse...bam! The motor quit. So, for the next two hours, I was refurbishing this motor. It had been hacked by earlier watchmakers...found a lousy solder joint that finally said "No more." I took the opportunity to do a thorough cleaning and rewiring. Working now. I have another L&R that has a motor problem...similar motor...so this was a good trial run to fixing it.2 points

-

Yeah, people begged to not jump into the deep end with 7s26 as my first watch but i'm glad i did even though it was torture at times. ANd this is smooth sailing for sure. Not sure if you saw but this is actually my second 7s26. I just finished my first ever repair and service the other day and it came out amazing! Here's teh before and after pic. ANd that's rough about your project watch. I got a BEAUTIFUL vintage seiko 7006 just in gorgeous condition, i haven't opened it up yet but it doesn't run and i'm praying the inside doesn't show any surprises. I did pick up a donor movement in advance that barely runs but that will be my first true project watch.2 points

-

2 points

-

2 points

-

Eyup forum members, i hope you are all in good health. A bit of a random/unusual question here ( of course what else can you expect ? ) Just a thought I've had, maybe something, maybe nothing, maybe stupid. But if i dont ask i won't know. Probably directed towards good case restorers. Gold case back engraving, the retirement watch sort of thing. There are plenty of nice gold watches out there but many have back engraving some with quite deep inscriptions. These tend to be cheaper than a non marked back. Seems a shame to lose that history but not all of us want to know what year Bernard Cratchet retired from East Scunthorpe sewerage works and that his colleagues will sorely miss his rendition of Dan Dan the lavatory man. So my question is this- can the engraving be filled and buffed, rather than just ground and polished as some engraving can mean losing quite a lot of material to remove it. If anyone has tried this can the inscription still be visible through the gold fill ? Thanks in advance peoples.1 point

-

If the filling is done correctly you shouldn't be able to see what it previously looked like. It will be expensive so you need to ask yourself is it worth it. My own feelings is it is part of its history and should be left.1 point

-

Hi, Many thanks for letting me join. I’ve only recently started getting into horology as a serious hobby- I was given a copy of George Daniels’ grand tome (Watchmaking) last Christmas- then decided understanding the workings of a watch was more interesting than just owning it. Having spent months learning, via books, the BHI course and Mark’s online lessons, then practising, succeeding (and failing!) I hope I’m now in a position to be able to contribute something to the forum. And plus, every day is a school day… Bill1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

I just opened up the other non-functioning motor. Other than the fact that the brush mount was broken, the motor works. Most likely, I can 3D print another mount. But the wiring must be replaced. These old motors are very robust, but wiring in the 50s was not durable. Insulation cracks and crumbles.1 point

-

I tell my friends and neighbors: "I can fix it if you can break it." However, I have thrown in the towel a few times!1 point

-

Been a while since i welcomed anyone, so here i am, and there you are Bill "welcome". Congratulations mate, a great hobby to have, both very rewarding and frustrating often within minutes of each other. Any help you require, your first port of call is to identify the movement to let everyone know what you/we are dealing with. Secondly some good clear detailed photos so everyone can SEE what you/we are dealing with. By now you will have some fair knowledge as to what to look for and where to look when ID ing the movement, a movement size is helpful also when searching through the bestfit books to match up the keyless works of a known maker. Pickies of timegrapher traces and readings come in very handy when fault finding, so if you have one then the up/down readings for a start and the verticals are great especially for the pros that are at diagnostics. Enjoy the experience and massive learning curve that is coming your way . Rich.1 point

-

Lovely work - well done. That's a rare watch and well worth saving. Lost part eh ? ... A watchmaker is the only race on earth who spends more time on their knees than a devout muslin.... As far as I know Favre never manufactured in Asia - didn't they all come from the Swiss factory ?1 point

-

that must be those new invisible replacement parts that are going around. I just cant see how they can work myself. "Who dares, wins Rodney" Cushty sunshine1 point

-

I couldn't see anything wrong in your videos - it all looks to be working OK Were you just mis-understanding how the cannon pinion works ? Without the pallet fork in, there is enough friction between the cannon pinion and hour wheel to turn the whole gear train. With the fork in, the gear train is effectively locked, and the cannon pinion should slip on the hour wheel to allow hand setting.1 point

-

1 point

-

Hello Bill and welcome to the forum, you will never stop learning with Horology its an on going process. Thats why we do it.1 point

-

Yeah you're both right. I didn't know there was that much friction between them! Certainly not enough to drive the entire power train. that was a rookie mistake because i wasn't really sure how the cannon pinion actually interacted with the center wheel. So it looks like my instinct was correct. My center wheel post was slightly bent causing the binding on the cannon pinion that was so bad it would have broken my pallet fork if i had forced it. Swapped it out with a new cannon pinion and center wheel and installed the pallet fork and everytrhing is working as expected.1 point

-

Perhaps I'm missing something, but you are just trying to use the time setting function right? If so, you need to get your pallet fork in place to stop the wheel train from free spinning. In the first video of the two you just posted it is not installed. The wheels will spin if the pallet fork is not installed. Secondly, on the dial side, I'd suggest at least installing the date jumper/cover plate that acts as the cover for the minute wheel. You just want to make sure it isn't riding upwards while your turning the crown, and not engaging with the cannon pinion. Since you've swapped out the center wheel and cannon pinion multiple times already. Can you just just take the watch at the state it is in from the first video, install the pallet fork & bridge on the rear side, and screw down the date jumper/cover plate on the dial side, then give it a test. Make sure you lubricate the center wheel before installing your cannon pinion. I like to use a grease, but I believe Seiko calls for an oil. There's only so many things it can be, and it sure looks to me that the lack of the pallet fork installed in the first video is the culprit.1 point

-

Hello Bill and welcome. Looking forward to your contribution and yes, you will learn a lot from this forum.1 point

-

Now that I have the jewel issue sorted out, I'm having a new problem. I figured it'd make sense to keep the question in this thread instead of starting a new one in the repair forum. Hope that's okay. This is my first time working on a day/date mechanism, so please feel free to correct any of my assumptions here. So there's a jumper gear at the red arrow here: When the stem is pulled out to the center position, it moves left or right depending on how you turn the stem, presumably to set the date in one direction and the day in the other. When the stem is in the winding or hand setting positions, it's held to the right so it doesn't engage with that brass wheel. The problem is that jumper gear is extremely difficult to turn. Without that plate installed, the train runs free and there's power at the pallet fork. When I install that plate, the the train doesn't run at all. The pallet fork just hangs free between the escape wheel teeth. The part I'm confused by is how did it run before? Is there something about the day/date mechanism that I'm missing here? As far as I can tell, that jumper gear isn't removable, so I'm not sure how I would fix it, either. I feel like I'm missing some bit of knowledge here, and I'm hopeful this board has it. EDIT: Well friends, turns out today I am a ding-dong, but I'll leave all this here for anyone in the future. In the end, I was able to problem solve my way to the answer, so I guess it's not so bad. This small gear is upside down. The long part of its arbor interfaces with the nose of the stem, which lifts the gear up off the center one that's connected to the 3rd wheel. Flipping it over fixed the problem. The gear I was originally talking about is still stiff to turn, but it's only used when setting the calendar works, so I'm guessing it's supposed to be that way.1 point

-

Its a Timex. Apparently the prescribed method of cleaning them is to drop them into some lighter fluid. I kid you not. Furthermore it works. Slightly alarmingly the mechanism actually keeps on ticking even when its in the lighter fluid. I'm sure all of this would give the modern health and safety gnomes a fit of the vapours. This one needed a couple of prolonged dunks, to remove all of the dried up oil and bring it back to life, followed by some fresh lubrication. This particular model is actually a front loader, so removing and refitting the crystal is the only way to get the mechanism out. Both processes are somewhat stressful as the scope for damaging things is pretty high, however it survived and is now ticking away nicely. I'll revisit it some time tomorrow to regulate it once all of those replacement hydrocarbons have settled down.1 point

-

Well I guess if quartz isn't your thing, then maybe a little bit of a Timex treat will brighten up your day. A 1977 Timex Marlin (26160 02477) joins the club following a couple of hydrocarbon baths and a lot of scrubbing and polishing. I also recently picked up a job lot of of NOS 1970s watch bands. Some were perhaps beyond saving, but there were a couple of denim straps that really ooze that 1970 vibe, so what better paring can you think of.1 point

-

Wow, thanks a lot! This Dutch website is perfect for me, because I won't have to pay extra import taxes. And 34.50 Eur for 4 movements sounds pretty reasonable1 point

-

For hole jewels, there are ones with straight sided holes and ones with olive holes as you have seen. Olive holes have curved hole walls, straight are self explanatory. Olive hole jewels reduce contact area and thus friction, and are generally used in areas that are most sensitive, like balance/ fork/ escape wheel. They also generally (not always) have a convex face opposite the oil sink. The convex face further reduces friction when used with a shouldered pivot, and when used with a cap jewel (oil sink facing the arbor/staff) promotes capillary attraction of the oil between the jewel face and the cap jewel. Many old high grade watches have convex faces on all the jewels. Some may also have olive hole jewels up to the escape wheel or further. If replacing a jewel, certainly go for olive hole with convex face for a balance, and it's a better choice for other places if the size is available.1 point

-

Hi I have seen his site, pretty useful there is also welwynwatchparts.co.uk who are of the same ilk selling second user parts, worth a look for the future.1 point

-

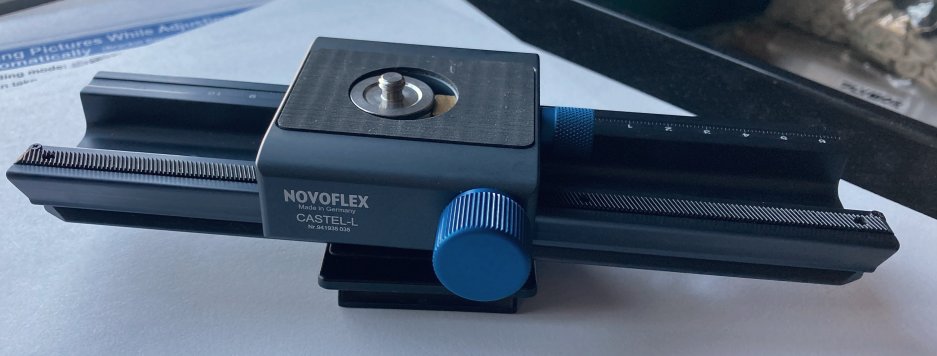

I purchased a Novoflex Castel-L from B&H Photo here in the States. Very smooth adjustment. So far I'm happy with it. It has been criticized for the way it holds the camera as well as the amount of travel per 360° turn of the adjustment knob but as I said, it's working fine for me on 1:1 macro shots.1 point

-

Perhaps it’s L&R,s were designed to keep us on our toes. The second time I used my L&R it caught alight. What fun. I did have it subsequently re- wired and refurbished.0 points