Leaderboard

Popular Content

Showing content with the highest reputation on 11/23/22 in all areas

-

2 points

-

what a lot of youtubers experience and what they choose to show us are often two different things. I used to watch an American hobbiest, when he finished a reassembly and placed the watch on his tg the result was almost always no or very little beat error and within a couple of seconds of time keeping, i might add with no regulation whatsoever on old vintage watches. "hey look at me i can strip down a watch fix it, oil it and reassemble it in a couple of hours and it runs perfectly every time woohoo '. Yeah right of course you can, can we now see the actual full footage with all the fluff ups Billy no mates. We cant believe all that we see and hear, in fact very little when it comes to being popular and money is involved. Mike at retro watches can be a complete numpty sometimes but at least he doesn't hide it.2 points

-

I'm not sure why you're struggling. If the inner coil is only slightly smaller than the arbor, it should be quite easy. I put the barrel on a bench block, sitting over a hole. Then hold the arbor in some sturdy tweezers (I use a cheap set of stainless steel, as I'm holding the arbor, not the spring). Get the hook on the arbor somewhere near the slot on the spring. Insert at a slight angle, and push down. I hold the barrel and mainspring down with 2 fingers (wearing cots) or brass tweezers to stop the spring pinging out, as you might have to jiggle to arbor a bit to get it in.2 points

-

I use 99% alcohol to wash and rise the parts, I've left parts in it for months and neve had a problem. I also have one of them usb heating pads that I put the parts on after I take them out of the jars jut to be sure that theyre dried proberly.2 points

-

Worn pivot on the cock side. A trick that works, is to flip the cap stone so the domed side faces the short pivot. Some folks call it dirty trick but it works. A chrono Seiko is worth getting new balance. This one doesn't need bin residency, I usually instal them in cheap pieces. Good luck.2 points

-

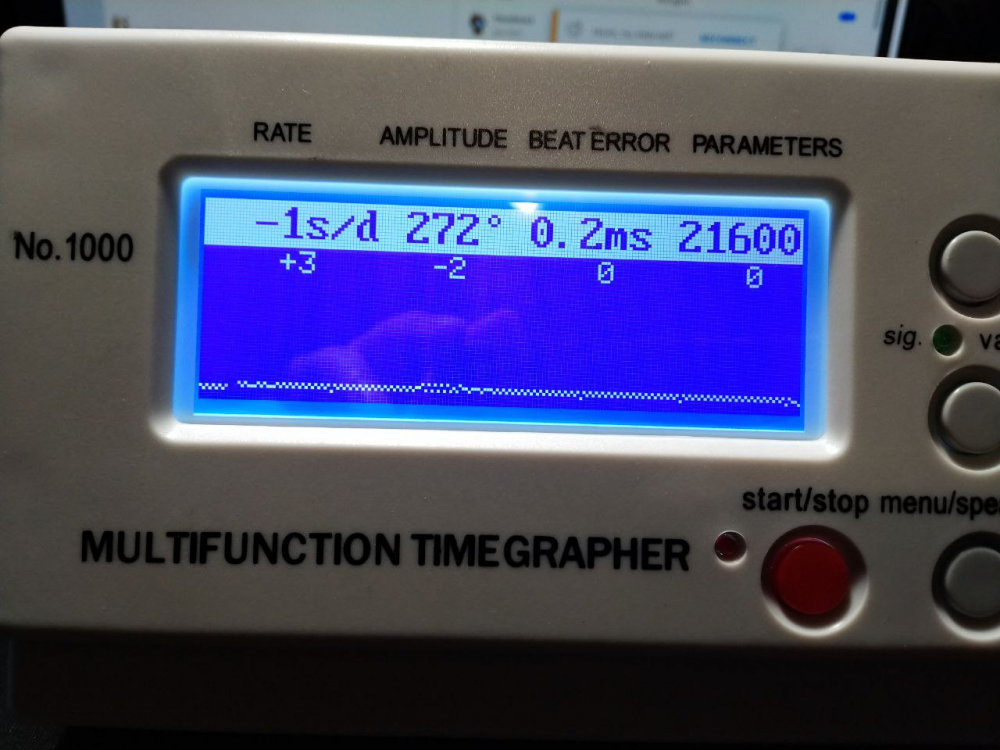

The optics are about as good as I feel like i could reasonably require. ANd so far i've only used the 20x, all iv'e really done with the thing was oil the escapement and it really helped to get right up in there and be able to see the actual oil as the pallet stones contact the escape wheel teeth. Yeah i rest my hands on the desk, steady the movement with one and push with the other, i might try two hands, that's an interesting idea. Also never doubt my minor OCD. The relubing of the escapement was the missing ingredient! Look at that amplitude baby!2 points

-

2 points

-

. Thats a real optical illusion, looks like a hole in the ring and parts of the hole folded in. Bizarre but pleased for you thats not the case.1 point

-

The glue for hairsprings falls under a interesting slightly different category than shellac. The Elgin watch company pioneered some of this in whatever they used wasn't supposed be affected by normal cleaning products. Then even Rolex uses it on I think 3035 and one other technical thing there's a note but occasionally it will fail. But if were talking about the Chinese glue then it will probably fail if you just look at her and definitely will fail in any cleaning product to clean the watch more than a couple of times. Than isopropyl alcohol is interesting for shellac in that it isn't as aggressive at dissolving it. Par very expensive cleaning machine at work the last rinse is isopropyl alcohol 99%. It's used to remove the final rents because it has a habit of not actually evaporating. As far as I can tell I've never seen a problem but I'm not sure how much I read the programming of the machine how long it spends in their I don't think it spends a lot of time it's only in there long enough to rinse off the previous rinse and then it goes right to the drying cycle. Then even alcohol that will dissolves shellac which is what I use at home on those rare occasions where I clean a watch. I'm only in the alcohol for a few seconds just enough to take the final rinse off and I go right to drawing and I've never had a problem. But I do know of someone who left their watch in the bad kind of alcohol for longer than they should have and the roller jewel fell out.. So basically really shouldn't leave a watch in a solution for any length of time as there is a likelihood of undesirable things happening. Bike leaving a long time in the cleaning fluid shellac is the least of your concerns as really bad things can happen with the cleaning fluids. Probably the rinse solution is the most harmless butI still wouldn't leave the watch in a solution for a very long length of time I just don't think it's a good idea. This is always one of the things that fascinates me with the machine. So how well did the vapor process work for epilam?1 point

-

It can be experienced Steve, i do now and then. I dont like to force anything personally, as its a bad habit i have to stop myself from doing. My trade is construction and after nearly 40 years of strongarming stuff to make it fit ive had to learn delicate handling and slowly slowly catch your monkey. If I'm struggling to get an arbor in place i use an old oiler to gently tease the mainspring to get one edge in, once you have a start the rest will follow. Gently being the apt word. The arbor doesn't particularly look overbig. It will go, just take your time, having the mainspring a slack fit is something you dont want imo more of a problem.1 point

-

This is one situation where you can use a little force ! Have you got a pic of the arbor sat on the spring ?1 point

-

Actually those both look Levin. The one on the right could be Derbyshire though, but they have more ornate levers (can't see it) and are usually signed. Same quality.1 point

-

Just be aware that IPA will dissolve shellac (look at the pallet stones and roller jewel) and some glues (where the hairspring attaches).1 point

-

Another machine modded to do the Master-matic forward/reverse! Huge thanks to Jimzzila!!1 point

-

1 point

-

If Mike's technique doesn't work for you (sometimes the coil is just too tight or there's no room to tilt the arbor), grab the arbor with a pinvice (or barrel arbor holder, which is really just a pinvice), and turn clockwise* as you keep firm pressure against the spring. It will open up the coil and let the arbor in. *Clockwise for a normal barrel, where when viewing the open barrel the spring would wind counter-clockwise.1 point

-

1 point

-

John's got it. First bath is the cleaner, with ultrasonic and the fluid is circulated through a filter. 2nd is alcohol, you do a rinse for about a minute, press a button and it drains into the distiller and in 6 minutes you have a new second rinse. The 3rd hatch is for stearic acid epilame. The bottom heats up and melts a layer of stearic acid there, parts go in suspended above, close, and in one minute a microscope layer has deposited. Super cool machine, but they were last made in the late 60s so they're old and run on vacuum tubes. I use a Greiner ACS 900 now. Below is a pic of one of mine. The parts are strung on wires that clip shut on the holder on the top right; I think one of the things that help it work so well is the parts are totally "free" in the baths (though small parts or parts without holes go in a little basket that hangs there). The whole part holder- which everyone in my shop calls the christmas tree- gets turned slowly during cleaning by a little motor in the lid, which helps even out the ultrasonics and presents the parts evenly to the fairly vigorously pumped cleaning fluid.1 point

-

Eyup Gert hope you're well. Rustin seems to think its based on Seiko 76xx movement, maybe not.1 point

-

Speaking of disassembling , if you plan to disassemble the movement, you can start from the rotor, then loosen the bridge screws and try pulling the crown then. Rgds1 point

-

Gentlemen and ladies, I'm embarrassed to say that the reason for the sudden drop in amplitude was not the fault of my WeiShi 1900, but my fault. The tip of the seconds hand was ever so slightly touching the inside of the crystal at certain points, making the amplitude fluctuate. Once rectified and the gain setting set to its default value, the TM gave the same results with the movement cased.1 point

-

Do you have the old platform? you do you need to count the wheel teeth and leaves to get the right one. If you do not look here and you can work out what you will need. https://www.m-p.co.uk/formulae/pivcount.htm1 point