Leaderboard

Popular Content

Showing content with the highest reputation on 10/29/22 in all areas

-

Here is "The Walpam" all back together. I still need to do a little tidying up around the crystal. Some quick on line research suggests the watch was sold somewhere between 1900 and 1910 from Walter Pamment's Jewellers, 137 Askew Road, London, W12 9AU Interestingly the property appears to have been built around 1900, and if you feel the urge to rent it today, you rent a shop close by do so for around £50,000.00 per annum. That price does seem a little steep, when you think that it probably cost a great deal less than that to build the place in 1900 Here is the view through the exhibition case back. All in all a very worthy member of the 404 club I would suggest.7 points

-

This is a bit confusing if you gave it to a shop for an overhaul what exactly did they do anyway? Then regulating to fix problems that are not regulation problems usually doesn't work Then it would be helpful if you gave us the movement number.3 points

-

I have had one of these SSQ models from a huge lot won well over 10 years ago. Problem was that as I wore it on my wrist the heat build up would cause the display to go all black. Several times I took the module apart and carefully cleaned all contacts with alcohol and other various electronic cleaners. No luck! Than I would let it sit for a few more years. A few times I tried to swap in a display glass from other modules. Again no luck. Finally the other week I got lucky and swapped in a new glass and it worked. But.... I noticed that some segments were not appearing on the second digit. Was my fault because on of the contacts between the circuit board and the glass was damaged when I lifted it off. What to ? Lets go search eBay and find one right? And sure enough I found one listed as "Parts or Repairs" BIN make offer and for just about 10 bucks one was on its way. Yes, I know what your thinking...the one coming it was going to have issue too and now instead of one broken SSQ I'd have two. Well, I guess I got lucky because here she is... So why did I go through all the fuss? Easy, 1975 was the first year Timex introduced an LCD watch and it has a unique feature. Which is that unlike most LCD modules that require two or more push buttons, this one only has what looks like a typical crown. You turn it and the minutes count up, turn it back and turn it again and the hours count up. Plus 1975 was the year I graduated HS. Won't it be cool to wear this to the 50th reunion that is only 3 years away.2 points

-

2 points

-

Turns out, the hairspring was touching the second wheel, this is really a small movement2 points

-

Hi The two documents attached will give you an insight as the the timing diagrams and their interpretation in greater depth. This may help you in your diagnosis. The fact thet the watch is running although not very well would mean as was mentioned probably a good service and may be a new mainspring would bring it up to scratch. Timing-Machine-Charts (10).PDF Witschi Training Course (1).pdf2 points

-

It's not stuck is doing exactly what it's supposed to do. Did you notice it doesn't look like the normal canon pinion? It doesn't even function the same for one thing it doesn't rotate its fixed on something. The something that's what rotates. We've actually covered this before somewhere in the message board. Typically on the vintage you'll find this if the canon pinion is As you notice very heavy and very smooth and usually sticks up but occasionally it doesn't typically it has a center pin that goes into a center wheel tube. What you need to do is support the backside staking set works really well for this so that the pin can come out. Then you can tap on the other side straight down as you don't want to break its hammering at some weird angle and the pins should come out. They're much easier to spot when the really vintage and they have the square on the back for setting. Yours is much harder to tell sometimes the other side will be a little bit bigger you can see it looks like the head of a ground nail for instance but yours is really hard. I snipped out some images from your images suit and see yours up close. You look really carefully at the backside of what looks like the end of the center wheel does it look like kind of a weird head of a nail? In other words is it a pin? Then images out of a prior watch C can see what you're looking at because the only way these come out as they have to be driven out and you absolutely have to support the backside otherwise distort the plate and doing it without the bridge in place is usually a bad idea because it has a habit of not being stable and you can break things They really would be nice if we had a tech sheet for every single watch in existence but this one's too old and more than likely to generic2 points

-

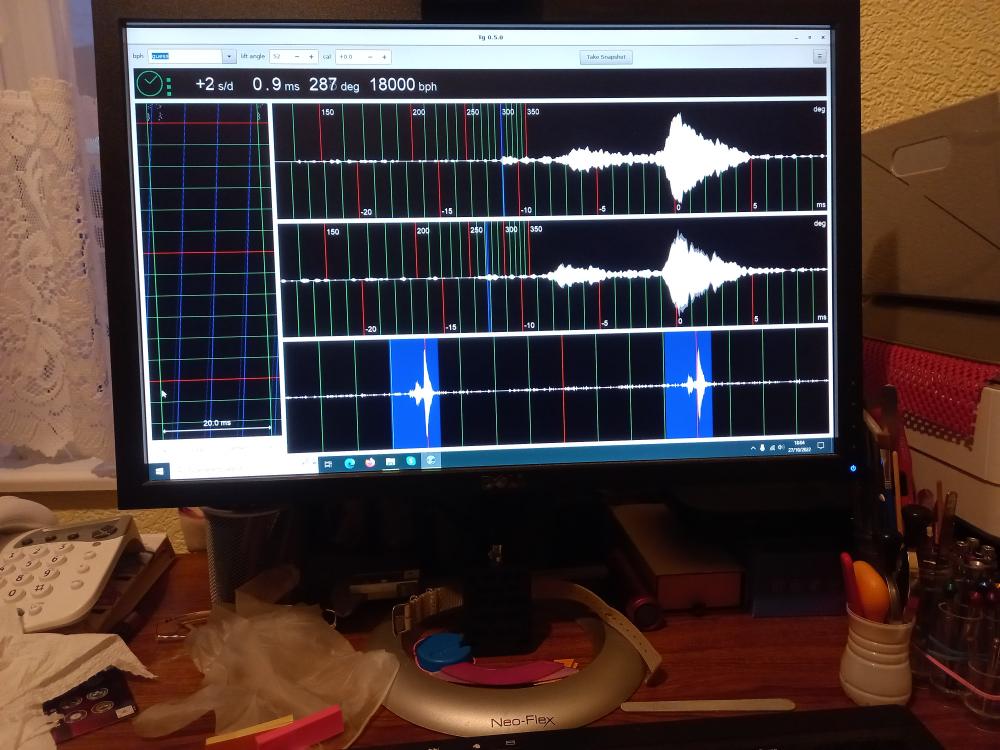

I've been looking at ways to check my watches, and a timegraph seems to be the way to go. The cost at this time is inordinately expensive. May be later. however, I made a startling discovery. I can have a very good system for free. My watch holder can hold a watch and be turned in many directions. Placed against the microphone of a spare webcam Timegrapher 0.5.0 for PC. Works a treat. See the results Saved over £1301 point

-

1 point

-

first step in timing machine interpretation troubleshooting is to troubleshoot the timing machine. The most important aspect of whatever you using whether it's an actual timing machine like the Chinese 1000 or the 1900 or in this case a software for the PC or a phone App the absolute most important thing is that you get a good clean signal. While the ticking sound of a watch is an audio frequency range the timing machines themselves the pickup is actually picking up the vibration of the ticking not the audio. Most things that are not timing machines have microphones that pick up audio sounds that are not actually designed for timing machine use. So whatever you use has to pick up the signal correctly or we will have a problem. then yes you really do have to understand all of this if you would like to interpret the results of your timing whatever. Because until we get a timing machine with artificial intelligence that will just tell you what the problem is you do have to understand. Otherwise as I said you will have a problem and I will explain farther down what the problem is. then we have a really nice video wasn't specifically designed for the purpose that I like the use it for it was designed this show us how wonderful their new escapement is but in order to show you how wonderful it is they have to show you the lever escapement which works beautiful for us. then the video shows everything is being absolutely perfect which works well for learning point of view unfortunately a real life the waveform isn't always as perfect as this but it is really nice for training purposes. So skip ahead to about one minute and two seconds we get to the lever escapement . You can see is the balance wheel is rotating the roller jewel is crashing into the fork and generates sound number one. the absolutely most quiet sound of the ticking and its key to everything if your timing whatever is going to work. then for the middle signals number two and three no notice they overlap to certain degree. Then in most drawings of the escapement oscilloscope they will overlap these to one signal so typically LC three signals one reality we notice five because the overlap. now we get to the next most important to locking sound which is number four finally crashing into the banking pin. These two of course overlap to certain degree. ideally should watch the video more than once there might be a test later on. https://youtu.be/g5c5RK4WFV8 then I've attached a whole bunch a images and a PDF while we continue our education into interpreting timing machine results. from the witschi PDF two separate images where of course the waveforms are consolidated to three each rather than five and they show the importance of two of them. The roller jewel sound is number one key to everything. Then if you want have amplitude you need the fourth sound and you can measure amplitude looks pretty simple. the notice in all of this so far we've been using the oscilloscope to look at things and unfortunately on most timing machines you don't get around oscilloscope. Although on most timing machines you don't typically need on oscilloscope because typically they pick up the signals correctly and typically will show you the correct results. Fortunately on our application for the PC in this discussion it has an oscilloscope and let's see what we can learn from that first I went online and found another image somebody else's and notice on the oscilloscope I circled it looks pretty darn perfect. We see three clear signals and nothing in between absolute quietness. This is ideally what were looking for. now we can see aware having our oscilloscope for your timing machine is really important let's snipped out an image for up above and compare with everything we've learned. We know that ideally background noise should be nonexistent and we see a lot of background noise if that is of high enough level the timing software might think it's a valid signal or? In other words it might interpret it as a problem in the watch something making noise that shouldn't be making noise and of course it could show up as random dots on the screen. Then the number one key signal doesn't appear to be super clear to me if it's not clear to software then your rate is going to be all over the place especially if it varies a little each time in other words you can't consistently trigger off something that it has to trigger off of. Of course if the rate is wrong because it doesn't get a nice signal amplitude will be wrong and basically everything will be wrong all because of a signal that's not quite correct then mentioned there was a problem of what if we do not get a clean signal? It may be we don't get a clean signal because the watch is having issues and running really poorly or we may not get a good clean signal if you're just not picking up the ticking sound correctly. The problem becomes where is the problem is if the inability to pick up the signal correctly or is the watch itself having a problem. We've done this a couple of times with people with phone apps where the problem was really in the app and the microphone that wasn't designed to pick up ticking of watch sounds. As the image I found online shows the software can work it just has to have a proper pickup that gets the correct signals otherwise we can end up with a situation like this of is that the watch having a problem or is it the software having a problem? Witschi Training Course.pdf1 point

-

I have been at the cottage on weekends making watchmaking hard. Back in a week however:) thanks for missing me.1 point

-

@jdrichardhasn't been around for a while. Here's hoping that's because he has something better to do, like mending watches, or some other joyful activity!1 point

-

Thanks. It is I an interesting piece. I should probably have taken more pictures of the strip down and cleaning process. There was some "fascinating" gunk inside the thing. It has a split in the base plate and a small screw to allow relative adjustment between the lever and the escape wheel, presumably to allow the manufacturer to dial in that distance for best performance, thus negating the need for very high precision of either component. The barrel also drives both the minute and hour hand wheels, and has a built in slip clutch. so it has an interesting stacked construction. All of this makes for a very simple but obviously robust calibre. Robust since it is still capable of ticking away nicely after around a hundred and twenty years. It is some kind of Roskopf design, but I didn't find any obvious makers marks, nor did I find anything matching in ranfft. The nearest is probably something like a Liga 315 which is very similar in external appearance. As to Mr Walter Pamment, I believe this "Walter Albert Pamment" may well be him -> https://www.geni.com/people/Walter-Pamment/6000000002814674500 In the 1901 census he is listed as Age 22 - Walter Albert Pamment worked in London as a Watchmaker. He resided in 1901 at 10 Galena Road, Hammersmith, London, England, which is a few streets away from Askew Road. I didn't follow the breadcrumbs any further, but certainly it is nice to see a little of the history of these old time pieces.1 point

-

Hi was there as washer on the hour wheel when you first started . When the dial is on the dial washer curves upward and is pushed down with the dial therefore holding down the hour wheel and canon. before you start bashing things try a dial washer and see how it goes with the dial on. One assumes its the right hour wheel and canon pinion, have a look at Ranfft site for the omega 711.1 point

-

An amplitude lower than 200 can never give a consistent performance in all positions.. This watch just needs a service..1 point

-

https://r.search.yahoo.com/_ylt=AwrJO1UaOF1jnfUAwBx3Bwx.;_ylu=Y29sbwMEcG9zAzIEdnRpZAMEc2VjA3Ny/RV=2/RE=1667082394/RO=10/RU=https%3a%2f%2fwww.electroschematics.com%2fwatch-scope-piezo%2f/RK=2/RS=8UX5eR3nkV.Yz.khuPW_kufAK0Y- The above contains all about watch o scope. I use it and its ok. If you have a problem with down loading contact *****@*****.tld may be they can help. The lite version runs for free and the paid for version $40 give a life licence and several other features. there is a simple amplifier and stand to make but once done no problem. I believe there is a compatible multi position stand now reccomended by W_O_S and an amplifier ready built.1 point

-

That's the coolest one to pass through here in a while. Possibly ever. The very specific history, to my mind at least, is what really puts it over the top. Nevermind the transformation!1 point

-

Looking a the two timegrapher readings it looks like all that has been been changed is an improvement to s/d. As JD correctly states this watch needs a overhaul and service. One side of the escape I suspect is just dirty or lacks lubrication.1 point

-

Ill definitely have to check that out ross as a compare for my tg. Good information to post matey thank you.1 point

-

So were these two tg readouts taken in same movement position and at same power level ? How much did you pay the repair shop? it might give us an idea what work must have been done on the watch or was just done to your wallet? and if you consider these readouts ceredible then perhaps you should take the watch back to the repairman and demand better amplitude. Rgds1 point

-

Ah ok yes looking at the minute wheel rear side its possible to make out the arbor for the hole, the mainplate photo now indicates the design. Not great imo with little integration. Curious why the small section is not solid and has a hole through it. Not quite sure how you will connect the two parts. This may not even be the correct part causing some confusion here. Lets have a look at the technical sheet to see what is going on1 point

-

Hi What make and caliber is the watch, Yes both parts would have been together, to put it back together will probably need a staking set to close the rivit. Unusual for it to be running free it has a hollow center where it sits on its pivot on the main plate. Find the make and caliber and look ok Ranfft's web site for details also we may be able to find the tech/parts sheet with the details. cheers.1 point

-

1 point

-

Eyup fella. What did this local repair shop actually do and charge ? if you dont mind me asking.1 point

-

Another 404 club pocket watch is on the bench tonight. Above we have the "as purchased" pics. Pretty filthy, even for the stuff I pick up, you have to admit. This is the pin lever Swiss movement, interestingly it has an exhibition case back, so you can see the lovely filth works inside. It needed a mainspring, which surprisingly I had in my stash, and also a deep clean and a fair bit of screw rust and green cheese removal and much brass plate cleaning, all by hand I might add. It is now running really nicely, and hopefully will be re-assembled and a new glass fitted tomorrow evening, but here is a quick taster of what is to come. The nickel case incidentally polished up bright as a new pin.1 point

-

Serviced this movement today. I just let it run down naturally. No issues with the service... The movement was all greasy/oily...including the dial. The oil penetrated the lume and looks pretty dingy. Normally, I would not consider restoring a dial like this from 70 years ago, but it is pretty ugly. Regardless, not gonna do it now because it looks like a challenge that I am not prepared for.1 point

-

Heat up the bezel so that it expands then drop the crystal into place. As the bezel cools it contracts and grips the crystal.1 point

-

It is true that our 'radium girls' developed cancer as a result of unknowingly ingesting quantities of radium. But 'other girls' have died from tobacco. If you have a fine watch with a well preserved radium dial, such as my Longines cal 18.88Z, relax a little and realse that you are in no danger unless you eat the dial. Radium itself in the quantities used on dials does not glow. It was the incorporated fluorescent zinc sulphide that glowed. But over the years this has been degraded by the radiation. Perhaps into zinc oxide. I asked Dr. Roland Ranfft to do a little experiment by painting zinc sulphide onto the non-glowing ancient dial numbers and hands. The newly applied zinc suphide glowed giving the dial its original look. He now supplies activated zinc sulphide for anyone who is a good painter or who can outsource the work. Alternatively, the modern phosphors such as Luminova will also glow permanently, and more brightly than zinc sulphide, when applied to old radium dials. But the 'look' will be less authentic.1 point

-

Always a good idea to put the balance&cock assembly plus fork cock and relevent screws ( no other part of the escapement) back on the mainplate and observe the oscilator in action, so you also have good access and view of the oscilator's components. Short pivot ( worn) for instance might let its shoulder or shoulder seat rub on the setting's chaton. Once you call the oscilation acceptable you would add the fork. This is elimination process in reverse , you bring parts to the party one by one to see which one affects the oscilation. Good luck pal.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

I'm SporTicus! Today's fine specimen is a "Sporticus" stopwatch. That hurdler doesn't really appear to be enjoying himself does he? This is probably an early BFG 611 caliber and was pretty shabby when it arrived, with no crystal, no bow, a bent hand, and not running, but that is par for the course in the 404 club I guess. It is all straightened out and running fine now, and even sporting some shiny new "glass". Fitting this required some acetone as somebody had previously superglued in an acrylic crystal, remnants of which were still firmly wedged in place around the bezel. Acetone is pretty good for removing superglue.1 point