Leaderboard

Popular Content

Showing content with the highest reputation on 10/28/22 in all areas

-

I recently gave information about Timegrapher. I thought someone might be interested in my approach to homemade tools. I made a mainspring Barrel press from two different sized shampoo tops. A small hole in the centre of each makes a gap for the arbour. A £4.99 presto tool. Cutting a groove with a dremel makes it useable for 5 spoke wheel removal. Spring saver whilst washing. Centre of a suction cap. Outer edge cut away. Inserted into the mesh basket, placed on top of springs means they do not get caught in the mesh. Just loving the hobby. Ross2 points

-

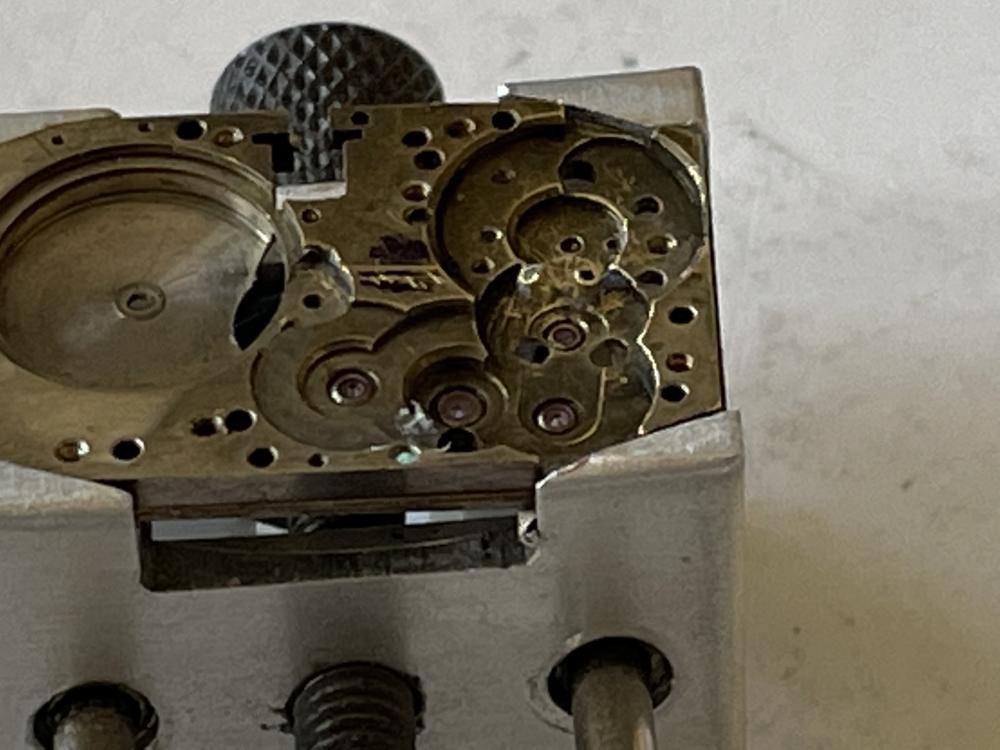

Another 404 club pocket watch is on the bench tonight. Above we have the "as purchased" pics. Pretty filthy, even for the stuff I pick up, you have to admit. This is the pin lever Swiss movement, interestingly it has an exhibition case back, so you can see the lovely filth works inside. It needed a mainspring, which surprisingly I had in my stash, and also a deep clean and a fair bit of screw rust and green cheese removal and much brass plate cleaning, all by hand I might add. It is now running really nicely, and hopefully will be re-assembled and a new glass fitted tomorrow evening, but here is a quick taster of what is to come. The nickel case incidentally polished up bright as a new pin.2 points

-

Heat up the bezel so that it expands then drop the crystal into place. As the bezel cools it contracts and grips the crystal.2 points

-

Vostok 2409 Service Walkthrough Disassembly Pictures (Please sort by name in ascending order) Vostok 2409 Service Walkthrough Assembly Pictures (Please sort by name in ascending order) Being able to service the ETA calibre 2824-2 was a long-term goal and a dream when I started servicing and repairing watches some years ago. However, my first “calibre love” was the Vostok 2409; a reliable Soviet/Russian 17 jewels manual workhorse without any complications which has been around since 1970. It is still in production and found in Vostok’s Komandirskie series of watches, by some called the AK-47s of the watch world, together with its bigger brother the Vostok Amphibian dive watch. Modern-day Vostok Amphibians use the automatic Vostok 2415 (w/o date complication) and 2416 (with date complication) calibres, but the Amphibian that I’m servicing in this walkthrough, an Albatross Radio Room, popular among collectors, is from the 1980s and in those days the manual 2409, as well as its predecessor 2209, was commonly used in the Amphibians as well as the Komandirskies. While I was servicing this watch, I noticed that the crystal didn’t fit perfectly in the watch case. Being a serious dive watch originally designed for the Soviet navy this was, of course, unacceptable, so I replaced the crystal and video recorded the event in my “Bergeon No 5500 Crystal Press Review”. For me, the 2409 was a great movement to get started with as it probably is the most affordable movement on the planet, and spare parts are readily available and cost next to nothing. A lost or damaged part never spells financial disaster. Also, eBay offers an abundance of used Vostok watches in decent condition housing this movement for as little as $20 and sometimes less. A brand new Vostok 2409 (www.meranom.com) can be had for as little as $27. Be aware that, almost without exception, the eBay listings always state that these Vostok watches have been serviced, but in my experience they never are. Well, maybe dipped in a can of naphtha, left to dry and then injected with a bit of oil here and there. I’ve seen horrible examples! A somewhat tricky bit about the 2409 is to remove and replace the anti-shock springs. For this, I use a self-made tool made from peg wood. It’s shown in one of the assembly pictures together with a description of how I made it. A very similar tool is demonstrated in this video. Later, as I was working myself through Mark Lovick’s watchrepairlessons.com courses, I trained with the Unitas 6498 pocket watch movement which is the selected movement for the courses. In all honesty, from a learning point, the Unitas 6498 would have been an easier movement to get started with (especially the anti-shock springs), but the tinkering with the Vostok 2409 was a low-cost and fun way to get started and made me better prepared for the courses which answered a bunch of questions and was amazingly instructive. Eventually, I plan to publish a “Vostok 2414 Service Walkthrough”. The 2414 is identical to the 2409 but adds a very uncomplicated date complication. So, if you want a whole lot of fun for next to nothing when it comes to money, there is no other movement I would recommend before the Vostok 24XX movements, and the 2409 is a great starting point if you have a desire to begin tinkering with watches. Be warned though; tinkering may take over a substantial chunk of your life!1 point

-

I have been watching the videos that Dr John C Taylor has made showing the very best of some of the top makers we ever had. Here is the link and you can them pick out what you would like to watch. https://www.youtube.com/c/DrJohnCTaylor I have to say he is not in my family tree but having the same surname at some point there is a connection1 point

-

Serviced this movement today. I just let it run down naturally. No issues with the service... The movement was all greasy/oily...including the dial. The oil penetrated the lume and looks pretty dingy. Normally, I would not consider restoring a dial like this from 70 years ago, but it is pretty ugly. Regardless, not gonna do it now because it looks like a challenge that I am not prepared for.1 point

-

I suppose in theory the glass could crack through thermal shock but I've never had one go yet. As to how hot, the hair drier will make no impact what so ever. A paint stripper gun would probably do it but I suspect might be awkward. An electric hot plate works very well. You have good control over how hot it gets, and you can lay the bezel down on it leaving both hands free to manipulate the crystal. I have always heated up the bezel keeping the crystal at room temp, dropping the crystal into place once the bezel had expanded enough. However, it occurs to me that you could rest the crystal on top of the bezel while you heat it. Providing the rate of expansion of the bezel is significantly greater than the glass you could just heat until the crystal drops down into the bezel. As the glass would also be getting hot there will be less thermal shock, reducing the risk of breakage.1 point

-

Many thanks for such a warm welcome (and the useful docs on terms and tools). Lovely little packages arriving in the post each day with various tools and watch parts, which is exciting in itself! Really superb sources of info - very much appreciated!1 point

-

From your first pic it looks as though this is a capsule type case with a two piece stem. The first thing to do is to work out how the crystal comes off. It looks like it may be a crystal assembly comprised of an acrylic bonded to a metal bezel. If you look the metal in contact with the acrylic is different to the case back. My guess is that the bezel is a press fit to the case back so a sharp blade should be able to separate the two if pushed in where the two different metals are in contact. Once the crystal is out of the way you can try holding the case face down (over a suitably soft landing pad) and slowly rotating the crown. You may need to jiggle things a bit but with any luck (and assuming it is a two piece stem) as the join in the stem becomes vertical the movement may just drop out. If this doesn't happen then it would be as well to have a really good inspect of the edges of the dial to see if there are any locking rings keeping things in place, or an access hole that would allow you to release a one piece stem. It's difficult to be any more exact without the watch in hand though so a little more exploration is the way to go.1 point

-

1 point

-

That is precisely spot on what I was looking for! I was looking around on cousins but was only able to find metal pins which you then would have to rivet yourself. The biggest problem is that I don't have the machinery to polish the rivets after so this is perfect. Big thanks(:1 point

-

Hello and welcome to the forum Here are a couple of documents you may find useful. 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

Welcome Silverye! That sounds like an interesting journey so far. Good luck with the tool shopping.1 point

-

Hey all, Like all of you, I too have just been bitten by the watchmaker's bug. I've always loved watches and have been planning to start my own business as a watch dealer, and in my quest to become an expert of all aspects of a watch, not just the market values and remembering reference numbers and such, I decided it was time to really learn and understand the mechanics of how a watch works. This quest was originally meant to just be me reading and watching videos online so that I can gain just enough knowledge to be able to speak to customers, and just know more than the next dealer. HOWEVER, I am smitten with curiosity and awe of this whole other world that is watchmaking, I have put everything else aside for the moment and decided to buy tools and a Unitas 6497 and just dive in head first. I just watched the Watchmaker's Apprentice, featuring the legendary George Daniels and Roger Smith, and now I can't stop thinking about watchmaking! Looking forward to this journey and it's exciting that I get to share it with you all to help me along the way.1 point

-

1 point

-

Thanks very much for the help. Neverenoughwatches - I did your trick and looked down the winder from the plunger end - not the arbor winding end - and that naturally orientates the hook with the hook on the arbor that came out of the barrel. ManSkirtBrew - Thanks for the Esslinger article. I'll make a note of it and add in my comments.1 point

-

We are all different mate and all prone to different diseases depending on our genetics. Cancers , heart diseases, respiratory issues, overactive immune illnesses, underactive immune illnesses,dementias etc, etc. Its about edging your bets mate, if cancer runs in your family then smoking is going to run your risk that bit closer. If heart disease then try to eat a healthy diet. Only fair to state the obvious that one person can be more susceptible to radium effect than another person. Precautions should ALWAYS be taken when working on old radium dials, but the risk of the individual should always be down to the individual and not influenced in any way.1 point

-

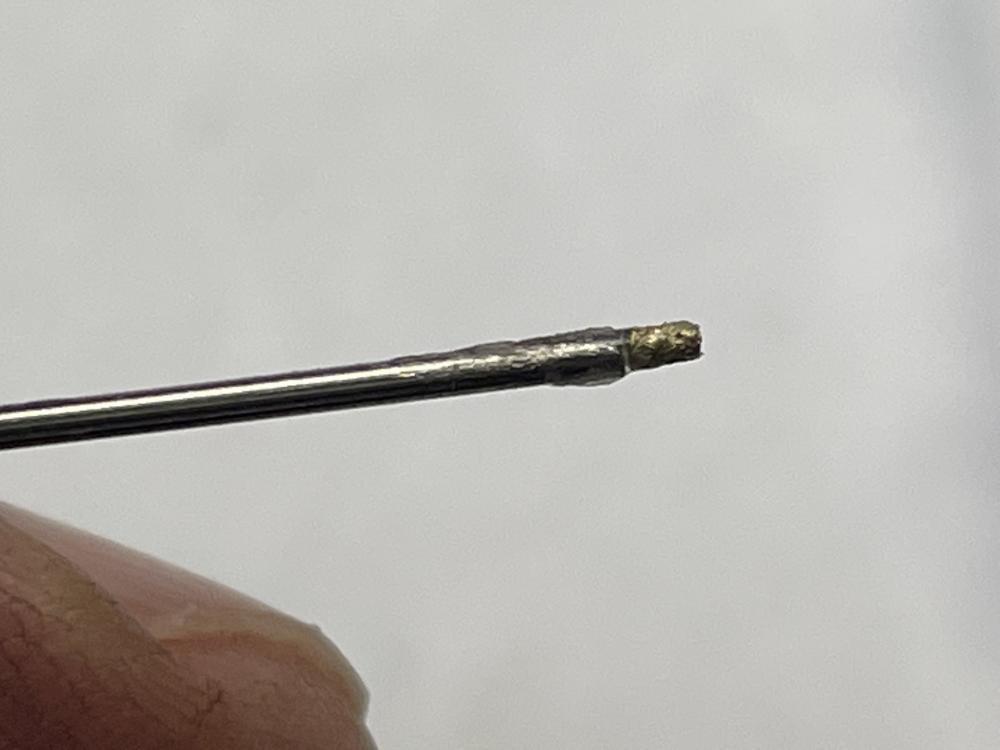

Finally finished installing banking pins. Pins are 0.030" in diameter and 0.050" in length. Knurled the pin between two files for a little surface area to hold glue. I tried Red Loctite , JB Weld and supper glue. The supper glue held the best. In order to install the pins in the holes I tacked the pin to the end of a straight pin with supper glue. Needs a little clean-up then start reassembly to see if t works.1 point

-

Problem solved in a rather unusual way. Since the old crystal is in good shape and fit the movement perfectly, I did this. Took a piece of aluminum foil and covered the crystal and over the module (capsule). Then I pressed that into the bezel. Using a surgeons scalpel I cut away the foil. It is a very tight fit and you cannot see the foil. The foil, incidentally, is 20 microns thick. That is all it took. My method is easily reversible (i.e., I can press the movement out without harm).1 point

-

I wonder if this stuff has a shelflife I hope not. Because of course I have a tube of it which is largely not used. was trying member why exactly I purchased it? There must then some reason for it it wouldn't of been for the normal keyless works because at that time I was using something else. conveniently looking online I can't seem to find PML stem grease which is what I used use previously. Conveniently right now looking online I can't find anybody selling which is sad it actually is a really nice lubricant. there are some discussion groups where basically the subject is forbidden to be discussed just because of that. That same discussion group I'm reasonably sure we lost a member because silly me thought you should lubricate the Canon pinion. I never know what quite to expect on that particular group but I was surprised that everybody else thought it should be lubricated also and despite showing tech sheets that much it's lubricated this person absolutely positively refused to accept that. Just because some books said not to do it but the problem with the book is the author is no longer with us and no way that I know of to talk to the person.1 point

-

A jeweler friend always cleaned rings etc in warm water, dishsoap (FairyLiquid) and a little ammonia Spoonful in the U/s for a min or two brushed with a tooth brush, swore by it , he never had any problems, thorough drying and a polish with an impregnated cloth.1 point

-

Like watchie and john said recently we can become quite obsessive over amplitude given that we have apparatus that allows us to measure a movements running accurately. It looks rather smart mate . If its keeping both reasonable time and reserve on the wrist and neither of those attributes are deteriorating then big thumbs up .1 point

-

There are varying grades of naptha in lighter fuel. Yours has a medium carbon to hydrogen ratio which makes it a mid naptha. Less carbon light naptha , more cafbon heavy naptha. Also lighter fuel not a pure grade naptha, supposedly with additives to help it burn, strangely enough never listed in the ingredients and no one has yet given any information as to what those addatives are . As far as i know any benzine product will not affect shellac even with a long soak, i have done overnight before on some stubborn grime. On the other hand IPA will dissolve shellac if left too long in it.1 point

-

1 point

-

If the escapement is in place then center wheel should be "locked" in place. Looking at your photos, you would need to put the 4th wheel, escape wheel and pallet fork back in.0 points