Leaderboard

Popular Content

Showing content with the highest reputation on 10/24/22 in Posts

-

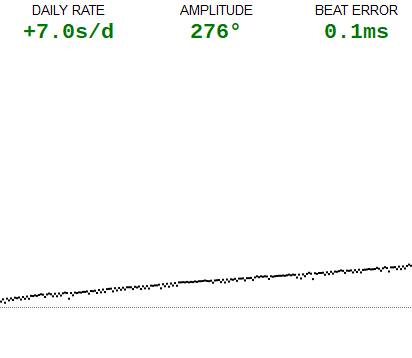

you would have been disappointed with the lecture I attended yesterday. The lecture was understanding what goes into servicing a Rolex in a modern Rolex service agent shop. so what the purpose this lecture is is to explain to people why it costs so much to get a Rolex serviced everything that goes into it parts that are changed etc. Then for timekeeping they don't actually follow Rolex specifications. Rolex will accept usually negative number like -1 and of course except zero seconds but this place will not it has to be plus something. In a previous version of this lecture several years ago the watch they showed timing specifications for was keeping zero seconds per day and he said that would fail quality control and have to go back and be redone for timekeeping. then amplitude 310 maximum fully wound up and half wind which is 24 hours ground down minimum of 200°. so typically when you see the spec sheets that list timing specifications they are not obsessed with a specific amplitude other than the minimum maximum and of course they are more obsessed with timekeeping. technically that isn't quite correct. Everything for timekeeping is depended upon the first sound which is the roller jewel hitting the fork. Unfortunately that's also the most quiet sounds. then the sounds are more complicated with the typically show although they do have a breakdown of the sounds that I've snipped out images for you. So you can see there's five sounds two of them are supposed to overlap. But what if they don't overlap like what if locking occurs and is a time delay before it crashes into the banking pins. Or what if something else is going on or any other external noises or noises in the watch what is that due to your signal. This is where it be nice if the Chinese machines had audio where you could listen and see if the signal sounds nice and clean. It's amazing how noisy the hairspring can be if it bumps into a rubs on something. then the problem with the example of how they measure amplitude of beats said right is officially an absolute perfect idealized waveform. What if the waveform isn't perfect then what happens. As you mentioned if your gain is not high enough and you don't pick up the first signal that everything's going to be really screwed up. Or if you're amplitude is superlow the waveform get stretched out the timing machine will look for locking at the wrong place pick it up in the middle which is quite common on the Chinese machines and their very expensive witschi at work with bikes to do that quite often and then you end up with an amplitude that's much higher than what it should be. Witschi Training Course.pdf3 points

-

Wow. I think that's the priciest screw I've ever heard of. (Insert ribald jokes about screwing, screwed, etc. here)2 points

-

2 points

-

2 points

-

I would use Molykote DX (or HP1300 if the parts have been surface treated) for the keyless works. For the barrel arbor (first wheel), center wheel (second wheel), and third wheel, use HP 1300. The cannon pinion also would use HP1300. These are the parts with lower speed, and higher torque. For the fourth wheel, escape wheel, and balance wheel, use 9010. These pivots face higher speed, and low torque. I wouldn’t oil the pallet fork pivots, although I think Seiko has had some documentation where the pallet fork pivots have been oiled. I think this controversy over Seiko oiling of pallet fork pivots has been going on for a long time. The pallet jewel faces, should be oiled with a tiny amount of 9415. Don’t worry over following every single tech sheet to the smallest details… wait till you get to the teeth of the winding pinion: some sheets call for them to be oiled as well, but you would have learned that gear teeth aren’t supposed to be oiled!2 points

-

The movement is a France Ebauches FE 140-1C! ranfft.de 17jewels.info2 points

-

That’s great you managed to solve it! Could you take a photo of the hole-closing attachment? I’m curious how a lever jeweling tool could close a hole where a staking tool didn’t.2 points

-

Today I've ben working on a 21 Jewel Peseux 320 based Accurist, probably from the early 1950s, with a number of issues including a broken stem. It rocked in at just under half of the 404 club entry requirements. Its now all back together and keeping reasonably good time, all be it a little fast. I'll regulate it more exactly if it makes it through the next 24 hours without any issues. The dial has a little bit of cosmetic damage (not my doing), and there was plenty of evidence of earlier attempts to work on it in the past, including that rather obvious skid mark on the top of the balance cock. I managed to slightly improve the dial, however it will never be perfect, but since it is a Peseux 320 for one pound ninety nine pence, can live with that. The band claims to be "Burberry" and "Genuine leather", but I have my doubts about both claims, however it was the only 17mm strap I had left in my stash. I may change it later, but for now, it stays.2 points

-

the code is the US import code. It's a way of identifying who actually imported the watch. I have a link that will tell you what the codes mean http://www.ranfft.de/uhr/info-uscode-e.html2 points

-

Yo, I'm new here, obviously, been lurking a while and decided it was time to join. Soooo just wanted to say hi.1 point

-

1 point

-

1 point

-

Some tech info for those interested. My research some time ago determined that both greases are calcium complex with an additional silicon dioxide thickener, and NLGI 1 consistency. They both have synthetic base oil and esters/di-esters. Both have viscosity improvers (makes a thinner oil seem thicker than normal as temp increases), anti-oxidant and corrosion inhibitors and 9504 has an EP additive. Oil viscosity at 20dgc is 176 cSt @ 20c for 9501 (ie ISO VG68) and 305 cSt at 20c for 9504 (ISO VG100). [VG is an industry standard for viscosity ranges]. They are described as high friction greases (probably the silicon dioxide). The blue colours are only a dye. My learned grease expert friend says the 9501/9504 are expensive formulations! HP1300 has a POA/SHC (synthesised hydrocarbon) oil base with viscosity of 1267 cSt at 20degc (ISO VG320). No info on additives but suggest it has anti-oxidant and corrosion inhibitors. Also likely to have EP additives. The red colour is only a dye, it is also available undyed. Apart from them being 'greases' and 'oil', the viscosity of the base oil (this is what does the lubrication!!) is significantly different re oil vs greases. This may suggest that the oil is thicker so it stays in place whilst handling high loads. The greases use lighter oils and esters for lubrication, and rely on the grease fillers etc to hold it in place. No doubt both would do a suitable job in keyless works. Phew!!! ** This info is from my own research at the time a few years ago and may not be 100% accurate, I accept no responsibility if this info is misused or misinterpreted. **1 point

-

Levin will sell me the screw for $125 plus shipping.1 point

-

Mike's already beat me to it, but these are the ones I bought. https://www.cousinsuk.com/product/seitz-jewelling-reducing-jewel-hole-tools?code=J30577 I use it with the regular jewel press, no hammer involved. The lever will give you a huge mechanical advantage.1 point

-

typically when tech sheets are different they were published at different times. yyou'll notice at the link below that the lubrication this all have numbers and names.. At one time they just had the names so 9010 is equal to Synt-A-Lube which is basically what you have on the Seiko sheet which is why it's 9010 https://www.moebius-lubricants.ch/en/products/oils it gets even more confusing depending upon which tech sheet you look at for Seiko. Don't remember but one model that the tech sheet is gone through several revisions originally it was yes oil the pivots that it was no you don't oil the pivots and then it was back to ESC oil the pivots. Typically yes Seiko oils the pivots and somewhere in the universe Seiko probably explains why they do it but we haven't found it yet. So the rest the world recommends not oiling the pivots but Seiko does it anyway. Then if you do oil the pivots you will or can lose amplitude and Seiko is typically run with really horrible amplitudes but it's probably not entirely for the reason of oiling the pallet fork pivots while you're on the website for lubrication make sure you download the lubrication chart is to see what they're recommending and get the product catalogs that lists all the lubricants with specifications then lubrication is also a problem because everybody has an opinion and everyone's opinion may be different than everyone else. Then it depends upon how opinionated people are as to whether we can have a civil conversation or not. you'll notice the recommendation here which by the way I happen to agree with if you're using the HP oil on anything other than jeweled bearings you should epilam or surface treat it to keep it from spreading.. If you look at the lubrication chart that you downloaded and look at the bottom of the chart you'll find it amusing recommendation for the HP oils were basically recommendation of where not to use it and then the recommending a different oil just because they can make things confusing by doing this. So my basic guess is if it's a jeweled bearings probably okay but anything metal on metal with HP oils needs to be surface treated or the oil spreads. Which is why on all the keyless parts I would recommend a grease of whatever choice you happen to like. I believe Swatch group recommends HP 1300 for the barrel arbor.. I prefer a grease.. The center wheel typically I do use HP 1300 but I do have a concern with a note that's on the bottom of the lubrication chart as to whether if it's a non-jeweled bearing whether I should be using D5. then cannon pinion I like grease then of course my grease currently have choices 9504 fortunately I'm at work and I don't have to pay for. Unfortunately that's another thing that we influence your choice of lubrication is the cost. Then for the entire gear train I like 9020 which is not a new list of lubricants up above.. Plus I like to use 9020 on the balance pivots even though that goes against the world trend of 9010 universally everywhere on the planet they use 9010. But I did say everyone gets to have an opinion on this and if it works for you then it's fine.1 point

-

I second Tom's assertion about misdirection. I'm a semi-retired private investigator who used to set up security measures for businesses on the side. My own watches are *not* easy for me to access (but not time-consuming either) so if a burglar had no idea where to start looking, they could conceivably need to tear my house apart for quite some time before finding any of my watches. It's not just a simple matter of stashing them in "the last place anyone would look", it's also a matter of forcing the thief to ask "Do I really want to bother with the hassle of checking there?" You can never get a perfectly secure place; if it can be accessed at all, there exists a thief who can access it. All you can do is slow them down. And I made up my mind to slow the potential burglar down as much as possible. Gives time for the coppers to arrive, you know.1 point

-

I've attached a chart to look up millimeters size and converted to something useful for the bestfit book.. llooks like 10 1/2l. aanother way to find it is to go here and search for the number.. Or somewhere on the site you can enter in size and various specifications and will give you a list but conveniently I don't know where that bookmark is clear on your own the find that. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk looking in the bestfit book gave me a clue and the website has a picture http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&FHF_150_0 then I'm attaching an image snipped out of the bestfit book. This is why wanted the size because he can't look at a picture until how big it is and searching through all of these is a pain. Which is why typically I won't do it unless someone gives enough information.. one of the reasons I'm deliberately not being helpful on this one is I purchased mine. So not sure who actually holds the copyright even though somebody will come along and tell you where to download eventually for free. watch-ligne-size-chart.pdf1 point

-

1 point

-

You are correct John the number 150 and the mark when blown up looks like the Eubauches sheild but the center is obliterated. with what looks like a dial sticker.1 point

-

Can’t say for certain but my guesstimate is that anything used in the day to day would be an alloy or just have a nickel plate itself, so it would pollute your solution. They don’t make things like they used to eh. I ended up ordering a second anode, they were 13.99 each CDN from Amazon. The first came and it was a bit thicker than I thought so didn’t feel like going at it with tin snips. I think the same product is on aliexpress for around $6, once you add 2 it automatically goes from free shipping to $9, and then there is the time.1 point

-

you see on the dial side there is a number 150? Did notice next to the 150 it looks like a symbol but it also looks like glue on top of the symbol . Usually inside that symbol is a letter but I can't see it because of the picture and almost looks like glue. Then if somebody doesn't give you the secret location of a downloadable copy of the bestfit book I'll look it up for you but I need to know that and it be really nice to have the diameter measured on the dial side1 point

-

I thought the funniest joke in our business was "Never use force. Get a bigger hammer", until @nickelsilvermentioned that there are situations where a bigger hammer really is needed. I can't remember the context right now but thought it might be a good idea in this case!? Anyway, I have never closed an arbor bearing so don't take my word for it.1 point

-

Thank you both for the replies. I remembered that I had one of the hole-closing attachments for my Seitz tool. So this gave me an excuse to finally restore my Seitz press. I pressed down on the hole with the correct attachment and in a few minutes the hole was closed up a little further than needed, do I broached it open a tad and we're all set!1 point

-

The larger the diameter of your punch the higher the force needed to perform noticable work. Not knowing what the base material is it's hard to say how much force will be required to displace it. If things on your bench are jumping up and down, your bench may not be ridgid enough for this type of work. If your bench is solid enough nothing else should move. Try putting the staking set directly over the bench leg (it should have better support there) and you may have better results (just don't hit it as hard as you have been until you know that you still need to). Best of luck. Shane1 point

-

My second question would be: are you certain the punches are large enough in diameter that they're not meeting in the middle of the hole you're trying to close up?1 point

-

Thats a bit better mate. Some smart phones have a macro setting which is ok. I find pulling back a bit and then zooming in digitally gives a better result. A microscope is invaluable for fault finding, even a cheaper one can be better than a loupe. Some folk just dont get on with loupes, I'm not particularly good with them. My missus uses a small cheap russian scope that works well, ive seen these for as little as 20 quid. I'll borrow it later and post up a photo of it and a shot of a zoomed in balance when i get home later.1 point

-

Great topic, I'm also looking forward to the responses as I've recently acquired a vintage gold plated ladies rotary watch that needs some cleaning. I was considering ultrasonic, but everything I've been reading states "do not put your gold plated jewellery into an ultrasonic". This appears mainly because of US cleaning fluids causing damage/discoloration, but some comments have mentioned the US vibrations may damage the plating. Honestly, I doubt US would damage plating through vibrations alone (unless you already have flaking plating I guess), but I'd love to hear what the experts here say. I figure ultrasonic cleaning would be fine with a mild degreaser like a dishsoap in distilled water though, with thorough drying after. IPA (isopropyl alcohol) wouldn't effect gold/silver/platinum in any way so should also be safe to use, for example as a wipe with cotton swabs or similar. If you want to use IPA or any other combustible materials in an ultrasonic cleaner you should use it in a sealed container, for example putting your case in a sealed glass jar with IPA, then putting that jar into the (water filled) US tank. Obviously remove the movement before cleaning the case.1 point

-

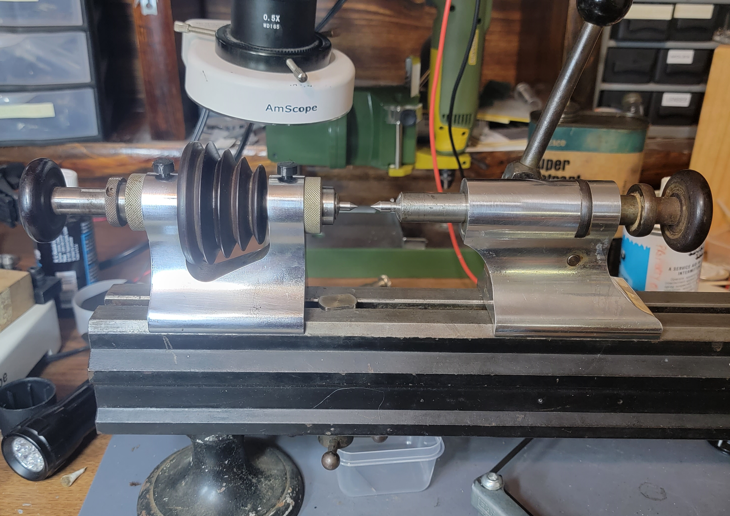

OK, the headstock and tailstock are pretty clean now. I printed oil caps because the originals were missing. I have the cross slide soaking now. One thing that is a little odd about this setup. The lathe bed is not Levin, which is not so odd, I guess, but it appears that it was not mounted to anything. So with the motor driving the pulley, what kept the tension? My plan is to remove the bell mounts and mount the bed and the motor on the same platform. The lathe bed, BTW, is very very heavy, so that may be why it worked for the former owner. I am loving this thing more and more every day.1 point