Leaderboard

Popular Content

Showing content with the highest reputation on 10/22/22 in Posts

-

G'day Everyone, I hope this is the correct place to introduce myself? I guess I'll find out soon enough. I've been a reader of this forum for a while, and have been subscribed to Mark on YouTube and a follower of his on Instagram for a few years. I've always been interested in watches, especially dive watches. My dad owned a couple back in the 60's and 70's. I have started tinkering and modding Seiko SKX007s' in the past few years and making leather straps to suit them. I decided to join the forum because I read a fantastic post on here about making bracelet end links from stainless steel sheet. That post has helped me a great deal in solving a problem. So, I wanted to come and say thank you! Cheers, Steve2 points

-

Haha funny watchie, thats not necessary lol. I'm not sure how to link threads. It was only a day or so ago, I'll find the thread. Here you go matey. Its only a short vid and sort of funny in an old American 70's documentary way. Good to watch the old master at work though. https://youtu.be/egCwtMMoOCU2 points

-

Watching it under magnification while it is running in the movement may give you some better indication of the problem. Are you able to post a slow motion video of it oscillating, others may pick up on something you might be missing. Then once ruling out that the hs is not the issue you could look elseshere for low amplitude. Thoughly cleaned and well lubricated an obvious must. I see mate watchie is here as well, as we both know from a few weeks back, power to produce good amplitude starts within the barrel. Pivot condition also extremely important, i have one on my bench at the moment that would just not pick up amplitude DU + DD My new monster microscope has revealed completely flat pivots at x40. A good reason for me to try pivot polishing. Eyup matey . Hope you are good. I haven't read your posts on the tg yet but it looks interesting and I'm curious about it. h s manipulation a very worthy skill under your belt for sure. I've been discussing vibrating with John and getting some good information, have a quick look he links to an old Fried video ( i was 7 at the time ) doing some crazy manipulating tricks, you may have watched it already. Its something I'm determined to learn. Start at the hardest point and work back to the easier aspects .2 points

-

This is the reading from my newly serviced ETA 2892-A2. As you can see, lowering the gain setting shows an amplitude of 296 degrees, and looking at the balance in slo-mo this seems to be near the truth. Setting the gain to its default value the amplitude drops by almost 25 degrees. Finally, when the gain is set to its maximum the amplitude drops by another almost 40 degrees. I have also seen the opposite, especially with Seiko movements. That is, to get the correct amplitude I would have to increase the gain by a couple of steps. So, before starting any fault-finding I always try the various gain settings to see if I can get a decent amplitude. If not it is time to start the fault finding. Also very good and true advice from @HSL " If you measure the amplitude just after servicing you will get a lower reading which is natural. " Good idea John! To tell you the truth, I have called a few watchmakers on various matters but have always been met with scepticism. Maybe it's because I'm honest and tell it like it is, that I'm just an amateur. They refuse to even consider the problem I describe and say that only if I take the watch in for a complete service will they be able to help me. Very disappointing indeed! They probably think I'm a stingy tinkerer trying to repair my own watch with the tools in my toolbox. Well, there are some very reputable watchmakers here in Stockholm and if I visit them in person I might be able to get better treatment.2 points

-

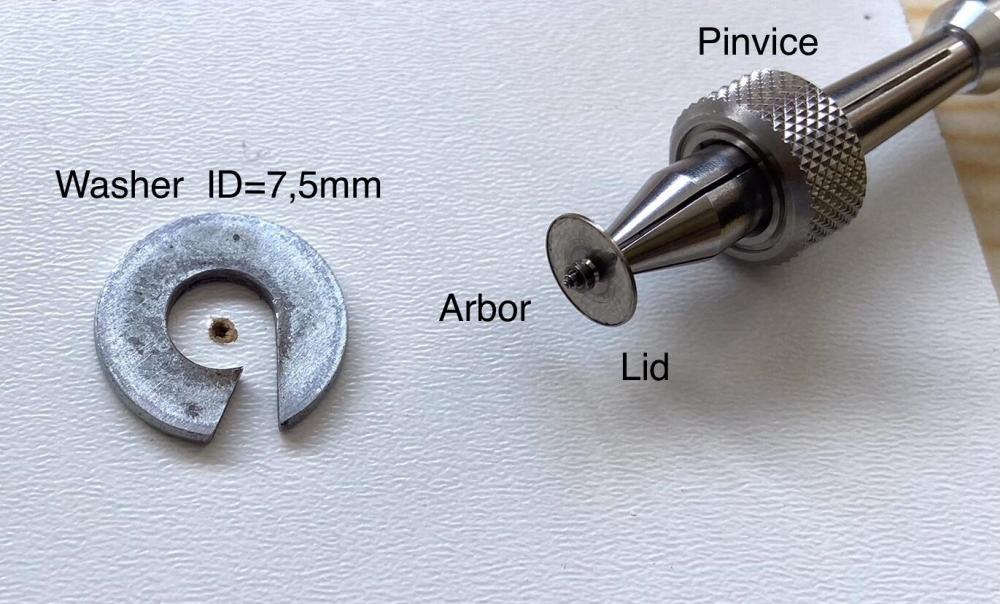

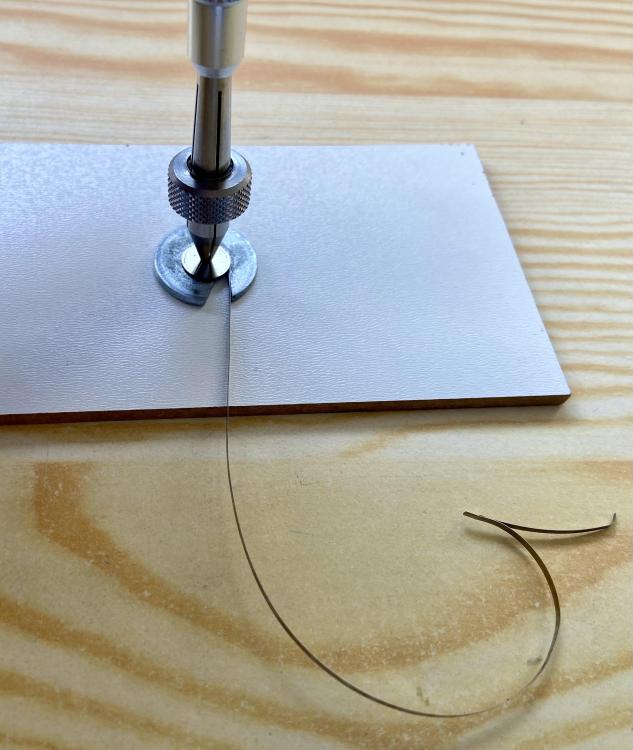

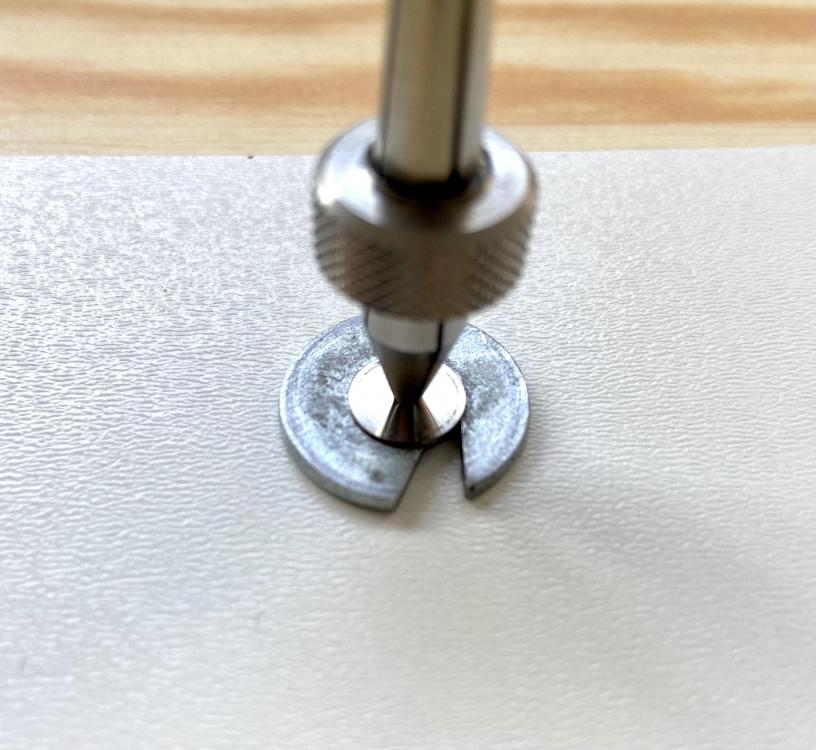

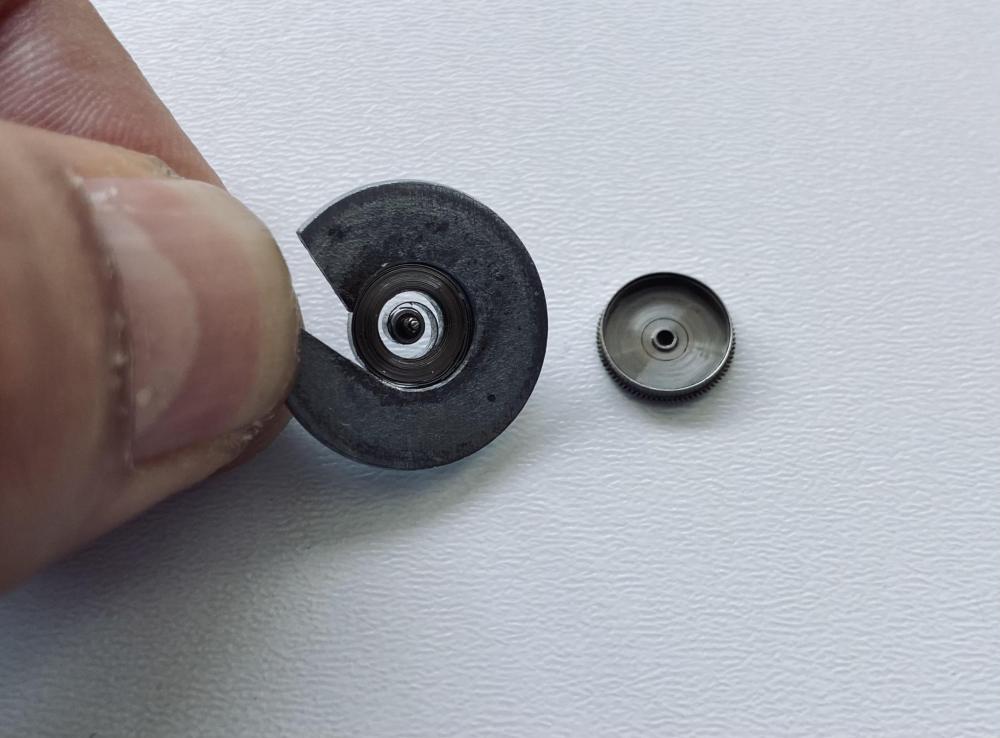

Inspired by the Mastercraft winder I tried to use its principle for a „quick and dirty“ mainspring winder. The spring I used for testing has an arbor diameter of 2,2mm (left wound) and the barrel has an ID of 8mm. The mainspring has a hight of 1,2mm. So I found a washer with the right thickness of 1,2mm, drilled it to 7,5mm ID and cut a slot in with my dremel. Then the washer was fixed to a board with three tiny drops of super glue. I used the original lid and arbor and my pin vice to complete the tool. The rest is selfexplaining looking at the pics. Any thoughts?1 point

-

Have a little search back Ross mate that same issue was mentioned a few weeks back with some fixes of reducing the inner coil to fit. Carefully was the order of the day. Introduction of heat was mentioned and using round nose pliers to wind around. There was a good hack that worked well if look back.1 point

-

Eyup matey. A press is a press, I would say the dies are what makes the difference in application.1 point

-

1 point

-

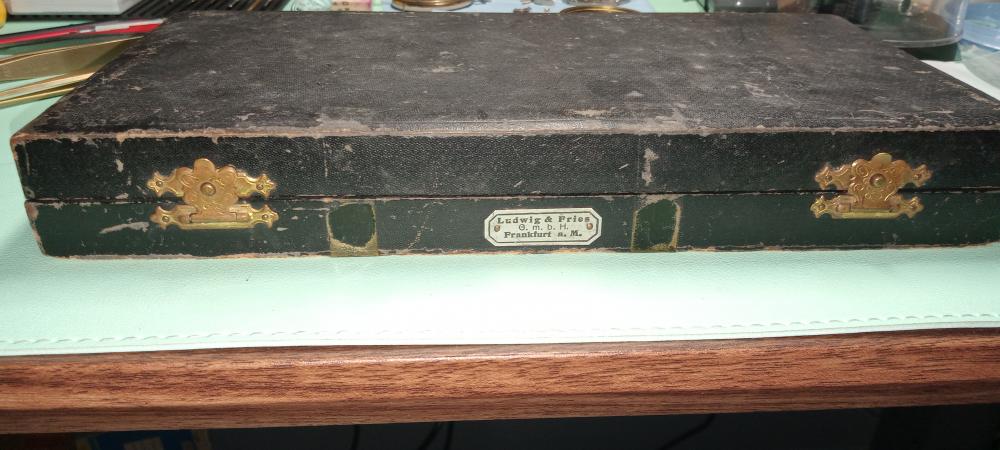

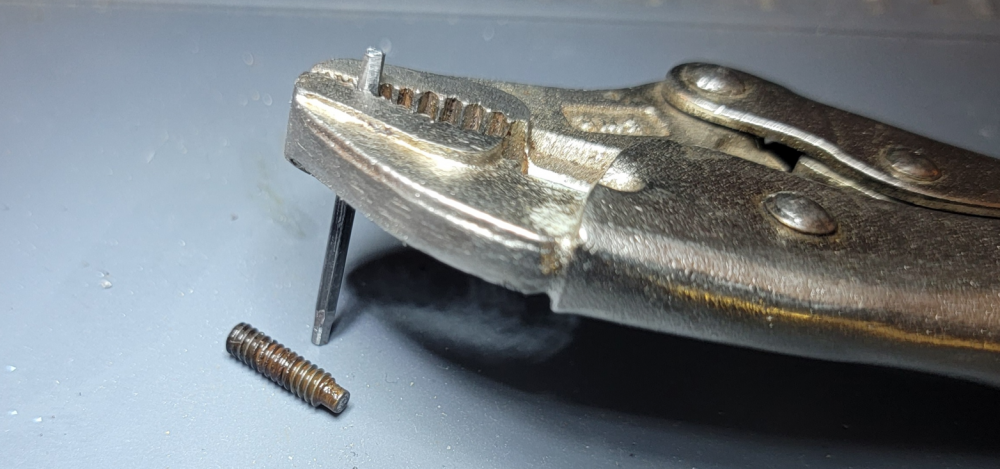

I think I did pretty good. Ofrei has bergeon jacots for over 4 grand! the guy with the used one claiming to be bergeon wanted over $1500 bucks. nah. i'm good with this one. spring drive complete with original bow string and extra string works great and all the lanterns are intact. little clean up, a little buffing and a drop of oil i'm good to go. first one up is a center wheel from a Waltham size 0s pocketwatch but I don't think I have the right size pivot holder. says Ludwig & Fries on the box but looking under my loupe I see no signature on the tooling except for the number "32" stamped on one end. either way it's in great shape.1 point

-

No, I haven't, but where's the link? I'm so interested I'd even be willing to pay you for it!1 point

-

I must say that I am very impressed with your ingenuity. I am one of the lucky few who owns a Master Craft Mainspring Winder, in mint condition as well. Well, what I wanted to say is that the Master Craft transfer plates are significantly thinner than the springs. I think it helps to ease the weaving of the spring into the transfer plate.1 point

-

No. My guess is that the coils are still coming together or rubbing somewhere.1 point

-

1 point

-

Can you get the balance assembly out cleanly, or is it trapped somehow? If you can, remove it and take some photos of the hairspring and pivots. Then remove the rotor. You will ideally need to take the movement out of the case and put it in a holder to reinstall the balance (this one or a replacement). Otherwise, the case will interfere with the balance and your lines of sight, and make the job 10x more difficult.1 point

-

one of the minor problems with the book is the author. For instance here's a link to a video that was made showing how to straighten hair Springs and notice how simple he makes it look. So yes if you're really really really good all of this should be really really simple https://youtu.be/egCwtMMoOCU1 point

-

Ouch, with that balance loose like that a lot of ugly things probably happened to the pivot and hairspring. Based on the fact that the balance is so close to the mainplate I’d hazard a guess that the pivot has broken off. You can buy a new balance and fit yourself, but that’s not always a simple thing. Probably best to grab a donor 7S26C and use it’s balance complete.1 point

-

I've done a bit of research so far and ordered a nickel anode today, as well as went a bit fancy and got a variable dc power supply. Lots of fun!1 point

-

Even with the screw removed, the pulley does not want to budge. There is enough slack so that I can push the outer bearing forward and spray it with a solvent so that it can be cleaned. The rear bearing comes off easily. So, I have cleaned it, oiled it, and reassembled it. Looks very nice. Will post pictures later.1 point

-

I’m from an engineering background, if it’s not broken it doesn’t have enough features1 point

-

I picked this up on ebay really cheap because someone listed it as a lathe attachment. It is a Webster-style winder/unwinder. I modified it by adding the 7/16 deep-well socket and the 1/2" male socket adapter. The deep-well socket accepts the letdown tools listed earlier in this thread. After I got this working, I found an Ollie Backer, so I don't use this one any more, but pretty proud of my mods.1 point

-

1 point

-

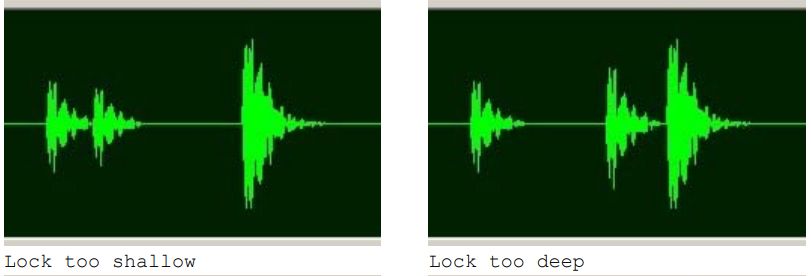

@ossing In the scope view you cannot see the "length" of the pallets, but - somehow related - you can see if the "lock" is ok or too deep. If shallow, ok or deep, it will occur on both pallet views! The middle one of those three main pulses of the tic noise indicates the start of the impulse that drives the balance. The later it comes (more right), the deeper was the lock. @Neverenoughwatches As you expected, a balance w/ hairspring alone will not produce a detectable noise for timing. You may hold them hovering, just the lower pivot touching the mic once every swing, as John said. But I have no idea, how exact and repeatable this method is. There is an electronic counting box available, but not for pennies, and you will need a Luthy, not cheap, too. I know the Swatch school Pforzheim/Germany uses this setup. For display they use the Witschi WE in BPH mode. At least the 18000 balances you can simply test with a stopwatch, timing e.g. 50 full swings. Frank1 point

-

The arbor support is a nice accessory to have. But as I use the Webster more and more, I find that it's not absolutely necessary. I just hold the barrel in a gloved hand and use it like the old English pattern winders. And safety equipment is absolutely essential. I use a cut-proof glove on my left hand and sometimes a wrist guard for extra protection. I always imagine a mainspring breaking and the jagged end slitting my wrist. I also use a face shield instead of just goggles. @oldhippy has taught my how to do some really scary things like removing a broken spring from the barrel, removing the tail of some mainsprings with a pair of long nose pliers and holding it till the power is released. And I thank God for every accident free adventure. Stay safe and enjoy Mike.1 point

-

A cheap version of a let down tool is a hardwood shaft with a slot cut in it to fit the key. fit over the key take up the slack and release the click and let the shaft rotate in your hand as a brake. Befor I built my own mainspring tool this is what I did you years and still got my own fingers.1 point

-

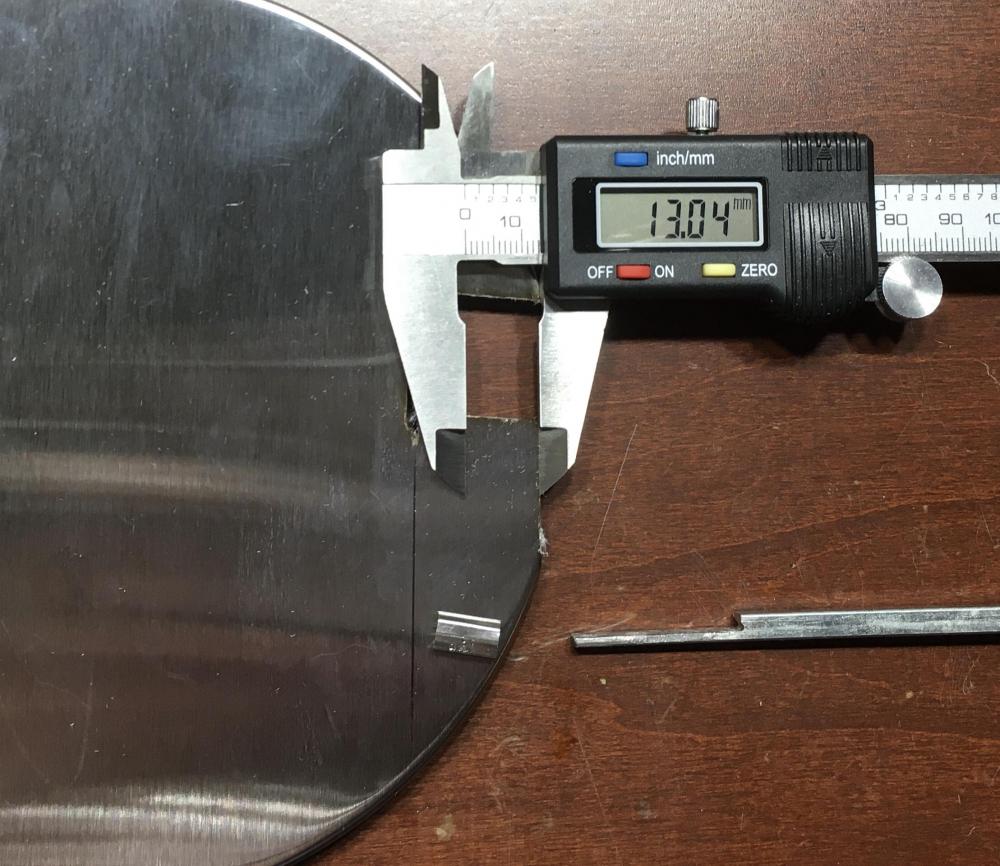

Bergeon does tend to do a fair bit of markup but not sure how much really on high ticket items. The basic Jacot straight from Horia is about 2400 bucks, with center wheel runner up to 3k and then more if you get one with a moveable head (up down)- they are very expensive new. Secondhand they can go anywhere from a couple hundred up to 5 or 600 (sometimes more) depending on how big and complete the set it. There are sets that go down to 0.04mm at the small end, many stop at 0.07mm. Some sets have extra runners that do 0.005mm steps. Some with center wheel runner, and some with all the above. Might have the built in spring drive, etc. One of the great things about Steiner/Horia, at least the "modern" ones, is they are very adjustable. And, parts are available. But there were many other makers of these tools and most are really nice- post some pics of the Ludwig and Fries when it arrives!1 point

-

Unfortunately it's a sensitive subject with me. It's a very frustrating thing to stare at the computer screen and well what you see isn't always what I speak. So I have frustrations getting what I want on the paper and then. For instance I answered something else today and I went through what I did previously for each the previous messages had obviously totally wrong words to almost the point where wondered how anyone could even read the thing so yes for me it's a sensitive subject. It's just frustrating because unfortunately I'm a perfectionist which by the way sucks Inwatch repair you do not want to be a perfectionist In watch repair. So unfortunately for me it's a sore subject as I've had people be critical of the past so I'm just bad with this1 point

-

I realise that you use dictation software (without a spill chucker) @JohnR725, and I only pointed out the error as I found it amusing - as many of the dictation errors are. So no need to become overwound1 point

-

Did you know you've never seen a message that I've hand typed. Every single thing here is with dictation software. The problem with dictation software is well sometimes I think it hates me. It doesn't always do the right word is not misspelled I can't find it with a spelling checker. Friends that I email comment a fine if they read it out loud to the word is not overwhelmed it should be over wound notice how dictation did that is two words anyway. So it's a dictation mistake the wrong word. That doesn't overwhelm me that just leads to anger and frustration but thank you for pointing it out. It's a very common problem is that people will say things about watches with no real idea of the problem. It's also a common problem that people get into watches unskilled people oftentimes children but sometimes the children are much much older and age like adult children and play with the watches. Then things happen bad things happen. This watch still looks complete it's probably the balance staff. But if it has really dirty oil bad oil it may not be running at all. Then if you do wind it really really you can break something. Then I suppose you would be overwhelmed at what the problem is. It's still a nice watch I have one on the bench yesterday I took it apart for cleaning up put it back together tomorrow. Then at least most of the parts are available. But that doesn't Spain somebody should start on that is their first watch never do family heirlooms is your first watch. So providing my dictation software did write that might be readable by the way that was my second attempt I usually have to do everything at least twice sometimes three times the hopefully get everything worded correctly.1 point

-

1 point

-

I thought it was a lack of money was the mother of invention, well it has been for me over the years with some of the gagets I have made1 point

-

1 point

-

As this isn’t really a “walkthrough”, I’ll just post some pics and descriptions here. You can fill in the blanks Here is a picture of tonight’s project and it’s original bent and scratched end link: The end product will basically be a piece of rectangular SS tubing with a butt or lap seam at the back (or could have the ends tucked into a “B” shape, etc...I started mandrels for this, but probably won’t pursue that route as it’s over-complicated). The key is keeping the face clamped flat, so it won’t warp, while making the bends. That, and making the last bend on the bracelet. You can’t bend it back without warping. Cut your SS larger than needed: measure the width of your lugs, then add 2-4mm. Cut a strip about 2cm long and the width needed.1 point