Leaderboard

Popular Content

Showing content with the highest reputation on 10/21/22 in Posts

-

I’m from an engineering background, if it’s not broken it doesn’t have enough features3 points

-

3 points

-

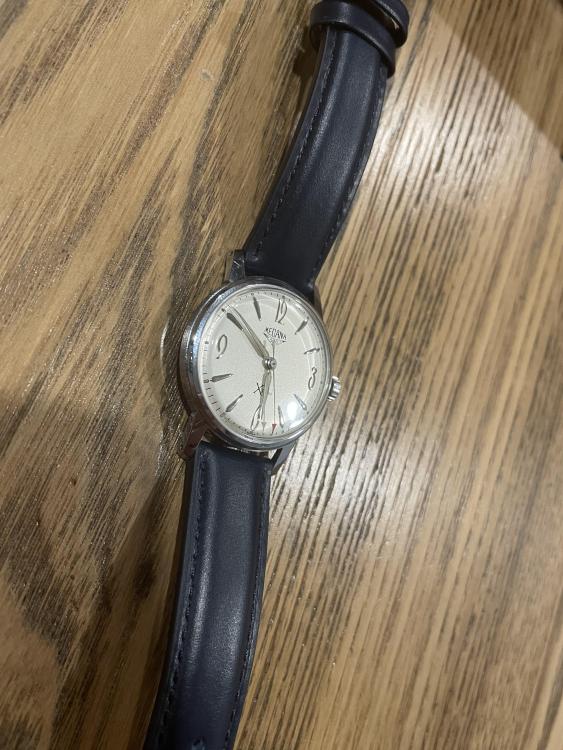

Hi all, Here is another project watch of mine, this is the third watch I've worked on so far. It was not in terrible condition when I got it to begin with. This is the first time I have sanded a crystal down and then back up again. There are still micro scratches but I find once I've put back onto the watch I don't notice them. This is a 1-jewel, pin pallet escapement. The Xtensa, I assume, refers to the shock protection on the balance. It was extremely frustrating to take apart/oil put back together the shock protection. The cap stone was not captured in the normal manner - it rather kind of floated on top of a donut shaped plate that held the 'hole jewel' that is not actually a jewel, under the spring. I was trying to be extremely careful of not breaking the spring or losing anything as I didn't want to spend on a donor movement. After at least a couple hours combined for both sides I managed to get them together at least. I would seriously consider staying away from working on a watch with this shock setting in the future, unless the price was right and I liked the look. Even though this is not so fancy on the inside with only 1 jewel, I understand there were tons of these pin pallet movements made and I enjoy the look, so hope it will last for many more years. I am happy to continue buying nice looking watches like this for very reasonable prices for my own enjoyment. The movement photo is before cleaning. Have a good night all.2 points

-

2 points

-

Hahahaaha yeah man were like Laurel and Hardy bud Thank you very much! As I said in another thread, I kinda gave up on looking for a proper vintage watch cleaning machine and with the issues guys have been having with the Pearl ones, I figured I'd have a go at doing something myself. And as you know, it started as something simple then ended up being a lot more complex than what I planned originally. It's about as close as I'm going to get to the fancy new Elma machines. The fact that I only need to change jars - everything else is pretty much automatic - buys me a lot of convenience and is another little pain taken out of the servicing process. I've not done a proper cost breakdown, but I'm about in the same budget as a Pearl machine but with high quality baskets and (I think) better cleaning action. If you want to do something similar I've got no issue sharing more details on what I've done. It's not terribly complex to be honest - most parts are found from companies selling 3D printer parts and the Elma basket complete I got from Cousins (which was easily the most expensive part). The jars I got from a local dollar store and built the machine around that.2 points

-

Regular members get 3 hours to edit posts. advanced members, patrons and supporters get longer. it’s documented here… closing this thread as it’s been answered and is now going off-topic.2 points

-

2 points

-

Hi all. Alright - what am I missing with this Wintex in terms of opening it up? I cannot find much online about the brand. I can spin the back with a rubber ball, but there are no points to put a case knife to be found. I have even looked under the microscope. Any input appreciated. edit - if at first you don’t succeed, try, try again. I found the opening for a case knife - it was filled with crud and/or case metal. Picked it out with tweezer end and I’m in business now. Feel foolish but I can’t seem to delete the thread.1 point

-

the other place I've seen that is in some of the books on watch repair they talk about using that method of manually timing by counting the ticking sounds. I would have concerns about stretching the hairspring but what about how did the factories do it? For instance I'm attaching a PDF on page 10 there's something a bit cryptic. It basically says as the balance wheel oscillates back and forth that lifts up and down and the Ruby plate moves up and down it doesn't actually say whether you are lifting up high enough to make a ticking sound but this indication is as the balance wheel oscillates up and down the timing machine times that somehow. but still I personally prefer that the balance wheel not be bouncing up and down is enough ways to destroy hairspring and stretching it doesn't seem like a good method even if you have some exotic machine that shows that method. would you know why the school is using this method versus the traditional way of just matching both balance wheels by looking at them? Then it appears to be that anyone who wants to vibrated hairspring beyond just some casual holding it and counting you're going to have to do some work like for instance in Bench Practices for Watch and Clockmakers by Henry B Fried. So it shows a picture of it was probably commercially made but a way of holding a hairspring and you should bill a make something like that and make the played a little bit bigger. Then there's another picture of where you get a master balance from just find a suitable watch with a suitable balance wheel and I would slice it out from the rest the plate because you need the rest the plate and you have a balance wheel and a way of holding it separate with a piece of glass and you should build his hand rotate and pretend it's a really nice vibrating tool for a fraction of the money. But Bill rapidly find out why everybody's using the electronic method but still you will bill a vibrator hairspring Greiner Vibrograf Spiromat Classic.pdf1 point

-

Nice looking watch. Odd that it's got so few jewels. I've never bought a movement with less than 15 jewels, and plenty of those have caused me trouble - so good luck with that !1 point

-

1 point

-

1 point

-

I was looking to see if there's any distributors near where you live and not in your country just neighboring countries. But there's probably watchmakers somewhere nearby maybe could ask nice and see what it looks like on their machine. https://www.witschi.com/en/contact/standorte/ a classic problem with Chinese products is variations lots of variations. Somewhere in the group we've had this discussion before most of the 1000 machines do not have that adjustment. Mine for instance does not have that adjustments. But some of the machines do have the adjustments. Then unfortunately they do not put revision numbers on the machine to tell us which machine is which. Plus the user manuals tend to not cover any of the stuff either so some new some don't. It tends to be all kinds of variations with Chinese equipment and you never know until you actually get it what you're going to get. And I saying that from experience with other products also1 point

-

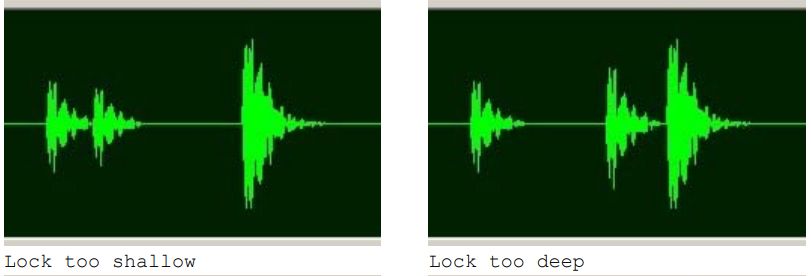

@ossing In the scope view you cannot see the "length" of the pallets, but - somehow related - you can see if the "lock" is ok or too deep. If shallow, ok or deep, it will occur on both pallet views! The middle one of those three main pulses of the tic noise indicates the start of the impulse that drives the balance. The later it comes (more right), the deeper was the lock. @Neverenoughwatches As you expected, a balance w/ hairspring alone will not produce a detectable noise for timing. You may hold them hovering, just the lower pivot touching the mic once every swing, as John said. But I have no idea, how exact and repeatable this method is. There is an electronic counting box available, but not for pennies, and you will need a Luthy, not cheap, too. I know the Swatch school Pforzheim/Germany uses this setup. For display they use the Witschi WE in BPH mode. At least the 18000 balances you can simply test with a stopwatch, timing e.g. 50 full swings. Frank1 point

-

Thanks for replying. Yes, it really is. I'll look into getting some appropriate grease for it. Moebius 8200 seems to come up on a lot of searches for it.1 point

-

That movement is absolutely filthy and needs cleaning to get all the old grease and oil removed. You will need clock grease for this not oil.1 point

-

It’s a great solution Gert, I might revisit it once I have got some other tool ideas out of my head that are not so ambitious but I want to do a proper job on them. Funny enough I was thinking along your lines for one of them using aluminium extrusions so might hit you up for advice when I get a round tuit thanks for sharing this, very inspirational Tom1 point

-

Hahhahaha yeah my brother also said I should do that. I said no. As a matter of interest, I use Hexane as a rinse so I have no need for drying the parts. By the time it's done spinning and I move the basket to my bench, the parts are already nice and dry.1 point

-

As far as the last question, isn't the visible cap jewel the only one you will expect to find on these 1-jewel movements, with everything else consisting of metal bushings and pins? The balance "jeweling" is not symmetrical.1 point

-

the code is the US import code. It's a way of identifying who actually imported the watch. I have a link that will tell you what the codes mean http://www.ranfft.de/uhr/info-uscode-e.html1 point

-

the biggest problem with using a normal timing machine would be it won't have enough range. When you start with a raw hairspring you'll be out of timekeeping by a very big amounts and easiest way to deal with that would be to have a timing machine that has a beats per hour mode which most witschi machines have and clock timing machines have. for instance this is an example of a clock timing machine with its optical adapter and their software. http://www.crackpotinventor.com/mset/tech/hairsprings/springs.html to even though I said normal timing machines won't vibrated hairsprings because the range problem that's not entirely true there was some timing machines that would do it. For instance the drum type machine the papers spool is inside the drum and pulls out a wraps around and once you've completed you can tear it off important if she'd out basically the drum type machine is interesting is if you look at the printout you can see the line angles up and down a can see how fast or slow you are going but if you are super far out of timekeeping it can actually spiral around the paper and you just have to count how many times and spirals and where it finally lands and you can figure out how far off you are by a very huge amount. Then you'll notice in the description it claims the holder for the timing machine can vibrated hairsprings. It's really hard to tell the picture but as a way of holding the tweezer so can suspend they hairspring with balance to just barely touches the contact plate and then give it a little motion would probably a puff of air as the balance wheel oscillates back and forth and moves up and down it will tap on the contact and show up on the timing machine.1 point

-

Hi I think thats a great soloution as you said in SA cleaning machines are in short supply (second user) and what you have created is as equal to if not better than many commercial machines. Bearing in mind you built it and know its quirks and as such can modify and repair it your self. brilliant.1 point

-

it's interesting is I've done side-by-side comparison with the 1000 1900 and the witschi that I have and I don't recall any problems but then I didn't spend a lot of time with at least 1900. I do have a Chinese 1000 though but mine doesn't have a volume adjustment maybe that's the problem. On the old paper machines was really important where you set the volume setting even though I do know they had automatic gain control. On the other hand the old paper tape machines were measuring amplitude they just needed to get a clean signal for timing. In the preferred signal is for all the machines the roller jewel hitting the fork which is the quietest sound which is why need the most gain. When you're playing with your volume settings when it should try another watch and see if that changes anything at the same time. It's when you're doing stuff like this that's why like the oscilloscope feature with the machine at work because I can look at that and see what's going on I get a clue what the timing machine is thinking or why it's not timing things correctly.. out of curiosity and looking at the manual for the 1900 and it claims it will automatically adjust for optimum signal level during testing. now the interesting problem is other then it explained that one arrow makes the whatever go up the other arrow makes it go down there is no hint as to where the volume or gain setting should be a. As I said on my witschi Turner on with the volume knob and turn it to the middle position and you just leave it there and I just don't recall ever having to move it around very much.1 point

-

@VWatchieIn an attempt to keep this forum and this thread on topic I’ve removed the political statement from your post - thanks for your understanding1 point

-

1 point

-

1 point

-

A cheap version of a let down tool is a hardwood shaft with a slot cut in it to fit the key. fit over the key take up the slack and release the click and let the shaft rotate in your hand as a brake. Befor I built my own mainspring tool this is what I did you years and still got my own fingers.1 point

-

Hi all - this is my first watch build from internet parts, following completing an online course. I went with the seagull st3621. It was difficult to find a version with this finish, and also the 6:00 seconds. I ended up finding this on eBay. On AliExpress there was only one version which I did not like. The 9:00 seconds movement seems more popular but the 6:00 subseconds is more pleasing to me. Movement from ebay as noted, and everything else from AliExpress. I disassembled and washed, lubricated the movement before use. The only issue I ran into was that it seemed the dial feet were ever so slightly too short and I couldn’t get them to bite on the dial screws. Eventually this was creatively solved by extending the feet with super glue, and also bending one very slightly. I wanted to get a nice strap and was not too pleased with the options on North American websites (and their associated prices) but was happy to find another Ali vendor that only makes straps. Cost wise it was still much more than other options on Ali but I am pleased with the quality and they may be my go-to for straps. I’m happy how this turned out and am pleased with the exercise. I have a few vintage watches lined up to work on next. Just waiting on a strap for a medana and then will post the results of that one. Take care. Also wanted to add that I was surprised at the lack of dials available. In my mind initially the choices were going to be significant. It turned out to be quite the opposite.1 point

-

I don't have any experience with Chinese machines with a gain settings so that I don't know. having looked at schematics for older timing machines they typically have automatic gaining controls built in. Even though there is a volume knob they still have an automatic gain control. Looking at the manual for the witschi machine that I have you tried on your set the knob at the middle position and I don't really remember ever having a problem with that. The manual does state that there's an automatic gain control so basically I don't remember having to adjust because it adjusts itself. Now the machine at work the very expensive witschi only has for you the level the numbers 1 to 4 and at least it has about oscilloscope so for having a timing issue will look at the oscilloscope and we can see why if there's a single problem. Usually with really quiet watches will just increase the number and I'm guessing because the automatic gain control it doesn't seem to make a spectacular difference of was the watches really quiet or the other problem. The biggest problem at all for timing machine seems to be picking up a good clean signal. So holding a watch in the timing machine pick up holders critical anything that interferes with that is going to disturb the signal while the signal is an audio frequency range it's not picking up audio it's picking up the vibration so anything that interferes with that will mess up with the timing machine sees., That workers with Seiko watches with their plastic movement holding ring case stop the watches will look horrible out of the case they look beautiful. But is not just Seiko watches things like a heavy Rolex watch or any heavy metal case it becomes sometimes problematic to pick up the watch. Sometimes if you put the crown to touching the pickup if you like you get a better signal otherwise the watch has to come out of the case then unfortunately that is a true statement. It's why you need to visually verify that the watch looks like it's doing whatever the timing machine says. The graphical display has to agree with what you're seeing and then the numbers have to agree with that also. So to see random dots on your machine you have a problem the numbers are worthless and you're going to have to troubleshoot the watch. If you go to a super low amplitudes more common on a Chinese machine or the machine at work even if it is more expensive if the amplitude is too low the machine will read the wrong part of the waveform a give you a nice happy amplitude which isn't there. That's where visually observing does it look like it has a nice amplitude versus what the machine tells you. so yes unfortunately you have to be careful on how you interpret what you're seeing and figuring out whether you're actually having a problem with you and your machine or whether it's the watch that's the problem.1 point

-

1 point

-

Unfortunately it's a sensitive subject with me. It's a very frustrating thing to stare at the computer screen and well what you see isn't always what I speak. So I have frustrations getting what I want on the paper and then. For instance I answered something else today and I went through what I did previously for each the previous messages had obviously totally wrong words to almost the point where wondered how anyone could even read the thing so yes for me it's a sensitive subject. It's just frustrating because unfortunately I'm a perfectionist which by the way sucks Inwatch repair you do not want to be a perfectionist In watch repair. So unfortunately for me it's a sore subject as I've had people be critical of the past so I'm just bad with this1 point

-

I realise that you use dictation software (without a spill chucker) @JohnR725, and I only pointed out the error as I found it amusing - as many of the dictation errors are. So no need to become overwound1 point

-

Watch Repair Channel on Youtube! Mark Lovick is our host here, and also has an online course you can take a look at. I took the first three levels and got a lot out of it.1 point

-

Mark has a good video showing his process (similar to the video linked in the original post but with clearer visuals) as well as the automatic oiler option: Esslinger sells a tool ($9) for feeding the oil through to the cap jewel if you want to go that route: https://www.esslinger.com/watch-oil-inserters-tool-balance-jewel-oiler/1 point

-

I have seen and heard of several variants of this cap jewel cleaning method, but none of them have felt really safe so I invented my own variant and was so happy with it that I recorded a video of it. Hope you like it and get use of this "safe" method for cleaning cap jewels.1 point

-

I've attached a lesson I wrote on the BFG 866, which includes refitting the hairspring. Just make sure to turn the boot 90 degrees with a screwdriver of appropriate size to enable the hairspring to sit between the boot and curb pin. Fit the stud, then close the boot. If your hairspring needs refitting to the stud, you'll need a small brass pin shown in the photo. I prefer to fit the HS when it is clear of the balnace Lesson 15. The Baumgartner 866 continued.ppt1 point

-

Just some thoughts about the amplitude in the 28XX series. To get maximal amplitude before regulating these beauties I use to let it take some time. If one follow the oiling scheme in the tech notes one should get a quite good amplitude. The important step in the process is to let the movement run for at least a day or two before starting regulating the movement with a time graph. If you measure the amplitude just after servicing you will get a lower reading which is natural. To get maximum lubrication one have to let it get worked in and spread out on the surfaces. To gain maximum amplitude on these ETA Movements or any one else I guess it is of most importance to learn how to oil/grease the jewels on the pallet fork with for example Moeibus 9415. In my experience this boosts the amplitude significant. To get an amplitude of 300 one have to do the complete service including main spring change. When I get the amplitude to 280 or higher i begin the regulating work. Hope these observations can help you in some way.1 point