Leaderboard

Popular Content

Showing content with the highest reputation on 09/26/22 in all areas

-

I have used 12% sulphuric acid, sold as Vissen by Bergeon, on nickel (German silver) parts to remove broken taps. I noticed that if the part wasn't super clean the acid could stain it, clean no problems. If you have discoloration like Frank describes, often rubbing wet blanc de Meudon might restore the original color. This is a white powder also called blanc d'Espagne which is readily available in Europe but not sure elsewhere. French chalk works the same. It's also used in ceramics and as a base for gesso so art supply stores may have it.2 points

-

You will want the balance complete. Not much info on the 6428, but if you want to take a chance, Look here - http://www.ranfft.de/cgi-bin/bidfun-db.cgi?11&ranfft&208&2uswk&Unitas_6428 And then here - http://cgi.julesborel.com/cgi-bin/matcgi2?ref=[^[DXMWJ Cheers!2 points

-

Update: I let it run 48 hours and it is doing really well, strong in all positions with the dial and hands installed. So I don't know why this one took twice as long as any other I've worked on to distribute its oils and stabilize. I did not clean off the escapement and redo the lubrication.2 points

-

Hi VW I think the tube that is being refered to is the extension of the second hand that fits over the shaft and as mentioned, and is when pressed on below the level of the minute hand. This renders any lifting tool useless as it cannot reach the "tube" bottom for a straight lift of the second hand alone. My own method and that used by many, is using a poly bag over the hands get the levers under the hour hand and lift. Never had a problem but thats not to say even with this method a badly rivited "tube" wouldn't be detached on lifting. Hi VW I think the tube that is being refered to is the extension of the second hand that fits over the shaft and as mentioned, and is when pressed on below the level of the minute hand. This renders any lifting tool useless as it cannot reach the "tube" bottom for a straight lift of the second hand alone. My own method and that used by many, is using a poly bag over the hands get the levers under the hour hand and lift. Never had a problem but thats not to say even with this method a badly rivited "tube" wouldn't be detached on lifting.2 points

-

Technically, I wouldn’t trust either of them, as both would want to embellish the truth. Its now common practice for tool manufacturers to manufacture at least some of their lower end tools in low cost countries, while manufacturing the higher end range in the home country. Other manufacturers have the bulk of the product manufactured in low cost countries, then ship it back home for final QC, assembly or finishing. I would imagine that under such a scenario, both parties (the contractor, and contracted to) would want to claim as being the complete maker of the tool, but the truth may be somewhere in the middle. On the other hand, it would be very bad PR if a company completely misrepresents where it’s products are made, especially if it’s relying on brand name for high prices: it would at least want to have some plausible deniability over interpretation of where it’s products are made. For the contracted to company, openly flaunting that it’s the maker for a big name is also kind of dubious, as it could potentially be a breach of NDA, or just killing the golden goose altogether. Not to mention, some of the claimed OEM makers of tools on AliExpress have products that do differ in minor ways from the supposed brand name products (in pictures), or just ship a different product entirely.2 points

-

Hi all. Hope this is ok, I did search first but found no similar threads. Given that many of us are not blessed with high salaries or pensions and cannot afford to buy high value tools from the Swiss makers, we only have what China offers for our hobby and as many have found a lot of what is sold on the likes of eBay turn out to be just rubbish and not even worth the low prices asked. After buying a few useless tools I started to look at some of their better quality offering, which although quite a bit more expensive, were still miles cheaper than the Swiss tools, sofar the few I have tried turned out to be of excellent quality. So to help others less well of could we have this thread for people to post about their quality Chinese Tools, for others new to hobby but put off buy high prices might find a better tool at a more appropriate price. If this is OK I will start it off with some of my recent acquisitions. Thanks. Paul1 point

-

If you can reach to screw from two sides you could also try with a screw extractor. I bought this tool some time ago and it worked really well. However, be aware that the tip of the extractors is very sensitive and easily deforms. Luckily the extractors are replaceable. Not cheap, like anything Bergeon, but as I said has worked well for me.1 point

-

Hey, thanks for your replies guys! Crystal clear! I think I read about this "tube"-problem on a Poljot 3133 (I believe) chronograph here on WRT (a service walkthrough or in that context by @Endeavor). Too tired and exhausted (from my infection) to look for it now. Anyway, so not chronograph specific, and luckily not something I have yet experienced myself. Hand levers, a piece of plastic over the dial, and being gentle while prying is also my method. It has worked perfectly so far and is much better than any specific tool (presto) I've tried, but I'm always open-minded about new tools and enjoy good tools almost as much as watches.1 point

-

Eyup matey, glad to see you better. Paul is referring to the tube on the backside of a second hand. Apparently this hand is super tight on a tag heuer, when he lifted the hand off with hand levers it sounds like the tube disconnected from the rest of the seconds hand and was left on its post ( seconds hand pivot ) that is my understanding of that situation. That was how i understood it WW. As you say most of us lift all 3 hands together, it could have been a sub hand but even so i still don't see how a specific tool would avoid leaving the tubd behind either. Maye paul can elaborate on this tool we are talking about.1 point

-

Hi welcome to the forum, In answer to your question "balance not moving" you mentioned its had water in it, yes. How long ago and did you dry it out properly, because if not the movement may have rust present stopping the watch. Or it could be a legion of things, broken staff, broken pivots, dirt , congealed oil ,the above mentioned rust, broken mainspring, seized train wheels, Have you dismantled the watch, ? so you see the possibilities. first can you post a picture of the movement out of its case less dial and hands, front and back so members can see the state of the watch as is before attempting a diagnosis. cheers thank you1 point

-

The Elma Suprol Rinse smells FAR worse According to Wiki, it's not very toxic : "Acetone has been studied extensively and is believed to exhibit only slight toxicity in normal use. There is no strong evidence of chronic health effects if basic precautions are followed.[71] It is generally recognized to have low acute and chronic toxicity if ingested and/or inhaled.[72] Acetone is not currently regarded as a carcinogen, a mutagenic chemical nor a concern for chronic neurotoxicity effects.". You need to use any of the cleaners in a well ventilated area. I use a heated ultrasonic with the chemicals in small open beakers. You can see the vapour evaporating from the surface, so I have a window open and fan on - still stinks tho ! I'd be interested to hear from anyone why you can't use acetone for cleaning watch parts.1 point

-

It's a shame that the "proper" watch cleaners are not sold in smaller quantities - like 1 litre. The cheapest I found is Elma WF Pro - 2.5 litres from Cousins is about £30. I use refined Naptha and IPA rinse for years, as I'm only a home hobbyist. They do clean well enough. But since switching to Elma WF Pro, it does clean better and gives the metal a nice shiny finish. And the 2.5 L will last me a long time.1 point

-

I was wondering about that, but thought i would see what develops before i open my gob. Unless the lifter pulls the tube instead of the hands which isn't possible as the tube is buried. I personally couldnt see how it would make a difference either. Apart from a more expensive occasional tube popper off-er.1 point

-

You need to rinse, as any naphtha leaves an oily residue. You can read (ad nauseam) on here about IPA dissolving shellac, but, as long as it is a brief rinse, you will be OK. When I used IPA, I limited my rinses to 30s-1m in the ultrasonic. I imagine a brief dip and jiggle by hand will be enough to remove oily residue, then blow dry with a puffer.1 point

-

I'm not aware of any reasons why you cannot use it. But, you still need a cleaner for the balance and pallet fork. If you don't want to invest in some proper watch cleaner, you can buy refined naphtha quite cheaply, which cleans well and is safe with shellac. (Or if you are going to rinse in IPA, you could just use lighter fluid).1 point

-

I have since changed computers and lost a few former bookmarks in the process, but if I can locate my source again for new cylinders and tampons, I will post the link here. But you'll need more than just parts. I use a special set of punches in my staking set, cylinder punches, to adjust or disassemble cylinder staffs. They were no easier to come by than anything else to do with these kinds of movements. Old Hippy is wise about this; these are not good practice movements for beginners. They are most often ebauche movements with few or no markings, varied provenance, and often have parts which were adjusted to fit the individual movement. That said, by no means are we encouraging you to give up on it. But we do recommend that it is to soon to begin work on this kind of watch. There is lots more to learn first. I have worked on several cylinder escapement watches that other technicians would not touch. And I learned first hand why they were apprehensive. These are very different. Different rules sometimes apply here.1 point

-

Good question. I once removed a screw with alum solution from a nickel plated chronograph plate. After, the nickel had considerably changed its appearance and looked different from the rest of the movement. I will not (and did not) do that again! Frank1 point

-

I have dental instruments which are supposed to be made in Germany but the metal has a yellowish hue, which is characteristic of surgical steel from Pakistan. I met the manufacturer at a convention as ask him point blank, when we were alone, if his instruments were made in Pakistan. And he answered me, without any hesitation, that they are 100% made in Germany. Prior to that meeting, I met the Pakistani manufacturer, who showed me a bagful of instruments with various brands on them, claiming to manufacture on behalf of those brands. The Germany brand was among them. So who is telling the truth?1 point

-

Hey everyone I enjoy tinkering and used to get my fix by making knives, but with a baby (now toddler) that hobby has been put on pause. My co-workers dad used to be a watchmaker but had to stop due to arthritis. I was lucky enough for him to give me some basic supplies to get started along with some busted movements and books. After destroying one movement I signed up for Mark's online course and have made my way through half of it while working on a couple of my own movements. Eventually I'd like to get to the point where I can buy vintage pieces and restore a handful a year. There is surprisingly little information on watchmaking and this forum has already been a great help. Cheers! Adam1 point

-

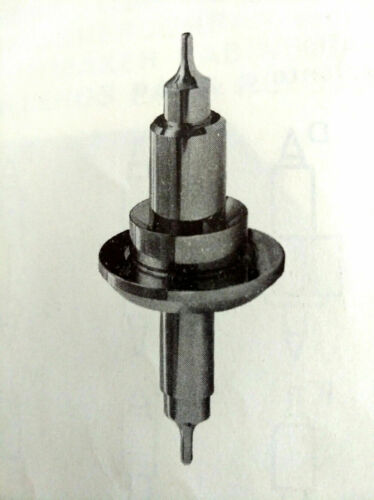

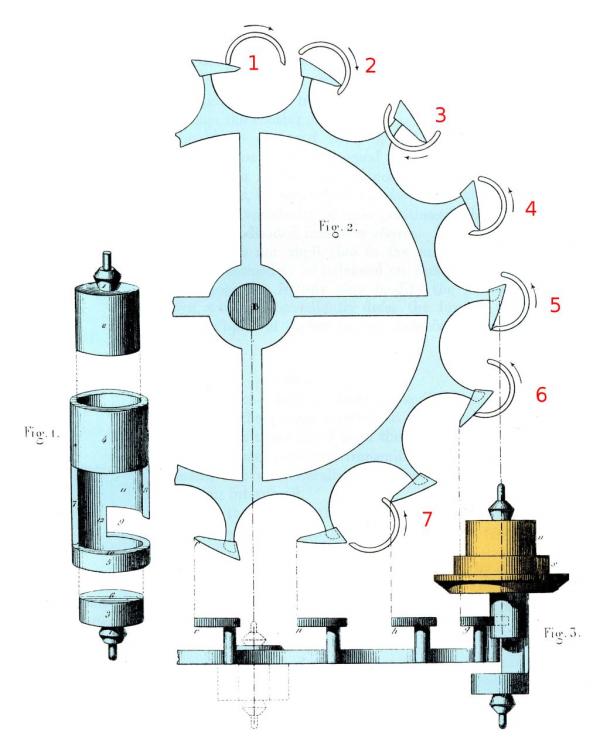

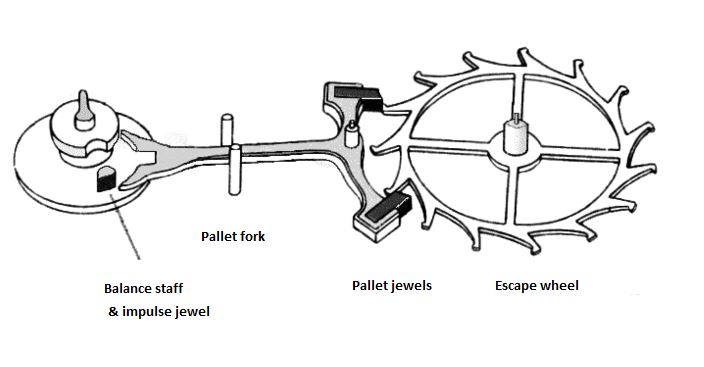

Yes you will find them on ebay. No cal or ref as I have already said parts are not interchangeable. It does not have a balance staff it has a cylinder which watchweasol has already pointed out. Here are a few photos so you can see the difference. A cylinder movement is not a good place to start for a beginner. Photo 1 Cylinder. Photo 2 Balance staff. Photo 3 Cylinder escapement. Photo 4 Balance staff escapement also called an Anchor escapement.1 point

-

It sounds as though you are happy with this situation and have no ill feelings towards Swiss manufacturers whatsoever.1 point

-

I have just taken delivery of one of these myself. After the nightmare I had with a Tag Heuer where the seconds hand popped off its tube when I used hand leavers like I always did with all the other watches I have stripped down, one set of Tag hands cost me £120, so the price paid for the hand lift tool £145 is not so bad if it saves me from that nightmare situation again. They are well made and a quality product, just got to wait for the next Tag to land on my desk to try it out in anger. Also remember not all these Chinese tools are clones or copies, some of them are the same tools some of the Swiss makers claim to make, they have their tools made in China and just package them in made in Switzerland boxes. I have some that are so identical the parts are fully interchangable with the Swiss version and all the machining marks are identical, showing they are off the same production line, and just sent to a different logo printer. The Swiss watch industry is a very shady industry, from watch makers only being bracelet makers who use a generic movement from a movement maker to the likes of Rolex who although they are a multi million company don't pay any tax because they are set up as a charitable organisation but only fund themselves, to their tool makers who have their tools made in China but claim they are made in Switzerland and charge over inflated prices for the same tool that can sometimes be bought direct from China at a fraction of the price the Swiss charge.1 point

-

Moving to correct sub-forum. ---- Why is this happening? Please don't be offended - from time to time, in an attempt to keep WRT organized, we need to move threads to another area more suited to the subject of that thread. Members can help the forum staff by checking for a suitable sub-forum before posting as this will help to reduce their admin workload.1 point

-

Thanks ifibrin. I would still like to try though with a bit of tool making experimentation before i shell out over a hundred notes There are also agate burnishers. I would say its just as much about dressing the burnisher to a sharp edge, a square edge or an appropriate radius to suit the pivot being worked. As it is about the material. Steel has the added advantage of being dressed as needed and then hardened. Stones and jewelled files much more difficult to shape to a fine sharp edge.1 point

-

Everything helps a little bit, but the fact that the rotor runs off axis really seems to prevent it from running like butter. I think it could run as is and it would work just fine, but I want to go one more step and see if a trued up rotor would really make the difference. I've been spending some time trying to design a rotor I could machine with the tools I have. I'll probably try to get to it this week and see if it makes a difference. rence.1 point

-

Hi I've worked on a tissot seastar and I get it close of course. Now I'm trying to close the back but I can't I cannot explain why just that it seems there is no room I join pictures Thanks for any advise I answer my own question I've inversed the movement ring so I came back to the picture and figured out. My advise for the beginner : take picture of the case and the rings before disassembling to avoid this experience it as much as important as the movement itself Thanks1 point

-

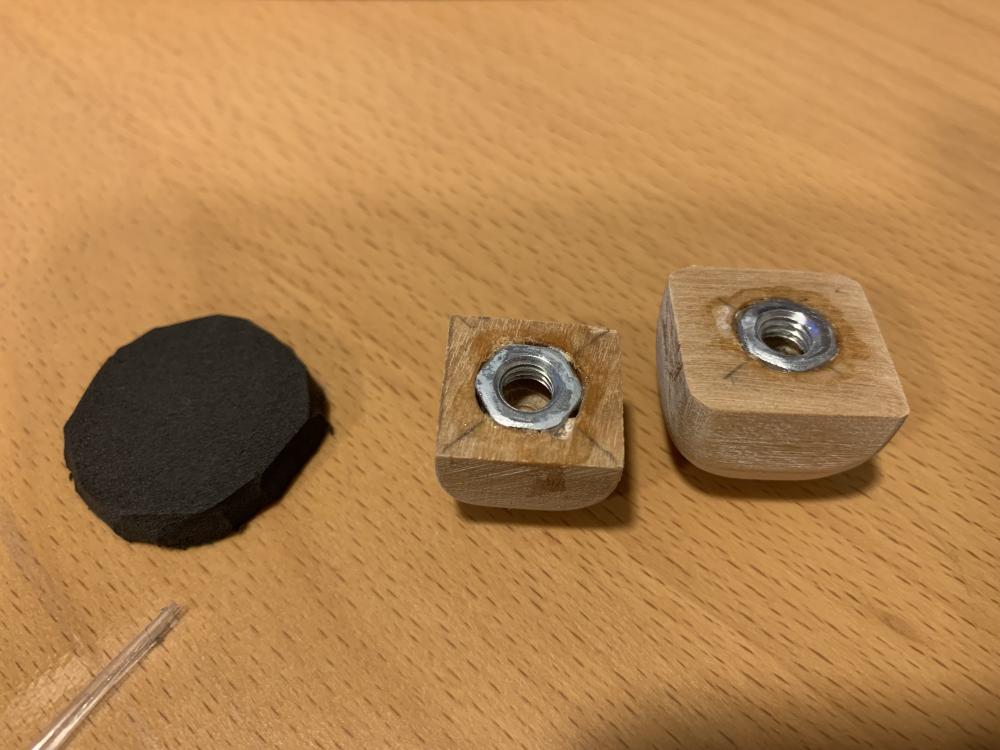

I actually did this a few days ago to put my 1st acrylic dome in. I have one of the cheap lever style chinese presses. I sanded down some scrap wood, put an M6 nut into the back and just used some super glue to hold it in. I put a small piece of foam over the dome when pushing on the crystal. Without the foam, I broke a crystal, but I chalked that up to also being too large and being the 1st time I have tried this, was using way too much pressure to make the larger size fit. The smaller size down is the one that ended up fitting.1 point

-

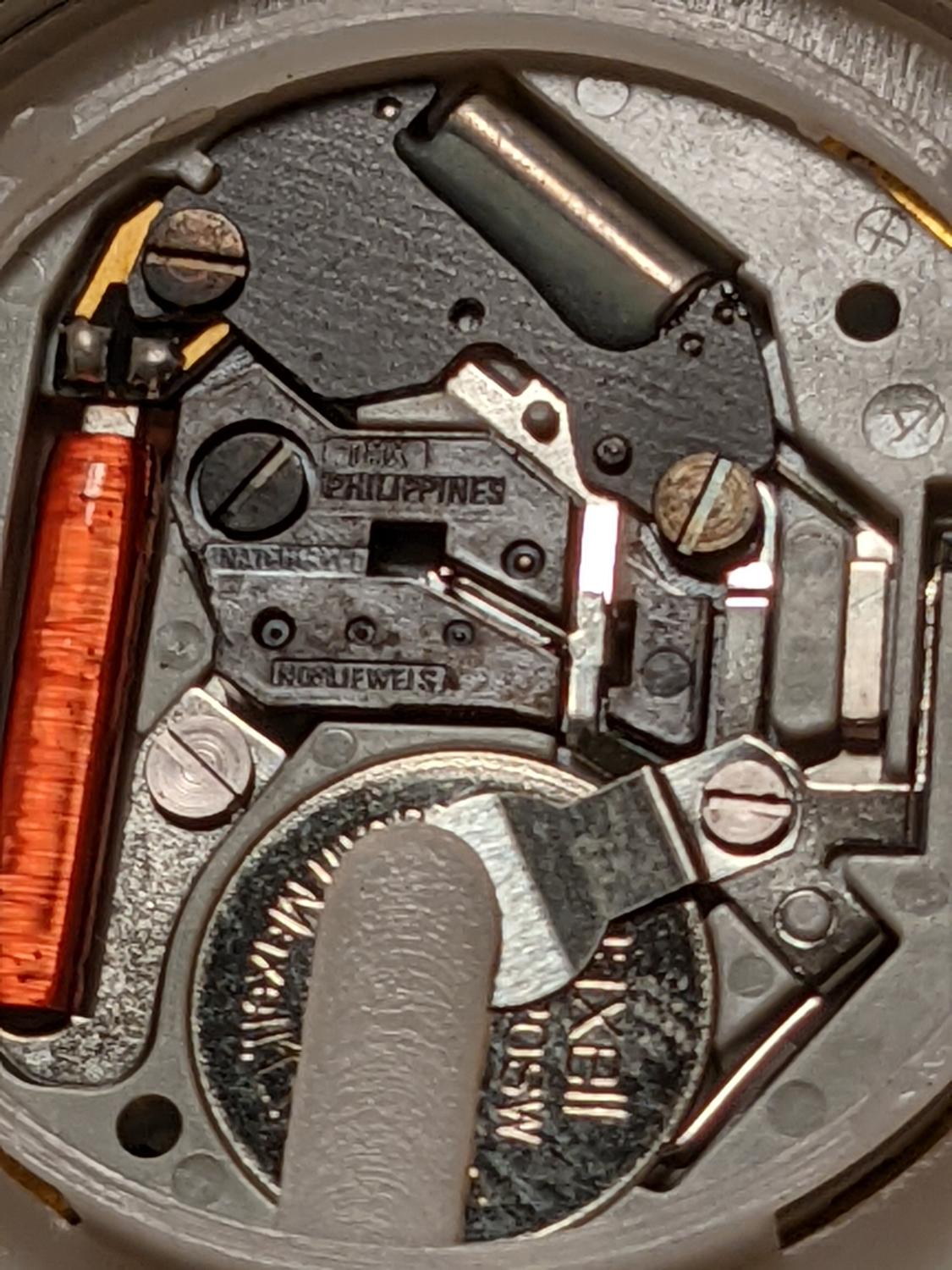

All of this is based on my hobbyist experience. Seiko quartz of this era came pretty highly regulated. They were designed in the mechanical watch era, with mechanical watch parts, and were meant to be serviced. If it is loosing that much time, it needs a service. I have serviced a few 754x movements that were loosing significant time. Without adjusting the trimmer, they all came up keeping time within seconds a month after servicing. I would not touch that trimmer screw until you have serviced it.1 point

-

Aw mate dont say that. You had a breakthrough yesterday, i even gave you a point and your watch challenge a nil poi. Here buddy take from this what you will, here are my stupid beginner fookups. My grandfathers watch, my first repair. Fixed it cleaned it oiled it, it worked after 50 years in a drawer great yes ? . Noooooo .One month later almost ruined, cleaned it in washing up liquid and water as recommended by a youtuber, oiled it with garbage oils, maybe didnt dry it enough ? . Rust took hold pretty quickly, used Rustins rust remover to derust the escape wheel, overnight soak, it fooking completely dissolved it. I was totally fooking gutted to say the least. Number 2 fookup. A smiths diver a great find yes . Yes until Richard the breaker got over enthusiast with a hair drier to dry the case front . Melted the crystal right off it, which wasn't particularly a problem because i was changing it anyway but in hindsight i should have just sanded and buffed it. No not just the crystal but damaged the fooking bezel as well, its now put aside until i find another bezel. Was i gutted ? Absobloodylutely mate. And there are more to mention. My point is am i still here, still learning and still repairing ? Most definitely. Moral of all this. Dont give up mate, we dont give up, we keep trying, we keep practicing , we keep learning and i can honestly say we really really do get better. Have you learnt from your mistakes and experiences ? i know you have. And will you make many more mistakes ? Yep just like we all have, and will you learn from them mistakes ? Yep just like we all have and thats why we get better. And you will have great moments as well and those great moments come more often the more you keep trying. So the best advice i can give you, comes as somewhat harsh, suck it up mate and keep going it will get easier trust me. X1 point

-

If you can see the oiling in the balance jewels and it looks good, and the watch is running fine and winding correctly with the automatic, just keep wearing it until the oil looks like it has depleted somewhat, amplitude starts to drop, or the rotor starts spinning when you handwind (sign the reversers need servicing). If a watch has been properly cleaned and serviced to ETA factory spec it really should run 10 years without issue.1 point

-

Hiya mate. I understand your dilemma completely, this is your love of quality and gorgeous watches drawing you in. I've noticed your posts and spoke to you often over this past couple of months and know how you feel about beautiful timepieces. Also your curiosity is wanting you to get hands on to further explore inside. Are you feeling a little nervous that you may effect its performance ? Haha mate if all this is true then you are just like me. Personally i would leave it be for the time being, its obviously in no desperate need for a service. I would want to give it some wrist time and I'm sure it wants to be worn first ( before you abuse it, only joking ).1 point

-

Don’t do it! I wouldn’t service that especially since the performance looks so good, that’s just asking for trouble. Maybe in a couple of years time…1 point

.thumb.jpg.3d46ee576b34a2419c769eb7a70d8dc6.jpg)