Leaderboard

Popular Content

Showing content with the highest reputation on 09/22/22 in all areas

-

I picked this up on my trip to MN for my canoe trip. As noted in another thread, I also picked up some cleaning machines. This cabinet is full of crystals, all neatly organized. I was shocked with excitement to see that none of the inserts were missing. This is pretty unusual for something that is probably 60 years old. I will never use all of these crystals, but they are there...just in case! I also got a gillion class pocket watch crystals, and post about them at a later time.6 points

-

I don't do work for the public, but my guy who feeds me work charges around 300 CHF for a regular watch, pretty much the same if it's manual, auto, calendar, and around 500-550 for a chronograph. I get about 70% of that- which is a fine deal for me, he definitely earns that 30%. I make out right at my hourly rate doing the work. He's kind of cheap for Switzerland, haha. Those prices don't count replaced parts or case refinishing etc. We (I) also will do basket cases, Roskopf movements, make literally anything from a pallet fork to vibrate a spring to whole bridges or whatever, so there's a solid client base and I'd say 70% is chronographs, 20% other decent watches often in 18K cases, and then the "please save my watch" or basket cases. We also (and I do also along with another client) depannage professionelle* for other watchmakers who break a staff on a piece where none are available and things like that. I'd estimate that about 20% of my time is spent helping other watchmakers hahaha. Often for a beer or a bottle of wine. Sometimes whisky. *Depannage is usually used in conjuntion with broken down cars and the AAA guy or whoever save you on the side of the road. The Swiss Franc is pretty much at parity with the Euro and Dollar these days.2 points

-

2 points

-

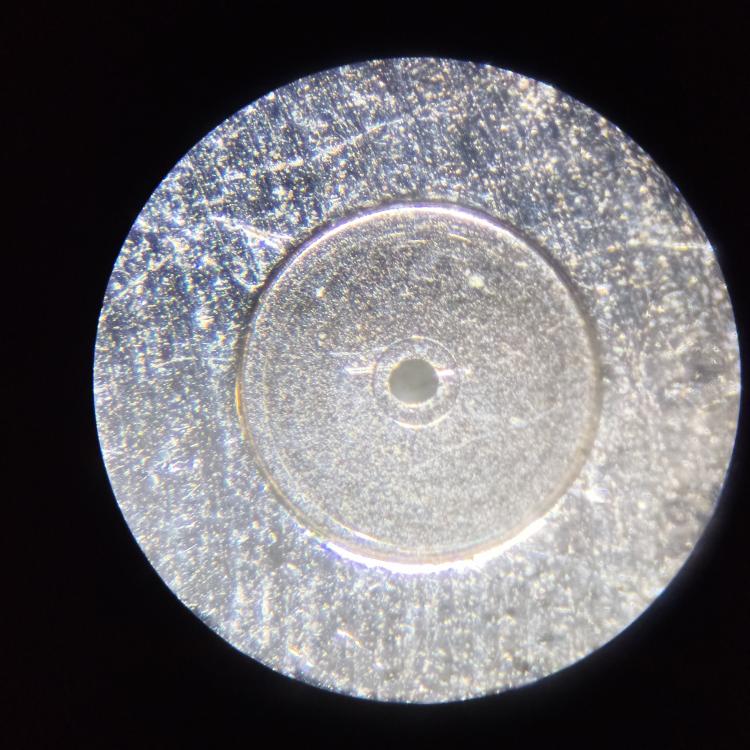

As mentioned, that wavy timegrapher trace sounds like a worn bush. Especially 4th wheel bush in the train bridge tends to go oval or irregular shape. This picture is from a 6105. I replaced it with a jewel from a 6119. Direct swap, no reaming needed. I have the Chinese Horia clone and it's a great bang for buck. Also there's often too much end shake in 4th wheel so that the wheel almost falls off.2 points

-

I think if the setting is unscrewed and removed there will be 2 jewels there. One in the setting and one in the bridge. Both have holes. The jewel in the setting that is screwed on top will be for the 4th wheel (sweep seconds) and the jewel with larger hole in the bridge for the center wheel. Both jewels would be oiled. The center wheel would have a tube for a pivot and is installed under the bridge in the photo. Remove the setting to confirm, then clean the jewels well. It would be removed anyway to adequately clean.2 points

-

I doff my cap to thee sir...You is truly a gentleman of taste and fine breeding... 50,005 plus a pound of genuine braking grease...and a genuine link removed from a watch strap worn by Sammy Davis Junior... But be aware I am a notorious mountebank chased from Monaco to Marrakech by debtors for my outrageous bidding on things others would scorn...2 points

-

I think I know what the problem is. Watch this video. The motor head should be lowered until it touches the rim of the bottle to reduce splashes and evaporation of the cleaning solution.2 points

-

1 point

-

Welcome to WRT @MJR123 I look on eBay for Seiko H601-5479 and found many for sale or auction. Your best bet would be to get a working donor watch and transplant the movement into your watch. Since the watch is of sentimental value, it's best to practice on some scrap watches first before attempting the actual transplant. Good luck and don't be afraid to ask questions.1 point

-

I just checked the published prices of a repairer here in the States that I know is quite good. In fact, he is not taking in new work because his backlog is too big. $220 base price to service an automatic with calendar. I think $300 is not too uncommon, and I once paid something around that to have my Oris serviced (years ago, before I learned watch repairing). If anyone is charging $500, it would be for "luxury" watch service. I think there is an independant Wostep trained and CW21 certified watchmaker here in Duluth, but I haven't met him yet, and don't know what kind of prices he is charging. I'm actually quite curious, I wasn't expecting someone like that to be based here. Cheers1 point

-

Its mainly on hold at the time being. We have some family staying for a while, so I'm doing my "Scottish Tourist guide" impersonation at the moment. On the plus side that does mean I haven't managed to fill the space with clutter yet, except for my ancient Gould 1602 oscilloscope, which seems to have died of lonesomeness in the attic, some time in the last year or so and is probably next on the resurrection schedule.1 point

-

It's used as-is, with a bit of oil (9010 is good). The tool has a conical sapphire in the tip that does the work- using an abrasive would mess up the tool!1 point

-

It seems this is from 1959. Furthermore, I wound it and it runs. Its still due a service, which I hope to do this evening, and it does feel a little gritty when setting the hands, so it may require a little work, but all in all a fine candidate for the 404 club and not a bad deal for 0.99p plus postage.1 point

-

Hi Looking at the case pictures you supplied previously it looks by the scars on the case that the bezel comes off complete with the crystal . You will need a sharp case knife to prise the bezel off. If the crystal has no tension ring you should be able to push it out. Some crystals (acrylic) require flexing using a couple of dies and a press to re fit. Crystals have various ways of being fitted and several different tools to do the job.1 point

-

Hi Guys Just my penneth, When servicing anything be it a watch or a car they all look the same but they all have subtle differences. So if you service one brand you become familiar with the product and as a result get quicker, through put is higher. If you service all different makes you have to become familiar with the differences and as result are slower as you take into consideration the differences and all the gotcha's you encounter. Hence the reason the independent watch repairer is a scarce commodity these days as all jobs are returned to central workshops. A typical example is Timpsons, They do simple jobs on site the complex issues are sent to a central workshop in Manchester I believe, where they have a team of repair guys probably specialists in Seiko, Tissot, Russian watches etc . and they do nothing else but those brands most of the time and become proficient at their line. When I worked on the Addo (Swedish) Accounting machines, the first total re build took 48 Hrs and I got it down to 12hs by constantly working on the same range, two and three register machine s, All electromechanical with levers and springs of which there were 10 or more different types for different jobs. The machine had close on 1,000 bits and they all had to work in unison quite complex. So by limiting the range you increase speed. all the best1 point

-

Totally agree watchie, i think 2 hours to setvice for an enthusiast they would be drastically cutting corners. Possibly for a pro, like you say with all the best equipment on something basic that they know inside and out. Maybe this person got lucky with a service, you know like a Rubik's cube (I used to do them as a kid, loved solving puzzles ) when everything falls into place, it doesnt mean they could do it that quickly everytime. We get faster for sure when we've been there before especially when its recently, auto pilot takes over with help from our memory. i have this when fitting kitchens if i haven't done one for a while. Putting cabinets together, a less complicated scenario obviously but the same principle. My first cabinet might be 20 mins, second one 17 mins third one 15 mins by the time my last cabinet is assembled i could be down to under 10 mins easily and thats maybe on just 10 repetitive procedures. So fast service is possible but only in certain circumstances so its not really a true representation of what the average repairer experiences.1 point

-

I would seriously suspect that to be a scam. It would be interesting to measure and investigate an Omega, send it in for the £130 service, and then measure and investigate when returned. Naturally, if the shop is located in India or Ukraine, where the cost of living is quite different from ours, that could explain a lot. I've heard people on this forum claim a complete service can be accomplished in under 2 hours. I didn't get into that discussion. It's just not serious. I sometimes need an hour or two to just get watch out of the case The only way to make a decent profit for about $500 a watch, would be to have first-class equipment, have done the same watch and movement over and over, perhaps even hundreds of times, know all the pitfalls and basically be able to overhaul it without even thinking. I guess that's why it actually works. Anyway, when I hear people whine about the cost of a proper service, all think is they have no idea about what it actually means. it would not mean a life of abundance (especially not in Sweden) as half of it would disappear in taxes, which is then misappropriated to everything but me and my family.1 point

-

1 point

-

I bid 50.000 guineas... but I reckon given a bit of tinkering you could possibly double use this also as a dialysis unit for diabetics. two birds for one kidney stone like as it looks impressively medical...1 point

-

Yes, thanks for that, that does seem to help keep the arm totally stable now1 point

-

Is the impeller held on by just the one screw on the side? I removed it and the thing was still stuck on the shaft.1 point

-

Watchmakers have for generations used loupes in a single eye, you would think that without binocular vision that there would be no depth perception. Not strictly true! Our depth perception relies on many cues other than our binocular vision, and learning to see "depth" and the relationship between things in our field of vision is certainly possible using primarily one eye. It takes practice, though. It took me a long time before I could use a loupe effectively, and one of the things I had to work at was not closing the other eye. Amazingly enough, having both eyes working is better than just one, even though the second one is not magnified and in my case out of focus and distorted. It takes practice, real watchmaking requires serious physical skills, and you don't get there by just watching videos Cheers!1 point

-

No, it didn't have that vibration at first. I've only put 10-15 watches through it so far and it started with the vibration after maybe 5 or so watches. I think that the vibration may be generated by the arm becoming loose so that as the arm starts to creep up, the arm isn't held under the correct amount of friction, so then the while unit starts to vibrate. I just ran it with an empty basket and paid attention to that little brass bit where you tighten the knob to fix the arm in place. It definately made a big improvement in how much the arm creeps up, which also pretty much did away with the vibration, at least at the beginning. However, you can see as the arm starts to creep up, the solution in the jar really starts to slosh around compared to when I first start the machine: This is without the jar to better see the basket and arm: I think (hope) that maybe I just need to figure out how to better tighten the arm so it doesn't start creeping up, but I don't really have any ideas on that. Pushing that brass part down before fully tightening the knob did help compared to how it acted previously but it doesn't seem to be enough to keep it from moving. Or, I guess it could be the basket or shaft is off center so that it starts to shimmy, causing vibrations, which is what is causing the arm to creep up.1 point

-

Sorry to hear, but I understand your vision issues, I truly do Definitely get the Barlow lens. Being able to work directly under the microscope is a game changer. I have glasses optimized for close work (Zeiss Office Book lenses), B&L visor I wear over those, loupes, and my microscope. I'm used to a routine that would probably seem quite cumbersome to someone else, but it goes like this for most work. Start with glasses on . If I'm moving a part, like from tray to movement, I put on the visor, otherwise I might not see if I drop the part. Once the part is under the microscope, I take off the visor and glasses. I have a cord so the glasses just hang around my neck. The microscope has diopter adjustment on the eyepieces so I can work without the glasses. This has become habit. When working with my staking set, for instance, I don't try and change the microscope setup. I have an adjustable table, so the microscope swings out of the way, and I raise the table to watchmaker bench height. I use glasses and visor to move parts to the staking set, and then a loupe as I use the staking set. Seems to work OK so far. I haven't used my jacot tool in a while, I think the next time I do I'm going to experiment with the microscope, as I have several different barlow lenses I can try, to see if I can get a good setup for that. I do change the microscope setup when using my lathe, the whole workbench gets changed when I'm turning. Some folks have a bench just for the lathe and a dedicated microscope, I'm not there yet. Don't have the space, and I have other tools I need before I invest in a second microscope. I my case, my vision problems are caused by macular degeneration, but in some respects I am lucky. There are now treatments that can arrest the progression of the disease, and in some cases reverse it. Unfortunately, the treatment consist of injections into the eyeball, which is downright creepy My current opthamologist is really good, there is no pain and only mild eye irritation for the next day or two, so I deal. Previous doctor, not so easy. Anyway, I'm just trying to illustrate that it is possible to continue even with challenges, just have to double down on the vision assistance and develop habits to compensate for less than ideal vision. Cheers!1 point

-

I'm of the opinion that so much can be wrong at the release side of the movement plus more complicated and delicate at that end. Assembly starts with the big energy giving components so why not begin fully inspecting and correcting there first. Like a car if it won’t start it ain't gonna move ,or if the engine runs rough then you're not going to be able to drive it very far before it stops.1 point

-

I've seen watch repairers advertise on ebay for servicing on good watches such as Omega. Around £130 which seems cheap to me also bearing in mind this wont inc. a repair. I would have to make an assumption that a pro would do a basic service in 4 hours but that is a complete guess tbf. Maybe nickelsilver will elaborate on that. I wouldn't expect this to be 4 hours hands on either, waiting for machine cleaning would free up time to jump on something else. I do this at work everyday in my field of work jumping from one job to another so that I'm constantly working through a full project. So as a guess 2 watches a day thats looking at well over a grand a week. Obviously running expenses can take a good half of that depending on premises etc. All conjecture obviously, as with everyone we wouldn't do what we do if we couldn't make a living from it. I do wish i had done something like this when i was younger though, beats grafting my nuts into the ground1 point

-

Thanks Andy, I would put money on it being a National Semiconductor module. I have seen similar but they had stickers saying as such. I did look into trying to dissemble it and thought the better of it. It seemed very firmly in the case. I'm going to have to dig out a copy of the hitchhikers guide now. Hadn't read it in some years.1 point

-

1 point

-

I did pay on PayPal with a credit card, but this was 10 months ago and outside of the time frame where they could have helped. It was in the middle of a cleaning cycle and it just stopped. There wasn't any type of burning smell. I just went and checked if there is a humming sound, and it actually started spinning! I've tested it more than a dozen times over the last two months and it never spun up so I'm not sure why it suddenly decided to start working. I did wonder if the original problem didn't come from all of the solution that winds up on the inside of the bottom base, where all the wires are running. It gets really wet in there because the arm keeps creeping up, flinging solution out of the jar. In the first and second positions (cleaning and first rinse) it works fine when in solution but in the third position (2nd rinse) it creeps up out of the solution and flings the solution everywhere. However, when in any of the three positions and in the spin cycle when it is just above the solution spinning off the excess, the arm/basket will creep up out of the jar. So I was basically just tied to the machine during the entire cleaning cycle as I have to physically hold the arm so it stays in place. Now that the machine seems to be working (for now), any ideas on how to get the arm to stay in position?1 point