Leaderboard

Popular Content

Showing content with the highest reputation on 07/26/22 in all areas

-

Continuing to work through the cheap vintage watches I got from taobao. Next under the microscope, I present the Golden Rooster. I call it differently because apparently I am a 9 year old boy. Basically it is the same movement as the previous ZTZA movement. This just calls it differently the 7120 movement? Another difference here is that there is 2 extra jewels, so instead of 17 it is 19. Feels the same to me. This one does feel like everything feels a better fit and the power train bridge did fell into all the pivots at first go. (Score!) Again a manual movement. I am feel like I gaining more confidence in taking it apart and cleaning and putting things back together. There was only 1 heart attack, when the incabloc spring refused to go back into the slot. A coffee and a cigarette after, was able to coax it back into place. Side note, since getting the stereo microscope really helps. Being able to see if you are holding on to small bits with your tweezers actually seems to help. Who knew? The golden rooster is from sometime in the 70s or 80s and from Shanghai watch factory. One annoying thing about these 3 watches are they are 19mm lug width. They are ok, but replacement watch bands costing more than the watch itself means that I have to use the ones that are supplied. Which is fine, but sometimes you want options. I humbly present the Golden Rooster, put back together.4 points

-

4 points

-

Good Idea, it will save time and trouble also the frustration of fitting the little springs. One thing , you will never know everything and never will. a man who knows everything knows nothing. You have the right attitude to succeed.3 points

-

Eyups all. Here we have not quite a 404 but a very very reasonably priced utter beauty. These things and their successor wristwatch counterparts are my absolute favourites. I recently posted here not my grail watch but something very close to it. A Dirty Dozen, ok nothing so rare that its difficult to come by but definitely limited numbers available and also quite well sought after. My searching has now thown up another mil spec watch. This is a Frenca G.S.T.P pocket watch. For anyone wonderering a General Service Trade Pattern watch, some ideas suggest Time piece but i prefer Trade Pattern. I'm not entirely sure which version is correct maybe someone can elaborate on this. Inside is a Buser 105 calibe, this baby is pretty big at 19 lignes. I took a punt as the dial looked suspect poor. But i got in real close and figured it was the crystal. Hardly a soul touched it on ebay, obviously nobody looked as close as me. It arrived today and sure enough the dial isn't half bad at all just a crazed and cracked crystal . Opened the back up and the movement is just as clean and perfect. Overcoil hairspring in perfect condition, jeez you could springboard dive off this thing its that solid. I so love military watches. Well-built, robust , reliable, practical, everlasting quality units ( bit like myself ). I should have been a soldier, i have appreciation of everything a good soldier stands for. Discipline, regimental, honour, justice the love for his country and where he originates from, fitness, action, courage, and especially camaraderie. The idea that i have your back and you have mine no matter what happens. I have mates like this, and there is nothing that i wouldnt do for them or they for me. Sorry got side tracked there. Here is my latest beautiful watch. I'm just dying to start researching its history.3 points

-

This Tevise watch was purchased by a friend of mine purchased approx six months ago. It keeps reasonable time but if he forgets to manually wind it it stops. It cost approx £30 new so he was not expecting a Rolex performance. However I was asked to look at it to see if I could get it to wind automatically. I did warn before I agreed to try and fix that these Chinese movements are prone to mishaps but if he was happy for me to proceed on this bases I would try. The movement is housed into the case via a snap back case back and plastic movement holder. Looking through the clear back I could see the rota was not rotating as it should. The removal of the movement was straight forward. The dial is just friction fitted via dial feet but to the outside of the movement and aided by some double sided tape. See pic the rota screw seemed not to have been fitted square. However see pic the rota is actually secured by a crude post that has the start of a thread that aids it screwing into a centre wheel which has threaded centre. This centre wheel fits into recess in the plate BUT it is incredibly slack / loose and I expect this is the problem. To fix this fault would be difficult if not impossible as the plate is too thin for a bushing or jewel. I did also notice there seemed to be no lubricated parts. So I cleaned all of the auto parts in my watch cleaning machine and treated all of the parts with Epilame( Fixodrop) and assembled. Assembly was very fiddly to say the least one of the jewels detached itself from its plate and I re inserted the jewel into the plate with a tiny amount of loctite. I lubricated all parts with HP 500 and put on test for 36 hrs and it seems the auto is now working. Summary: Overall looking at the movement through a microscope, lots of scratches and dings.It is very poorly assembled and as you would expect for a £30 watch all parts are not made of quality materials. My advise be very cautious when working on these movements and if asked to repair give the customer a cautionary warning before agreeing to repair.2 points

-

Yes absolutely true but to be fair for £30 it’s a good watch. My friend is very happy my payment by the way is a few beers.2 points

-

Yeah, auto oilers aren't as easy to use as you would hope. It takes a while to get to grips with it and to set it up properly. As above, you still need to remove the cap jewels to clean them and yes, they're more tricky to keep together if they're not oiled.2 points

-

2 points

-

Has anyone else tried to 3d print faces for older watches i have a 1976 tissot digital watch which had a cracked face. Unfortunately trying to source one of these has proved impossible so I had a go a 3d printing one just to see the outcome. Obviously its not perfect but just trying a proof of concept.2 points

-

I looked it up at Boley. You just type your movement-case number in the search field and there you go: https://boley.de/en/case-parts/seiko/8239.7s26-02w0?q=7S26-02W0&p=0&s=102 points

-

Even though I have been on this blue ball of ours for half a century, I still have toilet humour like a boy. Yes you did, and you are so right. Thank you very much!! I am going to be quoting you for this line now buddy, this is a good line. Thank you Sirs, this is getting fun. I read somewhere that when you first start something, you know nothing. When you know a little, you think you know everything. Then when you know more, you know that you there is so much you do not know. You know? I like to think I am at the stage where I now that there is so much more to learn. So next on the thing to arrive is one of these auto oilers. I am excited to see how much stress I can save by oiling the cap jewels this way.2 points

-

I also do not have an automatic oiler yet. Just remember that they do not automatically remove any of the crud from between the stones and if you do take the stones out to clean, their easier to manipulate after oiling (it holds them together). Good luck. Shane2 points

-

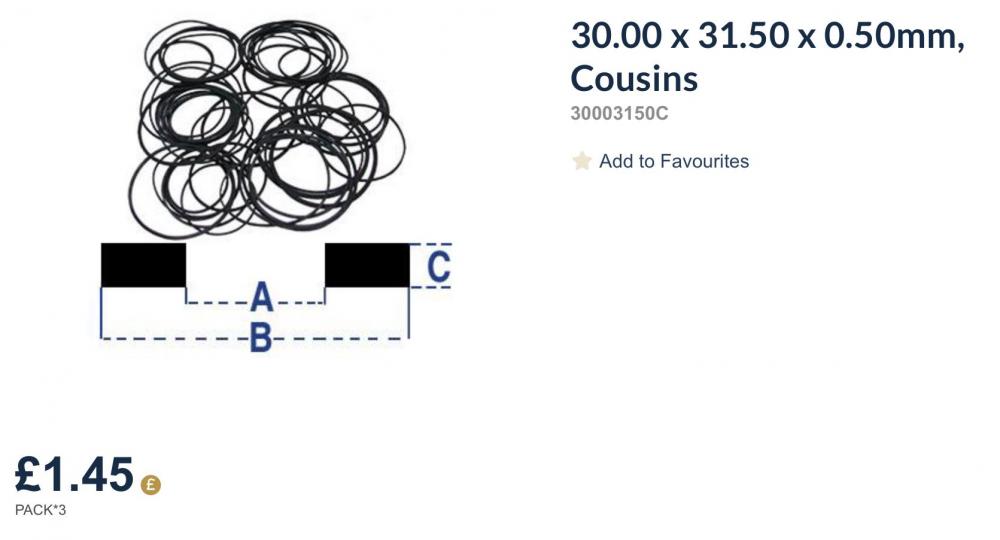

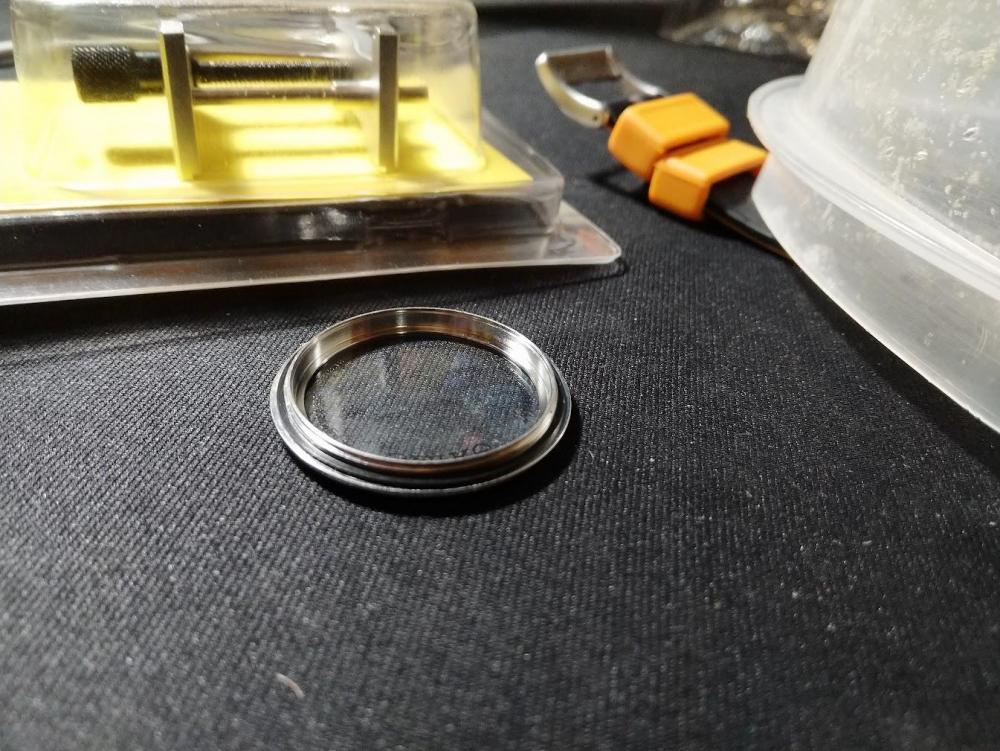

Again, this watch like many others uses a flat gasket not an O-ring. Its inner diameter is the threaded dia. of the case back, same it would be for a snap-on caseback. Said gasket inner diameter is the most important dimension of the gasket, the others being the outer diameter and thickness. In case of flat gaskets these two may vary, but clearly are in a fixed relationship when it comes to O-rings. When buying from a scrupolous seller like Cousins UK it's very easy to see how all this is organized and makes sense.2 points

-

Yes, a standard staple wont fit a some 7mm+ mainsprings unless you file it down. The other way to do this is to just purchase 0.2mm spring steel, and then fashion it into an arbor hook instead. This should be very easy now with the help of the staple jig. Here is an example purchase link to buy these (choose 0.2mm), hardware shops also sell them: https://www.aliexpress.com/item/4000995284553.html Great, because it is quite difficult for me to come by these type of vintage mainsprings. I do work on a bunch of Vostoks/Raketas, but they are mostly from the 80s. I will send you links to a bunch of experimental 10mm designs via PM. I'm sure you are fully capable of handwinding your way out and moving on, appreciate you spending time to make the video to help the rest of us. Hopefully a better version comes out of this. Thanks.2 points

-

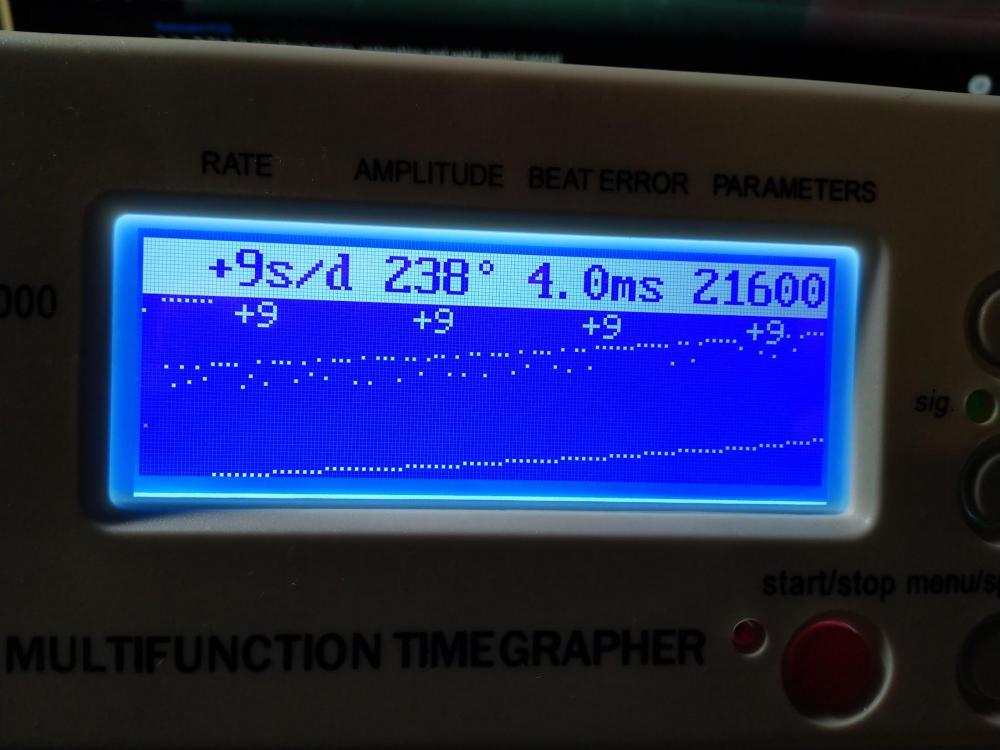

A It would still be interesting if you could just adjust the beat a little bit maybe like 1 ms just because it be interesting to see then how about an experiment you can rotate the microphone in steps but you can also rotated in a linear motion if you like. If you put the watch at Crown left and just start to gently rotate it how far in either direction can you go before the noisy line goes away? Then regarding timing machines I have an interesting video. The real purpose is to demonstrate how wonderful they are escapement is versus the lever escapement. For which we can care less about because were never going to see this escapement anyway. At around one minute and seven seconds we get to the interesting part for a lever escapement. If you look at the witschi documentation you understand which parts the waveform the timing machine needs. There is a nice video showing where those sounds come from. https://youtu.be/g5c5RK4WFV82 points

-

Hi David, thanks for the video. You seem to be doing it correctly, but the barrel walls are in the way. This is a 10mm spring, so you are using the 10mm winder set, correct? It seems to me that you have found a limitation with the winder, in the sense that the barrel walls are too thick for your particular mainspring. Some solutions: 1. If we were to reduce the thickness of the wall, do you think this will solve the issue? 2. If the opening angle was wider, will this work?2 points

-

I wouldn't count on finding a good replacement for these, and much less on having an easy job of replacing them without breaking something that is whole at the present time. I would try first to gently straighten the pin with some wide tip tweezers. And then with the watch running, observe if and where it touches and correct it so that it moves evenly in between.1 point

-

The newer barrels are "sealed" in the sense that the lid is a bit tighter fit, so no dirt can enter it. Plus, the watch around it is often a diver's, or very waterproof anyway. That removes the need to "clean" it. All is needed is to lubricate the arbor ends so that a little oil can get in between them, lid and barrel. Only after much (decades) continued use, when the mainspring will be genuinely bust, one will need a new barrel complete, and good luck finding one at a reasonable price. Cleaning and lubricating, braking grease or whatever else can't give back elasticity to a tired mainspring.1 point

-

A fiberglass brush pen works great, but you must do that with mov.t removed, away from where you work on mov.ts, then wash abundantly, dry with blown / hot hair, and inspect with an eyepiece for any left debris. If the parts list has the mainspring as a separate part then it's not a "sealed" barrel and can be serviced like any other. If only the barrel complete is listed then as you refit the mainspring with bare hands it may get distorted or contaminated. There is no readily available metal winder available for these. The GR generic mainspring that one can buy is stupidly expensive and doesn't give the performance of the original one, which does not requires braking grease thanks to its design and metallurgy. These are the reasons why the wisest choice is to leave the barrel alone.1 point

-

4R36 is an updated 7S26 which is an updated 7002. They are very similar in design and you can see the evolution as the movements were improved over time. Seiko never wanted to have the barrels pulled apart on any of their movements. It just became more finicky since the 700x series. It’s debatable that you even need to open the barrels even on the older movements when doing a service, but many choose to do so (myself included). But there’s arguments for and against so to each his own1 point

-

1 point

-

Zodiac 52 parts sheet attached might be of some use. cheers Zodiac 52 (1).pdf1 point

-

I'd use a 10.0 or a 9.5. You usually want to be at least one size smaller than your barrel diameter. Zero's designs allow for ANY size of housing. It can be a little tricky to figure out the steps, but once you do, you can print any size. I am NOT trying to push my stuff, I am just trying to offer solutions. If you don't have 3D printer: I am selling these on eBay, I can print any custom size you may need: https://www.ebay.com/itm/1254283486751 point

-

Probably that means either one, but didn’t wanted to mention Citizen explicitely. I recommend that you do a large amount of practice on other easier and cheaper mov.ts to be well prepared for when that time will come. Which can be surprisingly longer than expected.1 point

-

It should be a bit smaller than that to allow easy transfert. However no perfectly matching set of housing and arbor exist to be ready purchased. I recommend not to take apart Seiko barrels, because there is no benefit to gain in doing that.1 point

-

Seiko doesn't mention any Citizen product. You may have read about "A oil", that's Moebius 9010. The magic hands ratchet wheel. S4 is graphite loaded grease which supposedly helps with metal to metal friction. We can't know what they use at the factory, and since the barrels it's supposed to be never opened and messed with (which is an excellent idea, albeit one that many beginners find difficult to accept) there is no recommendation about in their documents. We know however that is back, sticky stuff that may look like S4. Do not be surprised however if opening a Seiko barrels you will find it totally clean and dry. Seiko has multiple factories and multiple lubrication standards, including terrible or none (except balance jewels).1 point

-

Another useful site for Seiko parts and donor movements is https://speedtimerkollektion.com I have used them many times a bit slow with delivery thou.1 point

-

Haha, thats because its the funniest . I get into trouble for it all the time. And bcause of this, a little bit of knowledge is dangerous1 point

-

This won't be a replacement for best practices in parts handling. Hopefully it will just minimize the downside when a part is inadvertently mishandled.1 point

-

Mike from myretrowatches.co.uk wore this t-shirt in his recent video. If anyone might be interested in buying one: https://my-retro-watches.creator-spring.com/listing/new-watchmakers-life?product=3731 point

-

I think the main job is to cultivate the skills where loosing parts is cut to a minimum, I tidy bench, clean work space and pars handling with tweezers also fit a bench apron to catch any fliers. My bench is enclosed on three sides with glass panels and when i am of a mind I will make the bench apron as well.1 point

-

Those look like as good an option as you will find. You will really need a special tool to unscrew* the old ones and screw in the new ones. The set in the pic is from Horotec and is great, but probably too much outlay for very occasional use. You can buy just the tips, and hold them in a pinvise or cobble up a handle. The tips are 15 bucks or so. * As yours are severely damaged they might not come out with the tool, especially the one that's already coming apart. As they are trashed anyway, here you can knock (like with a hammer) a stout cutting broach into the tube and use it to unscrew. They can be really tight, but I've always managed to get them out this way in the end. The new pushers may need some adjustment. I find generic replacements tend to be a little long, which is good, as you can shorten the screw part (the part that pushes on the watch component), but lengthening them is really tricky. Ideally you would do this in a lathe but you can simply file them carefully. Need a screwhead file to put a new slot in then. https://www.cousinsuk.com/product/multi-function-fitting-removing-tools-horotec?code=P192541 point

-

I have ordered from them. I have only had one issue with one shipment and they did make it right. To save themselves on shipping charges, they held my replacement part until my next order (frustrating). If that is my only problem, I have no real problems. Shane1 point

-

Your watch uses a FH2980B02 case back gasket. The Cousins reference 29803140C gasket is equivalent and I've used it many times as a sustitute. I don't know about Esslinger or other US houses.1 point

-

1 point

-

A Cracking job all three back and working Quite an achievement and no mis haps. The attitude is good back off have a coffee, calm down and go again and get a result again well done.1 point

-

The Seiko 7S26-02W0 like the OP has uses a flat gasket, like any other regular Seiko 5. Seiko uses O-ring and grooved case on diver's watches. Both types tend to use always a same, common size.1 point

-

1 point

-

It is not too complicated! When your o-ring is covered in the case or case back at the outer circumference start with the outer diameter and add 2 x thickness to get the inner. If the ring is held at the inside start there. The thickness should provide some squeeze when the back is pressed or screwed on, but not to much. The rubber material can not be compressed but only deformed. So any squeezed volume has to move sidewards and needs room for that. It‘s a good idea to purchase two or three slightly different o-rings to find the best fit. I have bought an assortment long time ago which often contains a matching gasket or at least leads me to the required dimensions.1 point

-

Hi Zero, yes i'm using a 10mm winder set. Reducing the thickness of the barrel wall, I think would help and also a slimmer version of the winder base might help to move the spring down and out of the way. I do a lot of vintage stuff and most of it tends to be this sort of spring with 11mm or smaller barrels. If you make changes i'd be happy to test springs through the new design, great project btw All the best David1 point

-

Thank you all for the advice and insights. It seems that I will have be looking for something more common then. I will be sure to check the topic of best movements for practice.1 point

-

There are various databases for that, Cousins, Borel, etc. It can be that they are not updated, but Cousins will update them on request. That being said to replace a caseback gasket just measure it and order a generic, that will cost while b3ing made of the same identical NBR material.1 point

-

I love coming in here. Another tip. I feel you man, I have been trying to practise too. You know what, since getting the stereo microscope and working almost exclusively under that. I have been able to not contribute to the swiss space program as much. Those little incabloc are still the bane of my existence. But that is why we practice right? I just put in an order for those auto oilers. supposedly you are able to oil it by poking the feeder through the jewel hole.1 point

-

1 point

-

No problem David, just a thought that gets you out of a pickle.1 point

-

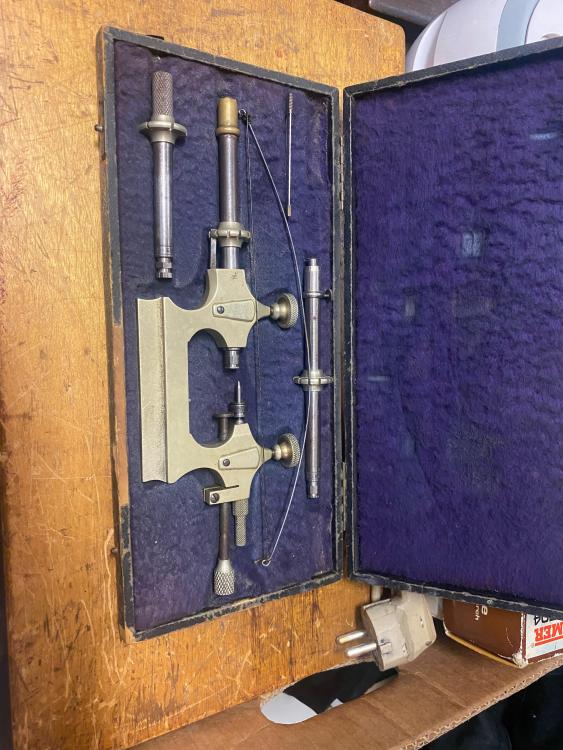

Ok, so lathe seems to be in great shape. I was thinking about buying a cross slide - https://www.ebay.com/itm/304526277611 seems like a good fit. I have been trying to see what the width of the bed is to see if the cross slide would fit. (I'm not sure if bed is the right naming btw, not sure exactly what that is called) As it turns out, the lathe came with a lot of extra tools. I can recognize the staking, jacot tool and the bow mill, but I do not know about the rest... I also suspect the lathe may be a 6.5mm and not 8mm (judging by what info I can find online), but I honestly don't care - I got a great deal and I think this will make for a pretty nice restoration.1 point

-

Thank you i have the staple jig, great little tool, I've also seen that video and sure that works fine for that type of main spring, but doing that on a tightly coiled spring well i can't do it without destroying the spring. On the type of springs used in the video it's easy no problem at all. On this type of spring https://ars.els-cdn.com/content/image/1-s2.0-S0142112310002781-gr11.jpg I can't even get it started without destroying the spring With this type of tightly coiled spring you need to move most of it out the way... with the other type it's easy Here is a video am i going about this the right way? Do i just move the spring out the way like this or do i have this all wrong. Thanks for taking a look and for helping out Sorry could not edit the post but i guess i'm trying to say at the start of the video 90% of the vintage spring is under the winder housing (compared with about 20% of a modern spring ), so i ether have to pull out 90% of the spring to get started or i need to push in 90% of the spring which i can't do. I'm probably missing something really basic, but so far modern springs are easy works flawlessly, vintage springs i can't seem to get them started Thanks again for taking a look1 point

-

It's rare for a pivot to get damaged with shock protected jewels (though it does happen). More likely on this caliber is the hairspring got shifted and/or possibly bent; it can happen in a way that would give your symptoms, and seem to be relieved with the added balance freedom of loosening the jewel spring. Some pics would help. If you have a phone made in the last 5 years it will probably suffice for this, no need for ultra close-ups at this point.1 point

-

If you removed both end stones , then you should see the pivot on the dial side too. A broken or bent pivot is the most likely senario which usually is visible under high magnification and rarely loss of end shake due to the shock, hairspring coil rubbing might also cause this. Does it run strong in all positions when you loosen the cock screw or remove the end stones? or does it loose amplitude faced down ? I don't suppose you yet have a timegrapher to give us some amplitudes, you might instead ink mark a dot on balance wheel and try slo- mo to get an idea of amplitudes. Its an etachron so I wouldn't recommend pulling the balance complete for closer inspection, but you can inspect/show a close up of the pivot without detaching cock-balance complete. A close up side view vid of the oscilator running be nice to have. Good luck pal.1 point

-

You said you wanted some advice. The two above are both pretty solid. Ask questions politely and graciously listen to your responses. If you can do that almost anyone will be willing to help you. The second I feel is key here. In trouble shooting, the fewer variables that you introduce, the easier it will be to see if you have found the root cause, understand the problem and effect real improvement. The luring curve is steep. Make the most of your efforts. The rest of your approach towards watch repair seams pretty sane. At the end of the day, it's all just advice and you will be alone with your watch. Good luck. Shane1 point