Leaderboard

Popular Content

Showing content with the highest reputation on 07/25/22 in all areas

-

Thought I would share this with the group. This weekend I was replacing a scratched up crystal on an old Omega Seamaster that had a small chip on the edge but I thought I would try out a few different alternatives to Polywatch to see what would work on removing the scrathes. I have to say I was blown away by how good Meguiars Ultimate Automotive Polish did. After a single application with some very minor rubbing the crystal came back to almost perfect. Considering that Poly watch costs close to $8-$9 here in the states (Depending where you buy it) for a small tube where as Meguiars cost $15 for a bottle the savings over time is incredible. I'm sure this is nothing new to you seasoned guys out there but I thought I'd post this for us new guys as an option. Another nice feature is it provides a nice coating on it that prevents finger marks from sticking to the surface.5 points

-

Hi everyone, Well it's been a while but I managed to find a new old stock balance complete. I fitted this about a month ago and the watch has been running brilliantly ever since. I am really really pleased with it. Just thought I'd bring you all up to speed and close this thread, thanks for all your help everyone. Gra4 points

-

If the surrounding ring to which the case screws were tightened is part of the case you’ll have a frontloader. If this ring is loose in the case its a movement holding ring and the movement gets out through the back.2 points

-

2 points

-

I find the silicone mats too soft, and the cutting mats too hard. I find vinyl flooring to be perfect, and cheap !2 points

-

Hi all. Hope this is ok, I did search first but found no similar threads. Given that many of us are not blessed with high salaries or pensions and cannot afford to buy high value tools from the Swiss makers, we only have what China offers for our hobby and as many have found a lot of what is sold on the likes of eBay turn out to be just rubbish and not even worth the low prices asked. After buying a few useless tools I started to look at some of their better quality offering, which although quite a bit more expensive, were still miles cheaper than the Swiss tools, sofar the few I have tried turned out to be of excellent quality. So to help others less well of could we have this thread for people to post about their quality Chinese Tools, for others new to hobby but put off buy high prices might find a better tool at a more appropriate price. If this is OK I will start it off with some of my recent acquisitions. Thanks. Paul1 point

-

Hi guys, I have started a project in Github to generate all the possible types of mainspring winder sizes from a single base design using a Python script. https://github.com/vishnu350/rs-mainspring-winder The STL files can be downloaded from the release section: https://github.com/vishnu350/rs-mainspring-winder/releases This project is a 3D printable "Rising Sun" watch mainspring winder for hobbyists. Mainspring winding for hobbyists has always been a problem, as most of us cannot afford the $1000 Bergeon set. Or sometimes, the appropriate size just isn't available. This forces most casual hobbyists to resort to handwinding or other similar stunts, which is not ideal. This mainspring winder is designed using FreeCAD to be easily 3D printed with no post-processing/finishing required. It will approximately cost $5/set by most 3D print service providers (use eBay to find someone near you). The design is parameterized, allowing you to dynamically change the size/dimensions of the winder and the entire design will be recalculated accordingly. The RS mainspring winder is a pleasure to use when constructed correctly, and can wind in both clockwise and counter-clockwise directions. I have uploaded a video describing the 3D printed RS winder parts and how to use it. Will appreciate any help or feedback as to further improve the design, as I actually do not own a 3D printer (I pay for each print). I also do not know the complete range of sizes that is required to be uploaded into the release section. Also, the optimal design parameters may still not be perfect, but it seems to work pretty well for me at the moment. Thanks.1 point

-

I'm not exactly sure on that one. Personally i would say logically not running would be safer. The watch is never wound when i demagnetise. Although picking up an automatic to demag would probably start the movement up. Even non running i visualise the hairspring being yanked down haha Ahh. I have been meaning to ask if it was cased. This could very well make a difference. Oh and Birb this throwing around of your watch onto the timegrapher. Possible that this may not increase your chances of it ever working any better or your timegrapher for that matter . can i ask how good your aim is and does it ever land in exactly the right place to begin timing it.1 point

-

It's not a pocket watch spring its from a 1960s Russian watch 10mm inner diameter barrel size. I'll do a video tomorrow maybe it will help show the issue better. @Neverenoughwatches sure i can hand wind the spring back into the barrel no problem, I was kind of hoping this would work as hand winding is always a crap shoot in my experience and as you say not best practice.1 point

-

When you're learning watch repair you really should keep a journal of everything you do. Like a before and after with the timing machine condition of the watch when you received it. Had need to go back and look the CF oh yes it was doing that before kind of thing. You need to get a brush and make sure your brush off everything on the back before you open the back. If that was a quartz watch should be having stopping issues because quartz watches don't like stuff falling into them. I doubt that's causing your problem oh and then of course there is the casing issue it's a Seiko in the case that can always be interesting I bet you get a different signal perhaps it out of the case. If you do try to time the movement out of the case make sure you do it dial up that way you can see the hands you can see the dial it less likely for bad things to happen. Typically way timing a watch you time it dial down but typically would not want to have a dial on1 point

-

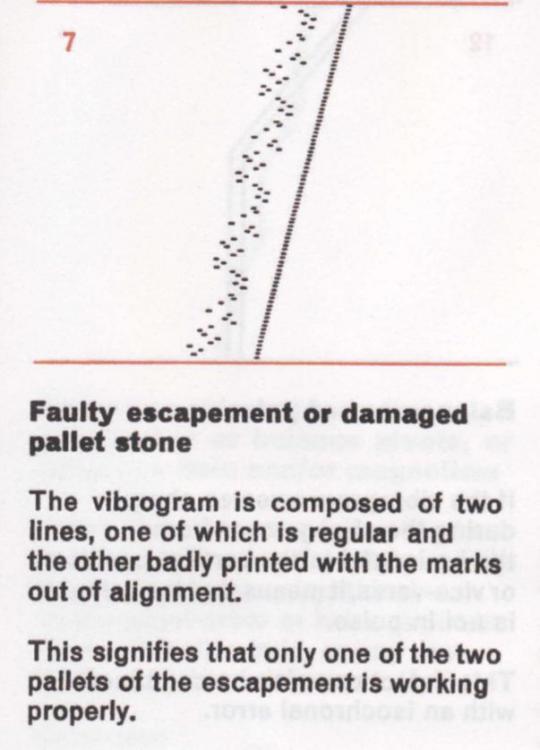

Was thinging about this earlier today. One side of the pallet skipping every other tooth to create that reading. Tbh i would have expected the escapement to halt. Maybe just not fully engaging. A worn escape wheel pivot ? How old is the watch ? Has it had much use ? In that position the escape wheel is drawn away from one of the pallet stones. The pallet stones not set correctly from the factory ?1 point

-

Good simple explanation Kalanag. I have just aquired a mil spec pocket watch with the same movement mounting. I now have to find a crystal lifter large enough to pull the front off a 19 ligne watch. I have not checked my standard Bergeon yet, i have fingers crossed lol.1 point

-

1 point

-

That‘s why I mentioned „Eastern Germany“ as the origin which was part of the planned economy of the uSSR from WW2 up to 19901 point

-

I'm really sorry. I read your original post wrong. I am now clear that the vintage circular spring is your issue. My guess is that the central coil of your spring is so large, that you cannot get any purchase on the arbor, with the hook latching in. Would that be a correct assumption? Can you measure the central coil diameter? Let's see how far off we are. Also, what is the inner diameter of your barrel?1 point

-

Yes both pivots are broken.EDIT. The are not, read below. What you see is the body of the so called tampons which are fitted to the cylinder. Pivots are much, much thinner than that. Replacing them or the cylinder complete is no easy job because these would need to be custom made on the lathe. That is work for a good watchmaker. If you want to learn watch repair I recommend that you avoud cylinder escapement watches and antiques in general, stick to what is recommended in our pinned topic You are correct, thank you for making me notice that. I had never seen this construction, easy to to notice as there is no hole. The other cylinder mov.ts I have seen all have pivots and hole jewels.1 point

-

The pivots are not broken. They are made like Timex pivots with tapered tips and therefore nearly unbreakable. The top bearing in the cock looks a bit disarranged which could be the problem. I‘m sorry to say that this watch is not really worth fixing imho taking the overall condition into account. These watches were sold in giant numbers for very cheap in Eastern Germany before the iron curtain fell (and even cheaper after that).1 point

-

It's rare for a pivot to get damaged with shock protected jewels (though it does happen). More likely on this caliber is the hairspring got shifted and/or possibly bent; it can happen in a way that would give your symptoms, and seem to be relieved with the added balance freedom of loosening the jewel spring. Some pics would help. If you have a phone made in the last 5 years it will probably suffice for this, no need for ultra close-ups at this point.1 point

-

If you removed both end stones , then you should see the pivot on the dial side too. A broken or bent pivot is the most likely senario which usually is visible under high magnification and rarely loss of end shake due to the shock, hairspring coil rubbing might also cause this. Does it run strong in all positions when you loosen the cock screw or remove the end stones? or does it loose amplitude faced down ? I don't suppose you yet have a timegrapher to give us some amplitudes, you might instead ink mark a dot on balance wheel and try slo- mo to get an idea of amplitudes. Its an etachron so I wouldn't recommend pulling the balance complete for closer inspection, but you can inspect/show a close up of the pivot without detaching cock-balance complete. A close up side view vid of the oscilator running be nice to have. Good luck pal.1 point

-

Here is something from Witschi that may help you a bit. Witschi makes the fancy pro timing machines, but the info in this course is generally applicable. Witschi_Training_Course.pdf1 point

-

You really need a jeweling tool to get that back together. Not saying it isn't possible without, but would be unlikely and very difficult. If those popped off from mishandling and the hairspring and balance were installed, I imagine the hairspring will need some work to get it true again. The regulator arm snaps into the stud holder, and the Incabloc setting holds it all together on the cock. You will need to press out the Inca setting, get the regulator together and place it on the cock, then press the setting back in in the middle of it.1 point

-

I'm picturing all of your parts rolling around and off your table, as well as the lights swaying back and forth over head as the boat gently rocks. I hope it's not that RELAXING!! I'm sure it is not as bad as my initial mental image. Welcome aboard. Shane1 point

-

1 point

-

I'm an orthodontist. I honestly don't think this is a workable solution, or rather I should say that I don't think it would work for me but that doesn't mean it won't work for others. You can always give it a try and if it works for you then that's all that matters. For me, my concern would be that by forcing your hands to fit into the cabinet in a very specific (and limiting?) angle, it may be difficult to get the angle that you want for your arms/hands. But the bigger issue will be that high plastic dome on the unit will for sure limit how close you can get with a loupe. I don't see how it would be possible to use a 10X loupe when oiling or inspecting as your head would be bumping into the plastic dome of the cabinet.1 point

-

That one is a lot nicer than the one I had in my office For the OP, I don't think there is a need to put a movement inside of a plastic bag. You can get the same benefit by just laying a thin piece of plastic on top of the movement and working through it like the below. It works for all the movement springs like this click spring, shock springs, etc. Same when putting the springs back:1 point

-

1 point

-

Was this watch a runner before the service.. The reason I ask is the wheels are different colours which might indicate one of them is not an original. I agree with the above regarding the elimination tests suggested. A wheel that is not turning freely is binding. A bent pivot or the meshing between the wheel is too tight. Or not enough end shake.1 point

-

I sometimes form a tiny little ball out of Rodico and stick it to the part I don‘t want to fly off. The additional weight prevents the part from flying. It just drops.1 point

-

Pinging parts often happens because you are gripping the parts too hard - The chronoglide video demonstrates what happens when you do that. Now that I have a light touch, every time my tremor acts up I'm dropping parts all over the place At least the parts just fall down, much better than flying off into the unknown.1 point