Leaderboard

Popular Content

Showing content with the highest reputation on 07/20/22 in all areas

-

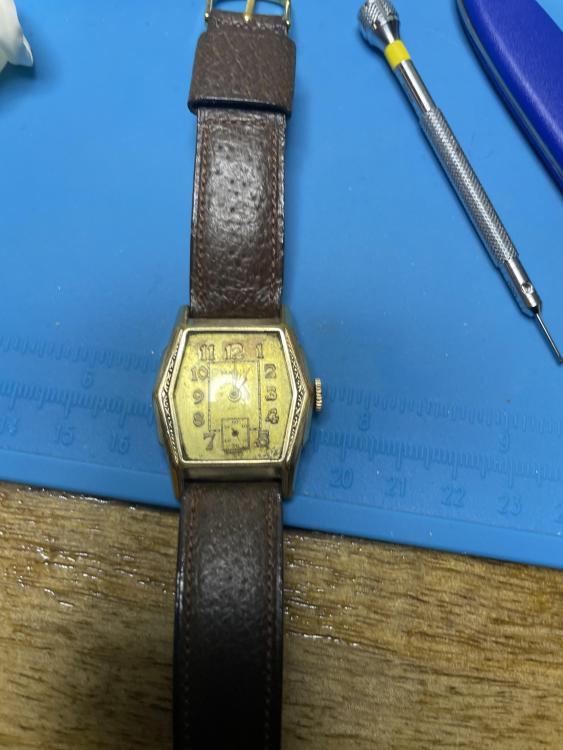

By chance do you have a link? Not sure I have seen it if he achieves any color other than flat white. i love original patina, but when a dial is just something I’m not happy wearing, or completely illegible, I restore it. So I’m not in either camp - I just want it to be something I want to wear. Here are a couple photos of examples - these however are not my watches, they are watches someone asked me to restore. They chose the colors. They are happy, so I’m happy. I am not familiar with them. Do they achieve the look I’m after? it’s a matter of preference. Some watches I leave as is. This Hamilton, though, I won’t be happy wearing unless I restore it .5 points

-

3 points

-

It is interesting that Seiko basically uses one oil (AO-3A)and one grease (S6) for the entire movement with the exception of S4 grease on two spots on the first reduction wheel. If Nicholas Hacko is correct regarding S4 also being used inside the mainspring barrel, then just 3 lubricants have Seiko workhorses running for years leaving the factory. For cleaning, I will be using isopropyl alcohol and naptha, initially in cheap glass jars then (after obtaining an inexpensive ultrasonic cleaner via Amazon) inside little single serve glass jam jars placed in the cleaner basket Will buy both chemicals from a local scientific supply distributor. They sell equipment and chemicals to various labs. Both can be obtained in 500ml bottles at reagent grade. Petroleum Ether 500ml Laboratory Grade CAS 8032-32-4 2-Propanol 500ml Anhydrous ACS Grade CAS 67-63-03 points

-

As an update, I replaced the double roller and that has resolved the problem. The watch no longer stops when it is in dial up (or any position). Still need to deal with cracked lower balance jewel (find the right sized friction fit olive jewel), increase endshake for the center wheel and replace the mainspring, but the major roadblock has been resolved. Thank you very much for providing a fast solution to my dilemma! By the way, I am now pressing the roller table in instead of trying to "gently" tap it with a hammer! Way safer I can watch the gap under the roller table close as I gently press down on the handle.3 points

-

1970s Verity 25 jewels ETA2789 turned into a field type watch. Running very sweetly at less than + 1 SPD in wear 285 degrees amplitude dial up. I was shocked with how bad the positional variation was with this watch, swinging between + and - 60 SPD crown left/right. With some dynamic poising I zeroed that right out getting 0 spd in 4 positions and +3 crown right and up. I now have a very fine timekeeper for very little outlay. I find that the rate of this watch is much less affected by temperature than Seiko 700X that I have worked with before. Also less affected by motion when on wrist. Steve.3 points

-

I've seen these dials referred to as "gilt" dials, along "silvered" dials. Champagne is a color available in both the real and fake gold leaf. Good Luck!2 points

-

It just depends how far you want to get into it. Certain plastics can and do react with solvents, its about finding out what works and what doesnt. Take a look at what your cleaner comes in. Is it metal, is it glass. I've never seen a solvent supplied in glass thats for sure. Yes naptha is supplied in tins, but as long as you are not leaving it in a plastic tub to reuse, like i said earlier it will distort certain plastics if left in them. All the proprietary cleaners come in a plastic tub, so there is obviously some bullshit being spoken somewhere, certain plastics are fine some are not. Ipa comes in a plastic containers, acetone comes in plastic containers. Here is a link to a compatibility chart if you are worried about using naptha in a plastic tub.. You will notice that pmp and polypropylene are the safe options. https://www.google.com/imgres?imgurl=https%3A%2F%2Fpreview.redd.it%2Fp1mj5ozddmu71.jpg%3Fwidth%3D640%26crop%3Dsmart%26auto%3Dwebp%26s%3Dc1212f6338b34f647cc35a0c3fa1a07b9cb87a7b&imgrefurl=https%3A%2F%2Fwww.reddit.com%2Fr%2FChemistrysafety%2Fcomments%2Fqc2rhw%2Fplastic_compatibility_chart_for_common_chemicals%2F&docid=3DhqE08qbp2WnM&tbnid=4ZGtsqq2AGDn9M&vet=1&w=640&h=775&hl=en-GB&source=sh%2Fx%2Fim2 points

-

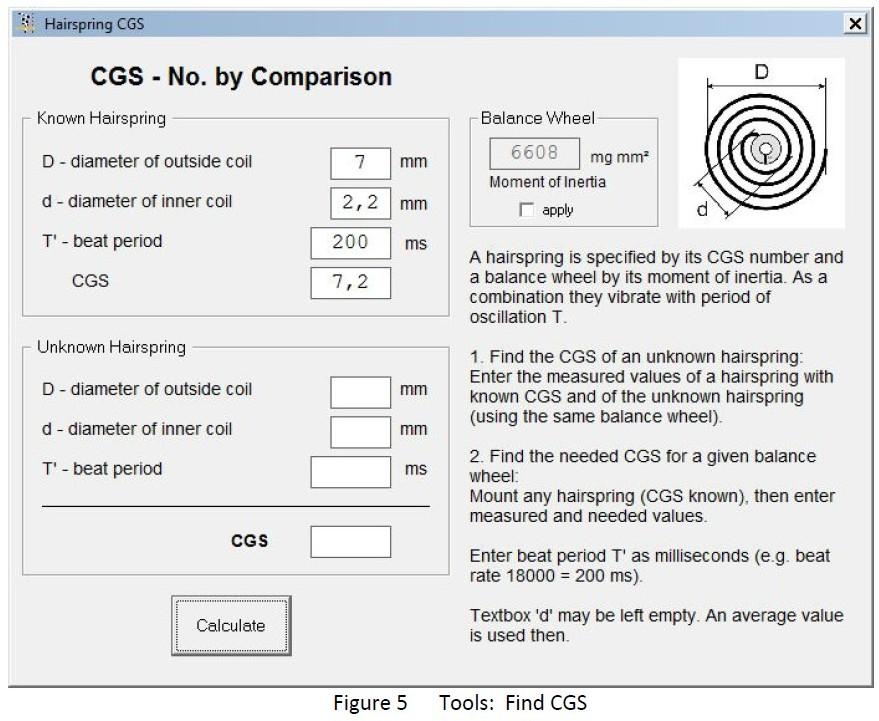

Happy owners of the electronic hairspring box for Luthys can use this tool in its evaluating program. Determines the CGS number of hairsprings (same what nickelsilver already described) and determines the moment of inertia of a balance wheel. The book that I know containing the theory is in German, sorry. Frank2 points

-

Here is my rough translation from French of the paper that explains what the C.G.S. number is. As far as I know, it's the only English translation that exits. My math is not strong, so I may have mangled some equations in my attempt at translation, if you find something that not right please let me know and I'll fix it. Cheers! 1934AFChr___4__233DTranslated.pdf2 points

-

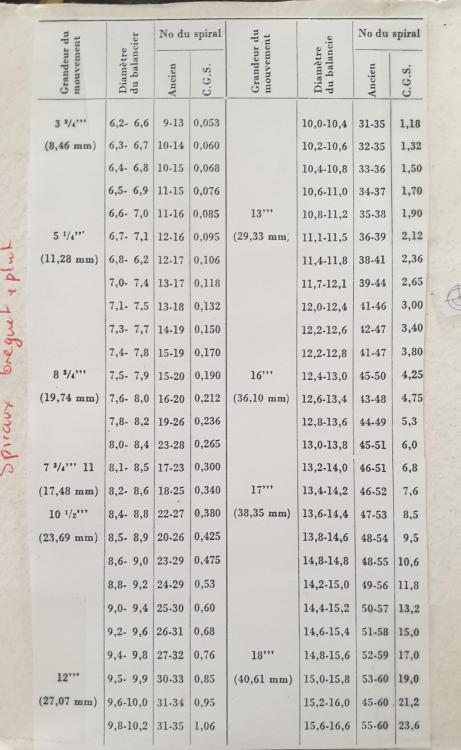

I don't know of a resource that gives all the math to determine hairspring CGS to a given balance except for perhaps Theorie Generale de L'Horlogerie by Leopold Defossez, which I think is only found in French and rather expensive. The list below I've found is pretty good for getting in the ballpark to size a spring. If you get a spring of a specific CGS that's close, you can calculate the actual spring needed with the formula K=K' (D/D')² where K= CGS to find K'=CGS of test spring D= diameter of spring wanted D'= diameter of test spring at vibration point2 points

-

I also don't subscribe to any camp. My preference is to try to get it as aesthetically pleasing as possible without breaking the bank or my back. Then there is the question of what materials and techniques are used for the restoration. Are they true to the period? I tend to use modern materials. Definitely not museum quality restoration work. Haha. As for the champagne colour that you are looking for, maybe you could try silvering the dial, then use a coloured lacquer overcoat. I've not tried it personally but I've cleaned many fake gold plated items that use this method.2 points

-

Sorry, my bad. I just got done shuffling jewels around within a different movement and I still have that job on the brain. I guess this is why there are different overall lengths among balance staffs for the same movement. Set up must be all in the part selection. I would think the staff should be shorter than the assembled thickness of the main plate and balance cock (without the capstone on the cock), minus the depth of that pocket and acceptable allowance for end shake. That looks like a significant difference between the two roller tables and what can be seen of the staff. Shane2 points

-

Yesssss My work today : Job for a friend (watchmaker) of a friend (also watchmaker), just need to replace roller jewel on an ancient 6x9"' omega. "Just"... -new staff installed by friend, not staked properly, balance out of true, fix -new staff 0.02mm oversize for roller table, turn and fix -staff too long, reduce pivot length -they kindly gave several roller jewels, all too small, find correct width and install, it's too long, grind to length, install (finally, it's fixed, right?) -bend in 2nd coil of tiny overcoil hairspring, fix get it ticking, great, 1200 seconds Delta in verticals, ok amplitude is low but... -poise balance by moving around numerous timing washers already in place on the abused screws, full service, replace mainspring (original was steel, coned, and set) Amplitude up to 275 flat, Delta down to 40, that's it for this one. I'm keeping the roller jewels they sent, that's my tip.2 points

-

You've had some very good advice so far, so I won't belabor it further. You've asked earlier what I found challenging initially and to be honest, well, all of it haha. Any automatic movement with day/date complications is going to be harder to work on than a larger traditional manual wind movement. Thing is, you don't know what you don't know so practicing on something that's easier helps build the confidence. But hey, if you up for servicing that 7S26 as your first project then I'll be the last to take the wind out of your sails. It's certainly not impossible because that's how I started, but that's because I'm pigheaded Only real gotcha with those are the two train wheel cap jewels on the top plate. My advice is to leave those well alone as they are incredibly difficult to clean/oil. I eventually got an auto oiler for those as doing it manually just took too long. Outside of that it's not an overly difficult movement, there's just a lot of parts to to keep track of and can be intimidating when you beginning. As far as amplitude is concerned there's a pretty large range of what is good for that movement. I routinely get them to around 270'ish degrees, but anything over 250 and you good. Getting it higher than that is less of an experience thing and more of a luck of the draw - bear in mind these are mass produced movements with a large amount of tolerance they need to operate in. Too much below 250deg is a sign that something isn't right and can be anything from needing a service or a tired mainspring through to excessive play in the main spring arbour holes and a chewed up top plate. The train itself doesn't have any wear that I've experienced so as long the movement is running, you should be ok there. Note that I'm talking about a mechanically sound movement here, not something that had a dip in the pool. As far as beat error is concerned it's more a thing of how patient you are adjusting it than an indication of the quality of your work. Only advice I can give here is to let that movement run for about two days after it's serviced before doing any kind of adjustment. Things need time to settle down after a service so resist the temptation to mess with it too soon as you'll likely have to adjust it again after a few days. So if you pigheaded like me then go ahead, just understand that it's not a beginner movement.2 points

-

Are you sure? Take a good look at the escape wheel from a side, wearing an eyepiece. The tips of the 'shaft' (which is called staff in watchmaking) must have two tiny extensions, called pivots. These are easy to break by beginners refitting it, producing exactly the symptoms that you reported. The wheel never fits the bridge. It fits permanently to the staff, which pivots fit the upper (on the main bridge) and lower (on the mainplate) hole jewels.2 points

-

Hello everyone, I found an ad online where someone is selling a Boley 8mm lathe (everything in photo for 600EUR). It looks like it's missing some pieces (motor, compound, vertical milling attachment, indexing/gear cutting plate etc), but it also comes with a bunch of other tools (depth, staking etc). From the info, it seems that the lathe is well aligned, no damage to the table or functional defects. I have been browsing ebay and it seems that it is reasonably easy to find parts for a 8mm Boley lathe, but I wanted to get the community's thoughts on this? I guess the first project could be to restore it, which seems like a perfect little task to get to know the lathe Opinions and advice is much appreciated, thank you1 point

-

I got a 7s36b movement that literally doesn't tell time and the whole thing can be replaced for about 30 bucks worst case scenario. I really don't have anything to lose here. Anyways, ordered the next round, jaxa opener, movement vice and my dumont #2's and my loupes will be here on friday and i'll try and get my runners regulated.1 point

-

Another way to do this would be to look at the old school rule of thumb on how to make a watch. This way it save yourself a lot of math physics and possibly computer simulation which I'm sure exist today. Don't know which book I read this in but basically repeated diameter for your watch which you already have. The mainspring barrel is supposed to be as big as possible to fit in one half of that diameter and still mesh with the center wheel pinion. The balance wheel is supposed to fit into the rim of the mainspring barrel. Seeing as how you already have a watch you have a barrel and you know how much space your balance wheel supposed to fit in that will get you really close to the diameter the balance. Then because you going to pick and choose from an existing balance wheel that's going to narrow things down considerably. Versus if you were making a custom balance wheel but you can have anything you want. Then the hairspring is relatively easy will need some math but not as much as you're probably thinking. If you have an existing balance wheel with no hairspring no problem just grab the hairspring and vibrate. Yes ill be totally wrong but we don't care is a formula I'm sure someone will come along and supply it to you shortly. Once you have a hairspring vibrated that's wrong you can do the math the calculated what you're supposed to have. Then with that new hairspring you can vibrate it to your balance wheel.1 point

-

Sorry, didn't realize you weren't US, as you were quoting USD prices. Other brands of cleaner are available, depending on what country you are in. If you are not cost constrained, it's worth searching them out, as they all will perform better than even lab quality reagents. IPA is worth having, as it makes a great rinse. Just make sure you are getting anhydrous (no water). Various petroleum products will work, I'm not sure that lab quality is necessary. When I started out I used VM&P Naphtha, which is available at hardware stores here, and is cheap. Purity isn't as much of an issue for the cleaner, if you double rinse, which you should. If you use IPA then make sure you heat dry, or you may have problems with water condensation on the parts.1 point

-

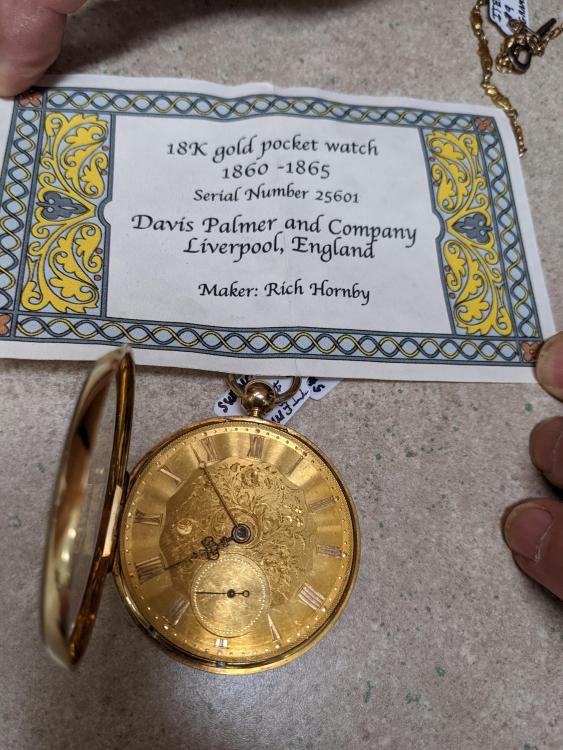

I bet he might be willing to bring it back so we can see the movement. Can't hurt to ask1 point

-

Hi Shane, When it comes to the theory and formulas, the book that I found that provides some of this is "The Theory of Horology". Chapter 7 in particular. AWCI has English copies of it on hand since it was out of stock for some time, but they are not cheap. Mathematical formula for a balance and hair spring T = 2 * pi * sqr root ( I / C) T = period, I = moment of inertia of balance around axis, C = spring stiffness. It goes on to provide formulas for hairspring CGS (same formula NickleSilver mentioned), stiffness, proportionality factor, variation of length, terminal curve ... This link has some information that might be useful as well (where he suggests getting a test spring with a known CGS and experimenting with it) https://www.watchprozine.com/watchtech/a-day-in-watch-school-part-six-hairsprings-/6112423/1223/ Cheers Terry1 point

-

As I am in the same stage as you, just started this as a hobbyist with great enthusiasm after watching hundreds of videos, I don't mind asking something obvious that tripped me on two of my first movement assemblies: If the pivots are indeed not broken, are you reinstalling it the right way up so its pinion is engaging with the third wheel or is it spinning freely in the wrong plane? A complete amateur's oversimplified observation is that sometimes the correct orientation of a wheels feels wrong, top-heavy, or upside-down. Take a photo at every stage of disassembly. In any case, this community is really helpful. I've been feeding them questions steadily for a couple of weeks and they've assisted me each time.1 point

-

A very appreciative soul, thank you. That goes a long way towards you getting help. I think you have covered your bases with learning matey. Videos, books and being here. Besides having your own personal watchmaking teacher by your side ( here is the next best thing ) or going to watchmaking school. My beginners advice to you is take your time and do not try to move something that wont move freely. If its tight do not force it, sit back and rethink your approach. There will be an easier way to ease or release the part you are working on. Practise a gentle touch, here you are working on the most fragile components you will ever encounter. If you think you are not capable or not the right person to do this as a hobby then think again. I've been a joiner and builder for nearly 40 years, I've lifted heavy weights, strength trained and bodybuilt for 15 years. Its very, very rare that i break a watch part, ive learnt to manipulate hairsprings. So you definitely can do it, just with practise. So besides this approach, be methodical and engage logic when dealing with an issue. Think your procedure through first, have it in your head before you do it. As you progress with your learning the disassembly and reassembly will become second nature. Until then take plenty of pictures of the movement, stage by stage as you disassemble. These will help you put back together what you cant remember. And trust me you wont remember even after a short period of time. Then one last thing as a beginner, do not get frustrated as this will lead you down the path of damaging parts. If you feel it coming on, then take a break. Good watch guys are here to help you so dont be affraid to ask any questions at all.1 point

-

Thank you SO much for replying to my question! I appreciate it SO much! I've just started this hobby and I don't have any teachers or anyone to help me here so I'm just learning from watching videos and reading. I think everyone is right it that I broke the tiny little pivot at the top of the escape wheel. I've been working on cheap 20 dollar movements that I've been ordering from Amazon. I also ordered a cheap pocket watch and so far that's the only one I've been able to take all the way apart and put back together and it still work. I think that its because the pieces are larger and harder to break. But I'll take ALL the advice that you guys gave an apply that to what I do moving forward. I'll hop on here in the future with any other questions as I move forward with this. If anyone has any good advice on what I should do to find a good learning aid please share. Thank you SOOOO much!!!1 point

-

Hi By the look of it you have had a great list and advice on what and not to buy, pity the little glass jars are unavailable in the US ans they are realy handy in the U/s, My Grand daughter works in a Hotel so got plenty. also movement covers, in the UK we have scented candles that come in what looks like a whisky glass, when finished clean it out super glue a marble on top and hey presto a movement cover, paint pallets make good dismantling trays al though I have a ladies eyeshadow kit cleaned out of course, with several compartments and a lid, also for parts cleaning the ball type tea strainer makes a good basket. I have seen these advertised on ebay for in excess of a £5. I too am Scots but being brought up in Yorkshire look not to waste money. As N.E.W said antything with a watchmakers tag carries a price Bergeon being the "best" at removing money from your wallet. Good loups, good tweezers(Dumont) and screw drivers F*F, Horotec and of course Bergeon are the things to spend money on. My cleaning machine Cost a £10 with no basket the ultrasonic transducers were buggered but I stripped it down and it all works including the heater the U/s generator works but of course no sonics. Used mainlt for clocks. A cleaning solurtion I used to use was beaucare a spot cleaning soloution (Trichloroetheylene) now bannes I think it used to be used in the dry cleaning industry years ago. Now naptha and IPA.1 point

-

I'd love to take more time to myself, i definitely make sure my weekends are me time. I've had a very rough last few years where a family member's healthcare expenses (This is the main reason we never get to stop working here haha. Healthcare.) wiped me out entirely financially, then covid killed my business. I would love to take a vacation but it's just not in the cards for god knows how long. Also i gotta pay for all this watchmaking junk now somehow haha What IS good for me though is high concentration zen like hobbies like shooting and probably watchmaking where i can just turn parts of my brain off, fixate on one thing and just not think about anything else and have something to show for it. Ok glad plastic will work. People elsewhere were talking all this stuff about how it has to be glass because plastic leaches into the cleaning stuff and puts films on your watch parts that gums up the oil. Getting into stuff like this it's always a process of cutting through the bs. Though for all i know it's not bs haha. I'll find something that will work on the cheap.1 point

-

Aw bless you. You should make time for yourself as well as your family. Its very important mate. Kitchen stores may throw up some goods cheap and just as useful. Here in the UK we have what we call pound shops. I often find alternative watchrepair uses from household items. (WW I'm still waiting mate, are you napping ) theres a young chap here needs help saving some money Any plastic tub or jar like these will be fine for your cleaning. Tbh. I prefer a plastic type as its a bit more forgiving on the watch parts. You need a low container to be able to work in, preferably with some diameter width so you dont knock it over easily. And just be aware that naptha will distort the tub in time. Ive not had a tub leak through as yet but i do keep the tubs with naphtha in in a glass or enamelled oven tray just in case.1 point

-

Maybe if your looking for the old gold cooler it might be worth doing an experiment gilding one with false gold leaf (a lot of clock and watch stuff around dials etc. used to be done with what was/is called Dutch gold which was a substitute for the real thing) HTH Tom1 point

-

Lol. No you wont. Its my whirlygig. Haha Why you cheeky monkey . But quite correct. And btw my wife is half Scottish Haha. I think you mean " The dog's bolocks " add another letter l. Auto bleep will not beat me lol If you are sticking to one specific watch type and one or two mainspring winders can cover your bases then this would be a better option. But i fix swiss vintage of all sizes so to have winders to suit everything i do is not financially viable for me. And yes quite correct about the damage. It took me a good day of practise with my giggything to get good with it. Although i never damaged even when practicing i did have my practise spring pop a couple of times. Do you not have a sharpening block ?. My choice for drivers is around 1500 grit. Tweezers around 1000 depending on the size of the tweezers. I like to have a little friction involved especially on the tweezers. Helps with gripping.1 point

-

you might try George Daniel's book on watchmaking although I'm not sure it's going to have enough theory for you. You want some of the vintage books on watch design watchmaking. For instance there's a link below there is a book the first one that popped up where I did a search then you want to search there for a variety of figure out the keywords as a bunch of vintage books that might find helpful then you didn't give enough specifications. Over coil are flat hairspring for instance? Flat hairspring is typically vibrated to that specific balance wheel. We've had this discussion before on the group there are basically no more raw hairsprings so finding a hairspring to vibrate for your balance wheel will be challenging. Over a coil hairspring is easier as they were meant to be replaceable. But that manger balance wheel has to have screws on it because you'll have to match the balance wheel to the hairspring. Oh then there's the other minor thing for the hairspring just as a reminder in addition to timekeeping purposes the energy of the hairspring is used to unlock the escapement so they hairspring does have some other properties they have to be right they can't just visually look right https://archive.org/details/treatiseonclock00reidgoog1 point

-

Have you watched Mark's video on dial restoration, where he re-silvers a dial then apply a heat transfer decal? Great video but it shows how tedious the process is and how it might be necessary to reboot and start over again. BTW there are 2 philosophies on restoration. 1) To restore to brand new, the day it left the factory look. 2) Keep the patina, as it tells the story of the article. Which camp are you in?1 point

-

Best I have done to date is to use some high pigment paint used for model making, put into an airbrush. Then the decal, Then spraying a clear coat over it. I have even used just regular white spray paint, and put it in the oven at high temp to give it a nice patina look. But nothing achieves that sheen I have seen on vintage dials. I have silvering powder, but have yet to use it on a watch dial - I think it was used more on clocks, as it is definitely SILVER.1 point

-

Out of curiosity where can I get some $60 hairspring cleaner it must be really good at the price Not as good at least why price but I have a couple links below. https://timesavers.com/i-9500836-one-dip-hairspring-cleaner-8-ounce.html https://www.jewelerssupplies.com/One-Dip-Cleaner-8oz.html https://www.jewelerssupplies.com/One-Dip-Cleaner.html Why don't you just practice something like moving the regulator and putting the watch in beat before you take the balance out.1 point

-

I think I can relate to that! (Sorry, I just had to get it out!)1 point

-

Yes. It is a crew on crown, and the threaded portion is still screwed into the case tube. It should be possible to remove it holding it with small pliers and unscrewing. You can try pressing it back into the crown, but it will not hold unless something is done to increase friction. All that is work for a watch repairer. A replacent original crown may be difficult to source, even for a Tissot official service center.1 point

-

Gary is right on there , without pictures as a guide we are guessing. But from what you say it does sound like the top or bottom pivots are broken or both. First check is was the watch/s you have been working on in a working condition before you worked on it, did you check all the pivots etc when dismantling the watch. As you can see there are many variables so good clear pictures of the movement front and back abd a side on view of the errant escape wheel/s will aid members in helping you. cheers1 point

-

Welcome, Usually we'll ask for photographs. There could be something you're doing wrong if EVERY watch you take apart isn't going back together. We'll likely want to see close-up photos of the ends of the pivot shaft of the escape wheel as well as the jewels (top and bottom). Are these "cheap" movements from working watches? or are you buying cheap, un-cased Chinese movements (like a Seagull ST36)?1 point

-

There's always these guys: https://billandsons.co.uk/services I don't remember how/why I ended up with their link saved, possibly due to conversations with a Swiss watchmaker who used them to refinish a dial on a watch he did a video service on YT.1 point

-

you know what one of my favorite diagnostic tools is other then using your eyes? Is something that lets you see the invisible the thing that sees the invisible is the timing machine. But I'm guessing the original posting person doesn't have a timing machine. multiple discussions here it leads to my mental confusion especially today. Seiko is supposed to be using synthetic oils at least that's what it says in the tech sheets but? Does Seiko actually use what they recommend on their service and tech sheets?. a for instance in the shop today work at the boss offers a service. He tells his customers who regulate the watch any watch to Rolex timekeeping. Yes I know what Rolex timekeeping is and he is the boss so he can say whatever he wants. So I get to be entertained with what he's doing. The case of the Seiko watches they usually running pathetic. Of course Seiko is tend to be low amplitude anyway that's not an issue that's a Seiko but at times the really low amplitudes. That means the balance wheel comes out pallet fork comes out it's rinsed off and it's nice and clean again fresh oil fresh oil on the balance jewels to running better and then he regulates them he's got really really good at that. Customers happy their watches keeping time for now but it does bring up the problem of why does fresh will make it better if the oil synthetic and it's supposed to last forever oh since I went back to read the original message I see a timing machine is in somebody's future just not fast enough for this discussion but it looks like at least he grasps that that be a good thing to have. Hopefully it's a real timing machine and not a app. either way I've attached the tech sheet for the Seiko in question. As others have noticed it's unlikely somebody is seen the decrease in speed ads in amplitude variation in other words the amplitude sucks. The regulator position becomes interesting in that wasn't always there? It's back to my fussing about timing machine it be nice to see what it has to say oh and then there's the other little problem of how do you wind this watch up? Wind it up the crown and how many times do shake this watch to wind it up? If you really want to have fun put a little mark on the ratchet wheel in and start shaking I believe JDM would probably know better I think about 11 turns the ratchet wheel and it's considered fully wound up. In other words if your hand shaking the watch the wind it because you're not using a screwdriver to do it the fast way it takes quite a while to line that watch back up again and it's not wound up your aptitudes going to be pathetic then as far as being seven years old may be did you purchase it at the factory? It depends upon a variety of factors watches made at the factory and then it shipped and did a distributor or sales agent sends it off to its final destination and then you purchase of their it's conceivable your brand-new shiny watch might've been sitting for several years somewhere so I know the watches at least seven years old conceivably older then the watch was sitting doing nothing for a whole year. Then the amplitude sucks it's always possible the oil is migrated is no longer properly on the pivots plus maybe the lubrication just isn't doing the job anymore either then the demagnetizer I would ask for a picture but I'm not only get one. Is it a proper demagnetizer for watch repair and do you actually know how to use it? Is a lot of times people don't understand the demagnetizer how it works and instead actually magnetizing watch. oh and why did I want pictures? For the same reason JDM wanted pictures we wanted know where they hairspring is and we just want to look at it and see if there's something that we see and grass that the original posting person didn't see you grasp. Especially if they hairspring isn't quite where it's supposed to be amazing what interesting are bad things happen if they hairspring is not where it's supposed to be. 7S26B_36B.pdf1 point

-

Lol. You're a card john Photos are really important birb they help forum members spot faults that beginners will be unaware of . When you get into repairing you will want to take plenty of these to refer back to. I would have agreed with you here Gary, as in any mechanical device keeping it running would be a fine balance of it not wearing out from overuse and not seizing up from underuse. But my thoughts on that appication to watches have recently changed. My sister asked me to have a look at a watch that she received for her 21st birthday. It stopped working over 30 years ago and had been in a drawer ever since. I popped the back off which was very tight and gave it a little poke inside with some rodico, everything seemed ok and the balance wanted to run. I gave it a little encouragement with a puffer and off it went. I put it on the timegrapher and the beat was a yard out at 9.5, regulated that and everthing was running perfect with an amp of 335 and 1 second a day accuracy. One of the best runners i had seen for a long time, off like a steam train in all positions. I turned my thoughts as to whether a service was needed. Looked again under the microscope at the jewels and everyone inc. the balance still had fresh fluid oil . No gumming up of oil had occurred at all. This was bought in 1978 so now 44 years old, synthetic oil I'm unsure but possibly. So my guess is with the back being so tight, this made the inside airtight and so having no degrading of the oil. So John when youve stopped being a card do you have any thoughts on this or do you need some pictures from me .1 point

-

Usualy screws that get ruined are the ones which don't want to come out peacefully ( often due to rust and the like). A 48hr soak in Coca-Cola gets rid of the rust. Please don't ask suger free or regulare coke. Regs1 point

-

Great sequence of photos (but it seems I'm often more interested in taking photos of small things). Congrats on your journey so far!1 point

-

Here's a beautiful super-seventies Favre Leuba inbound from India. It would be entertaining to restore it but the truth is that I only picked it up for the mainspring barrel. It should (fingers crossed) be a fit for a Zodiac project I'm working on as the FL 1164 shares parts with the Zodiac 72- we'll se how it goes though.1 point

-

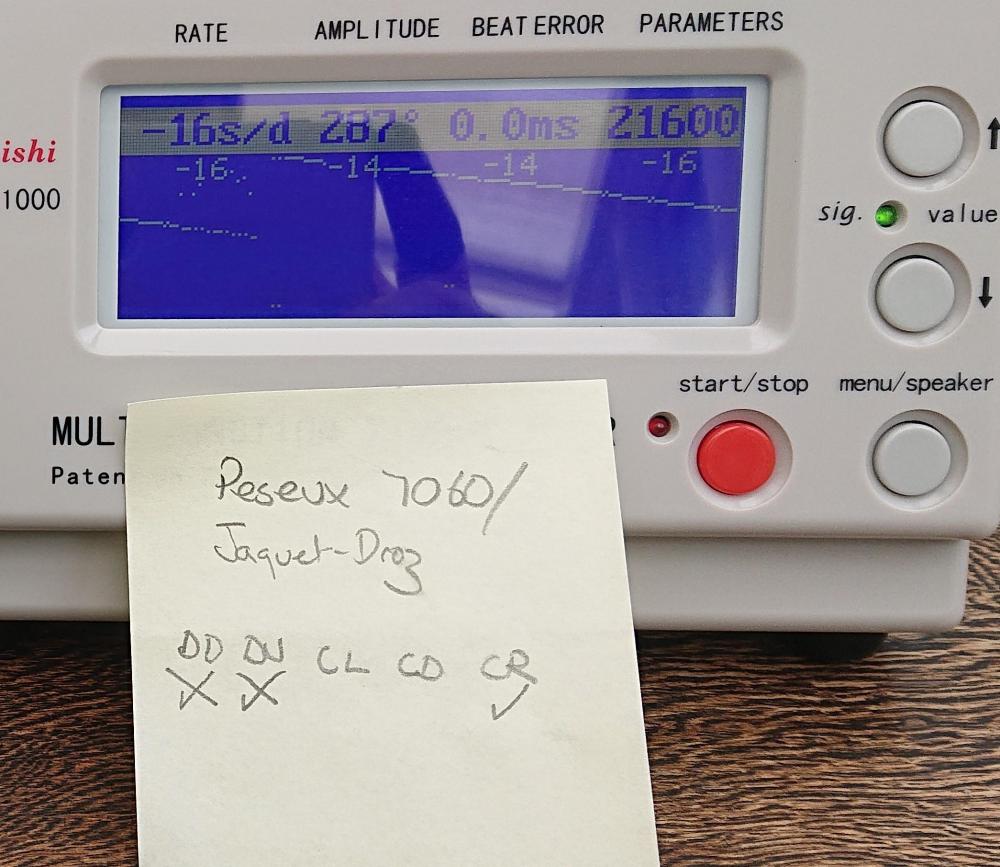

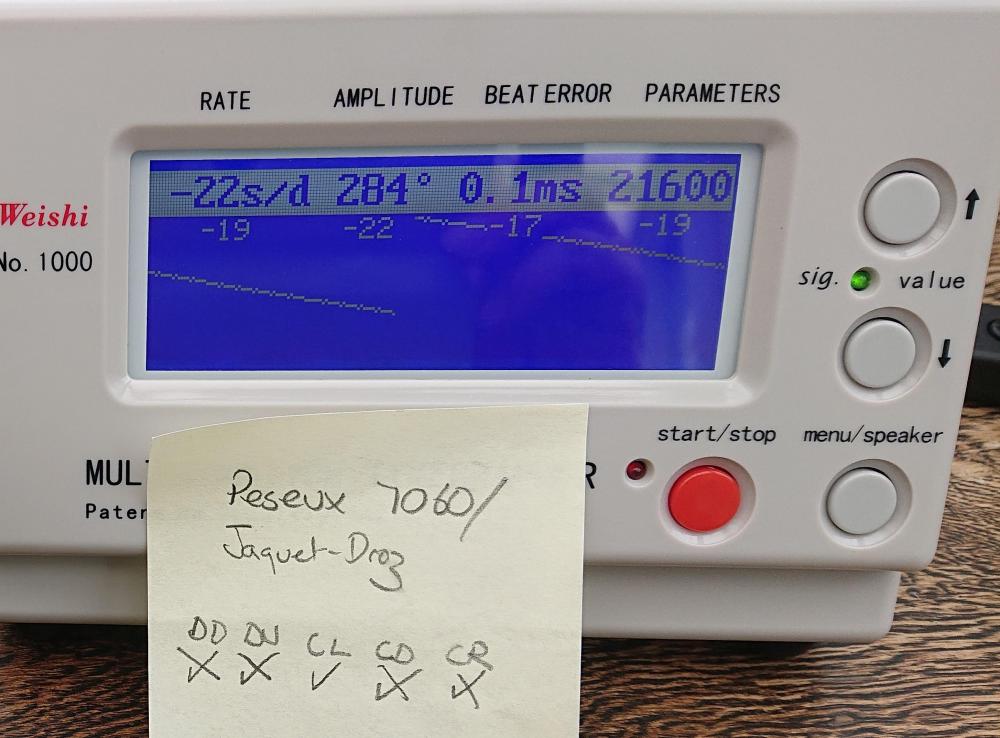

Eight months ago when I began my watch repairing journey, a relative passed me this unusual gold-plated pendant watch to "have a go". They had worn it daily for decades, till it stopped working (and had long gone out of fashion), and put it in a drawer. At the time I had no test equipment but it was running slow and didn't run for long either. Having opened the case to see what the movement was, I put in in a box of "future projects" as I wanted to continue practicing on junk movements. Now I'm gaining confidence having serviced about forty movements and inexpensive watches, I thought it was time to repair it. This is what I saw on the time-grapher: The movement looked clean: Though the finish on the dial side is poor: During the strip down I noticed some unusual wear to the underside of the centre wheel I cleaned the movement and reassembled to try and see what was rubbing on the wheel. It was pretty obvious once I checked the play on the barrel: I asked the owner when it was last serviced. The answer was I don't know, maybe never. I know it was worn daily for twenty or thirty years and dates from the 70s or 80s. I'm amazed that the only sign of wear I found was the top barrel pivot hole. OK time to order parts. I ordered a fresh barrel arbor, barrel bridge, and mainspring. The barrel itself showed no signs of wear or cosmetic damage. I think only the very tip of the teeth were catching the second wheel. It's a shame that I couldn't find a barrel bridge with the same finish. I've not posted pictures of the disassembly as it's a totally straightforward movement. I cleaned, reassembled, inspected and lubricated (941/9010/HP1300/MolyslipDX/8200) the movement. For cleaning I use naptha and pegwood on the pivot holes, followed by a three stage cleaning in an ultrasonic bath. I epilame the inca jewels, pallets, and escapement wheel. I use a superfine oiler and check each pivot under my microscope for correct oil levels and cleanliness. On this occasion I ran the watch for a few minutes, then lubricated the tip of three escapement teeth. I'm experimenting with different methods as I also like to remove and oil the exit pallet. I can't find a difference in results with either technique when you get it right. I probably make more errors oiling the ascapement. Putting it on the timegrapher. 280, 300, 320, 340 degrees, SNOWSTORM!!! Sorry I didn't get a picture but I quickly removed the movement as I could hear it knocking, in order to release the main-spring. I checked the replacement spring and it's measurements were the same as the original however the curve was a little less pronounced. It looked fine, I'd simply replaced it as a matter of good practice. So I cleaned the original and put it in. Now the timegrapher results show unexpectedly high amplitude, but it's not knocking. Dial down Dial up was within a second and two degrees of dial down, and the other vertical positions were similar to the crown right. On reflection, this watch will spend almost all of it's life crown up, so I readjusted it optimised for that position accepting a greater error dial up and down. After a few hours of running-in the differential between the horizontal and vertical positions has reduced. The various vertical positions all perform similarly so I won't post them all. These are after an hour or so of running: So I learned a few things on this movement. Firstly I should have picked up on the play in the barrel as I disassembled the watch. Then I've have known as soon as I saw it the cause of the marks on the second wheel. Secondly, I learned that a new spring even of apparrently correct and identical specification may cause knocking. Finally, a lesson I learned early in this journey (taking care of the dial) remains visible on the face of the watch, where I marked it as I opened it all those months ago. You can only see it under a lupe, but it's there on the seconds dial between 15 and 20 seconds.1 point

-

Thank you all. Nucejoe, mea culpa. I did not search first. I read the other thread with references to (microscopes in it) AFTER I made this post last night. From what I can make out, seems the ARY are far superior than the straight arm projecting parallel with the temple piece to which 1, 2 or 3 round glass lenses are attached. I guess I was looking a person to say that those are high quality. Seems that is not the case. I think I'll get another 10x loupe with dedicated head band, and save up during the upcoming months for an ARY.1 point