Leaderboard

Popular Content

Showing content with the highest reputation on 07/17/22 in all areas

-

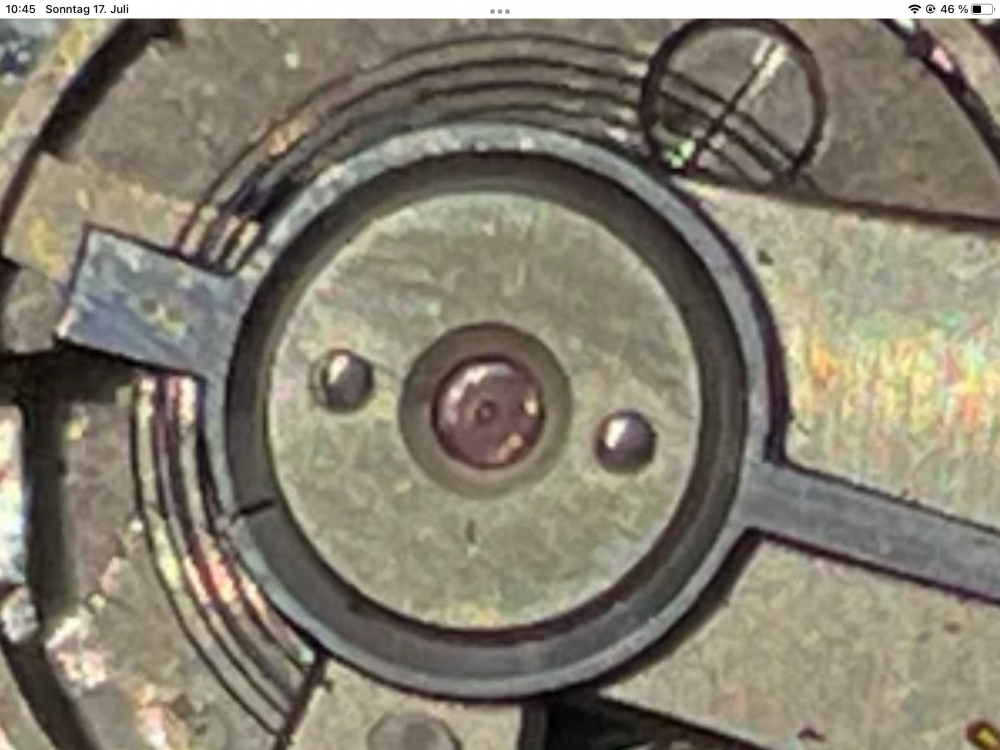

As alluded to in my introductory post my current victim is a Raketa 2603. Disassembly and assembly is complete, and it's still running. phew! Haven't purchased a timegrapher yet, but it's still satisfying! I'm about to do a second run through but clean and oil this pass. A couple of lessons learned. I lost the yoke spring (440), it has gone home to its family. Also, one of the two screws on the settings lever spring (445) is stripped. After reviewing my initial images it appears there may have been damage to start with. Any tips to avoid stripping? My gut instinct is to use the largest screw driver possible that fits without fouling the case. Luckily, these movements are affordable and plentiful. I was able to find a set of four 2603's for around 12 dollars. So I'll have spare parts and practice movements. Also, I purchased the Burgeon 4039 after struggling with the 4040 for this movement. Below are pictures of my journey. I thought I took a ton of pictures and afterward was surprised how few I had!? Definitely more pictures on new movements from now on. Will take more images of the train of wheel orientation and keyless works configurations on this teardown because those appear to be the interesting bits IMO. To Be Continued... Realized, I didn't have an after!3 points

-

There is a good chance of the jewels being the right ones when lower and upper jewels look the same. If the jewel is set too high pushing it down is your best option, but thats not the only option, there is a chance to adjust them by shimming the cock. If you don't have a jeweling tool try pushing the jewel with a wooden stick, make sure the jewel doesn't mind budging and not decide to break. The incab shock system lets you flip the end stone over so its domed side faces the pivot. Such tricks lets you get the watch running without special tools, None are standard repair approaches. Regs2 points

-

I'm not sure that the number in the Benrus designation is a 49, that seems too high. Could the leading numeral be an elaborate "1"? In any case, the AP family for Benrus is listed in references as using the Peseux 150 as the base movement (which isn't an entry in the Ranfft database). When looking for equivalent movements, note that this may be one of the families that had multiple train bridge arrangements - Benrus used the consolidated version but it looks like others had a separate bridge for the escape wheel.2 points

-

Also SII (Seiko) makes these https://www.sii.co.jp/en/me/datasheets/ms-rechargeable/ts621e/ Electronics distributors (Farnell, Digikey, etc) have them.2 points

-

I posted a fresh picture of my Buler Solar LCD watch in the WOTD thread today. As I said, its still going strong and nothing has blown up (so far), so I think my choice of an alkaline LR41 cell was safe (if, arguably, not actually recommended). Some of you may find this interesting. https://www.batterypowertips.com/difference-between-primary-secondary-battery-chemistries-faq/ .. and the original WOTD post in 2020 is here. When correctly used, the designation of LR cells are for Alkaline, AG cells are silver, however it is rare for sellers to use the correct designation and LR41 is used interchangeably with AG3 and so forth. The cell I uses is strictly speaking an LR41 and not an AG3, but it actually has both stamped on it.2 points

-

2 points

-

The "P" logo on the dial side would seem to suggest a Peseux movement. Ranfft shows 200+/- Peseux movements. You'll want the diameter before you go looking there. I don't see enough detail in the keyless works to look through Bestfit. Are those mini OREO cookies ?2 points

-

do you mean like the back layout of the plates are a little bit different? As long as the wheels are in the right place in the watch more or less looks right it should probably be the same thing. Often times the movements get modified a little bit. Like you might have finger bridges over each the wheels or some other times it might be a much bigger bridge oh the other thing to do is it suggested there were equal to other watches go a look up the other watches see what they look like http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Bulova_10AE then here's a listing of stems compatible with yours. I don't suppose even have a partial love your original stem because if you did we could measure the dimensions and see if they compare to this stem http://cgi.julesborel.com/cgi-bin/matcgi2?ref=V\ZDXK\[1 point

-

A little trick that lets the joy of seeing a first repair running happy is worth showing to beginners. Don't you agree? Bigginers usually don't care about loosing a bit of amplitude. Rgds1 point

-

All I've greatly benefitted from these forums over the past few years as I've been spending more time at the bench with watches in various states of repair and an ever-growing collection of tools. I decided it was time to actually join for three reasons: 1) Although it seems that nearly every possible question has already been asked and answered somewhere on the site, I'm to the point now that my ignorance seems to be more unique and I may have to start asking my own questions. 2) It will be great to have access to all the service notes, manuals and other materials that people so graciously upload here. 3) I have reached the point where I may just have something useful to contribute when others have questions every once in awhile. I've always been a fan of mechanical watches and often took them apart as a young boy, but my interest in putting them back together in working condition was kindled by some Benrus military watches. This led to acquiring Benrus civilian watches with similar ETA movements for practice in servicing and repair, which then expanded to Hamilton, Clebar and other watches from the tritium lume era. I'm nearing retirement after a career in medicine and research, and with more time to soon be available I'm looking forward to taking on more complex tasks (and actually using the staking set I cobbled together from numerous online auction lots).1 point

-

1 point

-

These (MT920) are typically larger (so called coin cell sized). I wonder if Panasonic do a smaller button cell version of this technology. https://industry.panasonic.eu/energy-and-building/batteries/secondary-batteries/coin-type-rechargeable-lithium-batteries/aaf4005/mt920-mt920 Full list here https://industry.panasonic.eu/productfinder?category=Secondary+Batteries&group=Batteries&lineup=Coin-type+Rechargeable+Lithium+Batteries&mode=FILTER_MODE&search=&series=Coin+type+rechargeable+lithium+batteries+(ML+series)%2CCoin+type+rechargeable+lithium+batteries+(MT+series)%2CCoin+type+rechargeable+lithium+batteries+(VL+series)&sort=attribute_283%2Casc You might get away with an MT621 I guess, if you can find one. https://industry.panasonic.eu/energy-building/batteries/secondary-batteries-rechargeable-batteries/lithium-coin-type-rechargeable-batteries/titanium-rechargeable-lithium-coin-batteries-mt-series/mt621-mt621 Not cheap though, and they seem to all have solder tabs on. https://www.ebay.co.uk/sch/i.html?_from=R40&_nkw=+MT621&_sacat=0&_sop=151 point

-

1 point

-

Is the wobble relative to being about the staffs axis around the jewel hole or the balance wheel centre around the staff perimeter. Two different wobbles that also look different but could be mistaken. You really need to inspect the pivots and jewels under good strong magnification to fully check their wear. There should be no staff axis wobble if both pivot and jewel hole are in good condition and they are staying located with each other. End shake state can be irrelevant as regards to balance wheel wobble or balance staff wobble as long as the pivots are staying located in the jewels within their cylindrical portions . Sideshake is relevant, excessive caused by wear or incorrectly matched pivots and jewels. So unless they are non matching in which case one or the other has been incorrectly replaced. As john has said the top balance jewel looks wrong.1 point

-

1 point

-

To check if pivots jump out of the jewel holes, 1- Put the end stones back on both lower and upper jewels 2- Lift one side of the balance wheel to see if they do jump out, best view to observe is from the side of movement. A trick to lower the balance cock is shimming it on the outer bound.1 point

-

Sweet! Thanks so much. Really hope i can find anything i might need for this bellmatic.1 point

-

So after some very early morning googling i think ive almost nailed my Dodane watchstems identification. It doesn't point me to exact movement or calibre but i can maybe get that from sizing. But i think i know the watches that they belong to. In 1980 the well renowned Ray mellor once chairman and president of the RHI, owner of the Cabot watch Company CWC , supplier of military watches and a strong naval connection man. Amongst a whole array of other accolades, approached Dodane to manufacture a movement for British military divers watches to which he would insert in his WCW watches. The order was for a batch of 100 watches only and then switched another supplier for whatever reason. The stems i have say Dodane 344. But also what i thought was two letters, is actually 3 letters R N D. The N was faded but is still visible. Royal Navy Diver. It seems i have a box full, now i know why the box was full of stems, for what was a very short order of 100 divers watches supplied by CWC to the British Royal Navy .You dont get much rarer than that. Unfortunately out 100 watches there is unlikely to be many surviving if so then super rare. 100s of stems to fit an extinct watch hence very little info or database listings. Possibly from an associate watchmaker of Mellor of his estate as the stems came from London. I'll keep doing the lottery and if anyone has a CWC diver with a Dodane movement inside, you know where who has a stem to fit it if you need one.1 point

-

your balance jewel does not look right it looks like a plate jewel. In other words it's flat versus a balance jewel that would have a curved surface. then you need to figure out the type of formal you have? In other words at the pivots bent is that's why it's wobbling or is the entire balance wheel wobbling? In other words when people change the balance staff things happen in the balance wheels no longer flat in relationship to the staff. I have a video below which shows the way the balance should look if you put it in a true and caliber. https://youtu.be/9n2HxCOU4hA1 point

-

In the USA, I've used: https://www.ofrei.com/ https://www.jewelerssupplies.com/ http://www.julesborel.com/ https://www.esslinger.com/ ...and Cousins in the UK: https://www.cousinsuk.com/1 point

-

Only kidding really. I’ll just be glad if it works. It didn’t before.1 point

-

In the "THAT NEVER HAPPENS!!!" category of watch repair, I have this new story to add: I picked up this old, dirty Helbros Invincible at a flea market because I liked the style and wanted to see if I could do anything with it. I got it home and took off the back...and it was like opening Pandora's box! Looking over the Helbros-branded Lorsa P72 movement, I could plainly tell that someone had been allowing a stray screw or metal component to just freely go romping about amongst the wheel train. Damaged wheel teeth, scratches, broken staff, messed up hairspring, a couple cracked jewels, but no sign of a loose screw or part - although!...there were two empty screw holes, one in a bridge and it was missing one of the dial foot screws. So I picked up another Lorsa P72 movement off Ebay that seemed to have everything I'd need (it had rust on the parts near the stem hole, but I was not worried about that). When the donor movement came, I just cleaned everything and rebuilt choosing the best parts of each. Ended up replacing the balance complete, center wheel, third wheel, two jewels, and the missing screws. Miraculously, the other wheels were undamaged; teeth, leaves, and pivots were fine. Once assembled and oiled, I set the stud carrier as close to where it should be as I could get it, and put the regulator dead center. Now, I only have a timegraphing app on my phone (limited funds you know). But the traces looked really good. So I've been wearing it off and on, and keeping it wound. Here's the dumb luck part - I haven't needed to regulate this thing yet! It's been two days, a shade over 48 hours, and it is now about 3 seconds faster over that time period. I need to read the specs on a Lorsa P72, to see if it can do any better but, so far, a gain of only 3 seconds over a 48 hour period doesn't sound terrible. I'm used to antique pocket watches and their eccentricities, so having a watch run this close to dead-on without having to regulate it six ways to Sunday feels a lot like a miracle to me. I'm starting to really adore this wrist watch.1 point

-

Hi This might be of some help Drexler-Elgin.pdf Drexler-School-of-Watch-Repairing-No-1.pdf Drexler-School-of-Watch-Repairing-No-10.pdf Drexler-School-of-Watch-Repairing-No-11.pdf Drexler-School-of-Watch-Repairing-No-2.pdf Drexler-School-of-Watch-Repairing-No-3.pdf Drexler-School-of-Watch-Repairing-No-4.pdf Drexler-School-of-Watch-Repairing-No-5.pdf Drexler-School-of-Watch-Repairing-No-6.pdf Drexler-School-of-Watch-Repairing-No-8.pdf Drexler-School-of-Watch-Repairing-No-9.pdf Drexler-School-of-Watch-Repairing-No7.pdf Gruen-Horological-Text.pdf NY-Clock-and-Watch-Repair-School-pgs-1-28.pdf NY-Clock-and-Watch-Repair-School-pgs-152-175.pdf Ny-Clock-and-Watch-Repair-School-pgs-177-219.pdf NY-Clock-and-Watch-Repair-School-pgs-29-57a.pdf NY-Clock-and-Watch-Repair-School-pgs-98-130.pdf NY-Clock-and-Watch-Repair-School-pgs77-97.pdf Wisconsin-Clock-and-Watch-Repair-Book-II.pdf Wisconsin-Clock-and-Watch-Repair-Book-III.pdf Wisconsin-Clock-and-Watch-Repair-Book-IV.pdf Wisconsin-Clock-and-Watch-Repair-Book-IX.pdf Wisconsin-Clock-and-Watch-Repair-Book-V.pdf Wisconsin-Clock-and-Watch-Repair-Book-VI.pdf Wisconsin-Clock-and-Watch-Repair-Book-VII.pdf Wisconsin-Clock-and-Watch-Repair-Book-X.pdf Wisconsin-Clock-and-Watch-Repair-Book-XI.pdf Wisconsin-Clock-and-Watch-Rpair-Book-I.pdf WisconsinClock-and-Watch-Repair-Book-VIII.pdf1 point

-

Today I'm wearing my 404 club 9ct solid gold Rotary Quartz. It too is sporting a natty new Moralleto band, and I have to say these straps are extremely comfortable. Its a bit of a favourite of mine. In fact I'd worn this watch so often over the last couple of years that the old strap was starting to fall apart.1 point

-

Fear! I still may do that, but I don’t want to ga backwards. Yesterday, I was finishing a 400 day, slipped and broke the spring. Easy to fix, but demonstrates that even simple operations can go bad. i agree, lengthening the spring is the right thing to do.1 point

-

1 point

-

Hi The bit of bag I use is very thin but tough and the hand levers I made my self and the tips are thin but strong enough for the job and made of copper rod fitted to a brass tube handle.1 point

-

Oh well.... i have to confess, i am also in this Club, but i started more than one Year ago and have not yet disassembled any Movement, i have too much Respect until now. But by assembling my own Watches (only 3 until now, two of them running well, the third needs a little bit Attention....) i killed 2 Movement (Clone 2824 and 2836) and will have to find out what went wrong. As i have enough Spare-Movements at the Moment, i am not in a hurry to try it and disassemble them. And yes, i like Tools, you never have enough; buy cheap, realise its too cheap, buy again better Quality or try to make the Tool yourself (oh.....). I have a Lathe (180x300 Class) and a Mill (100Kg Class, a BF20) with a selfmade DRO on it, so basically i have the Tools to make Tools (my other Hobby is building Live-Steam-Locomotives in Scale 1:22 thats the Reason for Lathe and Mill). But in the World of Watches, everything is so tiny and my Fingers are so big, but i will be able to gain Practice and Patience and Trust. Yeah, i am retired, Age 67 now, short on Time due to other Reasons....... regards, Ernst1 point

-

I don't get to post here very often. But I picked up an interesting specimen at a local flea market: a TruTime talking atomic watch - for a dollar. The vendor didn't know much about, except that he didn't know how to make it work. To be honest, neither did I at that moment, but I intended to give it a shot. I figured if I failed it would still be a cheap lesson. I happened to have a 2032 battery for it, still very fresh. As a precaution I cleaned the contacts and blew it out a bit. Put a touch of quartz oil at the very few pivots it had, and it just sat there at first. So I went online to search for the setup instructions. With their aid, I got it set and running. Now what? I don't need a talking watch. And I don't want to just sell it. My oldest daughter has a friend who is legally blind, and her sight is degenerating. So I'm giving it to her. Best use I could think of for it. I have to find the link to have a braille copy of the instructions sent out.1 point