Leaderboard

Popular Content

Showing content with the highest reputation on 07/15/22 in all areas

-

In the "THAT NEVER HAPPENS!!!" category of watch repair, I have this new story to add: I picked up this old, dirty Helbros Invincible at a flea market because I liked the style and wanted to see if I could do anything with it. I got it home and took off the back...and it was like opening Pandora's box! Looking over the Helbros-branded Lorsa P72 movement, I could plainly tell that someone had been allowing a stray screw or metal component to just freely go romping about amongst the wheel train. Damaged wheel teeth, scratches, broken staff, messed up hairspring, a couple cracked jewels, but no sign of a loose screw or part - although!...there were two empty screw holes, one in a bridge and it was missing one of the dial foot screws. So I picked up another Lorsa P72 movement off Ebay that seemed to have everything I'd need (it had rust on the parts near the stem hole, but I was not worried about that). When the donor movement came, I just cleaned everything and rebuilt choosing the best parts of each. Ended up replacing the balance complete, center wheel, third wheel, two jewels, and the missing screws. Miraculously, the other wheels were undamaged; teeth, leaves, and pivots were fine. Once assembled and oiled, I set the stud carrier as close to where it should be as I could get it, and put the regulator dead center. Now, I only have a timegraphing app on my phone (limited funds you know). But the traces looked really good. So I've been wearing it off and on, and keeping it wound. Here's the dumb luck part - I haven't needed to regulate this thing yet! It's been two days, a shade over 48 hours, and it is now about 3 seconds faster over that time period. I need to read the specs on a Lorsa P72, to see if it can do any better but, so far, a gain of only 3 seconds over a 48 hour period doesn't sound terrible. I'm used to antique pocket watches and their eccentricities, so having a watch run this close to dead-on without having to regulate it six ways to Sunday feels a lot like a miracle to me. I'm starting to really adore this wrist watch.6 points

-

For a professional everything that makes work faster and easier is a good thing. But a beginner or hobbyst should not put himself in a position where he depends from that as he can't tell one part from another. Divsions, pictures, etc are all good things but don't let move away the main goal: to learn what each part does, why it looks like it does, and if two parts or screws superficially look like each other, being able to tell the difference and its reason. In other words, there is a big difference between doing something by following a script, and doing it by fully understanding what is what. The latter approach is the most important asset, and will be with one for all his life.3 points

-

3 points

-

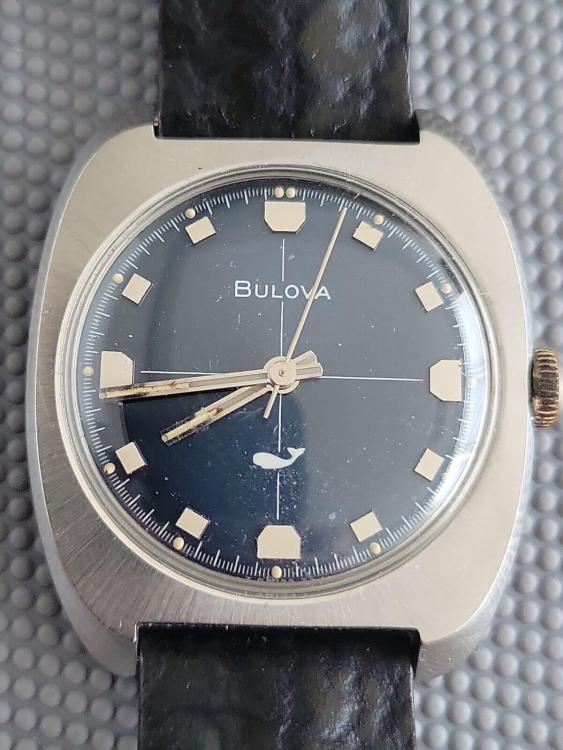

Too many in the latest haul! Sometimes the stars just align that way at the expense of the wallet. Got these 4 coming, and I have a NOS dial/hands for the 2nd watch, a Bulova Sea King 'FL', which it looks like it will need. That first Bulvoa with original band is straight out of the 1970's, chunky and bold, something I could see either Starsky or Hutch wearing :). I have a soft spot for Mido's and this one looks NOS, can't wait to give it wear on the wrist. The Waltham was so clean looking and fairly inexpensive that I couldn't pass it up:3 points

-

Hi peeps. Hope you are all well. Just wondered about anyone's thoughts as to this new old design that Longines are using. Always loved this 50s 60s look but wondered why they are using it . Who is thinking of the same reminiscent brand and dial design that i am ? Looks cool and i think first time in a mid level brand ( not that have much respect for the swatch group but as a specific brand I've always liked Longines )2 points

-

your first watch shouldn't be a repair at all. your first watch should be exactly what the paragraph above says it should be a running watch in known condition. People need to develop hand eye coordination and successfully reassembled a running watch and verify it is still running. that ideally they should practices several times as you really need to do it several times to get good at holding your tools tweezers etc. then your first servicing or cleaning should be something newer not vintage where it becomes restoration/repair. Also the other problem with vintage especially if it wasn't running is you may just be doomed to failure because it just may not run at all. Vintage watches have gone through lots of hands and they weren't always kind to the watch.2 points

-

You ought to be able to measure the size of the hole in the plate and the size of the pivot hole in the jewel and then order replacement jewels from a supplier like: https://www.ofrei.com/page939.html or Cousins since you're in the UK https://www.cousinsuk.com/category/jewels-pallet-endstone-jewel-holes Of course, you'll need to be able to knock the broken ones out and carefully insert the new ones and adjust the depth to achieve the correct amount of end shake. This wouldn't be what I would suggest as your first watch repair project. I know that conventional wisdom seems to be that a first watch repair should be a pocket watch. This is due to the fact that a pocket watch is generally larger and easier to work on than something newer/smaller. Having flopped around with this hobby for several months now I'd offer that your first watch "service" ought to be one known to have been running when you got it. Optionally, a cheap Chinese movement like the Seagull ST36 which is essentially a pocket watch design will allow you to dis-assembly, lubricate and reassemble something that has all the pieces and which ought to run when you're done with it. The ST36 is shipped "dry" from the factory and will require lubrication. It'll cost you 30 bucks. The problem with the advice of doing a pocket watch is that we all run to eBay, look for a pocket watch and discover they're in pretty bad shape and often with multiple problems (that we may or may not know how to diagnose). Then there is the issue of parts. As JohnR noted above, there isn't a warehouse full of 100 year-old watch parts sorted by make/model. Some of the more common watches that were manufactured in volume (like Elgin or Waltham) are easier to find and often you'll be able to find two movements that do in fact share some parts, but even there you need to be careful because it is very likely that even 2 movements identified with the same designation made years apart will be different enough that most parts won't be swappable (well, probably you can swap screws). You might put this one aside and think about something else.2 points

-

GS Hypo is a very good option. It's designed for gluing crystals so it won't damage the acrylic, it's more than strong enough for the job, and it dries fairly quickly. Carefully applied using an oiler any mess can be cleaned up with IPA.2 points

-

I have several watches I wear on occasions and only two have the chrono functions, both were presents. I cycle the chrono functions just to keep them moving on occasions but not worn on a regular basis. the others are just plain watches with day and date, at my age thats all I need, I have stopped clocking myself at 1/100 of a sec.2 points

-

y you would like to identify the movement why? when the world moved away from semi hand made watches cottage industry watches and mass production started the Swiss/French flooded the markets with watches like this. The only reason the serial number is there for inventory control purposes there are no spare parts for this watch for instance.2 points

-

From what I see I would say its one of those movements where you have a square at the back for setting the hands the square is part of a long pin that goes through the center wheel and is friction tight with the cannon pinion pressed on. It doesn't have the normal keyless work. More then likely it is Swiss or French many of these movements were made on or near the border of both countries.2 points

-

Nice. Simple yet frugally elegant. Like a well dressed tramp Oh and if thats your jumper its laid on Andy then you need a new wardrobe mate.2 points

-

I don't agree with the idea that the first watch a beginner attacks has to be a working one. The evidence is a total beginner will typically do many typical mistakes which will turn one into a broken piece of for sure. Working in the wrong position, without a soft mat, on carpt carpet floors. Then being proud of having lost "only one screw". That still one too little in my book. Handling the hairspring / balance with heavy hands, or having "unfortunate accidents" and driver slips. One can't realize how delicate it is before trying. I won't link the horror pictures here. Breaking screws because they were not market left. Or because they had to be left, but they were right. Getting impatient or frustrated, then force and break something consequently. Myself for one have do all the mistakes above, and then some of my own creation. If you have any love for your watches, or your reputation if it's not yours, especially about unreplaceable heirlooms or of some value, leave them alone. Practice first on something wortless, even a quartz cheapie, just to learn how to handle tools and parts correctly. Even if you have watches videos that make that look easy, you may find that is not. Sure, that won't tell you if you are able to put back together a working watch. But, that's not all what matters, you will get there eventually, but having spared few innocent victim in the meanwhile.1 point

-

Today I'm wearing my 404 club 9ct solid gold Rotary Quartz. It too is sporting a natty new Moralleto band, and I have to say these straps are extremely comfortable. Its a bit of a favourite of mine. In fact I'd worn this watch so often over the last couple of years that the old strap was starting to fall apart.1 point

-

Sorry to disappoint you, but its a cushion cover. Well at least you didn't assume it was my underpants.1 point

-

This is the posts for a nail clipper tool I designed some time ago with post from LWS for his mods. Maybe of some use. https://www.watchrepairtalk.com/topic/13621-cannon-pinion-tightening-tool/?tab=comments#comment-125998 https://www.watchrepairtalk.com/topic/18130-cannon-pinion-tool/#comment-1553121 point

-

Yes sir , i want to re attach a hour maker Thanks guys i will try to buy that adhesive , hope is available in my country (indonesia)1 point

-

These may not be friction fit jewels. Early pocket watches often had jewels that were burnished into the plate. A small lip was left that after a jewel was set in, which was burnished over the edge of the jewel to hold it in place.1 point

-

1 point

-

I like that look! A lot! Usually, pocket watches are more my thing, but if I wear a wrist watch, THAT ^ is typical of the style I'd go for.1 point

-

1 point

-

Eyup Adam or should we be calling this young marvel fan Wolverine. As John has laid out the harsh reality for you this is more than likely only going to be useful for practicing purposes. How much more of the watch do you have and what condition is it in ? Young fella1 point

-

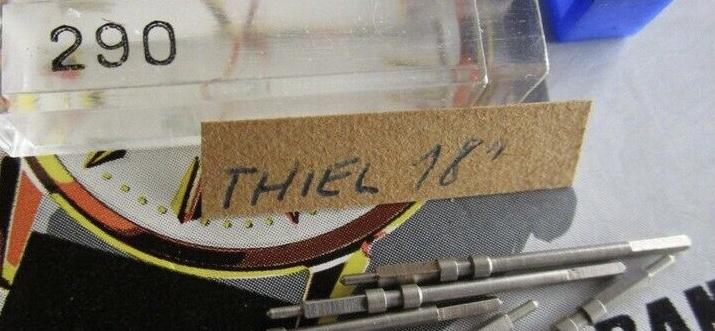

I have had a search for that particular stem as a nos ( New old stock ). Ranfft are listing two. A w290 and a w302. It seems the umf 1 from before 1968 was renamed the umf83, then in 1972 bacame nickle plated. So yours is in that 4 year period. A stem database check may be needed to find out which stem you need out of the two. So also bere that in mind if aquiring a donor that you need the brass coloured movement mainplate plate. Apparently a tough old boot, i may look for one to add to my collection.1 point

-

Here is some more information about the caliber: https://17jewels.info/movements/u/umf/umf-83-31/1 point

-

Using an old oiler, and some 90min Araldite epoxy resin should work. As far as I can tell, the epoxy resin does not contain any solvents, and has to be mixed just prior to use so that it will cure… Do note that you have to get the long cure time epoxy, so that you have time to position the stuff. Using less epoxy works better, so that it will not ooze out the sides when you press it into position. You may have to play around with how much epoxy resin your oiler will pick up at a time, as well as how much can be deposited, so you can apply the minimal amount of epoxy to the markers. Dial markers don’t face that much force, so you really need only a tiny amount of epoxy resin to hold it in place. If the dial marker has pins to position it on the dial, you can just apply the epoxy resin to the holes on the dial, then place the dial marker with its pins on. You should clean all surfaces that you are applying the epoxy on prior to attaching. Do take a look at this thread too:1 point

-

well dad(dad? ain't called anyone dad in over 40 years?)you caught my attention. how did it go? I did this once before and along the lines of what weasol (hi WW!)said above except i blended mine flush from the one side and then took a scrap spare stake I had laying around and turned the end of it as small as I dared, sounds you have the ability to do some lathe work... one tap and the little slug popped right out. and yeah then get yourself some brass or bronze tapered pin blanks. I get mine from Esslinger.com here near me(actually the place is only 20 minutes away-I get stuff fast!) good luck and keep us in the loop. I'd like to see how you did it. note: blending the end near flush eliminates the chance for the stub reg pin to further mushroom or worse. its fussy micro work but it does work.1 point

-

I thought we were named The Ping Club? Life member here... welcome aboard!1 point

-

An interesting tour of the Vostok factory. The watches are assembled without gloves! When you get a brand new Vostok, you better do a thorough clean.1 point

-

Added two more pennies...I think that will do it. Now I need to craft a stylish weight to use instead of pennies.1 point

-

Cool. Tool manufacturing my favourite. You're way too organised for me mate. I'm like the chef that has to have every gadget and cooking utensil out on the worktop. You want to see my watchroom, you know the goldfish that grows to the size of its bowl, well there is no water left in mine.1 point

-

Today I got a chance to look at a 1972 Kelton Armachoc. This is pretty much identical to a 1972 Timex Marlin, although it may or may not have been produced for Timex in France, rather than at their Dundee factory. Some of the parts may have originated in Scotland as there seems to have been some cross pollination between the two factories. I paired it with a rather nice Moralleto new, old stock strap, from a job lot of such straps I picked up on ebay around the same time I purchased the watch. The watch was somewhat scruffy when it arrived as, curiously enough, most of the 404 club members are. It cleaned and polished up very nicely and is running well too.1 point

-

Welcome to the forum and to our exclusive club of screw losers (most here are no longer members of the Lost Another Screw Club but it's possible that we all have a few loose ones). Here's a good, animated web page to look at as well as a short, seven minute video that might be of interest.1 point

-

I only know that because I've used it at work since i was twenty. There are different strengths and different thicknesses depending on its application. I use a thin one when I'm trimming up with upvc mouldings and a thicker one for jointing mdf trims on kitchens. The thicker one generally needs an activator on one component for the bond to start up. I sometimes use spit if I'm on a mission. Some plastics react badly acrylics especially and polycarbonate to even the fumes and other plastics dont stick at all. With the varnish you have a little bit of flexibility in there and it can be corrected, cleaned and dressed up if necessary and careful. But always the best result comes from applying just enough to stick the markers but not enough that it creeps out when applying pressure with whatever adhesive you are going to use.1 point

-

Hi as a rule they are a taper fit put in frm the topside and pressed in, so the best way will be to press it out in the opposite direction. With it being a taper it shouldnt ruin the hole, then cut and polish. pins can be got from cousins as an assortment at not to great cost. gook luck cheers1 point

-

Good call Paul, the fumes do react with certain plastics causing hazing. Superglue has virtually no correcting ability and any overspill will almost certainly ruin a dial. I have used clear nail varnish applied with a very fine oiler in the past. As with service lubes, less is more.1 point

-

I find a tiny drop of Gloss Enamel varnish works wonderfully for gluing small item like hour markers, another option that works is tiny drop of simple PVA glue, dries almost clear with a small amount of flexibility once set. If using a Cyanoacrylate make sure it's fully dried before letting it anywhere near an acrylic crystal, unless you are into fogged crystals that is1 point

-

Assuming that your goal is to simply re-attach rectangular hour markers I would use any cyanoacrylate "super glue". The trick will be using a small enough application so the extra glue doesn't get all over the dial face. A photograph would help.1 point

-

No help but maybe reassuring: had a fairly recent (20yo) Patek manual wind in a few months back with some oddball hole a cap setting superglued in as the Kif spring was broken. Guess they lost the original jewels too. Friend has a box full of envelopes of Kif material so managed to get it right. Crazy thing is it ran. Very, very poorly, but ran. That's why my client bought it, "ok it just needs a service!"- and a soak in acetone, haha.1 point

-

1 point

-

I watched the Vostok video. YouTube figured I liked it, and served me up this one of the Raketa factory this morning: If you're not hip to the tech, you can turn on closed captions, and under settings have it auto-translate to whatever language. It's a bit hit or miss, and started out good, but toward the end of the video (I assume when things started getting technical) it pretty much fell apart into an unintelligible word salad. The first half looks to be just hanging out in the gift shop, but they do ultimately show the actual manufacturing. Very different from Vostok. Vostok is much bigger, but looks like ancient tools being kept alive by accident. Raketa looks much more like what I would expect a Russian watch manufacturer to look like; old tools, but reasonably well maintained. If I were to buy a new Russian watch today, I'd definitely be looking at a Raketa over a Vostok.1 point

-

This is today's pocket watch of the day. A defiant with a lovely enamelled dial by fattorini. I've come to know a lovely retired antique dealer and his wife at Bridlington carboot in East Yorkshire. Bought a few pieces from him inc. A pre ww2 engraved glass bowl by Lalique and a couple of nice bigger timepieces ( carriage and mantle clocks from him ). Today a Smiths floating balance westminster wooden case mantle clock to replace the buyer's remorse one i got from an antique shop. and he actually gave me a non working pocket watch that he bought years ago that had never worked. He popped it in his pocket on their way out hoping he would see me today. I had a look for him but only had 3+ reading glasses so all i could see was the hairspring coils looked stuck together somehow. He said if it was any use to me i could have it, what a lovely old gent, thank you Steve and Myra x. Here it is absolutely swimming in oil. A chip pan movement ( Kalle ).1 point

-

1 point

-

So here it is. I couldnt wait to post this as I'm over the moon with it. I've wanted one since i started collecting. Would you believe i asked the universe for it ( the right way ) two weeks ago. So a couple of weeks ago i was at n.cave e.yorks carboot talking to a guy about watches . He had a couple of non descript clocks that i wasn't interested in but i asked if he had any watches. He said no not with him but at home he had a w.w.w. ( very large clue as to what is coming )wristwatch that he had had fixed but had broke again. I asked if he wanted to sell it and if so bring it in two weeks time when i come back up this way to see my sister. He said ok. He told me it had a blackface and he thought it was an Ingersoll. I wasn't aware Ingersoll made www watches and had never seen one so i thought maybe he's mistaken. So anyway keen to go back yesterday morning, i mooched around the carboot for an hour taming my anxiety and excitement ( i dont like to rush a universal gift, its not respectful and can get taken away as quickly as its given ). In doing that i also picked up a lovely 404ish clock. Eventually i made my way over to the guy's inside stall. Now then matey how's you i said , gud he replied, I've brought you something. He searched through a carrier and i was thinking it cant be much of a watch to chuck it in a carrier bag. A minute of searching and i thought hes forgot it never mind. Ahha he says pulls it out and hands it to me ( the watch ) . I look at it and look at him. Then I look at it, and I look at it , and then I look at it some more. Oh crap its a w10 military watch. He tells me the mainspring has gone, i said no it hasn't, its just fully wound. Have a look inside he said if you want. I had taken a screwback remover a loupe and a piece of rodico with me. I undid the back and peered inside. Its a Record i said, oh at least i know what it is now he said. I had a little prod with the rodico, unfortunately one of the staff pivots had broken, the top one. I said what do you want for it, he gave me his price I'm not saying how much but it was cheap. I said no i cant give you that, so he came down a tenner. I said no i cant give you that either. He said I'm not taking any less that that for it, i said i know your not, your going the wrong way. He looked at me confused, i said take your first price and double it. He looked at me even more confused. Mate its worth more than double what you want , I've got to fix it but I'm happy with that if you are. He wouldn’t take double and we settled in the middle. I gave him his money, we chatted for 15 mins and then shook hands, before i left he said i think i have a couple of pocket watches at home, ill bring them next week, if you come again you can have them. Wow Universe what have i done to deserve your praise. So here it is. As far as i can tell up to now. Its a redialled record dirty dozen (possibly). The movement is the same as the Record DD, the dial serial number relates to the Record. I have yet to date it yet but the movement 022K according to ranfft started being manufactured in the 1920s. Anyone that has some serious knowledge on military watches, i would be so grateful for any help working out what i have here. Here it is i absolutely love ❤ it .1 point

-

the only minor problem with using the manual using the meter are you using a Mercury battery? If you have a Mercury battery than your fine but if you using a silver cell you have too much voltage. For phasing I use what they described here. http://members.iinet.net.au/~fotoplot/accphs.htm1 point

-

1 point

-

1 point

-

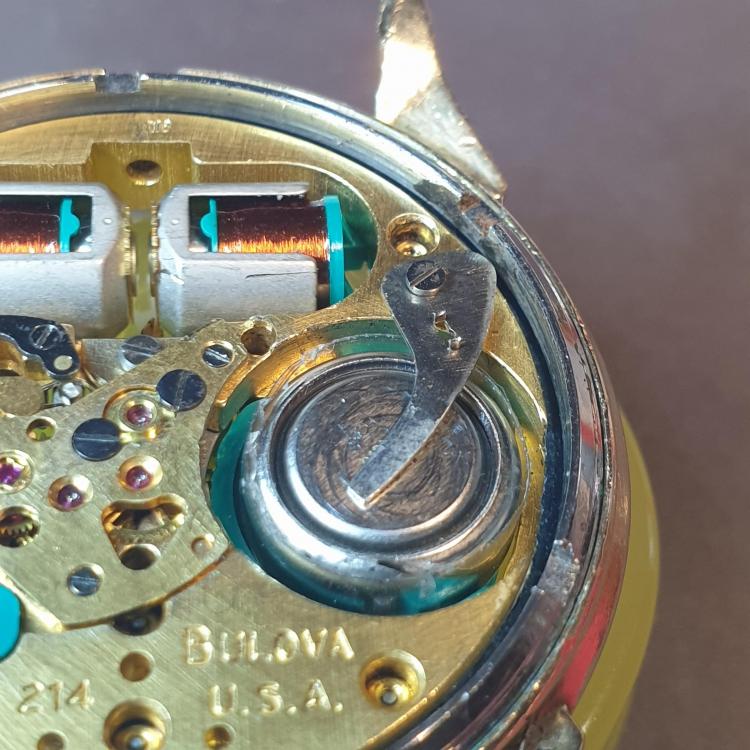

Hi there, here is the manual for the movement in case you need it. Apparently the movement was made by Citizen and assembled in Switzerland for Bulova. Graziano 242.pdf1 point

-

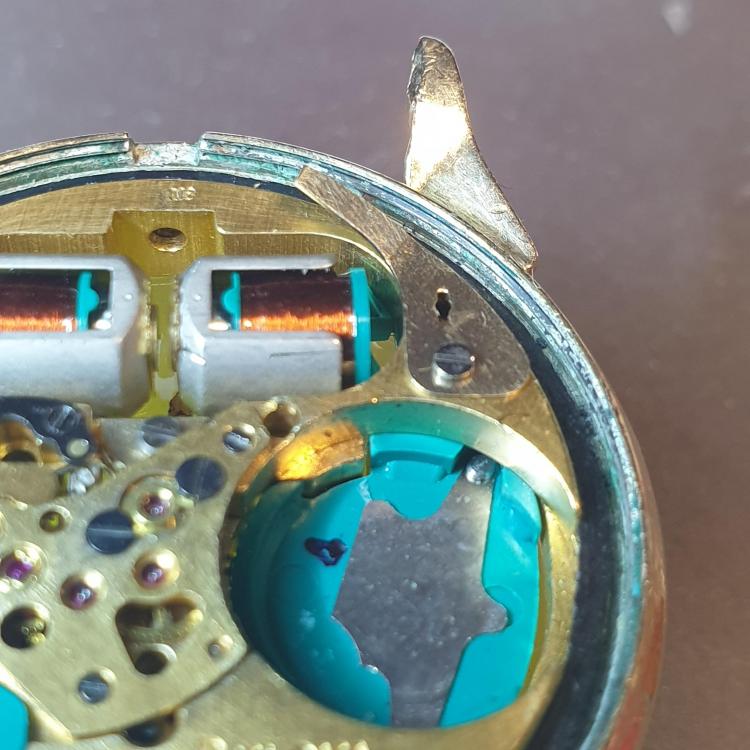

I've been servicing Accutrons for some time now. But yesterday I just had an AHA! moment. When phasing the 214, I had been using the power from my Accutron 700 test meter to supply voltage to the watch. I would clip one lead to the ground strap and used one hand to press the positive lead to the battery terminal. This leaves only one hand to adjust the pawl finger. I was thinking of a way to make a battery clip hold the battery in place to make this procedure easier. Then it hit me.... All I needed to do was to flip the ground strap upside-down and use it as a battery clip!1 point

-

Could the side-shake in the cap jewels, coupled with a slightly off-level hairspring cause slight wobbling, only perceptible at high (i.e. 10 times) magnification? de Carle in “Practical Watch Repairing” mentions that the side shake of the balance wheel in the cap jewels should be up to 5 degrees from the perpendicular of each side of the staff, which would certainly allow for a slight wobble if the hairspring wasn’t perfectly parallel to the axis of rotation. I admit this question is purely academic, since this would have no effect on the time keeping of the watch.1 point

-

Here are some pics of my nail-clipper mods, for those hobbyists who do not have lots of cash!! Only cost would be for a suitable drill for the setting screw hole (tungsten carbide needed as material of arms is very tough), the rest from the 'bits box'. The original pin for the lever was 5mm diam hence the crimp screw diam, this could be different for other clippers. Any epoxy would do but JB weld sets very hard. The setting screw can be any size provided it does not compromise the integrity of the arm (ie weakening it across the arm) and the locking nut fit re fouling the crimp screw head. The crimp screw could be in the other way but thought easier to have both screw heads on same side.1 point