Leaderboard

Popular Content

Showing content with the highest reputation on 07/14/22 in all areas

-

Interrupted cuts I have got a new small bike, quite happy with it but it needs few details sorted out. One is that final drive ratio is a bit short, finding a suitable rear sprocket was no difficult, and it looks from another planet compared to the original. Only problem, there is a wide groove cut where the fixing nuts sits, I think the original has a bending tabs there or something. I'm afraid a lot of guys would have cobbled somethin up but not me. So I went to machine from 4 stainless steel M10 washers. Interrupted, off center cuts, the original sprocket was perfect for the setup. This is the inner side cut which is actually a boring operation. Cheap brazed carbide tools did fine, in the end they chipped and wore out, it would have been good to rough cut the work before, but my angle grinder was somewhere else. A lot of of small cuts and too much time, but in the end the result was impeccable. Bottom right how a round washer would have done... very poorly and ugly. The custom washer are thicker than the cut, so the nut never touches the sprocket, and all is square and safe.5 points

-

Alright, there is another detail that I want to show. The kind of thing that doesn't change working, but is just too ugly. The original Phillips screws for the ABS ring... Stick 2mm on the front, 10 on the back, horrible zinc plated. I got SS A2 socket screws, taper head. But the ring holes are smaller that the standard (that's why the original didn't flush) , so I had to undercut their back on the lathe. That is done with the compound slide at 45deg. Perfect! Compare below.2 points

-

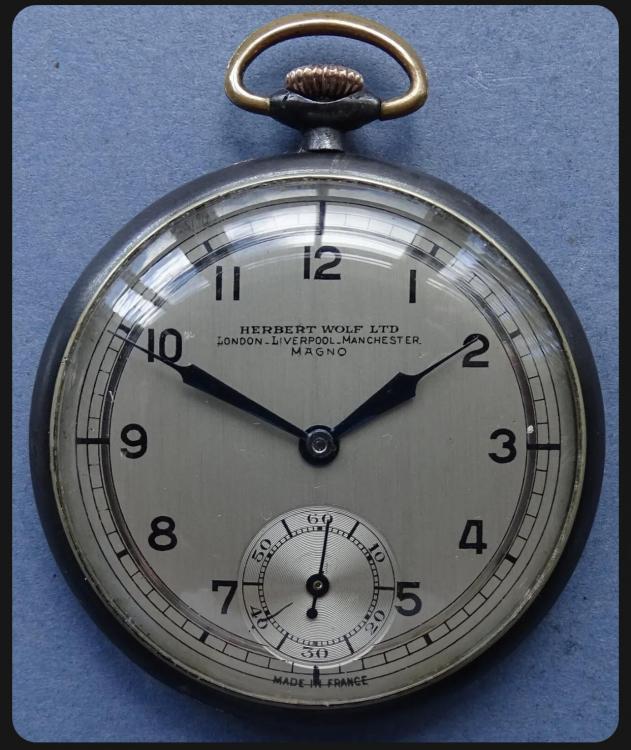

Good luck with this movement! I‘m not so sure if this is a good start for a beginner expecting a „gorgious“ result. The hairspring looks bent and the pivot holes badly worn. You should take it as an object for practicing assembly work and be happy to see it just running.2 points

-

Herbert Wolf Magno, more likely an importer, I can't find his name in Watch and clockmakers of the world vol 1 or in vol 2. Looking on the net and finding swiss watch movements even one that was in a 9ct Dennison case with a very high class movement. The names on your dial tells us he had shops or outlets in those towns and LTD tells us it was a company. The watch movement you have is at the low end of the market, very few jewels only for the escapement and not the train. Looks like a gun metal case. The movement fits the case and dial perfectly. With movements that are not fully jeweled look out for wear in the pivot holes and the pivots.2 points

-

1 point

-

Not an achievement yet, but I purchased this pocket watch off Ebay in the hopes to get it shiny and running again. I have no tools apart from some precision screwdrivers so will probably need to purchase some before I tackle this thing. I do believe when it is cleaned up it will be gorgious and hopefully I can get it running. Will keep you all posted here.1 point

-

Today I got a chance to look at a 1972 Kelton Armachoc. This is pretty much identical to a 1972 Timex Marlin, although it may or may not have been produced for Timex in France, rather than at their Dundee factory. Some of the parts may have originated in Scotland as there seems to have been some cross pollination between the two factories. I paired it with a rather nice Moralleto new, old stock strap, from a job lot of such straps I picked up on ebay around the same time I purchased the watch. The watch was somewhat scruffy when it arrived as, curiously enough, most of the 404 club members are. It cleaned and polished up very nicely and is running well too.1 point

-

1 point

-

Hello and welcome to the forum, I have attached some reading for you. If you are serious in getting into this facinating hobby have a look at Marks watchfix site regarding online courses they will give you a good grounding. Congrats on the forhcoming wedding, watch repairs will take a back seat for now, maybe. all the best. cheers 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

There could be a third way. Turn a small brass plug, it might have two diameters, although doesn't need to. Drill the plate where it has to go and fit it with a slight interference.1 point

-

1 point

-

I only know that because I've used it at work since i was twenty. There are different strengths and different thicknesses depending on its application. I use a thin one when I'm trimming up with upvc mouldings and a thicker one for jointing mdf trims on kitchens. The thicker one generally needs an activator on one component for the bond to start up. I sometimes use spit if I'm on a mission. Some plastics react badly acrylics especially and polycarbonate to even the fumes and other plastics dont stick at all. With the varnish you have a little bit of flexibility in there and it can be corrected, cleaned and dressed up if necessary and careful. But always the best result comes from applying just enough to stick the markers but not enough that it creeps out when applying pressure with whatever adhesive you are going to use.1 point

-

How about a fine needle ground down to slightly under the same dimension but not to a point as this will have the effect of spreading the pin. The needle in a self locking pin vice. Popping to my watch room to investigate. I have the bloody covid nonsense so confined to staying in for a few days so i may as well be useful1 point

-

No offence taken from either of you. Sometimes conversational nuances get lost via text communication. Being a fairly direct person myself sometimes things that I type seem standoffish when thats not my intention at all....most of the time. In regards to the topic I ended up ordering some case retainer springs from Cousins; fingers crossed that one of them in the assortment fits. I have also emailed a company that makes custom bezel rings to see if they can help me out.1 point

-

Hi as a rule they are a taper fit put in frm the topside and pressed in, so the best way will be to press it out in the opposite direction. With it being a taper it shouldnt ruin the hole, then cut and polish. pins can be got from cousins as an assortment at not to great cost. gook luck cheers1 point

-

I find a tiny drop of Gloss Enamel varnish works wonderfully for gluing small item like hour markers, another option that works is tiny drop of simple PVA glue, dries almost clear with a small amount of flexibility once set. If using a Cyanoacrylate make sure it's fully dried before letting it anywhere near an acrylic crystal, unless you are into fogged crystals that is1 point

-

As best I can tell these pins are press fit, so that's what I would do. Put in from the back , cut close to the back, tap with a stake to fit tight, cut flush and polish back. Trim the part sticking out to match the height of the existing pin, and adjust spacing between the pins. I may try the drill method, after cleaning up the broken stub so the drill doesn't wander. I'd probably go pin vise, my archimedes isn't fine enough to work at that scale. The other issue is bit size, I have down to 0.3mm, but even that looks a bit large. These things are small1 point

-

Check the thread profile at the crest. It might benefit of careful smoothing with a fine file.1 point

-

I used a safety razor blade. It is a technique I have used before. What I do is slip it in the gap and rock it up and down. I do this on the sides (not the lug ends). Sometimes, I break the blade but that is OK, I have plenty. There is that fear, as you say, that I will slip and damage the movement or cut myself--not sure which is worse!1 point

-

It‘s an UMF 83 caliber that was built in different variations between 1923 and 1990: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&UMF_83&1 point

-

Ah thank you. Well its not anything important or expensive, so it is meant for learning and practicing, getting it running will be the biggest problem. Thank you for pointing out the problems with the watch, these are things I have missed by being a total beginner at this. Also what I meant with gorgious, was polishing the case and getting the glas/crystal clear and shiny again. I think it will look fantastic when that is done, running or not.1 point

-

Hello guys, i have just found this Herbert Wolf Magno pocket watch and got it so I can practice. However I am a little concerned about its authenticity since it’s a UK watch with a Made in france on dial. I know this kind of situation was very comom (assembly in a country, inported to another one), but I couldn’t find this situation regarding Herbert Wolf watches (all watches I found on internet are fraved with swiss made). Does anyone have any idea about this one?1 point

-

1 point

-

Welcome! This will certainly give you something interesting to manage Certainly consider Mark's self-paced, online tutorial courses. This animated web page will give you a lot of insight into the guts of a mechanical watch.1 point

-

1 point

-

1 point

-

Hi I actually own an Ingersoll Terrier.Like you I could never find any advertisement or reference to a Terrier.I had the watch serviced a few years ago and the guy who overhauled it(now retired)used to work for Ingersoll.He to said he had never seen one.The watch runs beautifully and although some of the plating has come off the case,it is still in good overall condition.It does look very similar to the Ingersoll Valliant but of course has Terrier on the dial.If you want pictures of it,I can always email some to you. regards Andy.1 point

-

Heck, not just beginners, you @JohnR725 and @watchweasol along with others have provided a treasure trove of information that has saved my bacon many times. Thanks!1 point

-

The Citizen has via a D-tour (Germany-Denmark-Sweden-Denmark) arrived. First impressions are that the watch is nearly as new. No scratches on the crystal, hardly any on the bezel and no signs of ever been opened. The movement looks untouched. However, the movement runs but has a tendency to stop. Perhaps no wonder if you see the "heavy snow in Switzerland" picture on the timegrapher ...... but this is the reason why we are here1 point

-

1 point

-

Hello Brad and welcome to the forum, First thing is to try it on a line release unit to see if the hands cycle under power. Remove battery first. if thats ok put a drop of oil on the pivot tops you can see and cycle again and then re try with a battery if still a non starter check the continuity if the coil. and if you can the output of the block for pulses using a meter on the micro amps scale. Attached is the tech sheet for the omega. 486_Omega1250,1255,1260_New0713.pdf1 point

-

Again, thanks for the warm welcome! Yeah, I have been >>>BULLET>>> or some permutation thereof since I first logged onto a BBS back in 1993...had to call myself something, looked around, my computer was in the reloading room, and sooo I became >>>BULLET>>> (plus some memorable numbers when I need them, most commonly "308") I started out shooting metallic silhouette pistol and rifle back in the '80s, then moved on to NRA Service Rifle, where you shoot tuned-versions of the M1, M14 and (nowadays, mostly) M16 rifles. Was on the SC State team for three years and went to Camp Perry for the national championships three times, where I was, in 1992, the TOP shooter on the third worst Service Rifle team in America. :-) In one match, I came in 285th out of 1600 competitors, which means I was thoroughly okay as a shooter, in the thick of the other okay shooters from around the nation. Drop one point or pick up an extra X, and you could move twenty places up or down in a heartbeat. I think eight more points and three Xs would have put me in the President's 100, but there were 185 people between me and that honor, soo... Along the way, I apprenticed to the gunsmith that built up the State Team's and our National Guard teams rifles and helped him build them in preparation for going to Perry...so, I got pretty good at building National Match Garands and '14s up out of parts, doing all the arcane tricks and tweaks you have to do to get them to shoot well...lots of fun. I also worked going general repair and cleaning work in a couple of gun shops around town...ah, evidence of a misspent youth... Attached is a photo I recently found of the two rifles I took with me to Camp Perry in '91-'93...I helped to build both of them, the top one is my personal rifle, built up out of rejected parts from the Marine Corps Team's armorer shop at Quantico on a Springfield Armory Inc. receiver...the lower one is my team-issued TRW M14NM, US government property...hated to have to give that one back, but apparently, it was needed more in Afghanistan rebuilt into a designated marksman's rifle than in my safe gathering dust...(that was the rumor when DoD ordered them all taken back up in the early 2000s, in any case)... Nowadays, I mostly just tinker with my own stuff, AR-15s or whatever...but once I get the lathe wired back up and running, I may hang out a shingle as a gunsmith once again... Oh, and one of my prouder possessions: a BSA Model 12 target rifle, about 1948-vintage, complete with Parker-Hale 7A rear sight...an ex-UK club gun, from what understand...shoots very well indeed... I am quite familiar with the BREN, and wish I were more familiar than I am...there are quite a few transferable .303 BRENs in the US, but they still go for tens of thousands of dollars each, and there is precisely one transferable L4 in 7.62 NATO on the NFA registry...Lord only knows what that thing is worth... All the Vostok stuff I had been ordering over the last month has been trickling in, first the Ukrainian stuff, and now the Russian orders are starting showing up...I now have 4 Komandirskies and three Amphibias on-hand...unfortunately, all of the Amphibias that have arrived so far are going to need to be overhauled before they can be put into service...cool! I mean, bummer... :-) And now, I am off to install a video camera and capture card and associated software and cabling for a client...they will be doing a two-week training starting tomorrow and that stuff has to be up and running, um, very soon... And again, thanks. -Tom aka >>>BULLET>>>1 point