Leaderboard

Popular Content

Showing content with the highest reputation on 07/11/22 in all areas

-

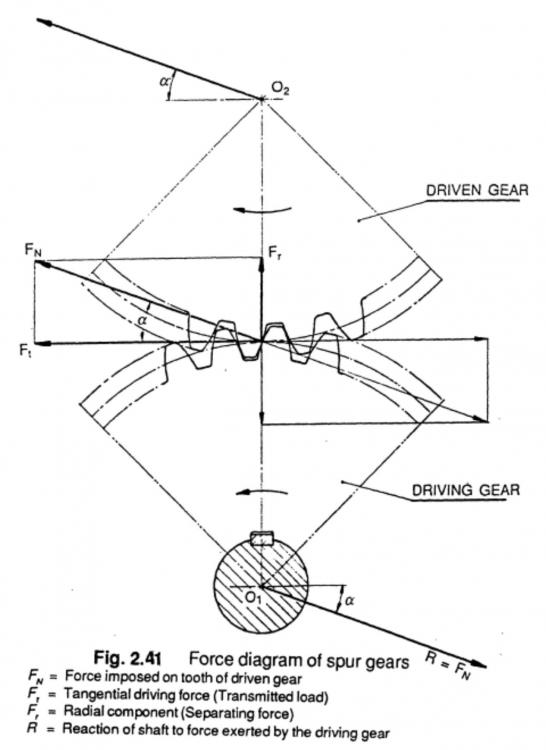

I‘m sorry to say that direction of forces acting in the bearings seems not to be right in your drawing. You have to start with the driving force on the two meshing teeths which is oriented perpendicular to their current contact plane. The bearing load of the barrel is exactly parallel to this force. https://www.drivetrainhub.com/notebooks/gears/strength/Chapter 1 - Force Analysis.html3 points

-

Today I took a crack at the three Jappy Beaucourt pocket watches I picked up around the start of the year. Arguably this one needs a replacement glass, but I think 150 years of scratches give it a bit of character. I may try to polish the scratches out some time, but successfully polishing glass is a lot more hard work than polishing acrylic. The one with the roughest dial became the parts watch, and I have this one running well (within a minute per day, which is acceptable in my book for an ancient cylinder movement), and a second one running, but still not quite in beat. In fairness the poorly running one had a pretty bad case of hairspring salad, so the fact that runs at all is pretty good going. It has an acrylic crystal, so it has obviously had some work done to it in the past. The one I am wearing is almost completely original, but for the winding click mechanism which was too far gone to be saved, so the donor (which also had a broken mainspring) provided that. The donor also provided a minute hand, following a minor calamity where the original one experiences some strange quantum entanglement event and winked out of existence. It may wink back in to existence again when I clean the area under my work bench, but I'm not holding my breath waiting for that. I've already crawled around on my hands and knees there for the required half hour trying to appease the horological deities, but nothing quantum related occurred. I grant you, the Beaucourt it is not quite as elegant as the "Defiant" in the previous post, but it is ticking away nicely, and I rather like it.3 points

-

No big deal here. This came to from from a friend of a friend...lol. First off, I noticed a busted staff, so I ordered one on eBay before ever digging in too much. However, I discovered that the balance wheel beam was split right at the staff. I did not do it. I removed the staff by chucking it up in the lathe and removing the rivet. So, I guess the last guy did it. I could tell that it had seen a few repairs. Somebody tried to clean the dial and left scratch marks!! Anyway, the new staff came in and it was rusty. Not uncommon for NOS purchase on eBay. I asked the seller to make it good and he did. But, just to be safe, I found a donor for $10 (same price as the staff!!) and ordered it. The donor came in today and, frankly, it was in better shape than the one I was working on. But, I just replaced the balance and balance cock, did a full clean and oil and called it done. The watch is running...timed out well for an old watch like this. I noticed that the ratchet wheel and crown wheel were both left handed. First time to run into that. Normally, I have found that getting the wheels in the going train aligned is a real pain for ladies watches. They just seemed to line right up for this watch. That's a happy face.2 points

-

Not Magic Its just knowing where to look, And John has the knowlwdge, I also have a computer full of info . Cant have too much . attached the 3800 base caliber tech info for you Citizen guys 774340894_2634_Citizen38003801380238103811.pdf2 points

-

In most cases the pivot hole will be surrounded by an oil sink, which in all but the worst grade stuff (even then) will be pretty concentric to the original hole location (not necessarily true on really old antique stuff though). In a watch you can "drift broach", where you use a cutting broach while applying lateral force to bring the hole centered again. Then continue to broach to size, keeping an eye on the centering. In a clock it would be more common to file it back to center. If there's no visual reference or you need it really really spot-on like an ultra thin watch, best is to use a faceplace, centering on what is hopefully and unworn opposing hole. Lacking that optical centering is great, like ifibrin mentions. Many watch and clock makers just run the commercial broaches through counting on them to center as best they can. The hole location will end up somewhere between the worn point and the original point. Obviously not ideal, but it works. This can get hairy if one wheel's location gets shifted, then down the road the next wheel in line shifts and when it gets broached to a new location things bind up.2 points

-

Welcome here. Do you have any previous experience? When a watch is precious by material or sentimental value, it is a definite mistake for a total beginner to attack it. The chances of a good outcome are small, despite the better intentions of the individual. One should practice first on pieces of small or little value, that will allow to get a realistic grasp of what is involved in terms of knowledge, skill, and tools.2 points

-

I like your style Ernst, fingers in other pies. Similar relative and applicable pies that come in useful for each other. Forget about the time you have available matey, Rome wasn't built in a day an all that. I wish i had done this years ago, maybe even for a living instead of tearing my body apart with a physically demanding job. But I'm enjoying it now so thats all that matters. Whatever time we give to this and whatever time we have left to do this or whatever. Every day is a bonus every day is a gift guys. Love every minute of every day in everything you do. And make as many people happy as you can along the way.2 points

-

yes the secret of where to look and what to look for. on my bookmark toolbar for the most part there is no individual bookmarks there are just folders of bookmarks. Watch repair related stuff takes up to folders otherwise the list goes down the page too far and it did allow me to categorize a variety of things. Then of course it's really nice that computers have much bigger hard drives than they used to have sizable quantity of PDFs accumulated over a very long time and continuously being updated with more and more of them. I just happened to be the first person here there are others on the group that will post tech sheets also. so I don't work alone here this is a team effort there iare other people on the technical supplying team. although that's an unofficial team we don't officially exist.1 point

-

Greetings and welcome! After quite a lot of time and angst I found out to my dismay that EVEN IF YOU GET a watch of the same model from the same manufacturer, often the parts are NOT interchangeable. In any case, there is a lot of knowledge contained in some of the lengthy threads on this message board. Mark L. has a series of self-paced, online courses that you might consider. Look here. This web page also has a lot of very detailed information on the workings of a mechanical watch.1 point

-

It's very unlikely that you can find an hairspring which matches the existing balance wheel and cylinder combo.Itvwould need to come from an identical mov.t.. In fact it would be good already to get it to merely run without any regard to timekeeping. It exisits a specific and very tight relationship between the size, material and natural oscillation of an hairspring, and the weight if the balance wheel. On top of that, cylinder escapement repair is pretty much a lost art today, it has not been cultivated anymore because it was so inferior to the lever escapement, that buyers and watchmakers quickly lost interest in it when presented with affordable alternatives.1 point

-

Hi You have recieved some good advice, I would only add have a look at the pocketwatchdatabase.com there is a mine of information , serial number lookups, exploded diagrams of pocket watches, so familiarise yourself with the workings of a watch, get youself some good tools and begin the journey. attached is a listing of tools, not compulsory but advisory. And buy only what you need. Its a rewarding hobby as many will attest but can also be expensive and frusrtating, plan wisely and good luck. Cheers 1612608791_ToolsfortheHobbyist (2) (1).pdf1 point

-

The Citizen has via a D-tour (Germany-Denmark-Sweden-Denmark) arrived. First impressions are that the watch is nearly as new. No scratches on the crystal, hardly any on the bezel and no signs of ever been opened. The movement looks untouched. However, the movement runs but has a tendency to stop. Perhaps no wonder if you see the "heavy snow in Switzerland" picture on the timegrapher ...... but this is the reason why we are here1 point

-

Had you checked the power reserve at that time? 2 years on a winder seems an excellent way to unncessarily wear out an automatic watch in all its parts. Good at least that it was then given a break. Anyway, since the watch has been just returned from repair, your first action should be to return to it. It is fair to give them a chance to set things right.1 point

-

1 point

-

Moebius is the only manufacturer worlwide specialized on watch oils with its tiny market volume and high R&D expenses. Moebius is located in Swizerland and part of the mighty Swatch group which dictates the type of lubricant to its licensed watch makers. Hobbyists are free to experiment with other lubricants developed for the use in micro mechanics.1 point

-

Someone will certainly tell you what is needed but I think that teaching on how to do by oneself is more valuable that serving the ready solution. 1. get yourself an eyepiece or at least a loupe. Very very important when dealing with watches 2. measure the old battery, that will give you right away the size because diameter makes the 1st digit, and height the 2nd and 3rd. And I am attaching a document to better make sense of that. 7009_Battery Cross Reference Guide.pdf 3. if no battery, measure the slot and proceed as as above. 4. if no watch, there are many websites carrying this information. Normally, in the first hits of a Google search result.1 point

-

You can download instructions and an exploded view / parts list of the Hermle 341-021 at Cousinsuk (https://www.cousinsuk.com/document/category/hermle-movement-parts-search).1 point

-

This is what I would do. Clean all that dreadful soft solder off. If you have the correct tap and die use them and see how things fit. If unsuccessful re bush the crutch and tap it. If by chance you cannot clean that solder from that crutch you will have to make a new one drill a small hole for the crutch to go in and use Loctite Threadlocker Red 271 This is a very nice French Four Glass with cloisonné and mercury pendulum with a very nice dial. Worth a few hundred pounds. So it need plenty of good care when cleaning and repairing such a piece1 point

-

they can and are allowed-you'd be surprised at how many are out there that do still exist and run. I know cuz I've worked on lots of them for years. most if not all have been retrofitted and upgraded with dead man switches and light curtains for safety, from the small 1 tons all the way up to the heavy hitters like the 400 ton that have foundations and pilings that go as deep as 40 ft. if you get anywhere near the business end of the press and it shuts it down in less than what it takes to blink an eye. they're fascinating to watch, much less fun to work on tho...this is interesting to see that they still use ancient presses in their facility. for further reading look up the history of Deuber-Hampden American pocketwatches and where the whole plant and several of its technicians went to in 1921...1 point

-

Yes, on a machinist forum I frequent someone wanted to sell some small presses and there was a unanimous cry "if they were made after 19xx they're scrap". Presses scare the bejezus out of me.1 point

-

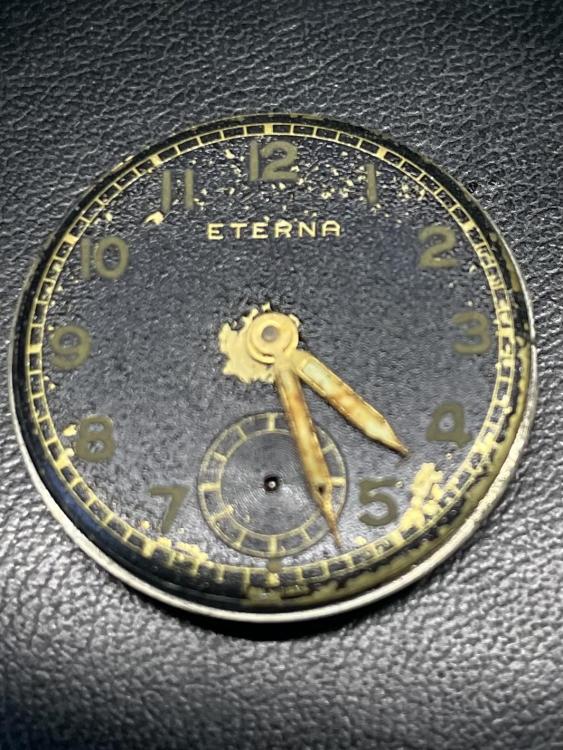

So, I started a separate feed about this watch a few days back - discussing the state of the face and how it was literally flaking away at the touch. I thought there was no coming back for this watch but.. …some days later with some love and attention I have managed to sensitively restore the face as best I could and I’m really pleased with the result. It’s running really sweetly after a full strip down and service, with a strong amplitude and losing 4 seconds a day. I didn’t know what the movement was so I reached out to Eterna directly (with some pictures) and they tell me it’s a 1020 movement from 1944. I attach some pictures of the before (first 3 pictures) and after (last 3 pictures) Let me know what you think?1 point