Leaderboard

Popular Content

Showing content with the highest reputation on 07/03/22 in all areas

-

Without Youtube, or should I say the Internet, I would never have gotten into servicing/repairing. So I guess you're right about that. Nevertheless, it wasn't that I just happened to see one of those watch repair videos that got me started. It was a strong inner urge to be able to service a watch (long story) that drove me to actively research the Internet for information about it. Being well over 50 years old, having young kids, and doing fairly well in my profession, going to a watch school just wasn't an option (something I mourn quite a lot). I remember watching some of the videos on the Watch Repair Channel but having zero knowledge of watch repair, those videos basically just made me feel intimidated and confused. I should say that these days with all the knowledge I have obtained over the years I appreciate the Watch Repair Channel immensely and there's basically only one other repairer that I respect as much as Mark and perhaps even more. That repairer has a member name on this forum being a combination of one transition metal and one precious metal Eventually, I found a Youtube channel named "Ratfaced git". It was hosted by a retired car mechanic named Dan. Naturally, his approach was much that of a car mechanic, rather than that of a skilled and experienced watch repairer. Dan hardly knew the names of parts, didn’t care much and was proud of it. It inspired me endlessly and gave me - at that time a complete mechanical idiot - the courage to try it myself on one of those Vostok movements that could be had on eBay for a few dollars. Honestly, without those videos, I’m not sure my interest would have taken off and that I would be writing this post. I have now taken several online courses and I have some of the books by Fried and DeCarle, and I have learned tons on this forum, but without that retired car mechanic, I'm not sure that would have happened. Have I butchered any watches? Well, butchered is a strong word, but to be honest, some of the watches that I have been working on would likely have been better off in the hands of a pro. For that, I apologise to the watch gods and the pros. Yes, they all make it look so easy, don't they? Complete and perfect service and repair of a Rolex 3135 in under 40 minutes, and for that, "the pros have the audacity to charge $500 or more". Having some personal experience of what it takes to just service a watch without doing any repairs, I'm personally amazed that the pros can even survive at those rates, but I guess they're really good at what they're doing. Nevertheless, I think these Youtube videos are great for promoting watches in general and that means more people will want to have "a real watch" and that is a good thing for the trade on the whole. Sure, some of those affordable vintage watches will be butchered in the process, and however sad that is, there are millions and millions of them out there. And, although there's a lot of ooohing and ahhhing in the comment sections, I rarely see comments where people express that the video gave them the confidence to service/repair the family heirloom themselves.3 points

-

3 points

-

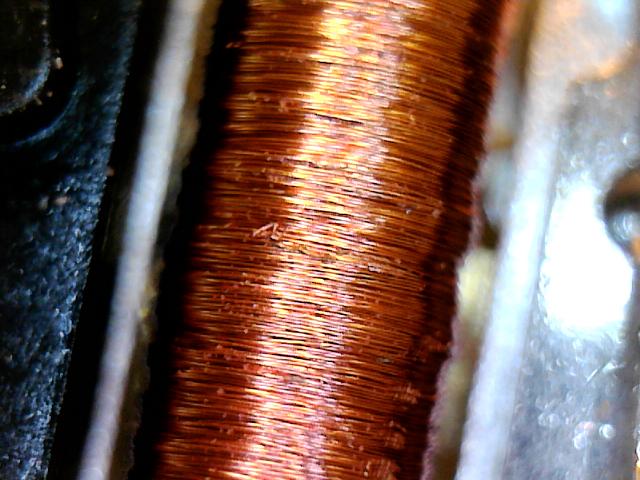

I have had good success by unwinding from both directions, then twisting the wires together and then, using an iron with solder already melted on the tip, touch the twisted wires. The insulation melts and the solder flows to join the wires. Often, the tag end will melt and fall off. It is worth the effort regardless of the value because "practice makes perfect" and at some point you may run into an expensive watch that needs this service.3 points

-

I would try conductive paint. This sort of stuff. https://www.ebay.co.uk/itm/314056794488?hash=item491f3e6178:g:bz8AAOSwHrVivlzd3 points

-

Hi In my opinion Optical Microscopes are far superior to digital scopes for one main reason and that is depth perception offered by the use of a Stereo microscope, plus its easer to work looking down at the work area rather than looking up at a screen, it just feels wrong. This is the one I use, you will need to add a Barlow lens which is about £20 to give a greater working distance between work and lens so you can get your screwdrivers etc in under the lens but that's it, it will take a camera should you want to add one, I did and its a boon to be able to review video or pictures you took during the disassembly to help remember where all the bits go, it does not need to be super hi resolution so again not too expensive. https://www.ebay.co.uk/itm/124373214244?hash=item1cf538a424:g:RBoAAOSwOQpfmcWS Its said that once you try a Microscope you will never go back to using a loupe and with that I can agree.2 points

-

2 points

-

2 points

-

He's wearing gloves, obviously didn't want to get his hands dirty. Hehe.2 points

-

Still, he tried to remove the centre wheel without having removed the cannon pinion. Maybe he thought he'd be lucky this time around, or maybe that was his way to assess whether the cannon pinion needed a bit of tightening or not (I'm sure he'd use his fingernails for that). A ticking watch. I remember years ago waiting in my seat to get off a plane in Asia while people were passing by in the aisle. Having nothing else to entertain myself with I noticed two things. Everyone was wearing and flaunting a wristwatch. None of them was on time (all were totally off without exception). Now I know which watchmaker they hired.2 points

-

The reduction wheel moves slowly and it is not under much pressure, so whatever thick oil (graphite or not) will work fine. Some minor design details like this are not very important. You can find that the same manufacturer changes them in between versions or generations and even give different oiling instruction in their various service sheets.2 points

-

you do know that you being extremely lucky in that if someone makes a reference to me the chance to me ever seeing it is practically nonexistent. I don't quite seem to spend as much time here as I used do so I miss a lot of things but since I was just here answering something typically I never think of Elgin watches at least pocket watches in either of those books although I do note the back of the bestfit book does have a Hamilton Elgin section nice for cross-referencing Hamilton numbers I typically never think of them for pocket watches so usually something like this I would take the serial number of which you conveniently gave us go to the pocket watch database on the left-hand side it says parts click on that you get a parts list what were you looking for? Then of course the other thing I do is I usually look in because I have is a PDF the 1915 Elgin parts Log as it's a picture catalog it's much nicer than the later one. then it was things like a balance staff that I'll go look at another book after you get the number to see just how many variations exist because that isn't always visible in the parts book of how many variations it might tell you their variations exist they just don't tell you how many variations.1 point

-

This is an absolute beauty from today's carboot from a posh old lass that was clearing her house to down size. Apparently passed down to her from her shorthand teacher 50 years ago .5 quid plus my fuel to get there 9 miles from home. I dont understand why some people part with these things . Its the loudest alarm clock tick I've ever heard, in mint condition. I did pick up an even better gem but thats for tomorrow unfortunately not a fiver but still a ridiculous price and something I've been after for a while.1 point

-

Don't feel you have to buy new either, plenty of used scopes turn up on eBay. Many of them have standardised parts... I originally bought a x10/x30 microscope but with a little research and shopping around I found more eyepieces that fitted (30mm) which increased the magnification to x20/x60/x90. The higher magnification is really useful on tuning fork watches and cleaning dials. I agree with @Paul80 about the optical scopes although I only have a cheap Celestion digital to compare.1 point

-

1 point

-

Very nice Andy , I do like Seiko as does Watchie. This is a lovely early 5 example, are you pleased with it ? I think i may win with mine though from a carboot this morning . Not fair to steal your thunder today matey. I'll post it up tomorrow along with a 404, if we are allowed the 5 quid mark now.1 point

-

Definitely doable. I've practised unravelling a line from the end with very fine tweezers and a thin roll end of rodico, i didn't find it difficult just a bit fiddly. I didnt attempt to solder as I'm still learning the skill of fine soldering. Give it a go Endeavor, if you have a replacement movement on its way, you can use this for getting some practice in before doing the replacement.1 point

-

Sometimes this trick works. Those of you with a delicate constitution may want to look away before I proceed. Place the watch with the crystal downwards on a smooth surface. Spin it like a top. Don't let the thing fly off the flat surface and ricochet round the room. Stop it suddenly. Inertia will jolt the mechanism and may get it moving. I'm not claiming this is a good idea, nor would I suggest you do it with a mechanical movement, but I have woken up a couple of quartz movements this way. You attempt this entirely at your own risk of course.1 point

-

I tried with a very fine tip of my soldering iron and some silver-solder. It worked "kinda" well, that's is to say that there sits some silver-solder across the spot but there is still a lose wire hanging on the side of the coil. Most likely I've baked a bunch of coils together I do measure a coil resistance again of 1.735 kΩ and assembled the movement ...... but sadly no life to be seen .... Perhaps conductive paint may have worked but since the new rules here in the EU that anything from outside the EU (not in the IOSS) cost, here in Denmark, by definition already £21; "postal import service charges". The good old get-it-out-China days are over. On the German eBay I didn't see anything "economically justified".1 point

-

Now you know why nobody is punctual in Asia, with the exception of Japan and Singapore. C'mon, admit it. You're hooked.1 point

-

1 point

-

1 point

-

1 point

-

Two things I screwed up on my 1st TS36: I washed all of the parts (including the balance complete and pallet fork) in naphtha and rinsed in IPA. Doing so dissolved the glue used to hold the hairspring to the balance stud. I had never taken an incabloc spring out, taking it out went fine somehow putting it back in I applied a little too much pressure and the spring took off to never-neverland. Just be careful and you'll be fine. In the end you're learning and the Seagull movement isn't a Rolex. You can afford to mess up. - Gary1 point

-

1 point

-

I'm not hundred percent sure what you're asking. But my interpretation is if you look at the automatic microphone timing in six positions two of the positions are reversed. That's because the timing machine expects the watch to be somewhere that I can't quite remember so dial-up and dial down are correct and I don't remember what the left or right crown positions are the other 21 set of those are swapped but it doesn't really matter for the discussion at all. You can change the programming in the machine but for some reason I think the machine thinks it's a case stopwatch even though typically it's an un-case to watch but the up and down at least that's correct the problem is all of this is really complicated. As you can see from the time plot there's variations in transmission power because the year train all watches will have this to some degree some watches will be way worse than other. The fluctuation in power will disturb things. The timing machine tends to average things that's why normally don't see the powertrain fluctuations. If you're paying attention to your timing machine you will see the numbers go up and down if the power fluctuations longer enough but even on this machine where it just gives you numbers you tend not to see that. It's actually one of the bad characteristics of this timing machine is when you look at the final numbers we often don't go back to look at the graphical display to see if it's moving up and down or see if there's no way as we does look numbers look great the watch is fine and the story so as I stated above you'll have powertrain fluctuations continuously oh and then there's that other little thing watches average out all of their problems so the timing machine will show you have a problem but the watch on your wrist you won't see these fluctuations still tend to average out unless the really really bad typically on all watches basically dial-up and dial down we usually be the highest amplitude. Usually the pivots have been flattened because you don't want maximum amplitude here but you always going to have a variation between ends of the pivots and the sides of the pivots. So you always going to CA amplitude difference for the most part. I've seen some watches where their seemingly were no differences and defective watches were sometimes there's an issue was something and it's actually better amplitude in one of the crown positions but that's a defective watch. Ideally the fantasy would be to have even amplitude all the time regardless of position other things that come in the play is JDM mentions the regulating system like the regulator pins. I have an image notice if they hairspring is centered in providing the pins are close enough together hairspring balances nicely between the pins you get a nice average even rate up until the amplitude gets too low and then you're slow. But what if your pins are farther apart then this effect is much more dramatic. So you actually see going between a higher amplitude a low amplitude you'll see the watch slowed down dramatically timing machine. You can tell immediately that your regulator pins are too far apart. then there's the other example of if it's touching one of the pins notice the effect on timekeeping. Oh other things what about the balance wheel poise is out of any concern? for this we get another picture. Notice around 220° is the interesting number were amplitude has no effect on poise. Higher amplitudes are better because there's less of fact low amplitudes basically at low amplitudes everything gets magnified not just poise everything will be much much worse is amplitude goes down. by the way L let you have the fun of this but go into Google or whatever your favorite search engine is Google wire jewels used in watches they explaining on various sites are quite amusing. seemingly for the discussion jewels aren't necessary? If the watches knew when it's not worn out the pivots are nice good condition the holes in the brass are nice and smooth and round at least for while it's not going to matter at all. But typically on higher-quality watches in other words that would have jewels they usually work a little harder it making things better. Like typically a 17 jewel watch we better than a seven jewel watch a 21 jewel will be better at least to a certain degree. So in a jeweled watch I'm going to assume that the pivots have probably been polished nicer than in a watch like this where they were made at a price. See of hopefully better pivots nice and shiny but not necessarily you can still polish the pivots on a watch like this and maybe they are polished the same degree as a jeweled watch. The bearings themselves the jewels properly made it very hard very smooth and they stay that way almost forever. Where is the brass the metal on steel wears out the holes become out of round. That's going to change the meshing of the gears uneven power. Typically on no jewel watches they eventually just wear out. But you can wear out 17 jewel watches also the metal on metal and people who don't like to have their watches serviced on a regular interval rust is really good at wearing watches out. then there's other things like the escapement. Get the balance wheel oscillating a not usually thinking about the escapement does it have any effect on anything? Like lift angle timing machine needs that but what is that number really mean as far as timekeeping goes? It basically means the time in which the escapement is screwing up timekeeping. Because the roller jewel except in this watch in this example it does never wore jewel has a brass pins sticking out on the balance it's a brass on brass if I remember right. The normal watch at the roller jewel it hits the fork it actually will slow down because it's an impact and then it has to unlock the escapement is a loss of energy. Then some point time he gets a kick that isn't precise time kick it's just a kick of the mainspring power and then it finally locks up in the balance is free to continue as a nice oscillation system but during that time span the escapement is screwing up things. That's why people try to design different escapement's like for instance here's a video. It's really interesting video it shows how the lever escapement works and then they talk about some other escapement will never see. But inattention like is that when the roller jewel hits the fork it's hitting a stationary object it has to unlock it is a lot of friction in the escapement is a lot boss here https://youtu.be/g5c5RK4WFV8 my interpretation of the original purpose of this discussion was look my zero jewel watch is perfect. So that we had a discussion on why jewels are total waste of time in some rare examples where seemingly watch works line without jewels. Although oftentimes watches made without jewels were meant to be easy to make usually very cheap and good put up with a lot of things being out of tolerance and it still run in seemingly still keep time. But unless they get serviced on a regular intervals usually than metal on metal bearings will wear out really fast and the jeweled watches will usually last longer. so looking at the original title it's actually a question of our jewels overrated and the answer is no they're not.1 point

-

When vertical the HSt slightly deforms and may start touching the regulator. In addition, the bearing friction shifts from the tip to the sides of the pivots. So it us normal for mov.ts if average quality to deviate 20, 30 secs / day or more. Fully correcting this deviation can be challenging even for top watchmaker, and it's part of the fine art of adjusting, which in the end depends on a lot of variables. In science and general technology the term merely mean its literal translation from Greek: same (or constant) time. However in watchmaking it's almost always synonymous of "small or no variance to power source status". That is because this was one of first problems that had to be solved.1 point

-

Precisely worth the effort on a low value watch if you ever think you might want to try it on a high value watch though! 404 Club's raison d'etre!1 point

-

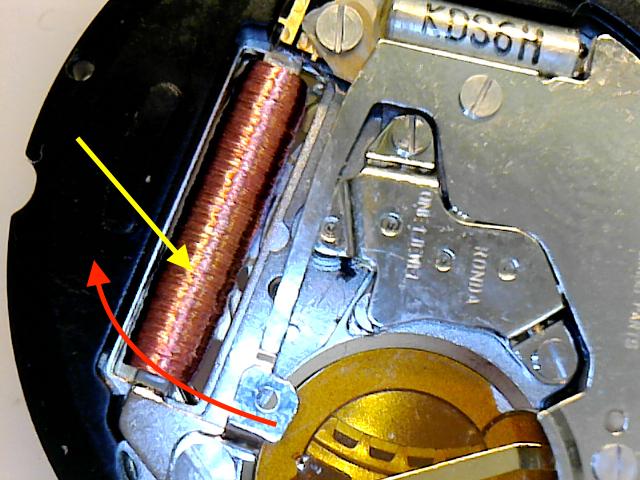

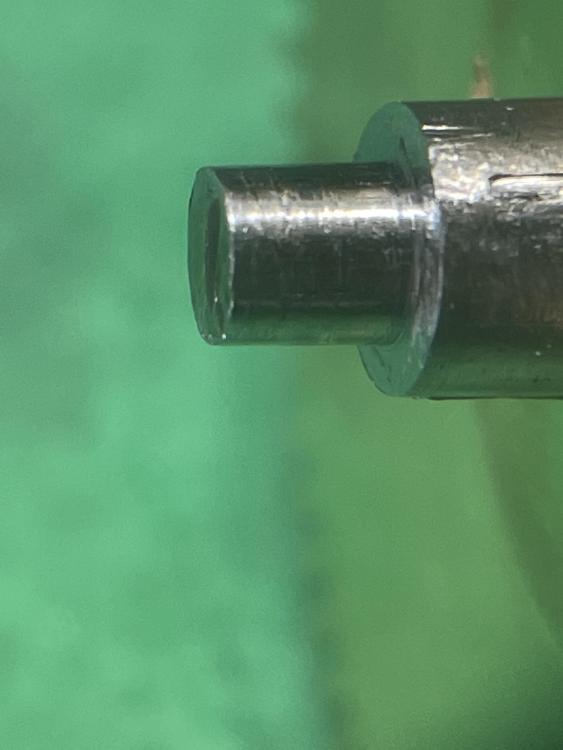

It might be worth taking a look at the coil under a magnifier. I have fixed a couple of damaged coils by applying a small dot of conductive silver paint (from the usual suspects on ebay) over the break in the coil. It doesn't always work, and depends on the damage to the coil. Coils can also sometimes be repaired if the break is on the top layer of turns, by removing coils back to the break, and re-soldering the broken end to the solder tab. This will slightly lower the coil resistance/inductance, but not by enough to affect the performance of the coil significantly. Its fiddly work, and arguably not worth the effort if the value of the watch is low, but if can be done. You need patience, good magnification and a very fine tip on your soldering, and 2mm or less flux core solder. https://www.ebay.co.uk/itm/403695201535?hash=item5dfe1becff:g:mRkAAOSwE5dimIom Solder gauges go down to 0.5mm or even less, which is ideal for this kind of fiddly work.1 point

-

1 point

-

Hope so matey. So disappointing when this happens , but its always a risk. Can we have a look inside and to see the damaged coil please Quartz has its place though, pros and cons against. I would say even for some die hard mechanical enthusiasts. It is still a part of the horological story.1 point

-

why don't you give us a picture of the diagram maybe we can make sense of it. wrong device similar name though unfortunately. The request is for a cleaning machine although I can see why there'd be a confusion I thought maybe this was a watch discussion until I read the text but I'm pretty sure it's a cleaning machine hopefully1 point

-

1 point

-

Hello and welcome to the forum, you might just find this a handy document. TZIllustratedGlossary.pdf1 point

-

1 point

-

1 point

-

Hi Mk, Welcome! Go to this web page - it's like a mini course in mechanical watches. Have you started fooling with any watches on your own yet?1 point

-

I have found it easier to reduce the height before installing the bushing into the plate. For this reason I try to purchase the correct height bushing. If the purchased bushing does not have a oil sink then I fit a bushing just a little thicker than the plate and reduce it down while creating the oil sink which helps hide the new bushing.1 point