Leaderboard

Popular Content

Showing content with the highest reputation on 06/26/22 in Posts

-

Here is the offending oil pot and as you can see the 8200 and D5 are fine but the one that contained 8000 is empty with just minimal residue left, I tried it twise and both times the 8000 vanished very quickly. I followed the advice above and put some 8000 on a mirror and left it sitting out in the open and now many hours later its still their shown no ill effect, obviously as suggested above the oil was obsorbed by the plastic oil cup, will not be using that again, will order some more glass or ceramic versions. Thanks for the help Paul4 points

-

Very nice dial, and watch! it piqued my curiosity and I found a nice article about it here: https://wornandwound.com/zodiac-story-behind-curious-point-series/3 points

-

plastic oil cups are interesting in that we don't know how the lubricants actually react with the plastic even though they were supposedly designed to hold oil. Real life to be designed to be cheap and I don't know if anyone bothered to test their chemical properties or not. Then the oil might not actually be evaporating hip might be doing something else perhaps at least the 9010 could be in that is if you want your oil the stay in place the surface has to be super clean. It's possible that the plastic has a film of oil would be perfect for this but it may have something on it that allows the oil to creep and spread. So the oil may not have evaporated it may have just spread itself away. Is where if you read the fine print on oils like 9010 specifically any time it's used in watch epilam is typically used. Which is there to keep the oil from spreading away. What I find for oil cups that I've always liked was individual glass cups. That's because I typically like to move the oil cup close to the watch one of boiling rather than reaching across the bench. then there's the other concern I had with plastic which is when you stick your Oilers in do you scrape the plastic at all? Maybe not deliberately but if you do scrape the plastic you're going to introduce plastic particles into the oil which isn't going to be good at all normally that might not be a concern except have your read the technical sheet for this oil it has a two-year shelf life. if you read the technical literature from the lubrication company only the HP oils are of concern. On the other hand if you read it any time 9010 is used whatever it's used with has to be epilam. Otherwise it has a habit of spreading hence the reason epilam on just about everything if you want to try a light oil why don't you try 9020. Then yes I use it on non-jeweled bearings as far as I know I'm not having a problem. then if you keep an eye on eBay oil cups will come up for sale. If you really like he can get the vintage individual agate ones otherwise shall find the glass ones that I find they clean up just fine because glass will clean up. Save your cheap you don't have to purchase a new oil cups use have to keep an eye open on eBay2 points

-

I have recent experience with this. Get a case for the DG or Miyota movement. The stem height between the 2824 and 2836 is different. I don't have the chart with stem heights handy but they are different. The Chinese sellers are not always correct with their descriptions. I guess that happens when you sell everything from watch parts to woman's apparel in your store. The DG/Miyota stem height and the 2836 stem height are the same. I tried to put a 2824 in a case that had a Miyota 8215. It didn't work. The dial was a mm or so off the case when I inserted the stem. I got a 2836 clone and everything lined up correctly. The Seiko NH3x and 2824 stem heights are so close it usually works. My inspiration to pursue this was the various Aliexpress watches that come with either movement. I found a movement ring on Ali that had the NH outer diameter and the 2824 inner diameter. I found that I needed a wavy spring to make up the height difference. Also found on Ali. A large o-ring kept the movement in place until the wavy spring arrived. I mention this because some cases are listed as Miyota/2824. In my experience this is not correct. NH/2824 (with different casing parts) is more correct.2 points

-

As I mentioned above, those small diashock springs holding the cap jewels on the third and escape wheel are a nightmare. The general consensus is to leave them in place for cleaning, then oil them through the hole. Unlike @gbyleveldt, I don't have an automatic oiler, so I use an old oiler sharpened to a point that I prod through the hole. It works fine. I have managed to use GR mainsprings successfully, but now we have the above tip about NH3xx mainsprings from @gbyleveldt, I'll be doing that !2 points

-

Nah man, they easy with an auto oiler. And I know you know how to wield an auto oiler in anger! Yeah, 7Sxx mainsprings are a pain. Top tip, the mainspring is the same as used in the barrels of the newer NH3x movements. So you can just buy the NH barrels complete for around £15 and strip their mainsprings for re-use in a 7Sxx barrel. A cheaper route might be just to buy complete 7Sxx based watches; I’ve picked up a whole bunch for around $10 each with perfectly usable mainsprings. Truth be told, I’ve had pretty good luck re-using the original mainsprings and only had to resort to harvesting where I broke mainsprings. And the reason they broke is because they’re a pain to wind in the mainspring winder because they’re a lot thinner in height that Swiss mainsprings. But using a #6 arbour in a #7 winder seems to be the trick for these.2 points

-

Today I'm wearing a "long wished" of mine, a (near-real) "Omega speedmaster date" and, obviously, it comes with a story See the story below as a fairy tale, it never happened for real ! We aim to be lawful citizen "Once upon a time there was a Swiss seller selling (very cheap compared to the chronometer grade ETA7750's) NOS Omega 1164 movements. The problem was that he was living in Switzerland, meaning that the movement would have become prohibitive expensive after paying all the compulsery EU-"dough". As it in fairy tales goes, he had a beautifull sister living in France With the movement secured, a high quality 7750 housing was found ...... but agian it was in Switzerland Prepared to pay the EU-"dough", it was sent. Perhaps with the aid of the Corona virus, the parcel went fairy-tale enough unnoticed through the various EU cash-in points " Both new Speedmaster dial & original hands were sourced within the EU. With a new original chronometer-grade Omega 1164, new Omega Speedmaster dial & hands and with a new high quality "close-to-the-real" housing, my long-wished Speedmaster-date was born; It isn't the "real" Omega Speedmaster-date, but mine has a very accurately running Omega chronometer-grade 1164 movement whereas the real Speedmaster-date has a "normal-grade" Omega 1152 caliber. For a fraction of the price it's good & close enough for me. I'm very happy with it !! BTW, both Omega calibers, the 1152 and the 1164 are based upon the ETA 7750. Not sure what Omega does to an ETA 7750 apart from their own Ω stamp in the main-plate and oscilating weight?2 points

-

I have this book, and it's good. One of my mentors helped with the English translation (I think he was noted but my copy is in French). It's not for self learning so much, more of a textbook to be filled in with class discussion. As a foreigner here, I've found that the kids who had this as a text are often lacking in practical escapement adjustment skill. It's funny because WOSTEP was quite involved in its genesis, and they teach (taught?) escapement work very well. Got a kid in the shop now that did their full training course and he knows escapements better than graduates from Vallee de Joux or La Chaux-de-Fonds. But a kid (well, now 30) from la Chaux-de-Fonds is hands down the best hairspring guy I've ever seen- but that's pure talent coupled with a desire to read any and everything on hairspring work (loaded him down with some Yank literature haha). It's a good book as an adjunct to the other older standard texts. Lots of neat stuff in there, but you can see it's scripted for the 16yo crowd.2 points

-

The above are movement holders for assembly and disassembly of the movement, not support for fitting of hands - although sometimes they can be a combined tool, this is not always the case. It's more of a concern when fitting new hands which will be tight fitting. Hands previously fitted and removed for service do not generally need to be forced down so hard to the extent that a jewel would be pressed out of position. However, if I felt it does need support and I did not have a dedicated hand support holder for my Bergeon 8935 for a particular movement (not all calibers have a specific one available) then I would use a jeweling tool or staking set to support the jewel whilst pressing down, I prefer to use my staking set as I have a particular punch with a soft flat tip which is ideal for the purpose.2 points

-

Hello from Texas - I got into this as a hobby and recently have taken my boys through Mark’s excellent course. They have loved it.1 point

-

if you can't source one there's people out there that can repivot it for you. Although it's probably not going to be cheap1 point

-

1 point

-

Haha. Gert I'm not sure what you mean. What swearing ? Besides I'm British its part of our privilege to swear1 point

-

A cheap Chinese ETA 2824 based clone. I tried to repair similar movement for a friend. The quality of the parts was poor - not designed to be taken apart and cleaned. In the end it was easier, and cheaper, to replace the movement - https://www.cousinsuk.com/product/skeleton-other-makes1 point

-

Without the luxury of having a closer look, it seems to be a press-on cover (?) If that's the case, I've had many times suc6 with a surgical knife in the grove (housing / back cover) and drive it carefully in using a small hammer. Once to gap opens, you can insert your case knife. There is a risk that you may damage the case-cover O-ring and for sure you will blunt the small scalpel.1 point

-

The design of the movement is definitely ETA 2824-2 but might be a clone. Normally the ring gets off after removing the two holding screws and the winding stem. No idea why thats not possible in your case.1 point

-

Welcome to the forum! How old are your boys? @LittleWatchShop is also in Texas. Folks are from all over and all are helpful. Gary1 point

-

I worked on one of my 6309 movements that had clearly been serviced. None of the plastic parts felt "normal". They seemed to have been softened and deformed. I have no idea how they were cleaned previously. I know that water and detergent pose almost zero risk to plastic. Detergent does a great job on oil and grease so that is how I do it. I don't have enough spare parts to test compatibility and new parts are getting harder to find and more expensive so I go the conservative route. This is a hobby for me. I don't do this as a business so speed is not a concern. I mess up plenty of other parts, messing up one less part is a plus for me.1 point

-

£50 is about 10X even a generously inflated £4.04... That's deep down the slippery slope. Still a good looking watch. Figure out what the "defect" is?1 point

-

The front looks mint, the back too if that is just sticky residue. Does it run? What is inside? Can't wait to see.1 point

-

1 point

-

1 point

-

About the Seikos. I've serviced two of them. Well, technically one, as the other was an Orient (my service walkthrough of it here). After this a swore never to touch any Seiko movements again. Although I'd really want to as they have so much going for them such as the magic lever and how the springs are integrated into the parts. IMO, superior engineering to the Swiss in many ways. My objections are two; Firstly, the cap jewels for the third wheel and the escape wheel (at least the 7sxx movements). They are smaller than dust particles and just a pain to clean, oil, and replace. Secondly, it seems impossible to find working mainspring replacements. I've tried several Generale Ressorts springs, a bunch of braking greases (including Kluber), and altering the bridle, but never succeeded. I always ended up reusing the original spring to get some sort of decent power reserve. Also, new barrel completes are far and few between and very expensive when eventually found. I wish things were different as I really like the Seikos. I my opinion they make some of the most beautiful watches on the planet.1 point

-

@VWatchie; Glad we have curious members like you !! Very interesting article and now I do understand more about the "red-dot" and why they are more sought after. In the article it is said that the models came with Quarz- and Mechanical-movements, one example was shown with an ETA 7750. The dial I bought fitted the 2824-2 directly so one wonders if the 2824-2 was one of other mechanical movements used? That the point-models were discontinued in 1998 means that the new dial I bought must have been a NOS left over .... lucky me ! Thanks for your input1 point

-

The items listed below I have found to be very useful in opening tight snap on backs This first one is a little expensive and I sam sure I paid a lot less for mine but can't find the original listing, but if its good enough for Richard Perrett its good enough for me. Shop around I think I paid less than £30 for mine, although prices are going up everywhere at the moment. https://www.ebay.co.uk/itm/134127834916?hash=item1f3aa45724:g:noYAAOSwSrBijIx7 This one is a very close copy of the one sold by Horotec at the usual fraction of the price, this one is useful as it does Backs, Bezels and Strap adjustments https://www.aliexpress.com/item/4000342694646.html?spm=a2g0o.productlist.0.0.74511ceatKOjg7&algo_pvid=c4bfb436-f750-480b-979b-806b69445bab&algo_exp_id=c4bfb436-f750-480b-979b-806b69445bab-32&pdp_ext_f={"sku_id"%3A"12000026992532652"}&pdp_npi=2%40dis!GBP!!25.91!25.91!!8.55!!%402100bde316562309460235614ea1f5!12000026992532652!sea This last one is a sort of oversize automatic center punch, just locate the blade edge in the slot between back and case and push until a click is heared and the back pops off. Yes I buy too many tools https://www.aliexpress.com/item/4000135973389.html?spm=a2g0o.store_pc_groupList.8148356.45.3e66c96cWmm37s&pdp_npi=2%40dis!GBP!£21.36!£21.36!£21.36!!!!%402100bde116561681137508886e9798!10000000409646739!sh1 point

-

Many case backs don‘t have a recess for the case knife, even though they have to be opened by a knife. Easy to scratch the back! Put pressure on the knife until it slips in and the back pops off. Avoid leverage.1 point

-

1 point

-

No sadly, I have given up on this cheap gift watch, but got a seiko that I need replacement parts for. Will start a new thread.1 point

-

Awesome! Seems like 420x season as I’m also busy with a lot of 4205’s. 4th watch in and I’m having a hard time with the balances as well. Someone’s been in there before me as not 1 of them so far has been unmolested.1 point

-

There's a little tiny speaker inside hooked up to a... Welcome to the forum! Here's a web page that has a ton of animated bits explaining the mechanics of a watch. It's very well done. You might also sign up for Mark's online courses. #2 and #3 are both very good. #1 is very basic and good if you know nothing and have never watched a YouTube video where somebody takes a watch that was dragged through the mud and makes it run perfect and sparkle - all in less than an hour (well, not counting the parts that get edited out).1 point

-

I find the video hysterically funny in a way. It looks simple doesn't it? It's actually quite an amusing video. what if you had a vibrating tool when it look as simple as this? Oh unfortunately in this next video he doesn't give the plans a way that's very sad I believe he sells the school and no I don't know how much it costs but once again look how simple it is https://youtu.be/htckrH3ae54 now the reality is this would be a nice tool to have because notice it displays the beats per hour as opposed to looking at the master balance wheel in the platform which can be it interesting singular. Oh and if you look at all of his stuff he's using an optical method if I remember right user picking up off one of the arms which is nice as you get rid of the sound aspect but companies like Greiner they make a really nice machine that none of us can afford that vibrates hairspring it might even do the terminal curve at the same time not sure about that there is a YouTube video that has that's of somebody really wants it all track it down for you other interesting video in the news as reference to wostep at the very beginning of the video because at least at one time they afflicted pain and suffering on their students by teaching them how to vibrated hairsprings. https://youtu.be/M5LEN66vxgc now in this last video ever notice that the hairspring doesn't have a stud like the other videos. so here the student had to take the collet hairspring pins raw hairspring form of the terminal curve temporarily pin it to the collet. He has just temporary that's a school that likes to teach perfection C have to go back and do another step in unpin do some other complicated stuff was just skim over. The temporarily penned put it on the balance wheel you make sure it's centered and flat and then you can vibrate and notice he has some extra hairspring because you need at least one full turn at the top to do the other steps. The reason I bring this up is the previous videos started with the hairspring it was already pretty darn close what if you hairspring is not close long did it take you to get that hairspring to look like the last video then of course I'm the bearer of bad news in order to learn how to vibrated hairsprings you need hairsprings and we've discussed this before but I will remind you in a way the Swiss no longer make raw hairsprings. It used to be they made hairspring is with the CGS specification and they would send them out and companies variety people to buy raw hairspring is and of course you can vibrate them. But the Swiss have consolidated manufacturing why make a whole bunch of generic hairsprings when Dell just make the hairsprings you need. Or even better yet send your balance wheels to hairspring company and they will they hairsprings for you which is what they do. The consequences are those little packets of necessary raw hairsprings that the students like to go through it a huge quantity because it's not easy to get to the point of that one video and up damaging a lot while you're learning they no longer exist. Now is the bearer of bad news as much is one of vibrated hairspring probably isn't going to happen because you don't have any hairsprings the vibrate you could try looking at eBay if you're lucky you might find the packet or to look at oh and of course the other videos with the stud those of already been vibrated so course it looks easy and simple because that's a finished product I know somebody who has a hairspring vibrating tool and he can never figure out why a comment that vibrated hairsprings is a total nightmare the pain in the ass to do because he's done that very thingies but the balance wheel then he puts in your the stud and markets vibrating about how close it is a different story for starting from scratch takes a long time to get to close to being vibrated here's a website where he shares his fun of vibrating Springs http://www.bobinchak.com/watchmaking/2017/4/26/hairspring-week-vibrating-the-hairspring yes additional tool is expensive but there are as some of the video show other ways to do it the Microset timing machine has a accessory for vibrating hairsprings. One of the old paper tape machines had a holder for tweezers so you could get the to the balance wheel spinning it would no action move up and down these time went up and down a tap on the microphone so you'd use the timing machine to do it don't know how well it worked but that was accessory for the machine so there are some other ways to do it of course you still need hairsprings not what I was looking for but you might find it interesting https://watchmaking.weebly.com/hairspring-vibrating-tool.html okay found it can't buy it from here though but you can see what it is the other material houses should have this. If you raise your hairspring up with the glass in the center is for the collet so they hairspring reflash is a lot easier to see the hairspring that is when it's flat on something https://www.amazon.com/HAIRSPRING-HOLDER-simple-spring-support/dp/B01NCN45S91 point

-

A guy on gumtree was after swapping 2 nice ones for a used van ? Random ! about six months ago. He didnt want to sell for cash ? Again rather random ! I was tempted to go buy a crappy van for a couple of hundred quid. Nice watch, its on my list and i have been quite lucky just lately. So Universe i know you are listening, i have a carboot tomorrow and i have been a very good boy this week1 point

-

Some use a pair of these 90 degree bent for manipulation, i have tried them but find a little too big. I might dress them ond day . I normally use some very fine tweezers to hold the hs and a super fine oiler or a cut down 0.2 or 0.3 mm accupucture needle to gently press agaist them to straighten out an odd kink i may come across. And to work on either a sheet of clean white card or a sheet of white pvc gives me clearer view of what i want to do.1 point

-

I used a regular lead/tin solder. ( 63% Sn/ 37% Pb ) I didn't use the really low temperature tin/bismuth type of solder because I think it has lower strength. I just clamped the dial in a movement holder and used a "third hand" to position the copper wire. I didn't use any special method to cool the dial side but I was told that some people do use a compressed air stream to blow on the dial. Practise on some scrap dial first. Speed is of the essence. Don't linger too long and burn the dial.1 point

-

You had me worried there for a minute. Just sat here checking every single one of the 24 sets, top and bottom and luckily all of mine are on spec and fit fine. The CNC man must have been on the ball when they made mine1 point

-

I'm after a "Pogue" (the yellow dial one), but the prices keep rising. If you're wondering why "Pogue" : As the story goes, during training for the Skylab 4 mission in 1973, NASA astronaut Colonel William Pogue used his 1971 Seiko 6139-6005 with a yellow dial to time various maneuvers and engine burns. While the Omega Speedmaster was the standard-issue watch for NASA astronauts at the time, Pogue didn’t receive his Speedmaster during training. When it came time to embark on the Skylab mission, both watches accompanied him into space: one as standard equipment; the other, a timepiece he knew and trusted. Thus, despite not being NASA-certified, the Seiko 6139 became the first automatic chronograph in space. This is how the watch earned its nickname, The Pogue. Also 6138 vs 6139 : There are two primary calibers: the earlier 6139 introduced in 1969 (and produced until approximately 1977), and the 6138 introduced a year later in 1970. The difference between the two movements is that the 6139 only has a 30-minute chronograph register, and the 6138 has an additional 12-hour register. Both lack an active running seconds and in terms of specs, they beat at 21,600bph and have a power reserve of 45 hours. Both also have a day/date indicator. The 6139 has 17 jewels, and the 6139 has 21 (and 23 for some of the rarer Japanese domestic market variants like the 6138-8000). Both variants lack hacking and the 6139 does not hand wind. In terms of size, the 613X is 27mm in diameter and 7.2mm (6139)/7.9mm (6138) tall.1 point

-

1 point

-

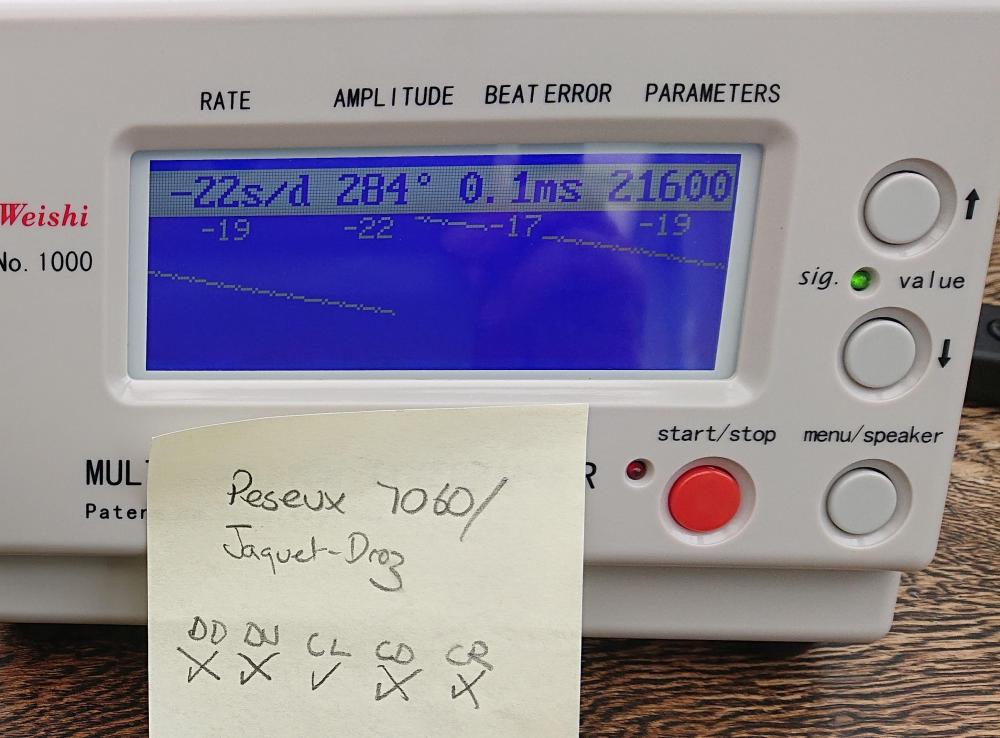

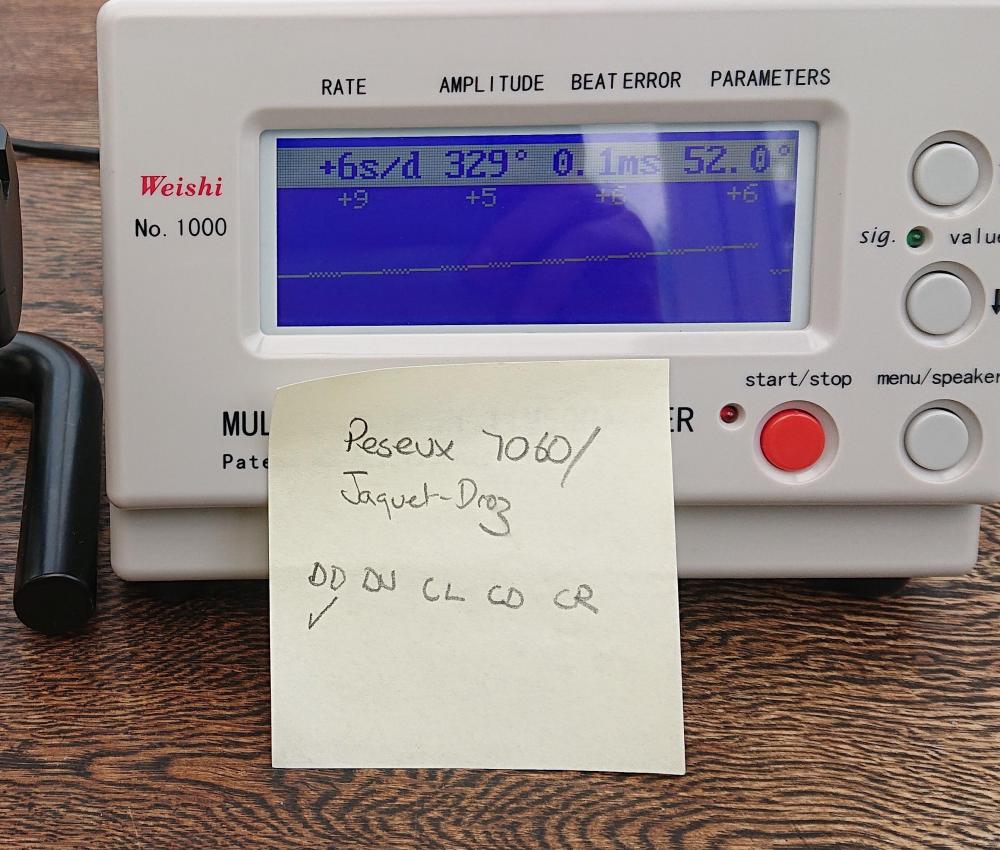

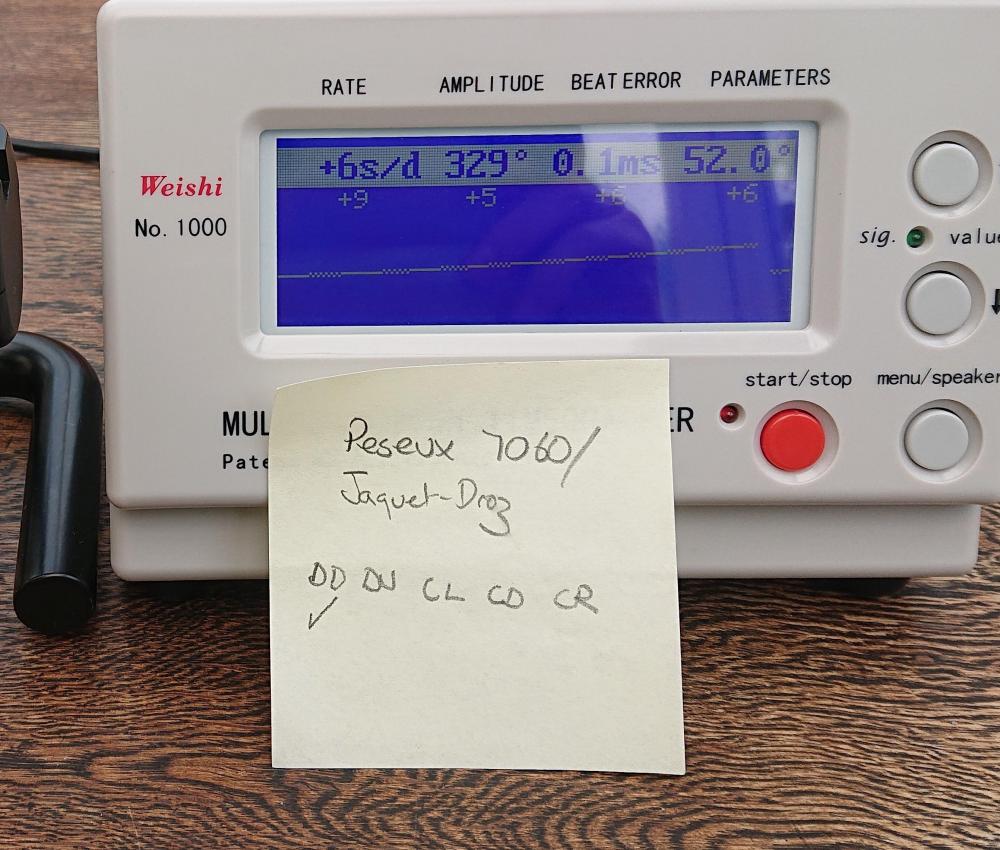

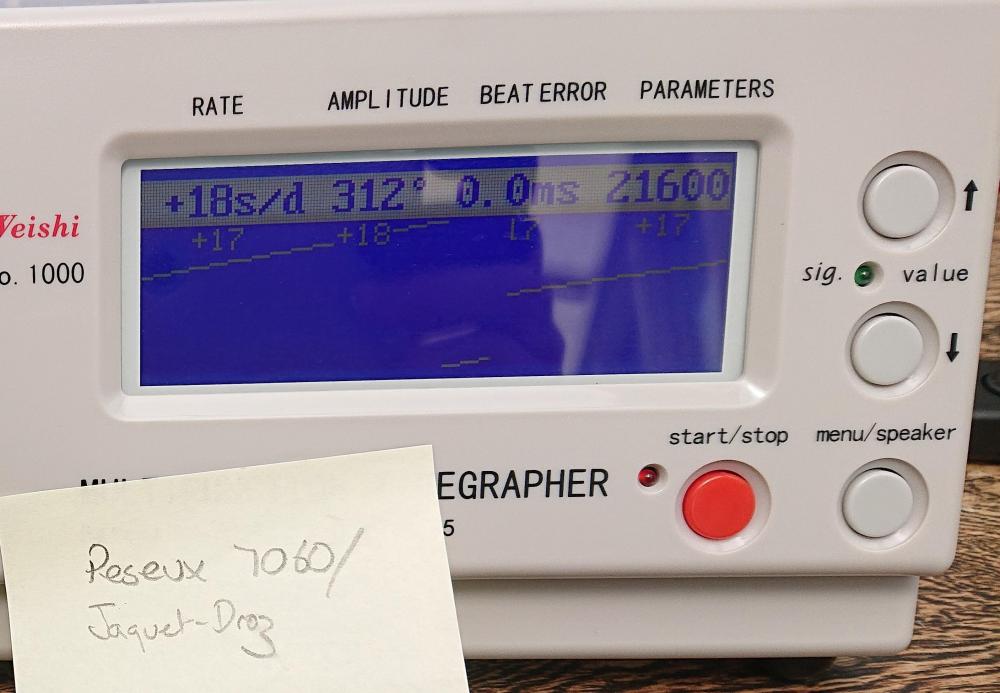

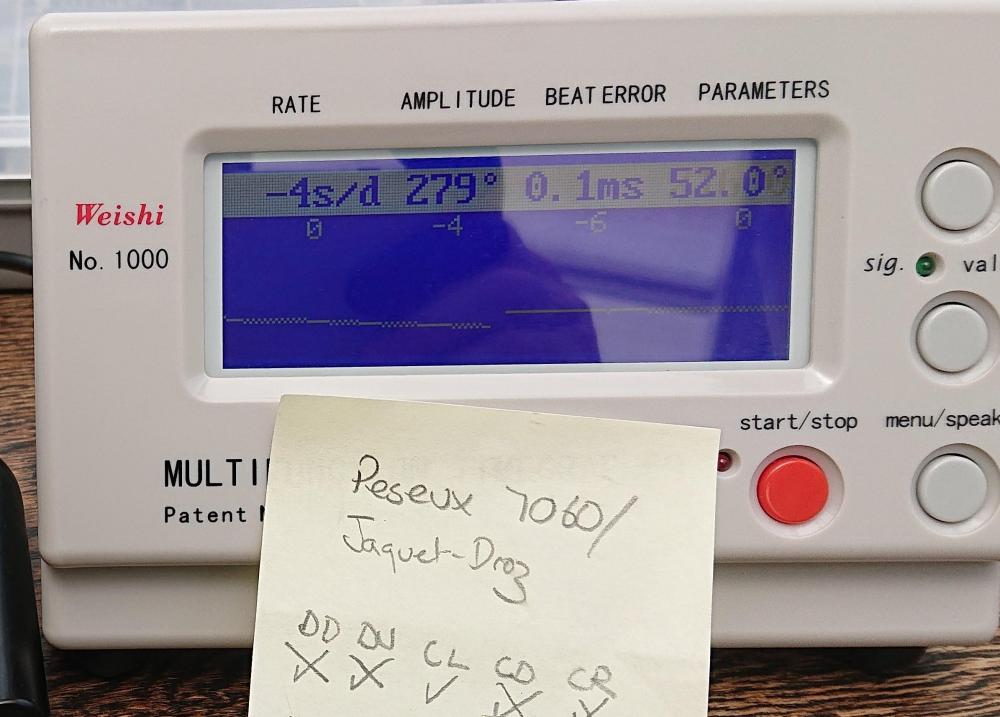

Eight months ago when I began my watch repairing journey, a relative passed me this unusual gold-plated pendant watch to "have a go". They had worn it daily for decades, till it stopped working (and had long gone out of fashion), and put it in a drawer. At the time I had no test equipment but it was running slow and didn't run for long either. Having opened the case to see what the movement was, I put in in a box of "future projects" as I wanted to continue practicing on junk movements. Now I'm gaining confidence having serviced about forty movements and inexpensive watches, I thought it was time to repair it. This is what I saw on the time-grapher: The movement looked clean: Though the finish on the dial side is poor: During the strip down I noticed some unusual wear to the underside of the centre wheel I cleaned the movement and reassembled to try and see what was rubbing on the wheel. It was pretty obvious once I checked the play on the barrel: I asked the owner when it was last serviced. The answer was I don't know, maybe never. I know it was worn daily for twenty or thirty years and dates from the 70s or 80s. I'm amazed that the only sign of wear I found was the top barrel pivot hole. OK time to order parts. I ordered a fresh barrel arbor, barrel bridge, and mainspring. The barrel itself showed no signs of wear or cosmetic damage. I think only the very tip of the teeth were catching the second wheel. It's a shame that I couldn't find a barrel bridge with the same finish. I've not posted pictures of the disassembly as it's a totally straightforward movement. I cleaned, reassembled, inspected and lubricated (941/9010/HP1300/MolyslipDX/8200) the movement. For cleaning I use naptha and pegwood on the pivot holes, followed by a three stage cleaning in an ultrasonic bath. I epilame the inca jewels, pallets, and escapement wheel. I use a superfine oiler and check each pivot under my microscope for correct oil levels and cleanliness. On this occasion I ran the watch for a few minutes, then lubricated the tip of three escapement teeth. I'm experimenting with different methods as I also like to remove and oil the exit pallet. I can't find a difference in results with either technique when you get it right. I probably make more errors oiling the ascapement. Putting it on the timegrapher. 280, 300, 320, 340 degrees, SNOWSTORM!!! Sorry I didn't get a picture but I quickly removed the movement as I could hear it knocking, in order to release the main-spring. I checked the replacement spring and it's measurements were the same as the original however the curve was a little less pronounced. It looked fine, I'd simply replaced it as a matter of good practice. So I cleaned the original and put it in. Now the timegrapher results show unexpectedly high amplitude, but it's not knocking. Dial down Dial up was within a second and two degrees of dial down, and the other vertical positions were similar to the crown right. On reflection, this watch will spend almost all of it's life crown up, so I readjusted it optimised for that position accepting a greater error dial up and down. After a few hours of running-in the differential between the horizontal and vertical positions has reduced. The various vertical positions all perform similarly so I won't post them all. These are after an hour or so of running: So I learned a few things on this movement. Firstly I should have picked up on the play in the barrel as I disassembled the watch. Then I've have known as soon as I saw it the cause of the marks on the second wheel. Secondly, I learned that a new spring even of apparrently correct and identical specification may cause knocking. Finally, a lesson I learned early in this journey (taking care of the dial) remains visible on the face of the watch, where I marked it as I opened it all those months ago. You can only see it under a lupe, but it's there on the seconds dial between 15 and 20 seconds.1 point

-

Ok maybe just a tad more . Fashion named watches, i hate them with a passion. A wild stab in the dark ( which is what some directors of these fashion companies should be receiving imo lol ) and a complete and utter guess tells me that fashion companies dont own or run watch factories . A perfect example, if not epitomises that statement, "a daniel wellington watch" notice i didnt capitalise the name. A mass produced chinese product that made its creator a multi millionaire ( good for him at the expense of unwitting buyers and not his name btw ). A dollar fifty cost to the OD for bulk buying, a hundred and fifty dollar cost to the retail buyer. The mark up in that to my reckoning is 10,000 percent wow. Supposedly a final adornment to a classy dressed individual (Really ? I'd be more inclined to ask the wearer " wtf is that you have falling apart on your wrist mate get yourself a real watch " ). I've yet to see inside one of these but it is coming as a friend has asked me to fix his as the stem has pulled out after two years of very occasional wearing ( such quality and reliability eh ). So stay tuned, a classical piece of crap will be making its way to the forum very soon.1 point

-

Apparently acetone works. I didnt have that so tried api overnight, it didnt budge so then naptha for a couple of hours. Still was tight so i just got stuck in with a craft knife to cut away, 30 secondss later it gave in and released. The superglue just peeled straight off. You can actually buy debonder which softens the glue in minutes, i used to use it years ago at work. Do you mean the problem of fakes? That goes against the grain of anyone that appreciates quality craftsmenship in anything and is willing to pay for that quality. Fake is as fake owns or wears. I consider myself to be a genuine person not create an image that doesnt exist, what you see is what you get with me. If i cant afford the genuine article I'd rather not pretend that i can. Sorry if that offends anyone thats just my opinion. This was an experiment to see what can be copied and how bad or good it could be done, I'm a very curious bugger. The solution - i don't believe there is one fakes of everything will always be made and will always be bought. We live in a facade world where everything has to look good even when its not, most of what we see and hear is just bullshit. And a lot of media just promotes that because it keeps us in our place, spending our hard earned cash and supposedly happy. This is where i dont fit in i dont even have a tv. Might be better if i stop here.1 point

-

I've no idea whether other members do have a "story" with each watch they own ? For me that's the case and this watch is no exception. A seller on eBay had a bunch (10 or so) brand new Zodiac dials (with "red-dot") on offer, I think €25 each. Initially I thought that they were too expensive, but somehow I couldn't get the dial out of my head and bought it. At that time I had never heard of Zodiac and had no clue about the meaning of the "red-dot" either. Weeks later the dial arrived and it was actually very nice and clearly of very high quality. Perhaps one more? ....... Too late, all gone. Further search revealed that these dials (and watches) are quite sought after and command much higher prices than what I paid, depending on the condition of course. With this in mind the dial deserved a good movement, nice hands and obviously a divers case (sapphire). The movement is a new automatic ETA 2824-2 (28,800bph) and even though the hands were bought separately, the lume of them (also during the night) do match the lume on the dial perfectly. It has become one of my favored watches to wear;1 point

-

1 point

-

1 point

-

1 point

-

Yesterday's carboot. £20 for a box of used watches. Well within the 404,the guy did say £14 at one point but i just couldn't take his offer. I do feel as though I'm cheating at 36 watches lol. Most are fashion, quartz, and ladies and not even worth their proportionally divided cost. But a couple in there worth more the full £20 i paid. An 80s Seiko lcd chrono with original steel bracelet, a new battery was amazed i had one so up and running. A smith 30 min stop watch barely used, a swatchwatch, a talking Radio shack, 3 basic mechanicals, a timex indeglo, a Predator diver a total beast looking of a watch, a map distance calculator, a fake Tag and Rolly, oh and what i suspect might be a 14k solid gold ladies chalet (no hallmark but stamped 14k, it does look solid ive scratched inside the case back) weighing 6grams not inc. the movement (i have yet to acid test )1 point

-

1 point