Leaderboard

Popular Content

Showing content with the highest reputation on 06/21/22 in all areas

-

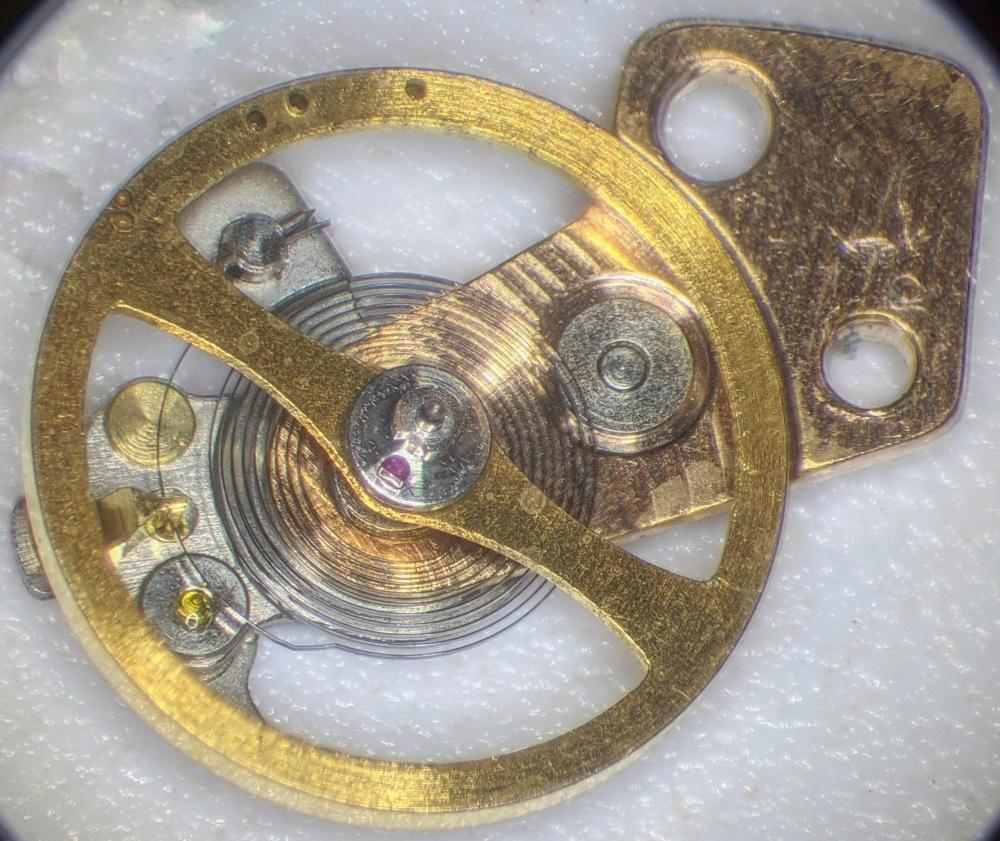

I'm not highly experienced and I didn't photograph this service enough to give a walkthrough and it was a straightforward thing, going smoothly for the most part. I just wanted to share the only glitch that I got on this one. I used a K&D mainspring winder and I made the mistake of rotating it the wrong way for just a couple of rotations. I then rotated the right way and went all the way through the process and loaded it into a barrel. Once I pulled it away, I saw that the loop end of the MS was completely kinked, folded over on itself. I imagine that rotating the wrong way caused the loop end to fold in under itself and then winding it up in the winder smashed it home. Of course, trying to bend it back caused it to break. I am guessing this could happen with any winder and nothing against the K&D. This picture is before that happened, after cleaning everything: In this photo is the MS that I broke. I had another laying around and used it instead. I couldn't remember where it came from, but I think it was an older one that I had re-loaded into a washer. I just grabbed it and threw it in, but in hindsight, I should have unloaded it and checked it for shape and hygiene before reloading it. You can see from the time graph that the amplitude is on the low side. It drops down to 175º in some positions. But otherwise, it is running well. I think it would be best to replace the mainspring. It will be interesting to see the difference in this amplitude with only that difference. If I do and see a noticeable difference, I'll come back here and update the post. Here's the completed watch, which also needed considerable case work, done a few days ago. What looks like an anomaly on the pic is actually refraction caused by the faceted crystal. From 1975, the Seiko 6106-7729:4 points

-

Remove the balance with the mainspring fully wound. Does the pallet fork flick back and forth enthusistically If you unlock it? If it does, your problem is in the balance assembly, if not, it's in the train. Let the power down again. Take out the pallet fork. Does the escape wheel spin as soon as you try to wind the mainspring? If not, take out the train wheels one by one working back to the barrel to find the blockage.4 points

-

3 points

-

A tight canon pinion will not impede the running. Putting additional pressure on the crown at full wind adds a lot of additional power- like, a lot, so no big surprise if it sort of runs when doing that. Klassiker has laid out the correct basic checks, only thing I would add is the pallet fork should snap back and forth cleanly with just 1/4 (or less) turn of wind on the barrel. I've seen NOS movements that had the original oil so gummed up it took multiple cleanings through a professional machine with full pegging of the jewels each time to finally get it to run correctly. Just a little gumming of oil at the pallet fork hole jewels will completely stop a watch from running. Normally these aren't oiled, but I see gummed up oil there so often I always peg those holes.3 points

-

The 4 blade tool works great.... but not the way you think it would work. Initially I had problems with the 4 blade tool. It takes a lot of pressure on the knurled wheel to actually wedge under the beze and advance the bladesl. When having to use so much force, you lose tactile feedback. You can't tell when the blades are not engaged proper or when it has traveled so deep that it is touching the lip of the watch case. In any case, the risk of damaging the bezel, watch case or the tool is very real. The way I discovered to use the 4 blade tool safely is to use a small hammer to tap on the movable jaw of the tool. I first engage the blades of the tool into the gap between the bezel and the case and tighten it lightly. Then I use the small hammer to tap on the movable jaw. The small amount of backlash in the screw threads will allow the jaws to move forward. If there is any "give", you will feel the knurled screw loosen and will be able to tighten it a little more. Continue this tapping and tightening until the bezel pops off or the blades stop advancing anymore. If the blades stop advancing, it probable means that it has reached the lip of the watch case. In that case, you can wedge a thicker blade into the gap under the bezel and pry it off. I hope this helps.3 points

-

Surely normal. But even a larger Seiko with "just" 210 deg amplitude can have a perfect pattern, sufficient positonal deviation, and more importantly, excellent timekeeping. In the end, that's all what matters.2 points

-

Would opening the watch void the warranty? Some photos of the watch would help us help you. Thanks.2 points

-

I am blown away! I happen to be working on pretty much the same exact movement at the moment. I am searching for a seconds hand for it, and a person who can replace a few jewels. I’m going to follow this as well, hopefully we can both learn from each other. Thanks for posting! PS: so far as I can tell, it’s a 19Ligne2 points

-

Dial feet soldering is actually not that difficult. I guess after years of electonic component soldering, @LittleWatchShop, you have become accustomed to using your soldering iron to heat the board and component leg, then apply solder to the joint. But this method would definitely destroy the dial. What I do is to apply a tiny blob of low fusing solder paste to the copper wire and dial with an old oiler, then heat the copper wire. The heat source can be anything that is hot enough. It can be a high wattage soldering iron, the carbon electrode of the dial feet soldering machine or even the flame of a microtorch. I usually use a microtorch. I'll heat the copper wire at about 1 cm above the dial and the moment the solder melts and forms a shiny puddle on the dial, I'll move the flame away. It will happen very quickly, so you have to be alert. The important thing to note is to heat the copper wire, no heat must be applied to the dial. So you'll need a sufficient length of copper wire for the job. I'm stingy, so I use a length of about 6" and cutoff the length I need for the foot after soldering. The remaining piece can be used again. I find that copper wire is still the best material for the job. I've tried brass, thinking that it would be stronger, but for some reason it doesn't solder so well. Try it out on a junk dial first. When you become proficient at it, then work on your actual dial.2 points

-

Hi Given the circumstances and the remote possibility of finding a new wheel I would be inclined to drill it out and turn up a new bush on the lathe, the core /bush that in the wheel is beyond doing anything with so best to rebush . More work granted but it will make a satisfying repair. good luck2 points

-

1 point

-

Good job @LittleWatchShop. I just hate KIF springs. Whether it's Elastor, Trior, Duofix.... I just lost a tiny Trior spring last week. I placed it in a tray while I cleaned the jewels and then oiled them. When I wanted to replace the spring, it just wasn't there anymore! Luckily I found a spare from a scrap movement.1 point

-

Yes, if you're not working on a Patek Philippe just go for it and learn !1 point

-

This site says: Brass should not be used as a base metal under rhodium in fine jewelry. Brass is cheap, and rhodium is precious. Because brass is used for inexpensive jewelry, a rhodium layer must be thin. But a thin layer wears fast. Brass is malleable, and rhodium plating would increase its durability but would not be a wise investment. Rhodium plated brass would need replacing every few months. You would soon end up investing more in maintenance than the jewelry is worth. This site says: The only way to remove the rhodium finish is to mechanically polish it off. This is not difficult on a piece where all areas are accessible to polishing tools. However there are some pieces that have areas where all of the rhodium cannot be removed, under stones for instance.1 point

-

I have ended up becoming close to a watchmaker near me as he has serviced 5 of my watches now and we have had a few conversations. He is a formally-trained watchmaker from Paris and has been in the business his whole life (he is about my age, near 60). He is not a fan of Seiko and admittedly a bit of a Swiss watch snob but he said that anything over 180º is nothing to worry about and there is such a thing as too high an amplitude. I agree with this. If the watch is running fine, that's what matters. But I think each watch design has a range that is optimal for it and when we service a watch, we want it to fall into the expected range. As a newb, I don't know what to expect really, but I have serviced a half dozen movements based on the 6106 caliber or similar to it over the last couple of months. I have seen anywhere from 180 to 260 degrees of amplitude so it is hard to say where it should be. I've seen this with existing and new mainsprings also. I suspect there are many factors that determine the amplitude and one of them is the mainspring condition and perhaps that is not the key factor either. I'm sure the balance has more to do with it. Even two watches of the same caliber will behave differently because they have seen different circumstances. All we know is what a timegrapher tells us, and we all probably put too much stock in what the timegrapher tells us. Our wrist, over time, tells us much more. I have ordered a new mainspring so it will be interesting to see what happens when that will be the only change I make to this watch. Stay tuned.1 point

-

I serviced two identical Citizen ladies watches (caliber 6900) which were in very good condition. But I couldn‘t get them above 240° (lift angle is 46°). Seems to be normal…1 point

-

Looks these like mostly nickel but it could be a proprietary mixture. Industrial electroplating can be very sophisticated, and non reproducible at home. Sure you can try, if you have previous experience it would help a lot I think. I don't have that either but I know that's not something easy or cheap to do.1 point

-

An interesting possibility, if I'm understanding it correctly. However, I think I should at least get 1 jewel replacement under my belt before I start techniques like these.1 point

-

@HectorLooi...makes it look easy. However, my problem was that the spring came off the hinge. I was having a devil of a time getting it attached to the hinge. Finally got it. It was tedious.1 point

-

Well done! Thanks for sharing mistakes also. That‘s how we all learn. I read recently that Seikos are low on amplitude. Please let us know whether a new mainspring makes a difference. I‘m not so sure…1 point

-

Essentially right. However; I removed a whole setting once in my beginning for a press-in jewel (key wound pocket watch). It worked, but the much too big jewel looked soooo ugly, I never did it again! Frank1 point

-

Don’t say that! It‘s just because the balance wheel is much bigger and less magnification is needed compared to the cap stone imho.1 point

-

I was looking to get a demagnetizer so read all the posts in the demagnetizer section, i followed your link to the homemade demagnetizer using the microwave transformer, it seems to be the same type of circuit used in the elma demagnetizer, so thought i'd give the homemade one ago. I already had a couple of old microwave transformers along with the other bits needed, diode, resistor, switches, i orderd a motor run start capacitor that came yesterday, i assembled it into a plastic biscuit box, it's a simple straight forward build, it works really well, i've never had a demagnetizer but seems better than the type you have to withdraw the watch away from slowly that i've seen discussed online. I've ordered a new box to remount it into rather than a biscuit box to make it look a bit more professional, once it comes i will post some photos of the finished demagnetizer. Thanks johnR725 for the link, that was a good find.1 point

-

Yes, that is correct spot to tap. I'm not sure about the quality of the Chinese tools. I've come across some tools with very poor quality steel blades. The steel is either too brittle or too soft. The 4 blade tool that I have is a gift from my mentor. He said it's made in Korea. So far the blades are still in good condition. Only the aluminium block has suffered some dents from the hammer.1 point

-

I would say something hard flaked off and kept going around in the bush which had no oil and wore a dirty big chunk out.1 point

-

If you checked the pivot with a micrometer and got 0.195mm, it will be almost certainly too close for a 0.20mm jewel; Seitz jumps by 0.02 increments from 0.20mm, so go for a 0.22mm, it will be fine. I don't know what the situation is with Seitz. I have the impression it might be defunct and everybody is selling old stock, but at the very least, it seems they have reduced the offering of sizes.1 point

-

If needed, as a last measure you can do that yourself quite easily. Both glass crystals and their gaskets are made in a large variety of types, and in every possible size. So unless there are very special features on a watch these two items are easily and cheaply replaced.1 point

-

You should disassemble the case first and measure the OD and thickness of the crystal and the ID of the bezel. Then you might find the right parts at cousinsuk.com. The dimensional overlap between bezel, gasket and crystal should be about 0,1mm to get a tight fit.1 point

-

The data sheet says 1,5g/cm3. So 45g is 30ml what I can confirm after having measured the dimensions of my bottle. http://www.epilamisierung.com/images/stories/te1420ea.pdf http://www.epilamisierung.com/en/1 point

-

When winding, the crown/stem doesn't engage the cannon pinion. If setting the watch is high effort, the cannon pinion is too tight, but if it is normal, it is not that. My guess is that what you are doing with winding is changing the alignment of the barrel arbor such that it supplies power to the center wheel without pushing it out of alignment or binding with it. I would bet it is barrel arbor end shake/wobble that is the culprit here. Possibly center wheel pivots/bushes alternatively. But misalignment will prevent the gears from meshing together correctly and cause binding.1 point

-

I think that you may have to get that canon pinion and center wheel off in order to know. I'm thinking that there is a rust/ seizing condition going on that is stopping power from moving through the train unless you use excessive force ( via the crown ). Also verify that your barrel cap is on completely, and not riding against the plate.1 point

-

have you tried using a little heat say from a lighter or jewelers lamp to remove separate the cyclops from it's adhesive? I removed one using a soldering flame and it slid right off the crystal. A little One-Dip later and the remaining adhesive disappeared. correct-the tape is to protect from scratches. What i'm more concerned with is safety. my fingers and razor blades just smacks of a bloodletting for me. Case knives work best for me when removing bezels. it takes a little muscle sometimes but they work.1 point

-

I bought it here: https://www.uhrmacherwerkzeuge.com/epages/62662707.sf/en_GB/?ViewObjectPath=%2FShops%2F62662707%2FProducts%2F4439.14201 point

-

Broken jewel can eat into the pivot so you wouldn't want to let the watch run and your sure to get just what you asy " a mess" if you try fitting a rubbed in jewel without the right tools and experience. So looks like this watch would have to wait for a while to get fixed. What kind of amplitude are you seeing? Regs1 point

-

1 point

-

Thanks for the advice. I assumed 1910's or 1920's myself. I've just measured the dial side mainplate diamater and it's 39.2mm. Thank you both for your replies.1 point

-

Eyup lads. A relatively easy and cheap way to measure the jewel hole. Done under a scope, a fine smoothing broach inserted until full thickness of jewel hole reached, mark the broach depth and then measure the broach thickness at that point. The pivot on a staff will be same thickness throughtout until it reaches the cone ( conical staff ) . Hope this helps chaps.1 point

-

BTW, congratulations with your first chrono Now that you got the drift of how many chronographs are put together, a recommended next could be an ETA 7750 (28,800bph). They are plenty around, indeed more expensive, but it's a nice movement to work on and you will wear it with joy. Try to get a 25 jewels with an Etachron regulator, these are very nice to adjust and can run very accurately. Just be patient and check eBay, or other sources, regularly. You may stumble over the right watch for the right price. Alternatively, like what I've done, source just the 7750 movement and later a case / dial and hands of your choice. These are all self-builds; A 1980's case / dial & hands (changed to sapphire crystal) with a 17-jewels ETA 7750; Next a "Festina" 25-jewels 7750 (with Etachron regulator) with a modern dial & hands in a very high quality Swiss diving case; Next; a NOS Omega 1164 (chronometer) with a separately sourced new original Omega Speedmaster dial & original Omega Speedmaster hands. Again in the same high-end Swiss diving case as the Swiss case shown above. Needless to say that this nearly authentic "Omega" came a whole lot cheaper than the original Omega Speedmaster date, which btw has a "normal"-grade Omega 1152 caliber. Both, the Omega 1152 and the 1164 calibers are based on the ETA 7750; Anyway, once you know the 7750 you can create many "middle & high-end" watches yourself. Your own imagination is the limit This one goes another step further, but below all the bells & whistles sits a normal 7750. Since the internet is "stuffed" with 7750 walkthroughs, there may be some tips in this write-up ? Suc6 with your endeavors !!1 point

-

1 point

-

Here it is. Open in microsoft word. Select all and copy (^a ^c) Open a blank notepad file and past in (^v). Save as mh.uue Open a command window in the directory where mh.uue exists. Run the following: certutil -decode mh.uue mh.FCStd Should work. mh.rtf1 point

-

watchweasol has given you the best answer. You will never find another wheel that fits.1 point

-

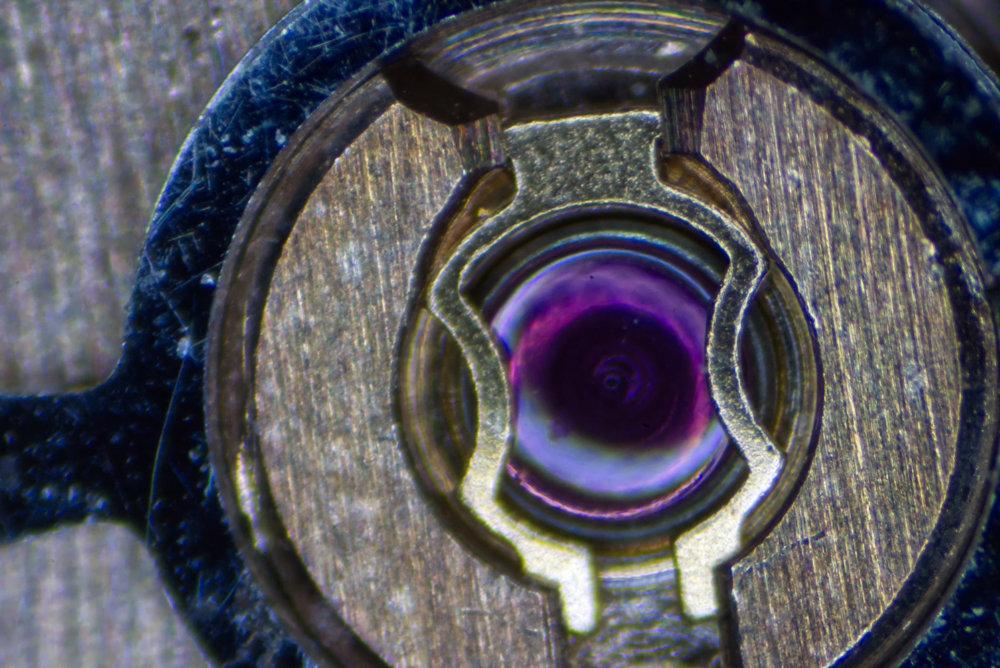

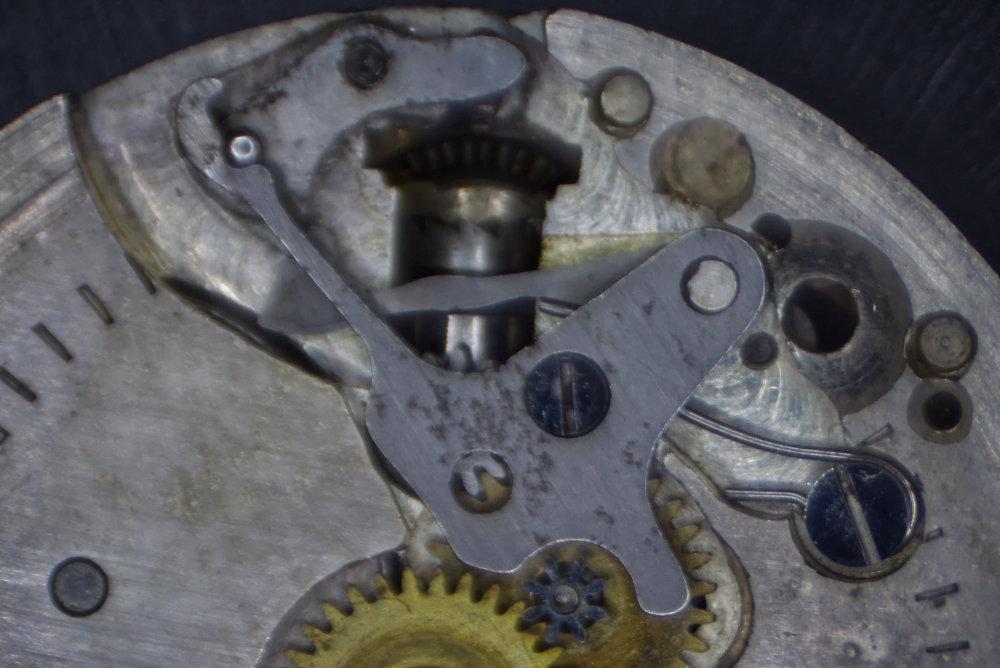

So, the camera adapter arrived today and I mounted it to my (existing) T-mount/A-mount ring and dropped that onto the scope. I then took and processed a couple of images. So far, it seems easier for me to get good images in focus using my macro lens and the ring light from the scope than using the camera mounted to the AmScope adapter. I'm attaching a couple of images (that have not been posted at full resolution) to show images from today's first attempts plus the set-up. The first shows the whole rig with the camera on top. You can see what the camera sees through the 3rd tube on the camera's screen. There is also a six inch rule standing up to give you and idea of the working distance. The second one shows the ring light over the movement pad with 2 movements. Then the image of the incabloc is the capstone on an Omega 620 and the keyless works is of the 2nd Buren Grand Prix. I struggled to get any images in focus of the Buren through the scope. I'm not sure if I want to be in focus through the eye piece or via focus peaking on the camera. I'm also not certain where I am with regard to the center of the lens and how the lens performs across its width (lenses often degrade when off center). Then, I wasn't 100% certain that the focal plane of the camera sensor was parallel to the top of the table and given the really small FOV, a slight angle could really impact image quality. So this is an exercise in learning.1 point

-

Hi The tech sheets for your interest. Along with JohnR725s information should give you the answers. 8597_Omega 9300, 9301, 9900, 9901.pdf1 point

-

it would be really nice if the message board would notify somebody if they're being quoted in a message as it was a miracle I found this at all? typically when I come to the message board I will occasionally notice the new messages on the right-hand side but usually I go right to watch repair and look for questions without answers. Or questions that have a limited quantity of answers because I assume everything that has lots of answers probably has an answer. But occasional will see something on the right-hand side that looks interesting that all look at it. strangely enough somebody else did this a couple weeks ago and I noticed it and I have their answer like I might have found an answer for you perhaps. did you know professional watchmakers can specialize? like for instance my specialty where I work is a vintage. Vintage is sometimes misleading typically it means pocket watches. But it could also mean tuning fork watches and occasionally quartz watch if they have to have it serviced and we can't swap the movement. Then Mather specialty is absorbing a heck of a lot of knowledge which comes in handy for answering questions. Fortunately for us you're asking about an older watch. If it was a new watch it would be problematic to get anything at all. Swatch group is paranoid with technical documentation and to get it you have to access it by username and password specifically would have to have access to an account. Then in the accounts come in various levels which determine how much technical documentation you can even access. Then if you managed to get this documentation their paranoid and they watermark every single page. So if you're lucky enough to find somebody that has such an account they're not going to share that information very far and risk finding out why Swatch group is paranoid and watermarks every single page. Fortunately as I said this is older watch they but we can find the documentation's somewhere else? the first link for anyone who doesn't know what the movement looks like the second link is cousins I would be searched for one of your movements and there is a PDF you can download. I'm not going to attach it to the message board because PDFs take up a lot of space on the message board. Then while you're here search for the other Omega movement you asked about because are both there. A little light reading and 42 pages there longer than what I normally see. I suppose it depends upon what you mean by modular? If I think of modular chronograph movement I think of something like the third link. n other words a company that makes modular chronograph movements independent of the watch company and then there brought together. I've seen a technical sheets for the chronograph movement I just can't remember what number it's under to find it. Then the Omega movements are interesting as well as I would call them more of layered construction. typically when you look at older designs of chronographs you have a watch that can function 100% by itself. Then the chronograph is built on the back side of the watch. Occasionally it will have components going through the front side for extra functions or something. But here you'll notice they don't even put the balance wheel in until everything else is been assembled. It doesn't look like he can get the watch movement to run without putting in all the layers the chronograph. https://watchbase.com/omega/caliber/9900 https://www.cousinsuk.com/document/search?SearchString=9900 https://journal.hautehorlogerie.org/en/the-dubois-depraz-chronograph-module-switzerlands-best-kept-secret/1 point

-

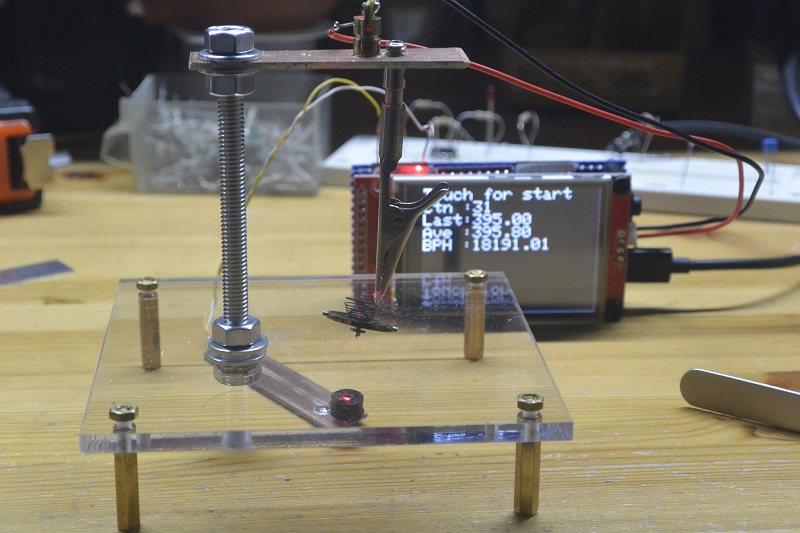

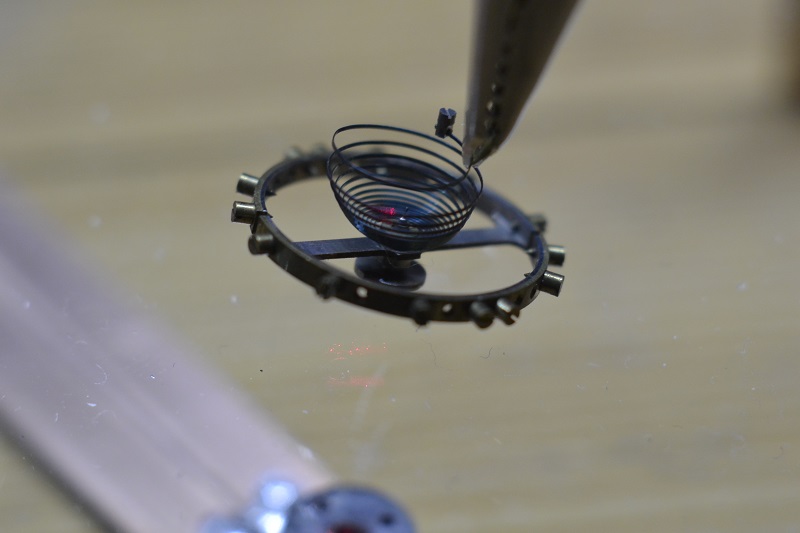

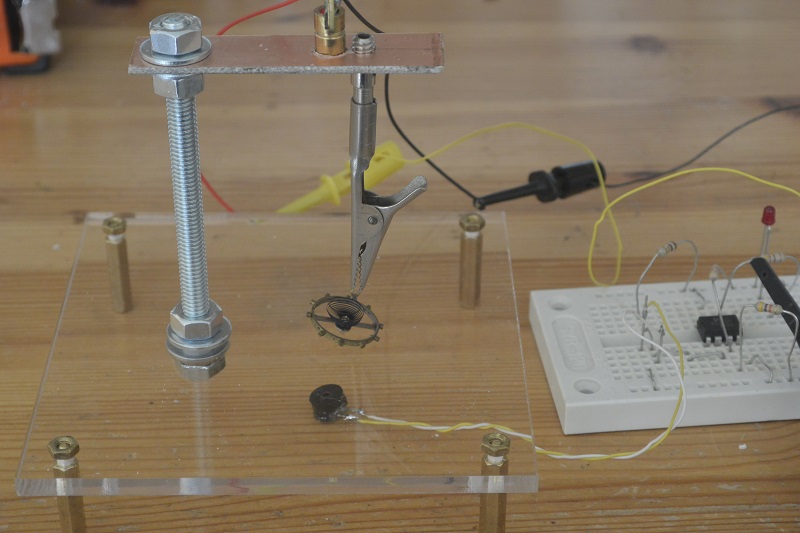

Hello guys, An attempt to make a low cost hairspring vibrating tool : Prove of concept : The hairspring (here it's a 18s balance) is clamp in a crocodile clip which has been grinded to be as fine as possible, a laser beam is set so that the beam is cut by the balance arm. The photo diode (from an old pc mouse ) is en-capsuled in a little housing to avoid parasite light (from what i thing to be an old TO3 transistor spacer found in my spare screws box). The IC is just a simple op amp acting as a comparator, the led on the output is used to visualize the that the laser beam is on the detector. First measure on scope : Doing some simple math show that an error of 0.1 ms on the measured value (which is 400 ms for 18000 bph) correspond to an error of 21.5 seconds / day. At that time base setting my scope has a resolution of 4 ms ! I switched to an Arduino based measuring system : I used an existing Arduino module based on a cheap stm32 and add a led (indispensable to adjust the beam) and the power output for the laser. The comparator is no more required as the stm32 has schmitt trigger inputs. The soft is triggered by the touch screen and accumulate a couple of measures in a circular buffer to compute an average value. This permits to eliminate aberrant measures that you can have when the balance starts to swing. Detail of the crocodile clip : In conclusion this is little tool (cost me only the plexyglass sheet, around $1.5) could be useful to match a new hairspring on an existing balance. The measures are relatively simple to do with a good consistency and surprisingly the croco clip do the job and you can get the balance swing for tens of second on the plexy. You need a resolution of 0.05 ms to be at 10 s/d and probably calibrate your measuring device. The main difficulty was to adjust the position of the laser beam. Hope this can give you some ideas. Regards1 point

.thumb.jpeg.47a54c96c07cb7d64b695e5ff6c0bcf0.jpeg)

.thumb.jpg.7054cd4077d4ffc8467ab1049f416591.jpg)

.thumb.jpeg.a2898f120fd62b57f850717d223f50c8.jpeg)