Leaderboard

Popular Content

Showing content with the highest reputation on 06/18/22 in Posts

-

3 points

-

I bought my son-in-law a 3D printer for Christmas, never having even seen one myself. He went on vacation and left it with me to play with for a week. I'm an old machine designer so I have no problem with designing things using 3D CAD software. I had seen someone else's idea for this and I didn't like their design, which used way too much plastic in my opinion and was too bulky. It took me a couple of hours to design it and 8 hours to print it. I had to chase the holes with a 1/4" drill bit afterward. It works the same for my Bergeon and Horotec pressers. I already have numerous things I want to do to change the design, but at 8 hours per copy, I don't think I'll make many more than this one. Let me know if you would like the STL so you can print your own.2 points

-

My collection changes regularly as I do lots of watch trading. I really don't need most of the watches I have and many are project watches that I intend to restore, some of which I will keep and some I will let go. But since I'm new here, I thought I'd share my collection with others so you can know a little more about me. Not included in this shot are some I recently sold, a Seiko 62mas and a Seiko World Time. Some of these are heirlooms or gifts from my wife of 40+ years. You can see I am a bit obsessed with Seiko. Sorry.2 points

-

Nice one Rich! No, I haven't seen that one yet. I have two that I got just before all hell broke loose so not much modding has happened since I got them, except for a new strap on one. I've also been thinking of changing the mirror finish on one of the bezels to satin or brushed, it's a little too much the way it is now.2 points

-

Imagining the detent and rest of the escapement is intact, the #1 thing is to let down all the power before removing the balance. If the watch has a fusee it probably has maintaining power so even if the barrel is let down there is still power on the fusee. So if it's not functioning, so you can't let it run down the maintaining power, block the train. If you remove the balance with power on there's a strong chance of the escapement unlocking and running away, usually taking out the locking jewel and ruining the tips of the escape wheel, possibly breaking the detent if a spring detent, and possibly breaking escape pivots.2 points

-

The Goldeneye is actually a quartz watch. That was an award from my employer. I would have picked an Automatic, but it was a gift so I'm not going to complain The co axial would have been double the price. Nice watch though, always fancied one myself but i cant swallow Swatch's ethics that are making watch repair more difficult for the amateur. As far as I'm aware the skx is now discontinued along with the 7s26 that's is housed inside. Stock supplys of them will be running very low now and driving the price up. I was able to get a new Japan skx13 as this info was starting to circulate. I preferred the smaller size and it was a bit more expensive but it is one of my favourite watches. Hopefully an easy fix for you mate. I'd love to hear about your experience while working on it please as i have a good interest in quartz repair. Maybe we can learn from each other, i need to refresh my knowledge on quartz. Eyup Gert. Here is a solid modded Amphidive Vostok i may have shown you before but it may help with converting Saldog to our darkside2 points

-

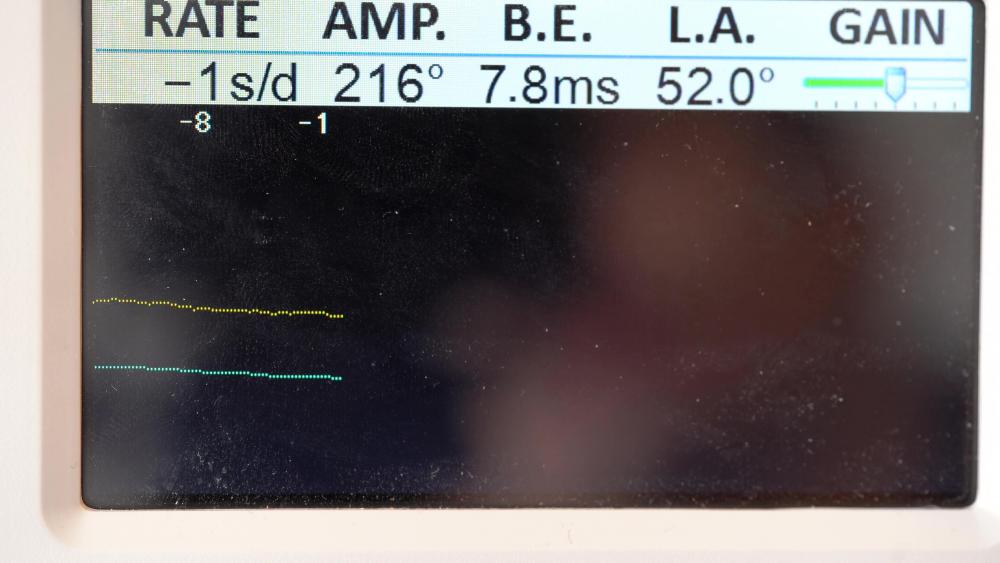

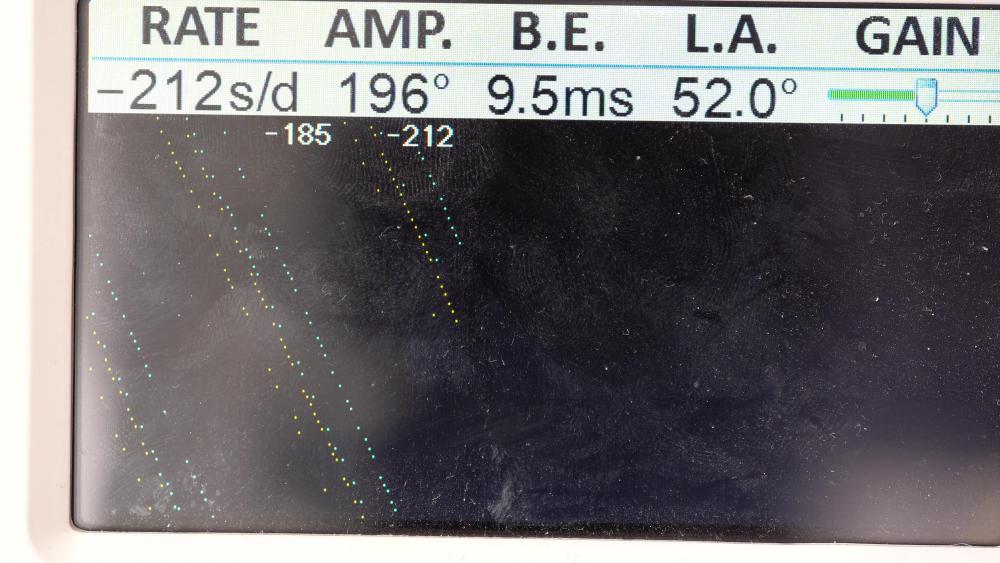

Hi everyone! This time I'm back again with a little something which turned out to be something of a hybrid project. I had repaired and planned a video on a Junghans watch with the 93 movement caliber to give to my younger brother ( which young adult doesn't need a nice looking watch) and had it all set out, planned and executed. The only downside was that the dial was slightly discolored on the right side due to bad cleaning on my part. Here you can see what I mean by that: But I happened to be at a local fleamarket on the day when I wanted to finalize the video and surprisingly found the exact same model! Even though the crystal was pretty scratched up, I was confident that the dial was in a good condition so I bought it for 10 Euros. And yeah, it looks like I hit the jackpot: So.. I got lucky and changed the dials in the end. But enough rambling around and here is the actual process of working on the watch movement: 1. Removing the movement from the case. This movement was from the “trilastic” model line of junghans and it got its name from the tri-legged support beams which held the movement inside the case. Just pop those up and remove the movement. Fun fact: While checking the inside of the caseback for marking I found one from 1981, thats so coooool! : 2. Remove the hands and and then the dial by unscrewing the dial feet clamps ( Forgot to take Pictures sorryyy) 3. Strap the movement into the holder and unwind the watch if needed. Then I removed the broken watch stem. 4. Remove the blued ratchet and the click spring 5. Remove the hour wheel, minute wheel, canon pinion and the very interesting looking yoke and its spring. 6. Then remove the clutch and flip the movement. The leftover lever will be released from the backside later on. 7. Remove the balance wheel and the pallet fork system. 8. Then remove the two screws holding down the mainplate and lift that. You can go ahead and unscrew the screw in between as well since that will release the left over lever on the front side. Do the same for the mainspring cover. 9. Remove the gear train and the mainspring And that's about it with the disassembly! Now moving on to the whole cleaning, lubrication and servicing part! Mainspring service: This Mainspring was something new to me since it had a very interesting arbor! Instead of the traditional small arbor inside the barrel, it extended outwards and acted as a lid and a wheel at the same time. While this is definitely cool, it also brings some negatives such as faster exposure to dirt and etc with it im sure. It looked fine so I just recleaned, lubricated and reinserted the whole thing: Lubrication: Here is a list of lubrications I used Moebius 9010 - All jewels Moebius 8200 - Mainspring and barrel lubrication Moebius HP 1300 slower moving parts such as canon pinion Moebius 9415 - Pallet Fork hooking jewels Molykote DX - Gearless works and high contact/friction zones (Front side only really) Oh and of course don't forget to clean and lubricate the balance shock jewels! Reassembly: Just reverse the disassembly steps or watch (no pun intended) the video for a step by step walkthrough. Timegrapher Test: Before Regulation After Regulation: Now i'm very happy that the rate is so much better. The amplitude can definitely be better however I would blame the old mainspring for that. The one thing that puzzles me really is the Bear Error. I've tried virtually every combination on the balance but the beat error does not improve. Maybe something is wrong with the hairspring? Final Result: After attaching the more aesthetic dial and recasing the watch and adding the straps, these are the final result pics: I must say I'm very happy with the whole process! Of course there were some up and down moments like when I destroyed the balance ( don't even ask) and had to get a replacement and such things but it all worked out in the end did it not? I was not sure how the beat error and the lower amplitude were going to show themselves while wearing the watch so I did a test wear for a week and the time only deviated by a second or two so I'm relieved! Now I apologize for the lack of pictures for a smooth documentation, I forgot and yeah, the rest is history. However, I have uploaded another fully commentated video so If you want explanations, more information or just a smoother experience go check it out: https://youtu.be/ZDXKiNnrmMk Any criticism, questions, comments and tips are always welcome and i'm happy to talk to you all! Hope you enjoyed it and until next time! Stay Healthy!1 point

-

Whatelse is there to wear out or break, its either the post or the bush in rotor. Seen broken ones quite often, not much can one do other than to repair or replace the broken parts.1 point

-

Thanks, this is the latest victim: a 1909 Omega 1900 Grand Prix PW, can’t find a second hand for it, nor can I get the crystal seated (the pressure ring it sits in is MANGLED) i know there are a ton of sources for hands, but I lack the tools to measure this hand’s size (the sub dial second hand) thoughts or advice appreciated!1 point

-

Hi! Rod here from Ottawa, Canada. I took up this hobby about 15 years ago. I acquired a lot of tools, and a lot of non-runners off of eBay, and even restored a few of them. But then life got busy. I just turned back to watch repair a few months ago after a conscious effort to devote more time to life and less to work. I did the Level 1 and 2 Watchfix courses, fully serviced an ETA 2801-2 and an ETA 2836-2, and I now have a disassembled 1908 Waltham Crescent Street on the bench. I will be checking in frequently for help and advice. And if by chance I have an answer for someone, I'll offer that too. I love old pocketwatches, but I have a few wristwatches that need some TLC too.1 point

-

Yep, don't know why I need the expense of a Holiday, I am at my most relaxed at the work bench. SWMBO Has a lot to answer for dragging me somewhere hot and sunny1 point

-

Wonderful thank you very much! I'll dust off the printer tomorrow and give it a go. Yes that 4205 is tiny and a pain to clamp in my 4040 type movement holder.1 point

-

Absolutely Saldog no problem. I prefer to keep watches genuine as well. Ideally two examples, one for each situation.1 point

-

Hah that's awesome. Whenever I waltz in with another watch I get the eye roll. Which is what I do when she gets a new pair of shoes so that makes us even hehe. Obviously the issue around Vostok is what it is, but that hasn't stopped me wearing mine. Most people don't even care that you're wearing a watch, let alone anything Russian. And based on some of what was said on social media, I get the distinct impression that the average Russian isn't enthused by events either. The same average Russian that put that Vostok together. But I need to stop there before I inadvertently open a can of worms. No worries man, everyone has their thing. I have some pieces here where I went for full and proper restoration. But some of the stuff I get is just too far gone and then I get the green light to go nuts. Mostly cheap Seiko's that was made by the thousands so they were never likely to be collectable anyway.1 point

-

I made up a quick model, using my standard design as a basis. Getting the fit just right can take some trial and error and this one has a clearance that has worked on other Seiko movements. The 4205 is a ladies size caliber with a 23.4mm casing diameter so a fair amount smaller than I'm used to. Try this out and let me know if it needs tweaking. Here is a link to the STL file on my Google Drive: LINK My printer automatically replaces large solid regions with 15% density honeycomb voids, making the total plastic mass much less. So this won't use much plastic. I like the large diameter base for stability and it is 15mm high, which I think is a good height. But let me know if you want anything changed.1 point

-

1 point

-

No sorry. As you say the chime mainspring is much bigger then the other two.1 point

-

I actually have Seiko S-2. It took a long time to find it and a few failed attempts to get Japanese sellers to send it to the US in the mail. It is a bit thicker than Mobius 8217. I would say it looks almost identical to Kluber 125 in color and consistency. In the package of grease was Seiko's instructions for application. Basically, you brush it on the barrel wall, barrel bottom and barrel lid. If you have opened a Seiko barrel, they are not shy about how much they used. I do suspect there is a specific amount that should be applied to each surface and it is taught in a class but not really published. There is no mention of drops of oil on the mainspring. There is the Swiss way and there is the Japanese way of doing things. Sometimes they contradict and clash. Don't be in a rush to default to the Swiss way on a Japanese movement. Auto winding reverser wheels in the Seiko 8305 come to mind. The Swiss wash and lube their reverser wheels. The 8305 Technical Guide says wash, no lube. There are only a few posts I can find on this issue. The watchmaker prepared them the Swiss way and the watch came back in two weeks not winding. When done the Seiko way, there were no further problems. The 6309 Technical Guide shows S-2 on the barrel wall, bottom and lid. Nothing on the spring coil. The instructions in the S-2 box say to brush it on. If oil and grease mix, it makes goo that does not act like either oil or grease. In a confined space, the two will mix.1 point

-

Yey suomaf mate i am so pleased for you. You should be very proud of yourself and your dogged determination to see it through to a successful end result, well done matey. All your trials and tribulations to get you there, you should consider as worthy lessons well earned, hell I'm proud of you. I very much look forward to our future conversations, i can see you are one to stick with us and this amazing interest for years to come. Speak soon matey1 point

-

One of the things I find interesting is the push for synthetic lubricants and we have 8200 which is not synthetic. If you look at a whole want to package is a mainsprings though oftentimes say pre-lubes or a reference that no lubrication is required but not disclosing why no lubrication is required so the theories range from it's a dry lubricant like Teflon which you can barely see all the way up to the metal just slides really nicely on itself no lubrication is required. A for instance Omega. I like to use that because I way more documentation for them than I do other things. So they have a vast number of working instructions 67 covers recycling mainspring barrels. Which is interesting because I've talked to people who work at Swatch group service center and they never recycle they replace. But here Omega tells you how to recycle your barrel. Basically it says how to disassemble and visually verify that everything is perfect everything has to look nice nothing is worn out nothing is well nothing is like what we would find in watches that were servicing that a been around for a while and they just aren't going to be perfect. But Omega expects perfect. Then of course they check the end shake of the harbor and the barrel to make sure that's right and adjust if necessary. Then the mainspring is cleaned with a lint free cloth no solvents no cleaning fluids. I've seen other references before to this and I'm not sure why they don't want them to be cleaned. The mainspring barrel is run through a cleaning machine complete with the arbor. Now that you have your nice clean barrel you're supposed to use epilam on it. Not the mainspring just the barrel in order. Then somewhere on the discussion group we've already covered Omega typically uses P125 for the breaking grease is applied in small quantities around the rim at stuff is usually really really sticky. I remember when I was working in the shop with the previous watchmaker doing a Seiko watch and I asked how much to apply he said around the entire rim of the barrel and that answer would be incorrect there's a reason why you have blobs because the stuff is really really sticky. When I wound up the Seiko and it hit the end I thought is to break the screw off the ratchet wheel. It's one of the reasons as curious about the quantity of Greece you are using because each of the breaking greases has different properties Then your nice clean mainspring goes into the barrel think it's closed up and no lubrication on that clean mainspring other than the breaking grease. So I guess that supports the theory that? They don't want it cleaned so maybe you're cleaning would watch something off may be it's probably the metal itself it likes to slide on itself But that doesn't explain why I typically use 8200 and all of my mainsprings. You do want to be careful not to get carried away because of if he is too much it will leak out of the barrel and make a big mess. But I'll skip over how I know the. So if we believe Omega it doesn't matter whether it's new or used no lubrication. Then I've seen people online sometimes I actually recommend the oil on the mainspring something a little bit lighter than the 8200. In the end for lubrication it all comes down to are you happy with the performance. Then do you stay happy with the performance for the next several years if so you've done good if the watch crashes and burns really fast then you did bad. Then yes you can do that with a really poor choices of lubrication. A note regarding the breaking grease? Somewhere I've seen it written out basically a wine the mainspring up until it slips keeping track of how many turns it took to do that then you let the power back off counting how many turns are laughed. This is where it be nice if someone would write this down for us so when the mainsprings slips you don't want at the lose 100% of the power. I'm not sure if there's a rule of thumb number of how much you should lose you just don't want to lose all affect. Then of course you definitely do wanted to slip when it reaches the end because acting cause a timing issue of too much power. Oh say: pallet fork pivots? Sometimes I wonder if the artist doing the drawings were given a Post-it note of what they're supposed to do and maybe not paying attention hundred percent. It would be nice to find somebody in Seiko that you can ask questions. The pallet fork lubrication is a major question people have. Then there is the amplitude question Seiko's run usually a much lower amplitudes. Apparently this is by design. Typically do not find it in any other documentation except there's one manual which is their alarm watch it actually tells you what the acceptable amplitude for Seiko is. As I already have the image I'm just attaching Okay now for pallet fork pivot lubrication? The rule is it's a non-rotating component so it doesn't need a lubricant. Then a lot of stuff is carryover from the past were organic oils would go bad and having her pallet fork glued together because the oil disintegrated would be a bad thing. On the other hand is all the rest the oil goes bad is probably not going be that bad maybe who is in a discussion once about the related the lubrication a newbie came and commented about and at the time I was thinking there is probably 1000 other reasons why there watch would be having problems except I was wrong. They had oil the pallet fork pivots but they used anchor oil. Anchor oil is an interesting substance the bottle I have is warders thin. It's so thin that when you apply it to the watch it spreads like crazy really fast so it's gone within no time. But apparently the early stuff had a really nice property of getting really sticky really really fast. So this person had the re-cleaned their watch to free up to pallet fork because it was glued in in about two weeks time. That's an example of not the used inappropriate oil in your past fork pivots then of course there's the simplistic of not lubricating seems to work just fine so why do it. Quartz watches are interesting in that their gear train does revolve but it revolves every time the stepping motor steps and the gear train has to move very fast or be lightweight because if there's a delay it causes an increase in power consumption in other words is more friction. So they do make a special oil for quartz watches it seems like that might be suitable for your pallet fork pivots even though you don't actually need any Then yes if you put heavy oil on the pallet fork pivots you will see a decrease in amplitude. I've also seen in as I don't quite remember the author of not going to say who the person is but I had seen a reference to lubricating the pallet forks because? But I'm only going by memory which may not be accurate in the days of the paper tape machines which is basically equivalent to the graphical displays we have today if you lubricated the pivots it made things I not sure if more stable is right but I guess made the display look nicer. Of course they're not measuring amplitude they're just looking at the graphical display. Then yes Omega's definitely change their mind over time. Their choice of insanely similar merchants on the key less in the late 50s slowly getting heavier but in my view still way too light. Then of course what they recommended you epilam in the late 50s versus today which is practically the entire watch. Although some of that is because they've always epilam practically the entire watch and the modern cleaning machines and fluid strip but awful lot faster so you actually see a document that says do it every single time. Then yes the Swatch group service center goes through a huge quantity of that on a regular interval but there servicing a lot of watches. I'm assuming when you buy it in huge quantities get a better price than the small blog that we buy1 point

-

It looks like a Kern & Sohne 4 ball Pendullum plate size 18x38 circa 1949 suspension spring required .0036” (.091mm) These measurements are based on the assumption the clock has the original pendulum ps you can double check by measuring the existing spring1 point

-

Had a quick look in the 10th edition of the book and couldn't find it I might have missed it will have a closer look later unless someone gives you the answer in the meantime.1 point

-

My old book does't have this movement. I'm sure someone will help you later.1 point

-

My general advice on this one is leave it alone. Bezels typically are not restored. They are replaced or left alone. Sometimes, we strive to restore a watch to new condition but often times, attempting to do that does not increase the watch's value at all. If the restore looks like an attempt to restore it more than an actual new watch, that is more distracting than just letting the watch be with all of its character lines. I am sort of like an OCD type of person and I do not like anything misaligned or out of symmetry. I don't like stains or scratches. It has been hard for me to learn this principle. When I'm shopping for a watch, I generally stay away from the ones with badly stained dials or bezels, but sometimes, the stains and scuffs can be attractive, but you need to learn how to appreciate that aspect. I have slowly come around on this and gone against my natural tendency. Some of my restorations are very subtle, letting the marks remain but just taking much of the light wear marks away. Of course, this is totally subjective and others will have their own opinion. This is just my humble opinion. I think your bezel looks ok as is. I also don't think there is any way you can make it look much better and I wouldn't use anything other than mild soap and warm water and a very soft brush or just my skin to clean it. Even then, that is risky as you don't want to flake off any of that pretty purple paint. Every time I've attempted to fix a dial or a bezel, I make it worse. Just my two cents.1 point

-

1 point

-

We're now all rocketeers again! Probably a Russian influence operation on Putin's orders to get us to work with Raketa watches.1 point

-

thanks i appreciate it!!,its been hard , i sometimes feel down but I cant give up, and i am happier when she is home, not stuck in some nursing home, I worry more that way,the care here is not very good,i was forever walking in and her not attended to,it seems as time goes on the hired help does less and less,I dont know how it is there,but the medical profession needs a change,thanks guys, different note :Should i try and do an internet repair service , I am a little afraid of just getting shipped watches that may not be real?? i wish i had a little shop like i used to but the RENT is SOO high and repairs are so low, I had no calls on trade work, not being certified,i apprenticed way back, but never joined a AWCI or anything and dont have the money to do that anyway i guess, BOY do i miss the 70's !!!!!!! windup watches galore!!!1 point

-

Beco Technic but the import rights will probably kill the difference for you. I had to switch suppliers for many things as I use to buy most in the UK beforehand. All thanks to some greedy EUssr politicians.1 point

-

Welcome to the forum. I'm also in Melbourne and collect/restore vintage Elgins.1 point

-

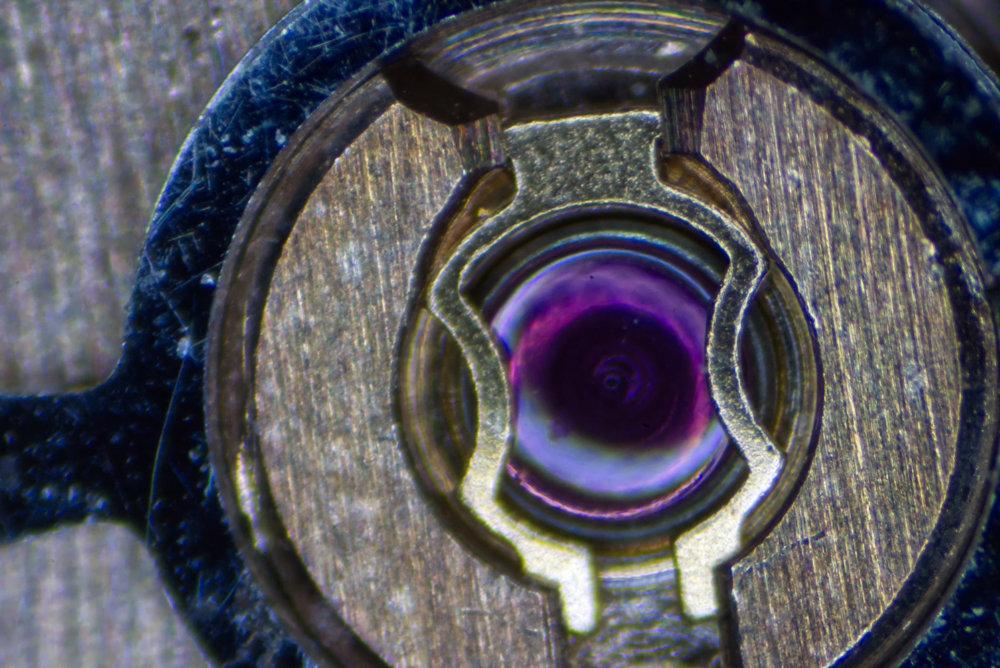

So, the camera adapter arrived today and I mounted it to my (existing) T-mount/A-mount ring and dropped that onto the scope. I then took and processed a couple of images. So far, it seems easier for me to get good images in focus using my macro lens and the ring light from the scope than using the camera mounted to the AmScope adapter. I'm attaching a couple of images (that have not been posted at full resolution) to show images from today's first attempts plus the set-up. The first shows the whole rig with the camera on top. You can see what the camera sees through the 3rd tube on the camera's screen. There is also a six inch rule standing up to give you and idea of the working distance. The second one shows the ring light over the movement pad with 2 movements. Then the image of the incabloc is the capstone on an Omega 620 and the keyless works is of the 2nd Buren Grand Prix. I struggled to get any images in focus of the Buren through the scope. I'm not sure if I want to be in focus through the eye piece or via focus peaking on the camera. I'm also not certain where I am with regard to the center of the lens and how the lens performs across its width (lenses often degrade when off center). Then, I wasn't 100% certain that the focal plane of the camera sensor was parallel to the top of the table and given the really small FOV, a slight angle could really impact image quality. So this is an exercise in learning.1 point

-

Usually in discussions I ask lots of questions. Which sometimes irritates people who are seeking a quick answers as they just want a quick answer Usual questions would be background history of the watch and why are you servicing it? Often times people are attempting to solve a problem but they're not always clear what the problem is and they don't give us a proper background history of their watch. In other words of we don't get a proper description of what's going on the answer may not actually fit whatever the person thinks are trying to answer. Then the path to having a repaired watch varies from individual to individual and even shops. How about a suggestion? How about another step evaluation of the assembled watch. Like for instance why is your timing machine think it's a snow globe? For instance when the watch was on the timing machine doing it snow globe imitation of what that the watch itself look like? What was the balance wheel doing how did it look? Then one of the downfalls the Chinese timing machine is it lacks audio. Know the beeping sound is not considered audio. Often times when you get no ways and random dots it would be really nice to listen to the watch and see what it sounds like. But to understand your snow globe effect we would need to understand or know what the balance wheel was doing was a running nicely or was a running pathetically? Then as you just got your timing machine timing machines are used for more than just timing a watch their diagnostic tool. You should establish a timing procedure. I like the time my watches and six positions cents dial up dial down and for crown positions. Within the last month or two we had somebody who was very puzzled the watch was perfect on the timing machine but sucked on the wrist that's because they only looked at their watch in one position. Oh I did attach a PDF of things you might find on the timing machine. Timing machines originally had paper tape that came out with dots printed on them know nifty numeric display telling you read amplitude beat EDS got a graphical display. Fortunately the graphical display whether it's a newfangled LCD digital timing machine or in old-fashioned paper tape machine the graphical displays are the same then you should have a timing procedure of? Usually when you're timing a watch you fully wind it up you let it run for about 15 minutes to about an hour it depends on whose literature you look at as to what their definition of fully wound is. But you typically never will time at the way wound tight things will be misleading. Then when you're timing your six positions and rotating microphone allow it to settle about 30 seconds works. Then measure for about 30 seconds Timing-Machine-Charts.PDF1 point

-

Woohoo I'm officially an addict, it's been a long slog. I feel like I'm 30 again staying up till all hours of the morning trying to get old Lara double Ds onto a crumbling rock platform. But I mean come on 400 points to the next rank up, really ? I do have other things to do you know, like getting out and having a life. Sadly enough no I don't , I'm afraid the forum is stuck with me. I Jest1 point

-

1 point

-

After carving a cat out of a block of some extra hard pine wood (I think that pallet came from the US.) with a blunt kitchen knife decided to make a whittling knife, my first ever knife. 100% recycled. Again wood is pallet wood, pegs from skip, blade is from a used table saw blade. Not perfect at all, but I am happy. I would need a proper belt sander. I left the markings from the file because i liked it.1 point

-

1 point

.thumb.jpeg.47a54c96c07cb7d64b695e5ff6c0bcf0.jpeg)