Leaderboard

Popular Content

Showing content with the highest reputation on 06/14/22 in Posts

-

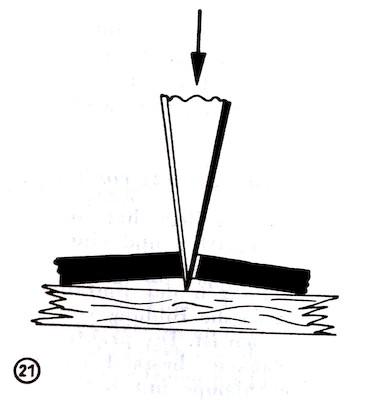

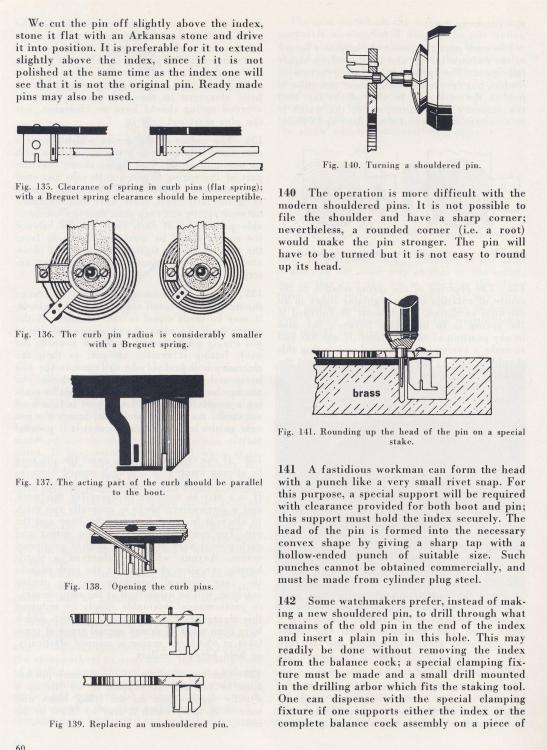

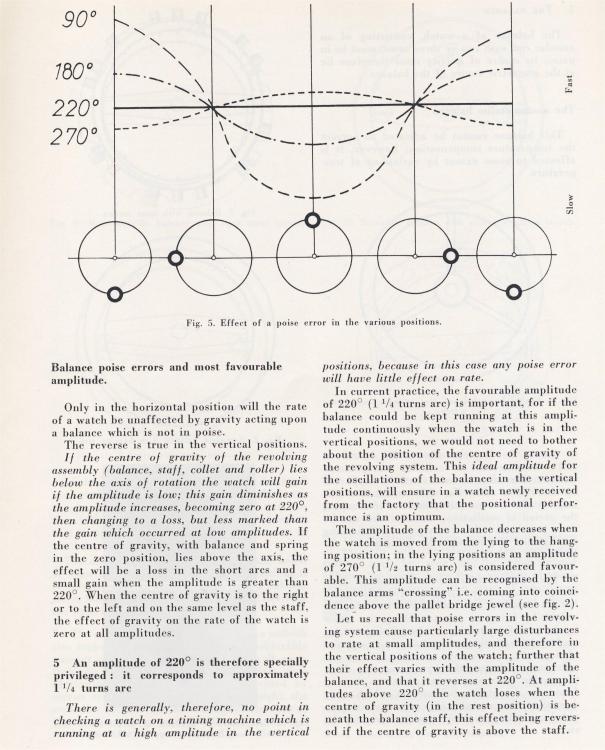

One of the best and most easy methods is a strong, at the tip sharpened tweezers and soft wood. It also works with tweezers without that step, just grip the blade strong enough. You will have more control on the result with slight hammer taps instead of just pushing. Frank (A typical drawing of great Jendritzki) ...and in an earlier copy of the same book I found a picture that directly adresses the issue of the bent blade:4 points

-

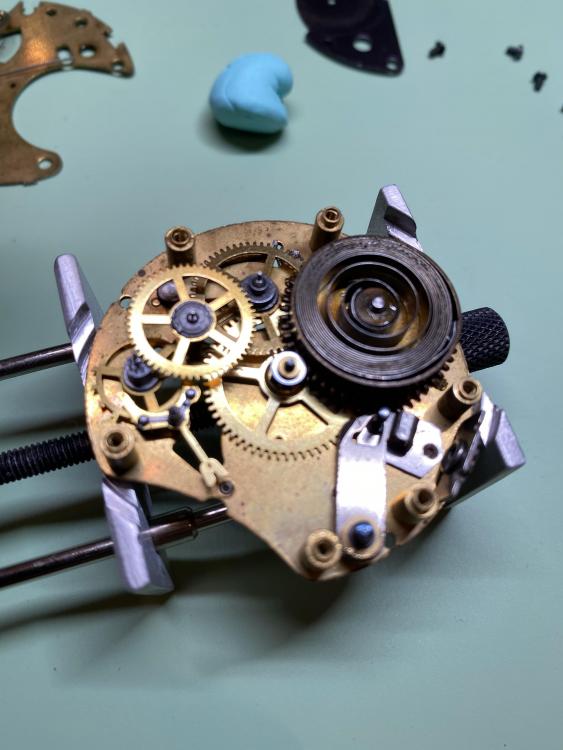

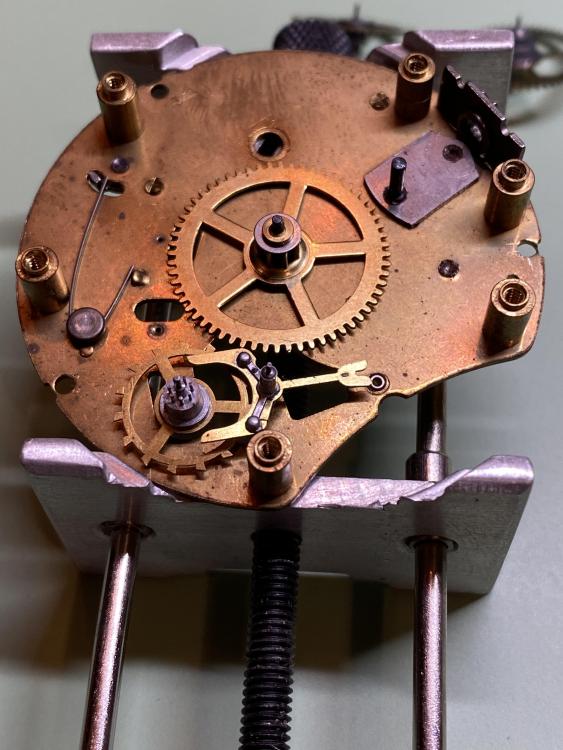

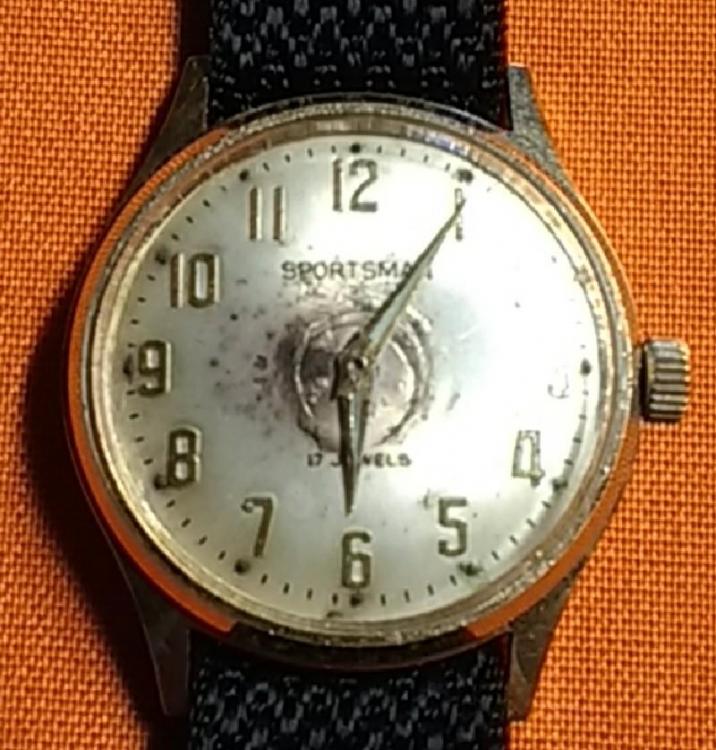

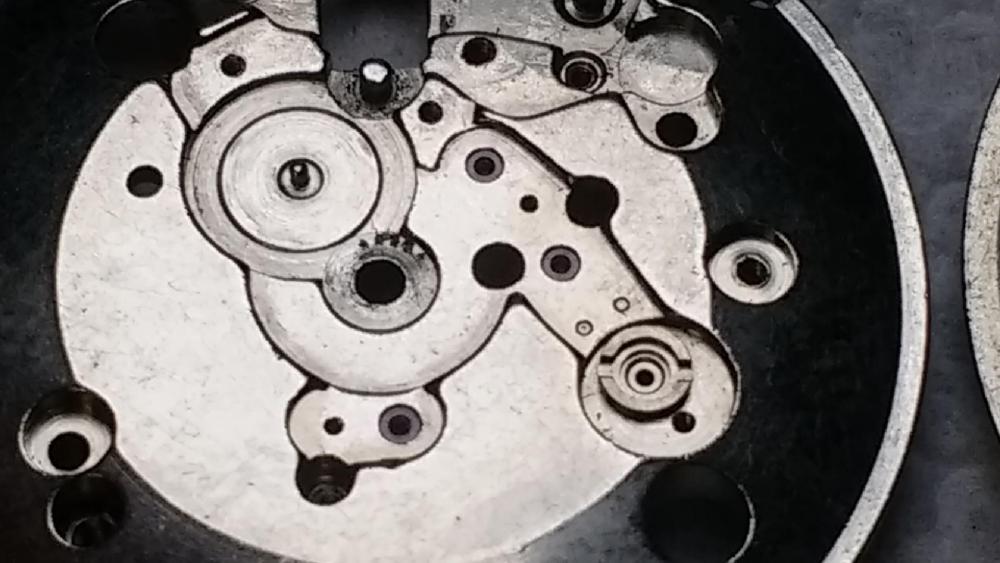

While I wait for Coca Cola to hopefully free the ratchet screw on my Elgin movement, I tried my hand at servicing a 66 year old dollar pocket watch that certainly wasn’t made with being serviced as a goal. Tore down the movement, cleaned and lubricated. Rather fidily getting it put back together given the poor quality of all the parts. Thought I’d share some pictures and the result.3 points

-

It's the old don't buy what you like, buy what you need, 300k for a scientific grade scope is miles OTT for watch repairs, where a few hundred for an Amscope stereo type is much closer to a watch repaired needs. Unless you need to see a pivot blown up in super high resolution on a massive monitor then you will need to dig very deep for the out of all proportion price tag the scientific scop will cost you. Still no one said this hobby was cheap, even if you are like me and are always looking for a tool bargain, have you seen the quality Chinese tool thread (plug plug ). This is the one I use. https://www.ebay.co.uk/itm/124373214244?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=PNBmY-cRSd-&sssrc=2349624&ssuid=cJqjENlHSBe&var=&widget_ver=artemis&media=COPY Can be had cheaper direct from China or for more if you want a boom type base. A 0.5 Barlow lens is need to give more space between the lens and base but that's only about £20 so not big deal really. One thing I would recommend if going down the stereo scope route and that is get one with simulfocus, so that if you add a camera to the camera port otherwise you will loose one eyepiece when using the camera. The one listed above is simulfocus Using a camera to video a strip down is a boon in helping remember where all the parts go. The cameras for these scopes are not too expensive either.3 points

-

Not at all. You don't reduce the power, if thickness stays the same. Length is the most tolerant size. About 10% +/- makes no difference at all. Bigger differences will gradually reduce power reserve (= running time). Frank3 points

-

I came across this device today, which has apparently been on the market for a while. I don't think it has been mentioned before, and maybe some of you will find it interesting: https://www.lisit.net/chronoskop/2 points

-

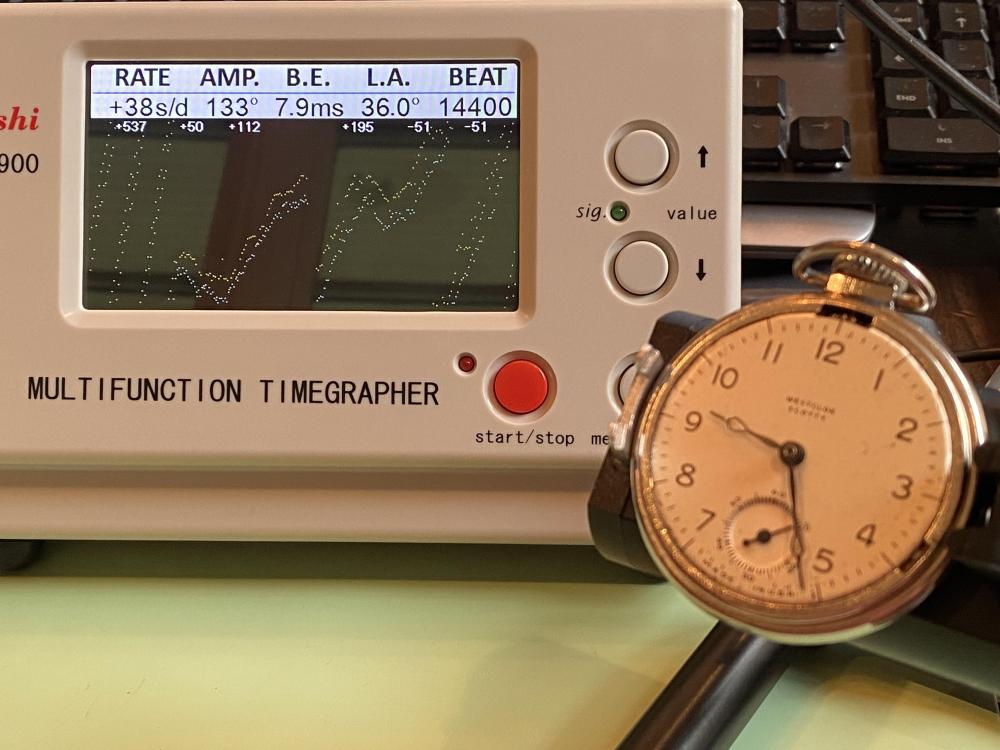

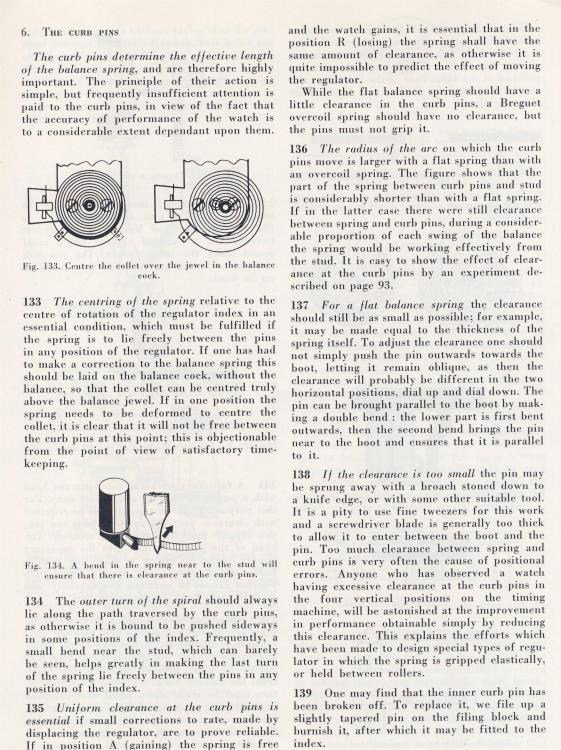

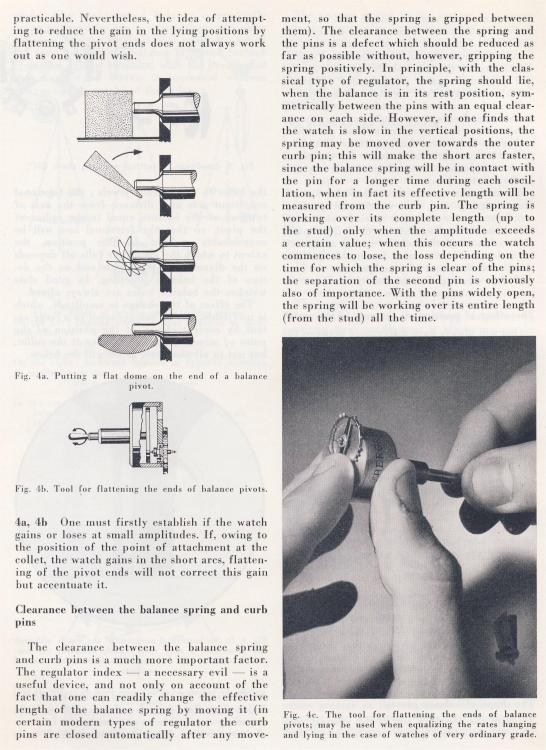

I think I got all the stuff on regulator pins plus a little bonus material then kind of as a reminder perhaps? The book is filled with everything you need to know to do precision timekeeping. It's filled with theory is ideas concepts everything which is nice except? You have a finished product the product is supposed to be chronometer grade? Okay went back to the tech sheet it's a top grade. Basically identical to the chronometer grade except it hasn't passed chronometer testing. Cleverly it doesn't say what the difference is? In other words what exactly do you really have to do? I was in the impression it was just possibly little tweaking here and there. Is where you want to be careful not to start to do things that maybe aren't necessary even though you have a perception that you need to do them to achieve the goals you desire? Won't be interesting is is the track down the companies were using this movement who get the movement chronometer certified then see if he can find the person who does the actual adjusting. Person is probably locked away in some safe fault somewhere is the most valuable possession in the company at finding that person might be a challenge. Then yes someone one of the vintage books it talked about the person who could do the adjustment to get the watch to keep precision time basically was the most valuable on the company. Normally in the images I trim things a little tighter but I gave you bonus material. Then each paragraph is a number which usually corresponds the picture which isn't necessarily on the same page. Then I forgot to ask I noticed the print outs up above? What you think of your nifty new timing machine?2 points

-

1- Rotate closed, all rates increased*. Rotated open, all decreased*. 2- If you rotate the stud, you shift the centering of the hairpspring. This can have multiple and surprising effects. ** Changing the pin gap can have vastly different effects from horizontal to vertical depending on the size and overall quality of the watch. The flat hairspring can deliver astonishingly terrific rates, in positions and isochronally. Again, I mention my friend who methodically trues and tidies up the hairspring before even looking at the machine. The gap at the pins becomes the big thing when all else is good. Play with the gap when you're sure everything else is perfect; when you get it too tight everything goes awry, same with too loose. As John mentioned above, the gap is as a rule of thumb the thickness of the hairspring, spread over the gap. But tiny variations on that can have big influences on rate when hunting down chronometry. And to a question from Joe above-ETA has some sort of lower grade ruby they use for pallet stones on lower grade watches. The Chronometer spec ones have real "natural ruby", which is actually produced and not out of this earth. Both work great, as many have observed "pedestrian grade" 2824s running like marine chronometers with the crappy pallet jewels and all.2 points

-

1 point

-

I haven't used LRCB stuff but they are reputed to be equal to Moebius. I'm sure they think they are superior! The big problem for a horological oil maker is the fact that all manufacturers use and recommend Moebius, or perhaps some in house lubricant, so it's an even smaller market for a small maker like LRCB. I am curious to try their epilame, but I have two 100ml bottles of Fixodop on the shelf so it will be a while.1 point

-

When I was giving my lecture on timing machines the second time at a nawcc meeting I had to be really careful when I got to the Microset section in that did I mention this is a really beloved machine by people? That's because I found faults with the machine I don't think it's perfect and I find at least one thing very very irritating. And it's actually mentioned in the book why he does it but I still think it's a flaw. If you are timing a watch the LED is flashing with each beat I think it makes a ticking sounds and there's a minor skipping it skips a beat? It skips the beat so it can update all the software and everything which with the microprocessor that shouldn't be an issue unless? I had a discussion with somebody else who seem to agree with me that well basically the Microset could be better. In any case every time it doesn't update it conceivably will skip a beat. So when you're timing a watch show here that skipping and I find it very irritating because I think there's a problem. I'm guessing when you doing clocks I think Emily really done one or two clocks with it you just won't notice. Other minor concerns with the Microset it comes in versions some can be upgraded some cannot. On the outside they basically look identical. The inside they did not look identical pictures below of what their earlier one looks like in a newer version looks like. In any case if you're purchasing on eBay unless they show a picture of the startup screen you may or may not actually know which one you're getting. I think mine was being sold as a second edition and from my really fuzzy memory I think his two second editions the original one and the second one in the second one can be updated in the first one cat or something is there are some minor yes have to be careful The other thing I really think with the modern microprocessor is a little bigger display it may be some words to explain what's going on sealed have to look at the manual. Probably if you use it all the time you know instantly what all the settings mean. Oh and Microset isn't the only one making clock timers in the US there's another company called TimeTrax it's been around for a very long time has multiple generations of machines. Then if you're thinking of building your own but maybe don't quite want to spend all the time and effort here is something relatively new that somebody else made. https://mesterhome.com/timer/index.html1 point

-

1 point

-

The crown tube still looks like it's been pushed to far in. You can see in the picture, it might not be touching the movement but it does encroach over the dial, that may be enough to stop it just dropping out as it should. Still you got there in the end, did the crystal lift do any damage to the crystal as the tension ring would hinder the correct working of the lift or did you get lucky ?1 point

-

1 point

-

A ? At first i thought some kind of lapping wheel, thought the stud was an arbor, but no. B - a staking block ? C - homemade tool. D- are these reaming tools ? Countersinks. E- a vice for hand broaching ?. F and G - for turning a balance staff on its balancewheel for repivotting like a jacot.1 point

-

Remove this wheel (red arrow) Hand rotate this wheel (green arrow) and watch the hammers, you are watching for the hammers to go down the line from one end to the other, which will be the quarter past or the last of a quarter too. When you are happy with that put the other wheel back on and clip it so it won’t come off. Move the minute hand by its center around, make sure no hammers lift on the warning, if it does you will need to take the wheel off again and move it one tooth. When you are happy with the chimes put both hands to the correct position. I would say you have to do it this way because the auto correct is not working properly. Any problems let me know.1 point

-

The express way is not recommended.. This method does not allow for inspection of pivots and if the bushing are not absolutely clean the the oil will just turn to a form of grinding paste. Also getting consistent regulation will also be problematic..1 point

-

There's a lot of good information in the stereo microscope thread linked up there. Unfortunately, due to moderator practices, it's a jumbled mess, and borderline unintelligible. A "real" microscope costs many thousands of dollars (my friend just bought one for her lab, and I think she said it was something like $300K). The AmScope options in the few hundred dollar range ARE the cheap ones. They're plenty functional for our purposes. Depending on you're location, you might be able to find a used one for cheaper, but without knowing what you're looking at it can be a real crapshoot. The only "cheap" thing you're likely to find is going to be a digital camera thing. They're not the easiest to work with/under, but it can be done. This just isn't a very cheap hobby, I'm afraid...1 point

-

@mikepilk; you are correct That's the way to set the "date setting wheel" correctly. However, I've seen too many broken springs of the date setting wheel due to the fact that the 12-11-12 method was used. I do know that the official Poljot instructions do say that's a quick way to advance the date, but at the time when those instructions were written the world was awash with 3133 spare date setting wheels. Times have changed. The world isn't awash anymore with these setting wheels and I do strongly recommend not to use the 12-11-12 method any longer. The little spring gets supported, and therefor sees less stress, when advancing the date turning the hands clockwise. In the 12-11-12 method the little spring sees a lot of additional bending forces / stress (read additional fatigue) and will break prematurely. The only way to repair is to pull all the hands & the dial. I'm of the opinion that the date mechanism is one of the 3133's weak-points. Best is to wait for the correct date (I'm sure that most of us do have more watches while waiting for the correct date) or advance forwards a few days.1 point

-

1 point

-

Yes the reprint is really nice and it slightly updated from one of the earlier editions.. I used to have a copy but I made a mistake of loading it to my boss who has decided never to return it. Amusingly he wasn't paying attention 100% and has embraced something it's probably in the book which has to do with the centering of the hairspring. So he likes they hairspring not to be centered because of something in the book. Except that also goes against what the book says. Fortunately I have an earlier edition and tomorrow all skin is basically just two pages of important stuff for the regulator pins. Not that the rest of the book isn't really important but there just to sections so they should be easy to scan in as a sample of the book So you can see what it looks like I was thinking because you have all those nice watches. Take the one that is running the worst if there is such a thing and experiment. I was curious if you open the regulator pins all the way with the hairspring centered whether it would still touch the pins? I know if you had a witschi timing machine you can go to frequency mode if you didn't have the regulator pins at all and you did multiposition timekeeping whether that would be a way of telling that you have an actual poising error versus a regulator pin issue? It be interesting experiment to try but probably not on your chronometer grade movements of for you probably may be able to remove the regulator pin assembly as I'm assuming it snaps in the same as the stud? In any case without going so dramatic you could open up the pins and see what happens on both a high and the low amplitude. The good find out what happens if you adjust the centering off so you're on one in versus the other. All the tests have to be done at both a high and the low amplitude. This way can see what the effect of doing all this is I've seen the lower grade and probably one of the manufacturing information sheets specifies what it actually is. The lower grade sapphire is pink in color it's not translucent. To me it looks like they took sapphire dust and somehow made it solid. So it has a nice pink color but not a nice transparent pink. I did look up out of curiosity when Joe asked the question and on the julesborel.com Website They don't have many of the watches from this company but they did have the 200 I was curious as to whether there were any parts specifications differences in other words is there a different pallet fork. B is often times when you look at the parts list you don't actually indicate that the chronometer grade is different. What becomes interesting though on the website is you get a balance wheel complete for $40 and a balance for the abbreviated And are using this words BALANCE, CHRONO Which I really assume means balance chronometer grade that will set you back $10 more. So otherwise if you believe the parts list that would be the only parts difference. At least for the SW200.2209.01.A.1 point

-

Hi friends, I could finally finished the elgin pocket watch. It took me many many days between sourcing the parts and working on the watch jjj. But it's finally done. I put a video together wrapping up the process. Here I'm posting the video and link. Thank you so much to every single one of you who tolerated me along the way. Without your advices I wouldn't have done it.1 point

-

I have 2 Seagulls which have 3 broken cap springs. These are the earlier generation Seagulls where the spring looks similar to the Inca but slides out instead of flipping up. The problem with these is the metal is not 'springy and they have broken. I find this quite common in chinese movements where the design is copied but the metal tech is poor, eg screws, springs etc. Anilv1 point

-

No, you still get whatever magnification there is exclusive of the eyepieces, plus the focus and working distance. The SM- head is 0.7X-4.5X on its own (base model is advertized as 7-45X w/ 10x eyepieces). Barlow does whatever it does for the Barlow you have, and then the camera adapter gets you 2X on top of whatever that is. So, if you have a 0.5X Barlow for the working distance, you'd have 0.7-4.5X at the camera. 4.5X is on the high side of a working loupe. Then, you can yell "ENHANCE!" at your monitor while zooming in and taking advantage of whatever resolution your camera has to take it from there.1 point

-

3 is a screw on back remover. 4 might be for punching holes in leather straps. 6 is a pinnion puller. 7 is a hand puller1 point

-

I know my cleaning regime is quite basic but it does work. I strip everything down to component level, inspect all parts under the microscope to check for wear, pegwood all the jewels and bushes and give a quick hand clean with the cleaning fluid and a paint brush to remove any large deposits, which also extends the life of the main cleaning wash. All parts are then sorted into little baskets which are then put in the jar with the cleaner, this is then cleaned for 10 minutes in the US Elma recommend 10 minutes max for their Elma Red, then it's 10 minutes in the first IPA rinse followed by another 10 in the second IPA. The Ballance and Pallet are cleaned in Essence of Renata. The above routine seems to work well for me with no dirt showing once cleaned. I know some don't like Elma Red because it's water based although the most anything is in it is 10 Minutes and nothing used in a watch is going to rust in 10 minutes. Also if left for longer than 10 minutes and your components have and flakey plating it may remove it for you, but I see that as a positive as it's better to remove it in the wash than have it flake off and jam a movement. It's also cheap and some don't buy cheap out of principal1 point

-

@gbyleveldt won't be able to reply for awhile. He'll be too exhausted winding them up.1 point

-

1 point

-

I love the movement holder, i nearly won one just like it on ebay the other day but my bloody phone crashed at the end. I was rather pissed off about it A nice easy hand one as well to make up for it. Mine has never failed me yet. Oohh pivot drills and holders, roller remover, hand remover, cool looking pliers, a cuddly toy, a teasmade, a and set of matching pans.1 point

-

1 point

-

Many thanks for the welcomes . I've got 4 Smiths mantel clocks and 3 pocket watches. A small collection but have only just taken the plunge with collecting at the beginning of the year after losing my dad. Here's some photos with basic info of what I currently own Photo 1 - Smiths Guildford 8 day Westminster floating balance, about 1962. My best runner. Photo 2 - Smiths 8 day strike (forgot the name), pendulum, about 1952 ish. Runs really well. Photo 3 - Smiths 8 day Westminster, mid to late 1950s. Works fine except the chimes are currently well out of sync. Photo 4 - Smiths Lisbon floating balance 8 day Westminster, early 1960s. Runs too fast and chimes/strikes erratic (one to fix with a donor floating balance unit currently in the post) Photo 5 - 1932 Waltham 16s full hunter in Dennison case & 17j P.S Bartlett grade 1908 movement. Excellent runner. Photo 6 - 1897 Waltham 16s grade 1888 open face with 7j. Runs but stops; think it just needs a clean and service, the balance looks good. Photo 7 - 1919 Elgin grade 463 open face 3/0S 7j. Fantastic little runner.1 point

-

Try heating the arbor instead of the screw, you want it to expand and break the joint.1 point

-

In my engineering days we used to release screw/bolts fitted with loctite or rusted in, by giving the screwhead a tap with a hammer. Maybe try this by putting the barrel with arbor on a metal block, using a wide screwdriver with point dressed to have a flat end and snug fit (but not wedge fit) in screw slot and tap lightly with a hammer. Just a few gentle taps though, nothing heavy or the screwdriver might split the screwhead.1 point

-

Soak in Coca-Cola for 48hrs, be generous with the àmount of Coca- Cola. None of the stuff you mentioned penetrate the screw thread as well.1 point

-

The barrel arbor might have a worn out hole and the last watchmaker used Loctite to secure the screw. I have done it before too. Drip some WD40 on the screw and leave it for a couple of hours. Then using the closed tips of your tweezer to pick up some acetone by capillary action and drip it around the screw to soften any rust or threadlocker. After a couple of minutes, you can try turning the screw very slightly. Be careful that the screw might have a left hand thread, so turn in both directions very slightly and see which direction has more give. I just removed a very badly rusted dial screw using this method this morning.1 point

-

According to a Harley Davidson mechanic that I knew many years ago, "bee's wax has a smaller molecule size than most petroleum based penetrating oils" and therefore should soak into tighter places. I have never tried this but if this is true, used with the soldiering iron trick, it might work. Repeated heating and cooling cycles. Shane1 point

-

That is fantastic! I always thought it would be cool to get a 3D printer….1 point

-

1 point

-

I received this watch in a large assortment of watches and movements about a year or so ago. I assigned very little value to the crushed Lorsa P72 inside, disassembling it just for the practice. The inside of the dial had the outline of the hour wheel and the main plate had the shape of the cannon pinion coind into their respective surfaces. Setting all of the pieces aside for quite some time I finally realized that I already had several replacement main plates for this movement. I settled on this orphaned plate, salvaging the jewels needed from the old plate and reinstalling them into this one. I also found a replacement hour wheel, escape wheel, cannon pinion and crystal from the many piles of used parts that I have been slowly sorting through. Several jewels, even some that I did not have out, needed to be adjusted in and/or out to aquire the requisite end shake, as well as the resulting engagement between one wheel and another within the train. I also needed to recurve the flattened dial to clear the newly installed hand work. As of today, I have been wearing it all week, pre regulation, and it has been consistently running about thirty seconds/day slow with a slight beat error. I will be adjusting the beat error and regulating it this weekend. My first intentions were to replace the dial, center wheel (it lost the second hand arbor when it got crushed) and find a replacement sweep but this ZOMBIE of a watch has been growing on me, as is (shown above). Thanks for looking. Shane1 point

-

1 point

-

A week ago, I measured an ETA 2824-2 housed in a Sinn 556 A watch, and the results were pretty amazing. I published the results in this post. Anyway, this made me reflect more deeply on the performance of Russian watch movements which I appreciate so much, and here follows my reflection. I have always maintained, and I still do, that Russian movements such as Vostok, Poljot, and Raketa are an excellent option for the beginning watch repairer. The reasons for this are several. They are all Swiss in their basic design. That is, they all use the Swiss lever escapement, but compared to Swiss movements like ETA, Sellita, Unitas, etc., they are usually just about a tenth of the cost of their Swiss counterparts when it comes to movements and parts. The beginning watch repairer is essentially bound to make mistakes resulting in lost and damaged parts, but when the cost is counted in cents, rather than in dollars, it doesn’t hurt anything but possibly one’s pride. Add to this those Russian watches can be very fun and cool in their design (like the Vostok Komandirskies) and ingenious in their function (like the Vostok Amphibians) and there’s very little speaking against them. Perhaps best of all is that once you have built up your skills and experience it will basically be no different to take on any Swiss lever escapement movement, like the famous ETA 2824, to name just a single example. So, aren’t there any downsides to these Russian calibres? Indeed, but not so much for the beginning watch repairer where the overall goal is essentially to be able to take the movement apart, clean it, lubricate it, and assemble it. In those cases, getting the watch to run reasonably well again, without introducing errors is definitely a success and very educational. No, the problem with these Russian movements arises when you have become proficient at servicing and repairing. Why? Because you might be thinking (like I pretty much did), that once you’ve serviced it to (near) perfection, it would perform better than from the factory, but of course, it won’t. So, when putting it on the timing machine its performance will still not show the kind of results that you would usually get from a healthy Swiss movement, and that makes it a lot harder to assess the success of the service. I remember @Endeavor once remarking to me when I was frustrated over a Vostok movement that I was working on, that “a Vostok is not a Rolex”, but the remark passed me by at that time. However, finally, the penny dropped. You might even have burnished the pivots, and adjusted the end shake and side shake to perfection (like I have). Still, the timing machine results are erratic. The rate and amplitude vary in a single position, and the positional errors can be quite dramatic. The reason for this, I would very much suspect, is that the manufacturing of Russian parts is far from perfect. The train wheels might be slightly skewed, the wheel teeth and pinions leaves not perfectly designed, cut, and polished, the staff pivots not equally rounded, the balance wheel rather sloppily poised, and so on. So, in my experience assessing the success or failure of a service/repair on a Swiss movement is generally far less challenging. Nevertheless, these Russian movements can be regulated to be very accurate, provided they’re worn and wound consistently. I’ve had Vostok movements averaging like quartz in accuracy. In this respect, Swiss movements (and high-quality Japanese movements) are much more forgiving. That is if you don’t wind a Swiss movement consistently and/or store it overnight in different positions it won’t affect the timekeeping as much as it would for a Russian movement. So anyway, when you can pick up a 200 meters water resistant brand-new all stainless steel Vostok Amphibian diver watch for less than a $100 I’d say it is still a fantastic option, and eBay is full of these Russian movements and parts for basically next to nothing when compared to their ditto Swiss. In conclusion, Russian watch movements are a great start but don’t expect the precision of Swiss (or Japanese) movements, not even after a perfect service.1 point

-

Sometimes I think what we have ignored and are well capable of doing on this forum is COLLECTIVE WALKTHROUGS. A type of help& advise in which members can choose a project like this 8810, anounce joining, and pledge to work together until completioton. The difference with what we alreday do, would be in collective walkthrough group , each memeber who joins pledges to works as if the project was his own. I think toptime is capable of overhauling a chrono complication or he wouldn't have attempted it, but have run to an issue which he hasn't so far figured out. HOW ABOUT THAT WRT?1 point