Leaderboard

Popular Content

Showing content with the highest reputation on 06/12/22 in all areas

-

Hello All, I’m relatively new to watch restoration and repair. I live in Australia. FWIW, over the past months I’ve been experimenting with approaches to ultrasonic cleaning. I wanted to avoid Naphtha and other volatile organic solvents as much as possible, especially in combination with ultrasound. I found a product manufactured by an Australian chemical company - it’s a sodium metasilicate based powder marketed specifically for water-based ultrasound cleaning of small machinery parts, electronic PCBs and jewellery. It’s economical, odorless and rinses without residue, leaving a nice shine. It removes dried, old lubricant very well without pre-soaking. Here’s my cleaning flow: US with the sodium metasilicate based ultrasound solution Rinse in warm water US Rinse in 99% IPA Hand dry with blower while I inspect the parts. The balance and palate fork I clean by hand in Naptha, with special attention to the pivots. I’ve found pushing and twisting the pivots in to a “magic block” white foam cleaning block/eraser to be effective and gentle on the pivots. This is simple, cost-effective and works well for my hobbyist needs. Watch industry standard cleaning products are expensive to source down here. Just though I’d share. Cheers, John in Tasmania.3 points

-

@Paul80 AmScope sells a DSLR-specific adapter that (based on their photos - the one all the way on the right) seems to use an lens adapter from the proprietary lens mount to a T-mount. I should know later this coming week. According to Wikipedia, C-mount is used on microscopes and for what it's worth, I just measured the tube that drops into the 3rd tube and it does have a female C-mount thread on the top (which would allow a C-mount lens to screw in). I want to mount my camera to the 3rd tube. I have three different camera types with different size sensors. I suspect that the device sold by AmScope to mount a DSLR will have embedded optics to compensate for the flange difference. I have a T-mount to A-mount adapter for my Sony a65. I had purchased it to mount my Sony to my Meade EXT telescope. I also needed an intermediate from Meade to connect to the lens mount adapter. I had thought that possibly what I already had for the telescope would work for the microscope (it still might). I can return the camera mount if it doesn't work out. Will report back after the rest of the stuff arrives but man, I'm really excited that I can see depth with the stereo scope despite my left eye problems.2 points

-

I picked up this 1959 Bulova 11ACC on eBay last week for $30. The movement was thoroughly rusted into the caseback--first time I've every used WD40 on a watch. Finally got the movement out of the case--got as much surface rust off the parts as possible (and chipped the intermediate wheel in the process ), cleaned it, straightened the sweep second hand pinion a bit (didn't want to tweek it too much), and reassembled. Keeps +/- single digit time in all positions with pretty good amplitude (270-220). Since I re-used the mainspring, I'm going to call it a win and move on to getting the case/dial and hands in order.2 points

-

It is stamped letter A type, the framed 2 letters code came later. It's a very common regular case type. Front loaders watches have the dial wider than the case opening, which doesn't happen here.2 points

-

That’s a sharp piece for sure! I authenticate and purchase luxury time pieces for a living, and am an avid collector, and while my qualifications apply mostly to other types, this watch’s rotor could very well be engraved and not be visible since the photos is so poor. meaning, many of these watches have the HAMILTON word engraved but bad lighting can hide it EASILY. Making it completely invisible in a photo. also, if the movement were replaced (or just the rotor, etc) and is genuine ETA you are still in good shape. Wait until you get it and can truly inspect. It’s worth the money regardless.2 points

-

2 points

-

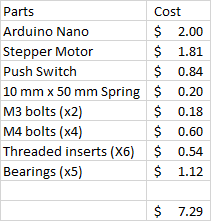

This isn't a watch repair or restoration, but it is watch related, so here goes. While browsing YouTube I stumbled across an interesting 3D printer project for a watch winder. Even though the concept and mechanics were sound, I wasn't too impressed with the aesthetics, and the part that actually holds the watch is ... um ... functional at best. So I did a bit of re-designing. If a picture is worth 1,000 words, a video must be worth at least 1,100. The original video I found ... My modifications. I've already built a few of them and they actually work. The question is if it is worth it, so I broke out the cost. The parts you must buy: (I bought cheap from AliExpress) Parts/Cost Arduino Nano: $2.00 Stepper Motor: $1.81 Push Switch: $0.84 10 mm x 50 mm Spring: $0.20 M3 bolts (x2): $0.18 M4 bolts (x4): $0.60 Threaded inserts (X6): $0.54 Bearings (x5): $1.12 Total: $7.29 The cost to print (based on 1kg of filament costs ~$20 and electricity cost are ~$.06/KWhr) Prints/Cost Bridge: $0.81 Outer/inner rings: $0.99 Mid ring: $0.40 Plate: $0.67 Base: $1.29 Bottom: $0.72 Arm: $0.07 Total: $4.95 So for $12.24 you can keep automatic watches wound.1 point

-

The scope will make life so much easier for you. Great viewing ability and working room capacity. Breakfast in bed for your good lady, a lovely bunch of flowers and a nice evening meal at her favorite restaurant tomorrow and she will forget all about your new toy. Then just keep a cover over it and use it when she goes out with her friends.1 point

-

Have you visited: https://pocketwatchdatabase.com/ I know Elgin, Waltham and Illinois made a lot of watches back in the day. Once you determine the exact movement you might be able to find the same movement on eBay that isn't running for a good price ($20 or $30 bucks if not in the fancy gold case that often made these special).1 point

-

Thanks for the info on the Elgin parts not necessarily being interchangeable. I bought this particular watch to practice on because it was the only one I could source locally (that didn't already run, so cheaper). My grandfather's watch is an Illinois Bunn Special that was made in 1926. I will definitely start looking into the various cleaning methods available to me (I don't have a machine at this point). I will practice on the one I purchased, and ultimately purchase an Illinois pocket watch that I can practice on as well. I plan on doing multiple watches before trying to tackle my grandfather's. I'm looking forward to the journey!1 point

-

So, last night I set up my AmScope SM-3T stereo trinocular microscope and inspected the balance that fell apart on me a week ago as well as the balance of the replacement ST36 movement that arrived the other day. I saw the large blob of glue/epoxy that holds the hairspring to the balance cock on the "new" balance. I inspected the impulse pin on the balance that fell apart and oddly enough it seems to remain firmly fastened however both pallet jewels on the movement that spent a total of 40 minutes in IPA were loose/fell out. I don't believe that the adhesive used to hold the h/s to the cock is shellac since it isn't brown/amber in color. I can't tell what they're using to attach the jewels. It also does not look like shellac although to be honest, there didn't seem to be much evidence that anything was holding the pallet jewels in place other than a friction fit with the fork. I wasn't able to move the impulse jewel despite pushing on it with some force - more than I used on the pallet jewels but I suspect that with all of the other degradation it would probably not be worth assuming that it's OK. I have to say that I'm impressed with the microscope and that I'm able to see depth after all. The scope is rock solid and I'm not worried that it will hold the camera once/if I'm able to use the AmScope adapter (which will hopefully arrive this coming week). My wife didn't seem very happy that I received yet another toy but she has had a 11" Celestron telescope for 20+ years so she was at least interested in peering through the microscope.1 point

-

Many thanks to all of you for your help. The movement is out of the case. I took the bezel off and used crystal lift. It wasn’t easy, it didn’t want to go, I had to use quite a lot of force to get the crystal out but it’s out now and I can get on with the rest.1 point

-

Not that deep. If you want the easy way I would fill it with silver solder, soft solder will wear out in no time. Make sure you burnish it and the inside of the hole. The best way would be to make the whole steel piece, but you need a lathe and mill but you could do it with just a lathe. Depends on your skills.1 point

-

Lol school boy humour the best. You may be right Gary. She doesnt know what shes missing haha. Kiersten my dear you need to revisit and have some fun with us and make a few grumpy old men happy. Haha1 point

-

If @KierstenMata ever comes back and looks at this thread she won't understand how we got so far off in the weeds. We may never see her watch collection...1 point

-

The crown tube keeps the mov.t down in place. It is removed lifting the opposite side, and refitted the reverse way.1 point

-

There seems to be a gap between the crown tube and the movement, difficult to tell from the photos.1 point

-

Looking at the pictures again could it be something as simple as the Crown Tube has been pushed in too far and is touching the movement, something looks amiss about it to me.1 point

-

Hi Iam in agreement with Old Hippy, best wait untill we get a picture of the movement before commiting.1 point

-

Every watch that we service and repair or attempt to repair is practice. It keeps us out of trouble matey, which tbh is something i need. A lot1 point

-

Usually in discussions I ask lots of questions. Which sometimes irritates people who are seeking a quick answers as they just want a quick answer Usual questions would be background history of the watch and why are you servicing it? Often times people are attempting to solve a problem but they're not always clear what the problem is and they don't give us a proper background history of their watch. In other words of we don't get a proper description of what's going on the answer may not actually fit whatever the person thinks are trying to answer. Then the path to having a repaired watch varies from individual to individual and even shops. How about a suggestion? How about another step evaluation of the assembled watch. Like for instance why is your timing machine think it's a snow globe? For instance when the watch was on the timing machine doing it snow globe imitation of what that the watch itself look like? What was the balance wheel doing how did it look? Then one of the downfalls the Chinese timing machine is it lacks audio. Know the beeping sound is not considered audio. Often times when you get no ways and random dots it would be really nice to listen to the watch and see what it sounds like. But to understand your snow globe effect we would need to understand or know what the balance wheel was doing was a running nicely or was a running pathetically? Then as you just got your timing machine timing machines are used for more than just timing a watch their diagnostic tool. You should establish a timing procedure. I like the time my watches and six positions cents dial up dial down and for crown positions. Within the last month or two we had somebody who was very puzzled the watch was perfect on the timing machine but sucked on the wrist that's because they only looked at their watch in one position. Oh I did attach a PDF of things you might find on the timing machine. Timing machines originally had paper tape that came out with dots printed on them know nifty numeric display telling you read amplitude beat EDS got a graphical display. Fortunately the graphical display whether it's a newfangled LCD digital timing machine or in old-fashioned paper tape machine the graphical displays are the same then you should have a timing procedure of? Usually when you're timing a watch you fully wind it up you let it run for about 15 minutes to about an hour it depends on whose literature you look at as to what their definition of fully wound is. But you typically never will time at the way wound tight things will be misleading. Then when you're timing your six positions and rotating microphone allow it to settle about 30 seconds works. Then measure for about 30 seconds Timing-Machine-Charts.PDF1 point

-

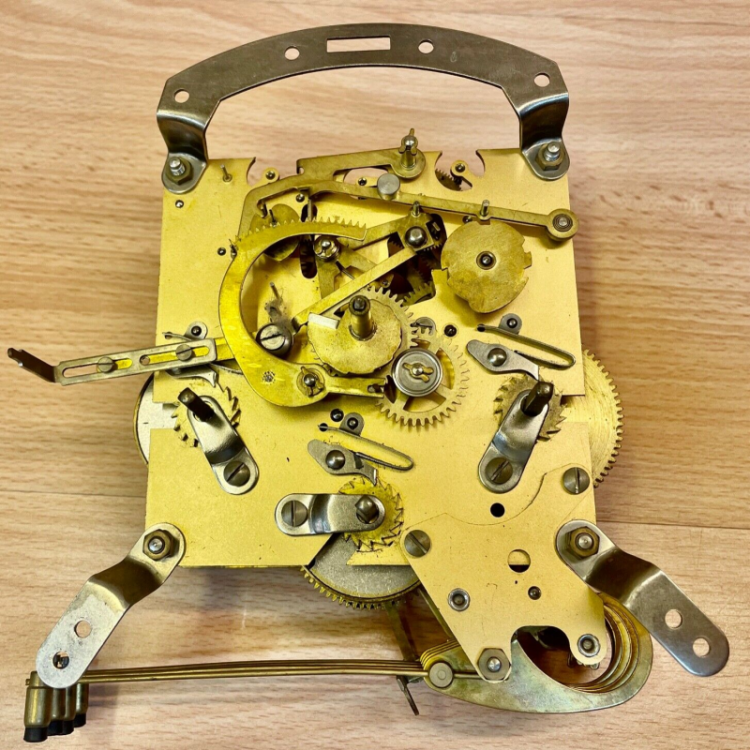

With out seeing the movement I can't really say. Its a strike, that top doesn't look right it looks more like the sort of thing you see on those German wall clocks which many confuse them with the proper Vienna wall clocks. Take that off and the case looks right. Here is an example of the type of German wall clock.1 point

-

1 point

-

We use a very fine steel wire for cleaning the spray orifices of our dental drills. Always wondered where to get those wire until I found out recently. They were acupuncture needles! The thinnest ones are 0.16mm. That is about the diameter of the pivots.1 point

-

1 point

-

I found the photos looking up the case number in the www. Unfortunately I couldn‘t find any hints concerning the disassembly. It can be seen that there is no letter on the case back indicating the construction type. Your photos let me think that the bezel could be pried off. Have you tried that? I don’t think it’s a front loader. But if the crystal is off you can carefully push the movement from the front side.1 point

-

The movement shouldn't be able to move just by loosening the dial feet screws, the dial feet should stop it moving, if you can move the movement independent to the dial the feet must be broken so glue may be involved to stop the dial moving, if the dial is glued then the movement will not come out because the hands are in the way, you may get lucky removing the bezel but it my just be cosmetic with the crystal still attached to the case. I suppose you could try refitting the back and using compressed are through the winding stem hole to pop the crystal out, provided you have access to compressed air, it can be done with a large syringe but I have only seen that work on a case were the crystal was designed to pop out, ie with a front loader.1 point

-

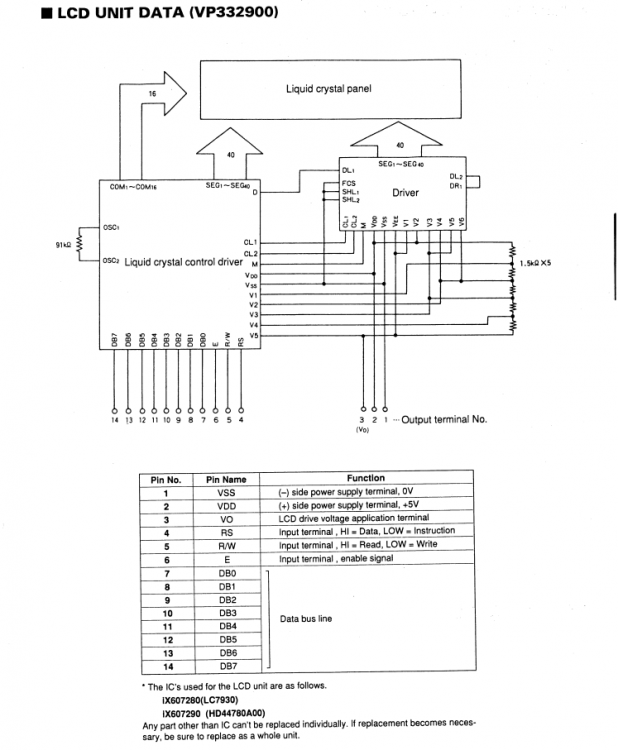

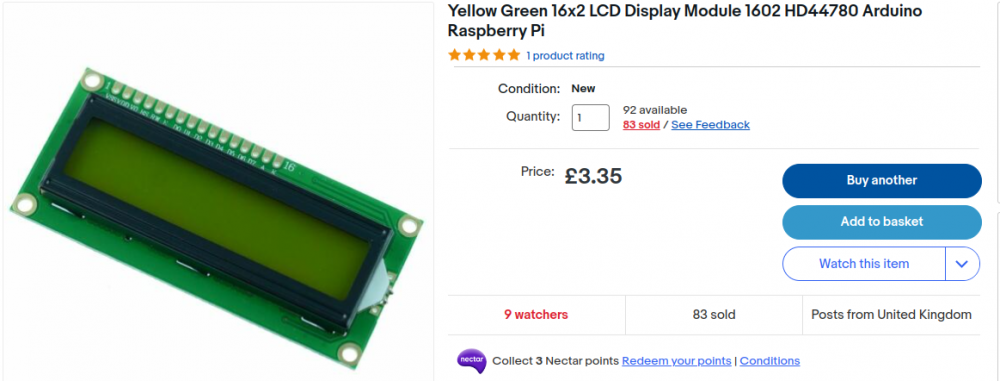

That was my though too. There is often also a CFL driver board which may have failed. I'll need to dig in to the manual. It is highly likely that I can replace the backlight with LEDs or even replace the entire display as it looks like a generic two line dot matrix LCD, which were common around that time. It is also possible that the thing is actually dead, and only the power light is coming on. However, armed with the full service manual, I feel my chances of success are reasonable. EDIT: @gbyleveldt I was curious to know what the display was, so I looked it up in the Service manual. It turns out they have used a Hitachi HD44780A00 which is good to know, as I can almost certainly replace the whole thing if needs be, or hopefully I can take it apart and fix the backlight. It may even use a filament bulb, since the display is relatively small, so a fluorescent backlight might be overkill. However since they are ubiquitous and cheap as chips, I picked up a generic "cheap from China" replacement, just in case. I'll need to check the backlight voltage (Pins 15 and 16, not shown in diagram above) as if it uses an EL or CFL light, or a 12v filament I may need to improvise. I'm sure I can use it for some other project if I don't need it for this.1 point

-

Nice watch VW, I’m a sucker for field watches and a Khaki is the epitome of that. Even if it turns out to have a swapped movement you still have a very nice piece there1 point

-

As you're just starting out your unlikely to have the proper supplies? A old balance staff works. Or in my case I have an assortment of miscellaneous staffs so I just found one of the suitable size and I use that or the item in the picture depends on the watch. Description is never quite right. This is basically the tip that goes on a handle but I gave up using the handle because end up bumping the wire in the something in a break so it's easier just to have the little piece to hold onto as the oil cups I have our individual and it has a rim I just place it in the realm of the oil cup so I know where they are. Then the pictures really nice and big because this thing is only about 2 1/2 mm long it's not very big it's really tiny. But it does work really well for getting the oil in.1 point

-

1 point

-

It seems to flow through fairly well, but likey will be better with larger and more holes through each section. Ideally i want to create more turbulance as once the fluid reaches the same speed as the basket that does reduce that effect as there is no backwards and forward motion. So i was thinking some extra material in there to agitate things up or and offset the spindle just enough to give a slight wobble of the basket without causing excessive wear on either the drill or the basket mount. Problem is the compartmentation wont allow the material to pass through each section and will probably block the holes also Thats why the basket insert with no sections, but didnt want the mesh baskets to bang around too much and also potentially damage bridges and cocks that wont fit in the mesh baskets. Agitation material ball bearings ? Possibly too heavy and may damage unprotected parts so soft airgun shot?. Again after a few mins all this and the fluid would reach the same speed. Enter MK II made from a cake mixer that spins on two seperate axis, one around the other which should agitate much better and also has a good range of variable speed. Figuring out how to mount the spindle will be a bit more difficult and may involve some welding though.1 point

-

your timing machine is definitely telling you something you have a definite problem. Brand-new movement what exactly does that mean? In other words you newly acquired a movement that was 100 years old in desperate need of servicing? The reason I joke about that is people purchase new old stock basically or movements that are new but conceivably their old. Some movements from some factories will come in little sealed packets or at least they ward exposed to the air for the last unknown quantity of years then it would be helpful to have something beyond the word Seiko like a model number a caliber number of be helpful? Then can you manually wind the watch up? Then yes even the Seiko is that you cannot wind from the stem you the wind from the ratchet wheel also the minor flaw of the Chinese timing machines are they do not actually have audio they have a horrible beeping sound. If you hold the watch close to your ear and listen to it how does it sound? This is where oftentimes listening to the audio you can hear things that sound undesirable and that tells you why it looks horrible on your timing machine. then it would be nice to have a picture of the movement on the timing machine just because I want to see how you're actually holding it. also if you move it around to a variety of positions like dial-up and then dial down and perhaps crown down allowing like 30 seconds between rotating the microphone do all of them look like this?1 point

-

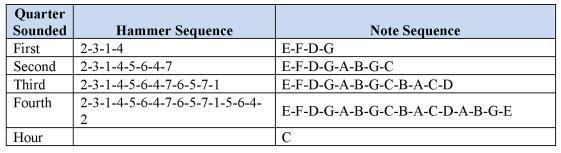

Hi this book contains a lot of useful material apertaining to clocks and watches. chapter 18 ( page 134 for chiming clocks.) If what you have quoted is one continious chime its not locking and the first quarter is a round of one round 2nd is two rounds 3rd is three hour is four followed by the hour strike as per OH's chart handbook_of_watch_and_clock_repairsa.pdf1 point

-

1 point

-

1 point

-

An SARB065. Can't wait as this is a beautiful dress watch Sent from my iPhone using Tapatalk1 point