Leaderboard

Popular Content

Showing content with the highest reputation on 06/11/22 in all areas

-

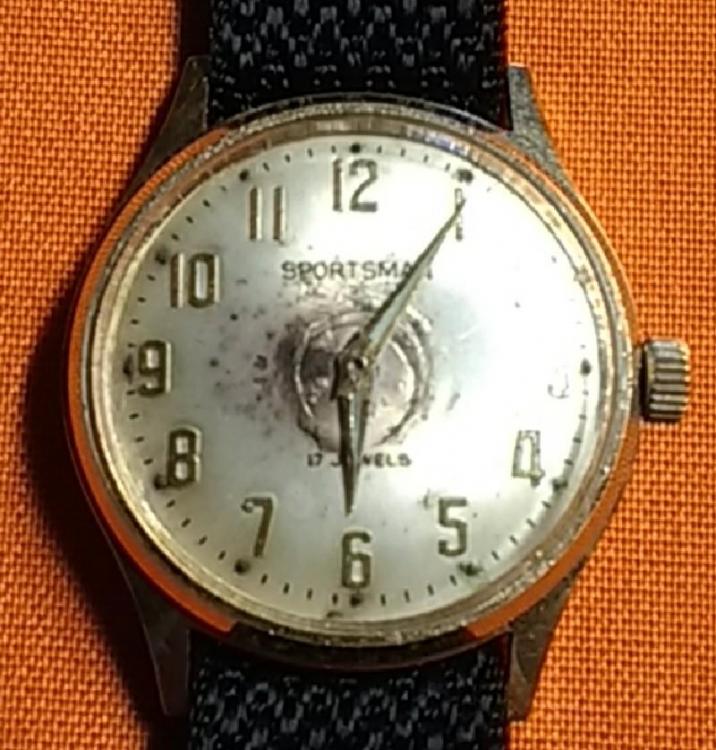

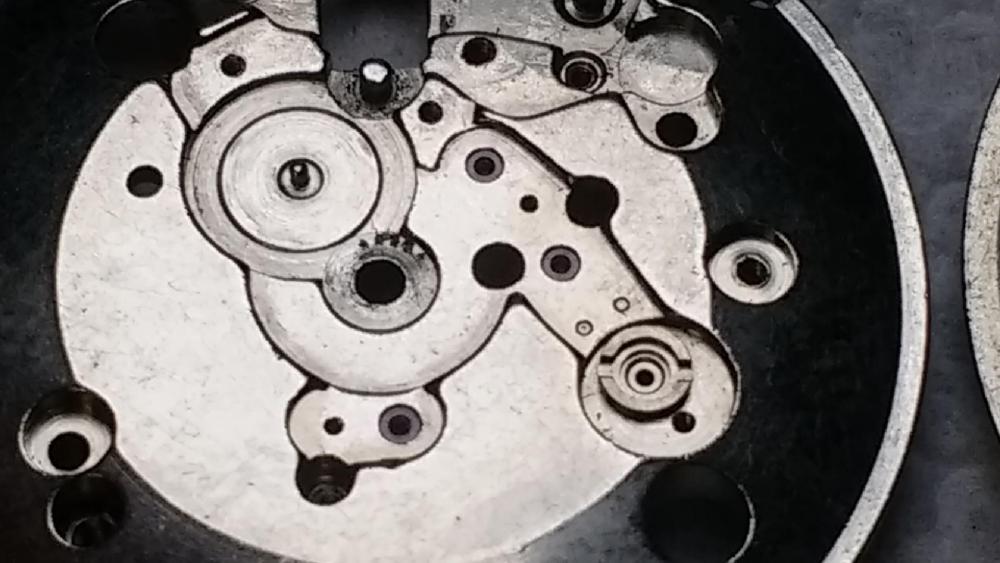

I received this watch in a large assortment of watches and movements about a year or so ago. I assigned very little value to the crushed Lorsa P72 inside, disassembling it just for the practice. The inside of the dial had the outline of the hour wheel and the main plate had the shape of the cannon pinion coind into their respective surfaces. Setting all of the pieces aside for quite some time I finally realized that I already had several replacement main plates for this movement. I settled on this orphaned plate, salvaging the jewels needed from the old plate and reinstalling them into this one. I also found a replacement hour wheel, escape wheel, cannon pinion and crystal from the many piles of used parts that I have been slowly sorting through. Several jewels, even some that I did not have out, needed to be adjusted in and/or out to aquire the requisite end shake, as well as the resulting engagement between one wheel and another within the train. I also needed to recurve the flattened dial to clear the newly installed hand work. As of today, I have been wearing it all week, pre regulation, and it has been consistently running about thirty seconds/day slow with a slight beat error. I will be adjusting the beat error and regulating it this weekend. My first intentions were to replace the dial, center wheel (it lost the second hand arbor when it got crushed) and find a replacement sweep but this ZOMBIE of a watch has been growing on me, as is (shown above). Thanks for looking. Shane4 points

-

If you look at the documentation that eta has they show it as being pure visual. The only thing they don't quite explain is You open up so you can center the hairspring between the pins but in the document I was looking at they don't explain when you close it just how close you want to go to the hairspring? Then down below I have a link to a book explains how to adjust your watch. You will note they're not using a timing machine they hadn't been invented yet So it's going to take a little bit longer to regulate your watch. Then a PDF extracted from a magazine you might find that of more interest. Then in case the name of the author is not familiar with or to you. He worked his way through the Elgin company becoming the head of research. The watch adjuster's manual [microform] : being a practical guide for the watch and chronometer adjuster in making, springing, timing and adjusting for isochronism, positions and temperatures by Fritts, Charles Edgar https://archive.org/details/cihm_03260 1946-08-HIA-OCR pages 9 to 13 poise Challacombe.pdf3 points

-

2 points

-

Yes, don't fill the cups- but you can oil them with the caps assembled by oiling the cup, then feeding the oil through with a fine pin, it will pull in and suck against the cap jewel by capillarity. Check that you have oil on the cap 1/2 to 2/3 of its surface. This is standard technique for non-shock (screwed together) jewel assemblies. Normally the hole jewel is convex when used with a cap jewel, this keeps the oil centered. Cheaper watches with caps will often have flat hole jewels working with flat caps- and the oil tends to run away. Bulova was high quality- the cap is convex where it faces the hole jewel; this does the same as a convex hole jewel.2 points

-

I don’t think so, because Seiko 5 construction "rules" do not allow that, but you need to post pictures from the top and side to tell. Also, on Seiko there is a framed code on the caseback which indicates the construction type.2 points

-

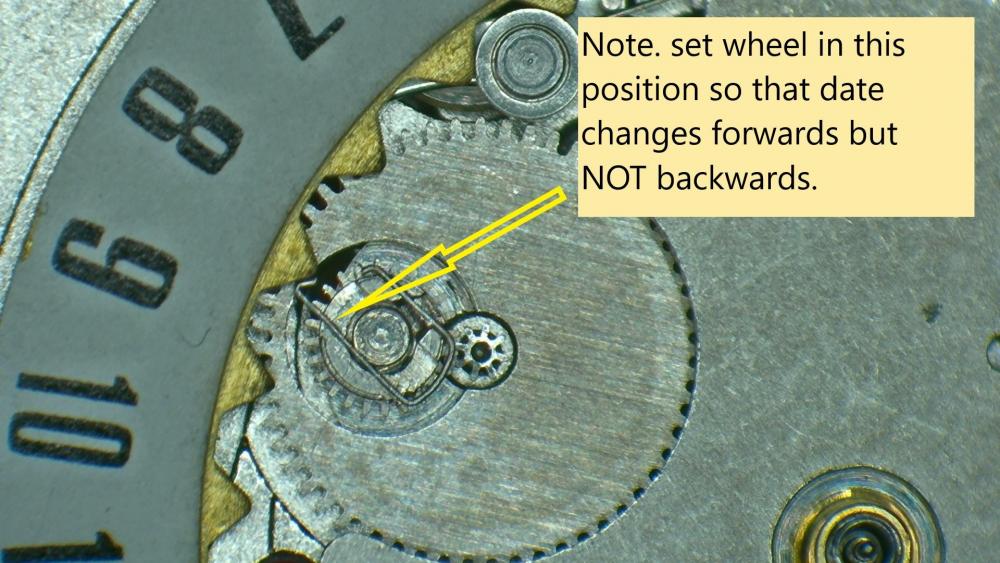

I just finished putting my watch back together, but the quick date setting technique would not work - change from 12-11-12 should advance the date. Once mine had advanced the date, turning the time back to 11 would turn the date back also. What I discovered is that the date setting wheel has to be in a particular position to work properly. The tab on the wheel needs to start pushing slightly past the centre of the wheel, as in the pic - I just turned the small wheel one tooth on the fixed central pinion, and it worked2 points

-

Hello all, new here. I’m in central Florida. My dad got me into collecting vintage watches a few years ago. After spending a pretty penny on having his repair guy do the work for me, I decided about a year and a half ago to start working on my own watches myself. I’ve gradually learned a lot, going from tearing apart a movement without knowing a thing, getting my first movement running again a few months later, and now doing fairly well on most watches I service. I know I have lots to learn still, and many questions I post may seem quite beginner like, so I apologize in advance. I’m completely self taught, only seeking advice from 2 horologists via email now and then who are kind enough to answer questions when I have them. But now I’d like to branch out and get the opinions of others. Thanks in advance!1 point

-

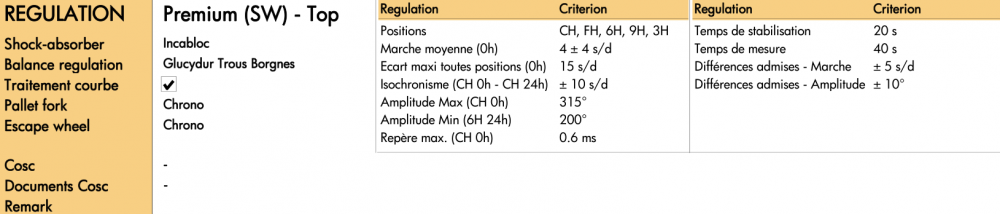

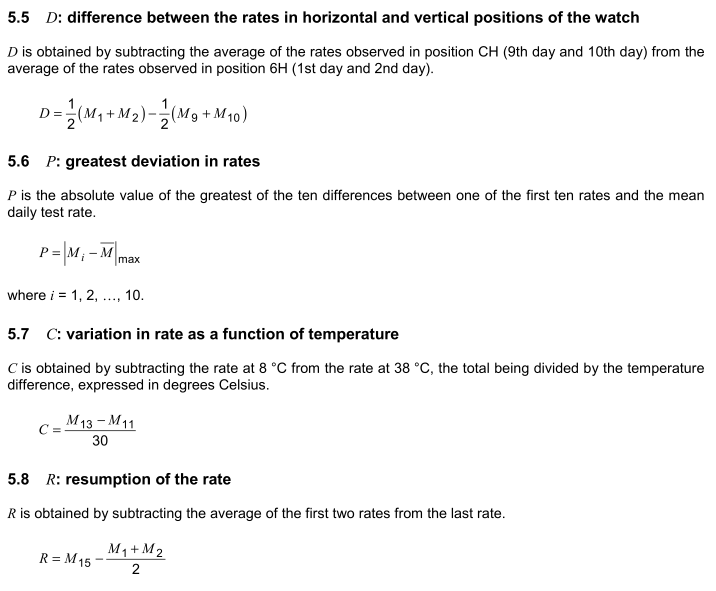

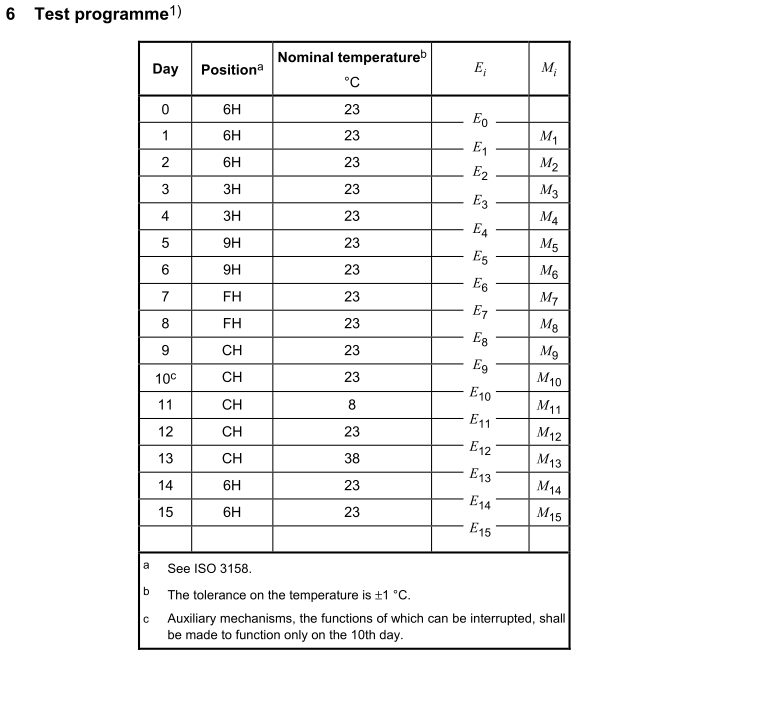

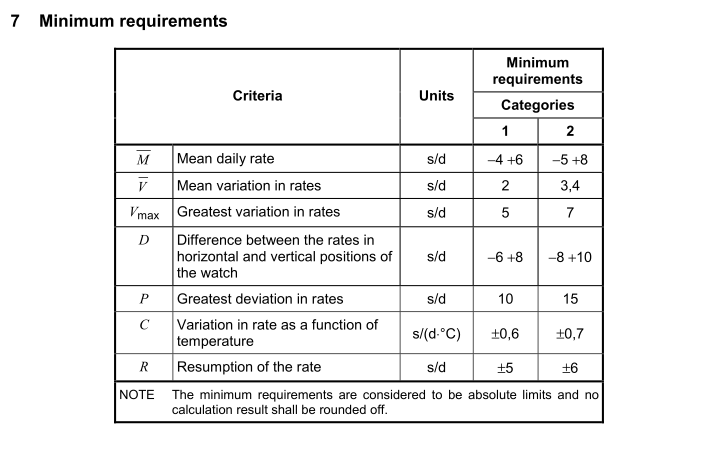

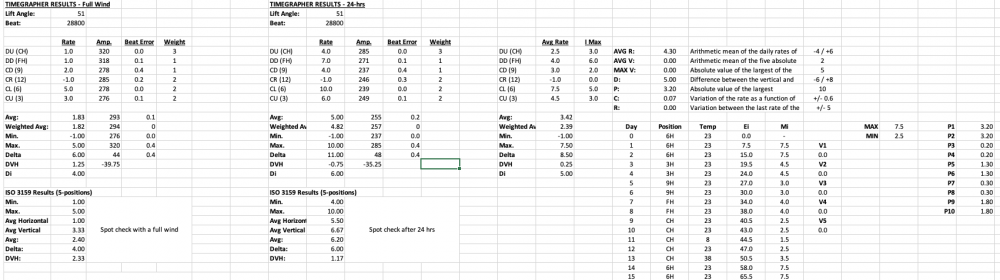

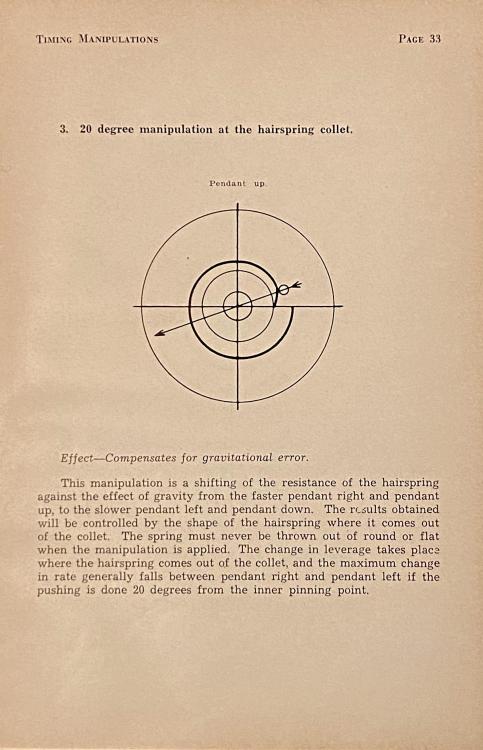

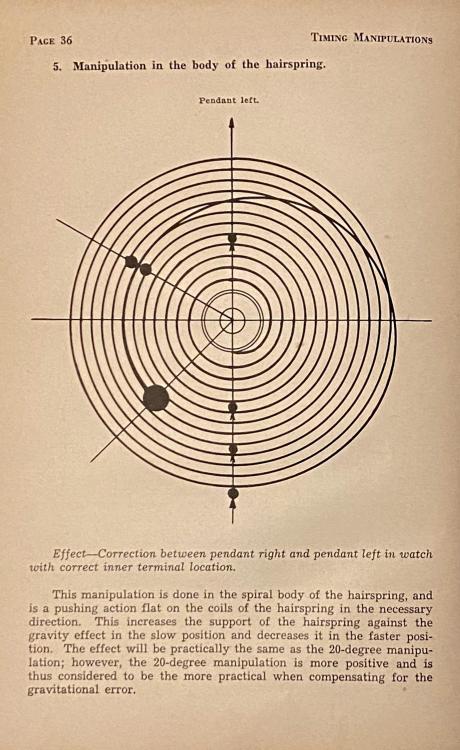

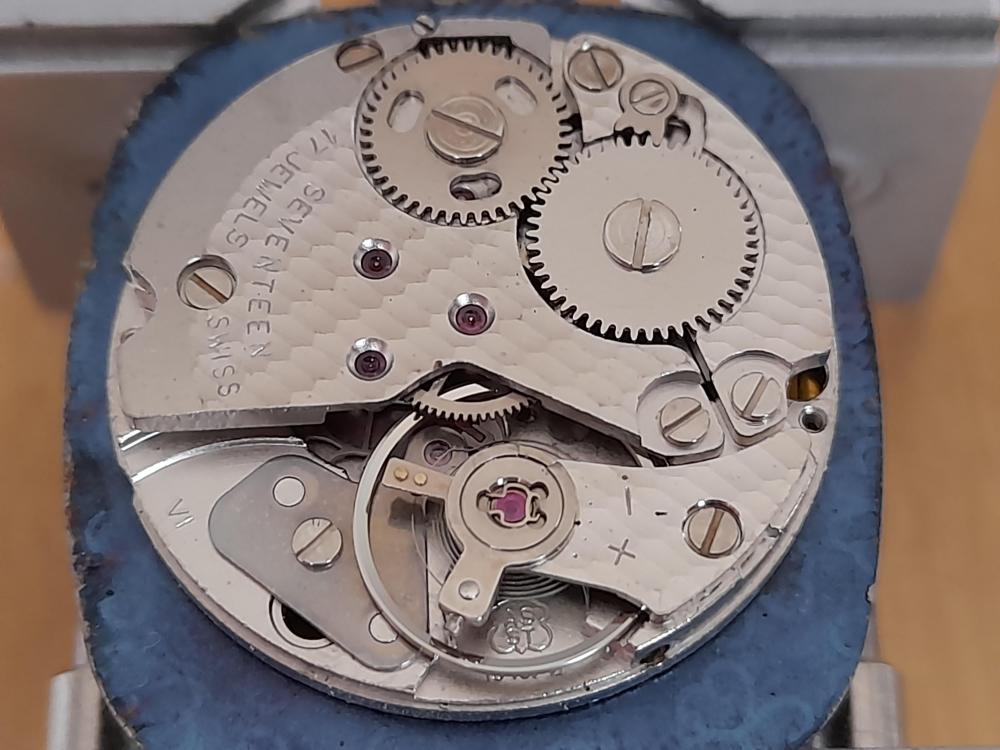

Precision adjustment for isochronism and positional error, so what's the question? First, the landscape of what I'm working on. I have a number of Sellita SW300-1 movements, Premium (Top) grade execution with chronometer grade pallet fork, escape wheel, and 5-position regulation to +/-4 s/d. Attached is the technical cut sheet for reference. I am working on fine tuning the adjustment of these movements in preparation to undergo chronometer certification, ISO3159 testing. For reference, the testing protocols: Out of the box, the movements are very good. In fact, as an automatic movement that will maintain a near full power reserve over the course of a day while wearing, these will perform exceptionally well. I have been using an MTG-9900A to test each movement at full wind and half wind with a 6-position 20-second stabilization and 40-second timing period protocol. With these numbers, I am capturing the instantaneous rates at 0 and 24, determining the average beat rate for each position, the isochronism for each position, and able to use these numbers to predict the approximate performance when the movement undergoes ISO3159 testing protocol. Here's an example of my data: So what's bugging me? Like I said, I'm very satisfied with the performance of this movement. On the wrist, it will time very good. Even undergoing ISO3159, it appears it will pass. To give myself some margin of error, I should slow the average rate down 1.5 s/d using the average rate between 0 and 24. Why? Because the test is 24hrs in each position so isochronism matters even though the reality of wearing an automatic doesn't matter as much. What's bothering me is the positional error between 6H and 12H. At full wind it is a 6-sec delta, at half wind that is exacerbated to an 11-sec delta. Because of the relative consistency between the other positions this suggests to me the balance needs dynamic poising or inherent to the design of an SW300-1 is a gravitational issue. Keep in mind these are factory fresh, top grade movements that, and I confirmed with Sellita, have been dynamically poised in factory. I will test out the theory of dynamic poising to eliminate the delta between 6H and 12H. But should the issue persist (and I think it will since I am seeing this delta on a number of the movements), I believe it is likely a center of gravity issue with the hairspring. Finally arriving at my question, how do you modify the hairspring to shift the center of gravity? Looking at Hmilton's book on hairspring manipulations, he recommends a slight tweak to the hairspring at the collet pinning point. However, the SW300-1 collet and pinning design simply does not allow for one to access the start of the coil in the same way it is accessible in a vintage movement. His next advice is to adjust the coil at the other pinning point. But his example is an overcoil, not a flat hairspring. How would I go about making a gravitational adjustment to the flat hairspring at the outer pinning point? And in doing so, how to I determine the direction of the manipulation, eg. opening the arc moves the center down, etc? Perhaps the question is moot considering the movements will wear well, the issue is an error between 6H and 12H and since 12H is not factored into ISO3159, maybe it's all a moot point. In any event, I'd still like to learn more about these kinds of precision adjustments to compensate for very small changes to increase the accuracy of a movement. Brochure_technique-SW300-1_2.pdf1 point

-

1 point

-

https://www.cousinsuk.com/product/oilers-3-in-1-incabloc-specialist You could get one of these. I just took an old broken oiler and sharpened the tip until it was fine enough. The jewels that you are oiling are from the gear train and the pivots are not as fine as balance wheel pivots. So the jewel holes should be bigger. Probably a sewing needle would be able to do the job.1 point

-

Hi. If it's like all of my Seiko 5's then it should just drop out the back but sometimes the thin plastic dial spacer you noticed is a bit of a fiddle to keep in place, especially if it's cracked and some watch rebuilders use glue, and it the use too much glue it can stick the ring, dial and movement to the case, I wonder if this is what's happened with yours, might just need a touch of brute force and ignorance to break the glues grip, should just need a slight twist of the movement to break it's grip on the case.1 point

-

I once cut a golf ball open in someone's bedroom to see what it was made of. When I hit the centre, brown goo squirted out all over the ceiling and walls. Oops.1 point

-

Hi try using a soldering Iron tip to apply the heat its more constant. check mits not a LH thread also, most are RH but wirth a check.1 point

-

Ahh yes - from experience I learned what was going to fly out across the room, and quickly taught myself how to NOT do that again1 point

-

Working on all of those watches? I wish my recent purchases were for that amount...1 point

-

I have been to Vienna it is a wonderful place but I wouldn't want to live there it is so vast and noisy. I like the peace and quiet. I would love to live in Austria in the Salzkammergut which is a long way from Vienna.1 point

-

1 point

-

Remove the bezel and see what happens. If it doesn't come out seek more advice.1 point

-

Hi A couple of documents regarding lubrication. good advice already received nothing to add. BTI-The_Practical_Lubrication_of_Clocks_and_Watches (1).pdf Moebius Oil_Chart.pdf1 point

-

Quite possible it comes out the front of the case after removing the bezel, But as jdm remarked we nee pictures from front and sides and back.1 point

-

@Nucejoe gave a pretty detailed step-by-step in this thread for re-securing the hs with epoxy. I'm planning to give it a shot.1 point

-

As HectorLooi said: don‘t fill the cups on the underside with oil. These cups are good for guiding the pivots into the holes when mounting the bridge.1 point

-

Are you refering to the 3 jewels on the train bridge with the Bulova mark? Those are ordinary hole jewels. The oil cups as you call them are not meant to filled to the brim, like a reservoir. You just need enough oil around the pivot to form a meniscus. It's a bit hard to see with low power loupes. I didn't really understand the correct amount of oil to use initially until I started using my microscope.1 point

-

Try a search on that design rich. I have a few different types totalling around 15. They often dont fit so i end up hand winding, which i dont mind as I’m very careful and have a simple little diy gadget that helps me with that. After a few practices with old springs i managed to get the technique down and it seems to work ok and the amplitude on whatever im working on seems reasonable for my self forced standards. I like things to be running well but try my best not to be pedantic about it, which is something i have to be careful about as i can be quite obsessive and my ocd will take over and screw my brain up big time, and lets face it i have enough going on in there as it is.1 point

-

1 point

-

It's 100% wrong to static poise with the roller off.1 point

-

Don't run away, I need all the advice I can get. Often it better to question someone rather than give them answers.1 point

-

Why? Do you think that components made by a 3D printer lack strength? Having worked for a high-tech automation manufacturer I can attest to the fact that 3D printed parts work just fine and for prototyping and/or building a one-of-a-kind, they are quite economic. OK, I agree with you on this, let's face it: 3D printed parts look cheesy and why make a 3D printed box for watches costing thousands? I hand wind my IWC each evening. It's the only automatic I own and I rarely wear it these days. I have always felt that watch winders were a bit of a stretch. I'm also curious why somebody with no previous interaction on this forum would choose to comment on a year-old thread on a DIY watch winder. So, Kiersten, please come back and introduce yourself and (at least) post a photo of your collection. It sounds like something we'd all like to see.1 point

-

Wow brains, class and beauty. Where did you come from ? We are all eagerly waiting an introduction Kiersten ! Ok Kiersten, we're going to need some details regarding what you are all about with watches. Evidently a luxury collector but what else ? Is there any repairing ability inside you or are you just going to make us grumpy old men jealous over your collection. Spill sweetheart, spill please1 point

-

Do your research on the tg rich. Knowing how the tg works and what the tg can and can't do will help you to understand how you can diagnose issues. No offense meant John, your words just sometimes comes across as a little harsh and until someone gets to know you, this can be misunderstood as I did. I know you are a kind soul otherwise you wouldn't be so helpful which I know you enjoy doing. Keep doing what you're doing you are a truly valued member and are held in high regard by everyone that knows you. Your advice is welcomed by newbies as well but sometimes above what a beginner can understand. No hard feelings John x1 point

-

No cleaning may not fix the issues, so I will disassemble, inspect each part, clean, re-inspect each part, reassemble. Put back on the timegrapher and if the results aren't reasonable, seek advice. I'm a relative newbie, servicing is one thing, fault diagnosis is another level. The prayer bit was a joke, I'm an atheist, no disrespect to religious people.1 point

-

Service it and say a prayer even though I'm not religious. It's actually running so yes a service, back on the machine and observer the results. Hopefully even if it's not running well, it will be running good enough to narrow down any issues.1 point

-

1 point

-

1 point

-

Welcome David! I haven't started looking at yard sales but you seem to be doing well. There is a lot of good information here for a new person who wants to start working on watches. Just ask!1 point

-

Just looked it up. I had to convert pounds to dollars first to find a calculator, and that worked out to $5.01. The 2020 equivalent would be $5.59 or £4.51. HTTP status code 451 is.... (drumroll) "Unavailable for legal reasons"! Pretty funny since a major source of 404s was Russia, and that's a very 451 situation at the moment! I dunno... What does the group say? Bearing in mind, upping the limit is a slippery slope, but it's definitely hard to ignore the macroeconomic realities of the situation... The low limit is 100% part of the challenge... It's what makes it fun, and what makes those victories all the more exciting... Is £0.51 worth the precedent? It's rare for inflation to back track, and when it does, it's rarely much. The next step is a 500 server error, but there are no steps after that... And when we get to 700, there's the risk of being confused with a group of religious nutjobs! I don't know. Maybe a £0.50 interval makes sense... Hmm....1 point

-

Thanks guys! This kind of discussion is why I come here. Absolutely fascinating!1 point

-

... and it has to go up to 11 I also bid on another Denon HiFi separate, this time a tuner. To be specific, a Denon TU-260L II AM/FM tuner, which I picked up for eight quit. I wonder if I can build a complete "Audiophile grade" system from the bargain lots on ebay.1 point

-

Ok so I'm a bit gutted I've just worked out my latest acquisition from ebay. 83 quid for 17 pocket watches. Which calculates to £4.88 each and not the required 404. Gutted I've not made the mark but very pleased with my purchase. Which includes 6 Ingersol not inc. the boxed one this was a seperate purchase at yesterdays carboot hunt. A kienzle, a cimier, a westclox, an excelsa, a french chronometre, 5 unnamed 4 of which are silver inc. 2 ladies, and a brass full hunter. Some of these ive not been able to get in the back as yet. This comes from the man that wasnt particularly interested in pocket watches that now has a total of 20. Hence Neverenoughwatches, which i may now have to change to neverenoughwatchesandpocketwatches.1 point

-

1 point

-

Congrats on your achievement! Great to see you progressing on your horological journey - can’t wait to hear about what you accomplish next!1 point

-

I meant the scope gets your working head height at a comfortable position relative to a normal bench height, rather than needing to bring the work surface up high enough to not cause neck injury. I went the opposite direction in my shop by cutting the legs off an already short stool to bring my head down to bench height rather than the other way around. It's not as comfortable for my legs, but was an inexpensive trial of the work height adjustment, and my toddler will get plenty of use out of it if I don't. Since I got my scope, I haven't used the stool for anything more than a foot rest.1 point

-

Not so much what's coming but what's arrived. I feel very lucky to win these two. Especially the Timex 100, lovely blue face. I didn't know Timex used a swiss movement back in 1975. Was it a short lived thing, or was this a more expensive Timex back then? Sadly it's not running very well, looking forward to finding out why. Couldn't wait to have a peek inside so posted a couple pictures too.1 point

-

I have been informed by the makers of the software of this board that sign-in with Display Name is very bad from a security perspective and this does seem logical so I have disabled it. Before you could choose to use either your Display Name or your Email Address. From now on, sign-in is only available using your Email Address which you signed up with. Your password is not affected. If you have forgotten your password then you can, of course, use the "Forgot Password" feature to reset it. Further to this, I have disabled the ability to sign in with Social Media apps such as Twitter and Facebook due to the constant battle with their respective changes in policy and requirements, I just don't have time to keep up with them which leads to website errors and a poor experience overall.1 point