Leaderboard

Popular Content

Showing content with the highest reputation on 06/06/22 in all areas

-

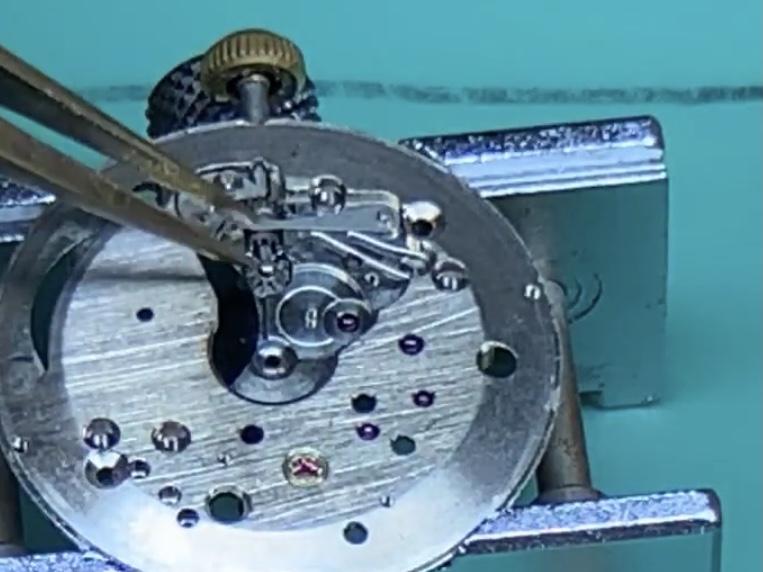

Epoxy five works but how you apply it and your approch greatly affectes the outcome. To keep the coil perfectly level and unstressed, do as following. 1-Install the balance complete on the mainplate and the cock as normal ( no other part on the mainplate) 2- Fill the stud slot with glue, you can put a bit of glue on tip of a screwdriver and apply it to the slot. 3- Turn the balance to bring the end of the spring near the stud slot and slide its end into the slot. 4- Place the whole assembly cock down on bench. ( cock down because the glue then wont get on the spring in case any of it drips down before it hardens) Let the glue dry . you will have a perfectly level and unstressed coil. The reason you want the balance complete and cock installed as the glue hardens , is because glue hardens around the spring when the spring is level so no need to try leveling the coil after glue hardens. I have done this at least a hundered times, I gurantee you be surprised to see a perfectly level coil Once dried you can scrape off any glue that might have run out of the stud slot. A clean in mineral spirit and quick dip in ISP or one dip. Done. Good luck pal4 points

-

I am retired and like fiddling. A friend asked if I could look at his great uncles pocket watch (1917 Elgin) and the saga began. I watched YouTube videos and became an overnight expert. Not really but it sounds good. I like working on them and have started amassing tools. I have repaired several, not the old Elgin yet, but have identified most of it’s issues. Currently working on a Bulova A-11.3 points

-

2 points

-

I mean... if stereoscopic vision isn't in the cards for you no matter what, the relative angle of the lenses on an optivisor or similar won't really matter. You might even be able to get away with a digital scope. All the benefits of magnification, easy image capture, and comfortable seating position without the drawback of the lack of depth perception (since it is not reconcilable). Plus, extra bonus: those dudes are cheap and plentiful.2 points

-

In principle you need a gear train that is connected to the barrel wheel as well as to the ratchet wheel. Turning the ratchet wheel lets the indicator hand move up and turning the barrel wheel lets it go down. What you want to be indicated is the „differential“ between ratchet and barrel rotations. Often a so called „differential gear“ does the job. It looks like a differential in a car drive train. But it‘s important to know that there are several very different setups for this differential function. https://loupiosity.com/2013/12/uncomplicate-complications-power-reserve/2 points

-

I keep thinking that I am proficient at serving until that oops moment happens. I'm still having mishaps but that magic moment when the balance springs to life makes it all worth it. I tend to get bored of the things I'm good at, still plenty to learn about watch repair.2 points

-

In the ‘90s I purchased a brand new alarm wrist watch for just around DM40,- (€20,-). Inside I found the Russion version of the well known AS 1475. Unfortunalely the square hole in the ratchet wheel (alarm spring) was stamped that much out of center that the winding wheel fell out of engagement each turn Nevertheless I like Russion watches due to their priceworthiness and Swiss based design. After the „iron courtain“ had dropped in 1990 I could buy brand new Russion watches and chronographs for nearly nothing at flee markets in Berlin. At that time I had to spend much more money for srewdrivers, tweezers, case openers and oil to do my first steps in watch making.2 points

-

Also check your pallet stones. Shellac is often used to fasten the stones. Alcohol dissolves shellac.2 points

-

2 points

-

I got it!!!!! After hours of futzing, I now have a functional keyless works. The yoke spring and yoke were in their proper orientation. The watch stem was true and nothing was worn. Thanks to all who contributed! I tweaked the setting lever spring a tiny bit, maybe not even noticeable, but who knows? But the real trick was to use pegwood to hold down the yoke while and after positioning it in the sliding clutch. Before proceeding, I screwed down the set lever screw. Then I tightened the setting lever spring screw, the pegwood pressed down so the yoke wouldn't move. The more I do this the more I see shortcomings in watch designs. Now on to the pallet fork and balance wheel and I'll be done with my first ever service of a watch.2 points

-

I was inspired by a post on the Watch Repair Lessons Facebook group showing a DIY watch bench. It's using a 62" Husky adjustable height desk with some added rails along the back and sides and a Vyco table mat on the desktop. My old setup was so cramped and jumbled together and now after getting rid of my old office desk, I have a lot more room to work and I can adjust the height of the desk to ideal. I'll eventually be adding some more drawers/tables along the sides for storage. It was (somewhat) cost effective with the desk costing $199 (on sale), the Vyco mat $75 (free shipping), and the rails just some pine from my local lumber yard for $14.1 point

-

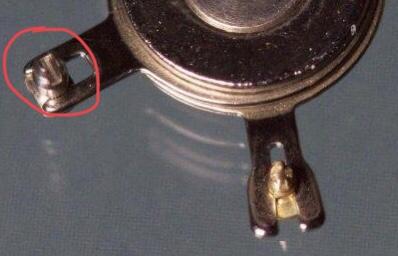

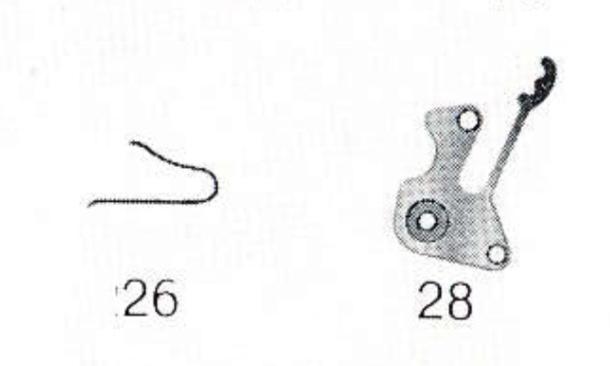

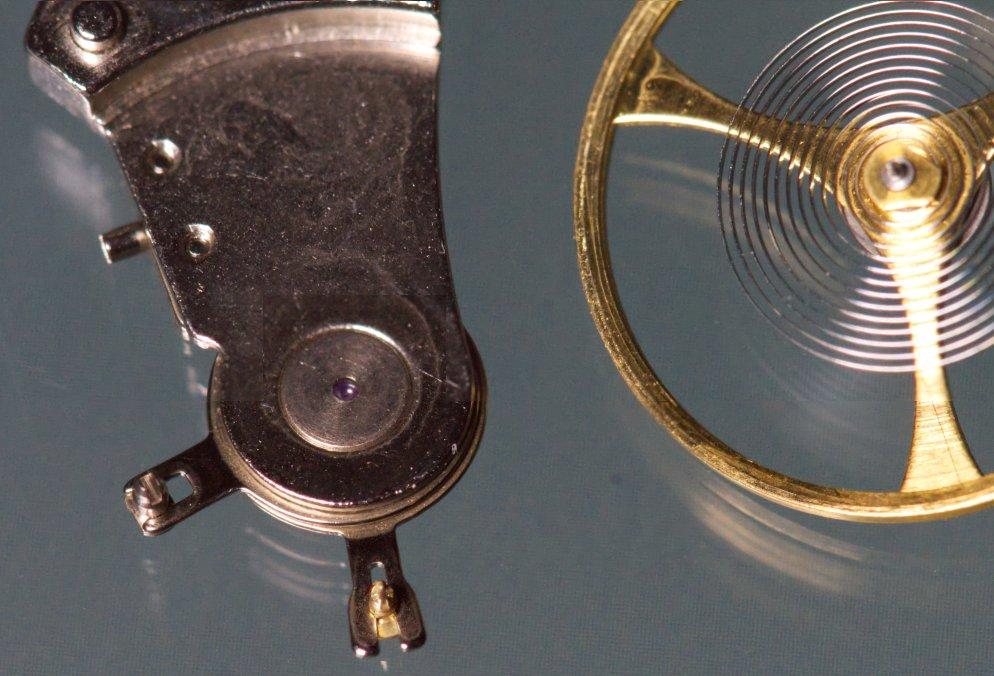

So, what could go wrong? A brand new, never even run Seagull ST36 movement. I put a wind on it just to see it run and then disassembled and cleaned it (despite the fact that it was indeed brand new). 20 min. in naphtha, drained, 20 min. 1st IPA rinse, drained 20 min. 2nd IPA rinse. Removed all components and blow dry with blower. Remove balance complete from main plate and rinse with One Dip and artist paint brush. Balance wheel and hairspring fall off balance cock. Can't seem to figure out how hairspring was attached. This isn't a good photo because you can't really see the attach point but there was definitely no screw. If it was a simple shim into the stud I guess I need to be more careful? I'll inspect the attachment under a microscope on the second movement (that I just ordered). These movements apparently ship unlubricated from the factory.1 point

-

Typical, I bought it because I like the fact that you can see the movement. I could of chosen any, including the fancy one you like. Anyway I'm having a go. Are clock mainspring winders as ridiculously expensive as watch mainspring winders? Yes, look at my post on clicks.1 point

-

I'm not tonking on anyone's seconds hand balloon. I have standards, very low standards maybe but standards all the same.1 point

-

I use both naptha and ammoniated elma. It makes the parts very shiny although i think is that necessary? It does stink i use an open plastic tub but have an extractor. I noticed pressure build up inside sealed glass jars when i used them, so maybe just a tiny hole in the lid to vent the pressure. I think you will know when to change the cleaner by looking at its state. I do filter the cleaner but monitor its cleaning efficiency. I also filter quite often just to keep the cleaning up to scratch. I cant say I've noticed the regular filtering effects its performance until its been used for a good while.1 point

-

Ok so I'm a bit gutted I've just worked out my latest acquisition from ebay. 83 quid for 17 pocket watches. Which calculates to £4.88 each and not the required 404. Gutted I've not made the mark but very pleased with my purchase. Which includes 6 Ingersol not inc. the boxed one this was a seperate purchase at yesterdays carboot hunt. A kienzle, a cimier, a westclox, an excelsa, a french chronometre, 5 unnamed 4 of which are silver inc. 2 ladies, and a brass full hunter. Some of these ive not been able to get in the back as yet. This comes from the man that wasnt particularly interested in pocket watches that now has a total of 20. Hence Neverenoughwatches, which i may now have to change to neverenoughwatchesandpocketwatches.1 point

-

1 point

-

You might find this helpful for the 2789-1, and this may help for the 2789.1 point

-

I've certainly been learning the hard way. My question lately has been: To what end? Maybe my goal is to acquire more tools? Thanks for the link to the other article! You're right Rich! Truth is that I'm so used to watching these guys on YT screw the balance back on the main plate before they run things through the wash that I forgot that I should do things differently. Not only was it the IPA, but by the end of the second 20 minute rinse, the IPA had warmed up. I'm sure there will be many more surprises along the way Joe - thanks for your detailed procedure! I should have inspected the hairspring/stud interface when I took it apart. I did notice that the impulse jewel does seem to still be in place but who knows if it is firmly attached. Same goes for the pallet stones. I'll give them a thorough check. I did go ahead and order another ST36, hopefully what arrives will be EXACTLY the same as the one I already had (I understand they come from multiple facilities in China). If they are indeed the same I'll probably clean, lube and reassemble the second one and then use the components of the first for more adventures in learning. Thanks everyone!!1 point

-

Either search the documents section of Cousins, or try here https://watchguy.co.uk/cgi-bin/files1 point

-

What specifically are you looking for? Current products have detailed service sheets but older and vintage one may have not. These are from a time when repairers were supposed to know their trade, and not so finicky about oiling, so all what's available is the parts list.1 point

-

If you know the Seiko ref number, the first 3 digits are the diameter. The attached document explains the Seiko crystal codesCrystal Codes.pdf1 point

-

It‘s most likely a modul from Duboit-Depraz or Soprod. There seems no documentation available.1 point

-

A week ago, I measured an ETA 2824-2 housed in a Sinn 556 A watch, and the results were pretty amazing. I published the results in this post. Anyway, this made me reflect more deeply on the performance of Russian watch movements which I appreciate so much, and here follows my reflection. I have always maintained, and I still do, that Russian movements such as Vostok, Poljot, and Raketa are an excellent option for the beginning watch repairer. The reasons for this are several. They are all Swiss in their basic design. That is, they all use the Swiss lever escapement, but compared to Swiss movements like ETA, Sellita, Unitas, etc., they are usually just about a tenth of the cost of their Swiss counterparts when it comes to movements and parts. The beginning watch repairer is essentially bound to make mistakes resulting in lost and damaged parts, but when the cost is counted in cents, rather than in dollars, it doesn’t hurt anything but possibly one’s pride. Add to this those Russian watches can be very fun and cool in their design (like the Vostok Komandirskies) and ingenious in their function (like the Vostok Amphibians) and there’s very little speaking against them. Perhaps best of all is that once you have built up your skills and experience it will basically be no different to take on any Swiss lever escapement movement, like the famous ETA 2824, to name just a single example. So, aren’t there any downsides to these Russian calibres? Indeed, but not so much for the beginning watch repairer where the overall goal is essentially to be able to take the movement apart, clean it, lubricate it, and assemble it. In those cases, getting the watch to run reasonably well again, without introducing errors is definitely a success and very educational. No, the problem with these Russian movements arises when you have become proficient at servicing and repairing. Why? Because you might be thinking (like I pretty much did), that once you’ve serviced it to (near) perfection, it would perform better than from the factory, but of course, it won’t. So, when putting it on the timing machine its performance will still not show the kind of results that you would usually get from a healthy Swiss movement, and that makes it a lot harder to assess the success of the service. I remember @Endeavor once remarking to me when I was frustrated over a Vostok movement that I was working on, that “a Vostok is not a Rolex”, but the remark passed me by at that time. However, finally, the penny dropped. You might even have burnished the pivots, and adjusted the end shake and side shake to perfection (like I have). Still, the timing machine results are erratic. The rate and amplitude vary in a single position, and the positional errors can be quite dramatic. The reason for this, I would very much suspect, is that the manufacturing of Russian parts is far from perfect. The train wheels might be slightly skewed, the wheel teeth and pinions leaves not perfectly designed, cut, and polished, the staff pivots not equally rounded, the balance wheel rather sloppily poised, and so on. So, in my experience assessing the success or failure of a service/repair on a Swiss movement is generally far less challenging. Nevertheless, these Russian movements can be regulated to be very accurate, provided they’re worn and wound consistently. I’ve had Vostok movements averaging like quartz in accuracy. In this respect, Swiss movements (and high-quality Japanese movements) are much more forgiving. That is if you don’t wind a Swiss movement consistently and/or store it overnight in different positions it won’t affect the timekeeping as much as it would for a Russian movement. So anyway, when you can pick up a 200 meters water resistant brand-new all stainless steel Vostok Amphibian diver watch for less than a $100 I’d say it is still a fantastic option, and eBay is full of these Russian movements and parts for basically next to nothing when compared to their ditto Swiss. In conclusion, Russian watch movements are a great start but don’t expect the precision of Swiss (or Japanese) movements, not even after a perfect service.1 point

-

Im fairly sure of that. There were no marks to the case back or screw ring which was pretty tight and had like a vacuum schlurp when the gasket lifted with the back. No scratch marks inside apart from the balance cock screw and a couple of very minor ones in that area. Its possible that a very good service was performed at sum point but i am leaning towards it never being opened. The oil is still present on the shock jewel and is an almost perfect circle in the center approx a third of the diameter of the jewel. This i was more amazed at than the tg results as the bezel plating has some wear but nothing heavy, crystal has a few light scratches. The only heavyish wear is on the crown though not too bad. It has probably not had a great deal of use, tbh its a little ugly but i dont mind that too much i will still wear it when i decide on a strap. Its only issue is the bezel, it has some play, im hoping that its a simple retaining spring replacement not too difficult to find. Ive not even looked at that problem yet as i dont want to get too involved before i return to and finish a few others. What are my chances of dating it, i was guessing at made in the 80s . No marks besides the encircled B under the balance. I will do a little research later and post up what i find. As always Watchie nice to converse with you.1 point

-

Welcome Ren. This is a great place to start, a mixed bunch of friendly helpful pros, enthusiasts and hobbyists. If i can just give you a few tips when asking for advice if i may. Be as specific with your questions as your experience and knowledge will allow. Add some good quality accurate photos as you can get, macro shots are a big help as very often a helper will spot something missing or broken or a part the wrong way round. Photos of the dial face also as the brand can be relavant in many cases. Both sides of the movement and plenty of the side you are working on. The make and calibre is very important to know, so mention this in the title if you know it. If you dont then the photos from the train side and keyless works will help others identify it for you. Pick out logos, numbers and any lettering you notice anywhere on the movement, these are very relevant especially if you need to source parts or others to help you to source them. Think I've covered most of the initial questioning criteria Ren. This all helps then you and others can get to work repairing and helping.1 point

-

I rinse both the pallet and balance in IPA but only dip them. No problem's so far but time will tell.1 point

-

1 point

-

Thats that will be the ipa that has done that Gary. I never rinse the pallet and balance in it . I noticed one of my joblot watches had the hairspring glued in from the factory as well. That aside the impulse jewel will have been glued in as well you may have lost that. Dont throw away your two rinse jars hopefully it will still be in there. Make it one of your first steps to remove and set aside the pallet fork and balance assembly, then clean them manually by hand or machine should be ok in naptha only if that is what you are using and at the very most just quickly dip them in ipa for a few second rinse if you are prepared to take a little risk but not a long machine rinse. 20 mins is probably too long for the ipa rinse and the agitation of the US will loosen and disloge any glue or shellac it sets to work on.1 point

-

I'm strugging to choose a strap for it. I cant decide on a tan leather which seems so wrong for a diver or a gold plate steel bracelet. I dont think a nato would work with the lugs width being so small and the watch being chunky and heavy. The lug widths for the boctok divers are stupidly small for the size of the watch at 18mm. Yet the vostok amphibia custom diver my missus bought me for xmax is 22mm so anything looks good on it.1 point

-

Watchmaking is learning the hard way. But it will pay off! I personally haven‘t seen a glued hairspring yet. Thanks for sharing! Glued Hairspring1 point

-

So far what I have seen them do skillfully in an hour takes me 5 or six. And not always with the same results.1 point

-

Head over to Jules Borel http://www.julesborel.com/ Click on the "JBL Watch Parts Database" on the upper right, A new window will open... Then select "Search for parts for manufacturers from A to F" Click on "Bulova', Then scroll to find the 17AE caliber Looks like they have the barrel arbors still available , for a reasonable price. Randy1 point

-

1 point

-

Hey! Don't give up at your very first failure. All of us have experienced it before. If you took up watch repair after watching videos on YouTube, then that's the problem. Especially if you watched Mark, our forum founder. He makes it look so easy that we, normal people, feel useless when we attempt it. Watchmaking is not simple. I'm sure you don't expect to produce a "Mona Lisa" after watching a few painting lessons on YouTube. So don't give up. Take a break to review and re-strategise. Work on something bigger like pocketwatches or table clocks. Practice makes perfect.1 point

-

Thats a good idea John, with every specific watch post name the watch manufacturer make and caliber if known along with the question. If not known then be able to edit the title when it becomes known. Its going to fail now and then when new to the forum are uncertain about what to do. But if instructed when greeted during introduction then majority of the time it will work and will build a reasonable searchable database as long as folk take the time and effort when creating the title. John fella, this isn't your problem mate, its their's. There is only one answer you need to give to someone who is poking fun at how you spell dictate or write . Here John you can borrow this from me to give them1 point

-

1 point

-

I'm finding the link works just fine which is what I suspected. The reason it's working just fine for me is I was just there the other day and I logged in. So you want to access the information you need to get an account. but if you get an account just to access these files are going to be disappointed. It doesn't have your particular case in their. I downloaded the index section C can see what they do and do not have. I know that Seiko at least at one time used print lots of Logs which presents a problem in that you need the right one. Seiko Casing Parts List (1977) I. Notes & Index.pdf1 point

-

it's good that you're still learning because all of us are still learning unless of course you're not the watch repair than you stop learning watch repair. Seiko a long time ago use the published casing reference books which may be out there in PDF form perhaps. I know there was another company that published the casing book for several brands conveniently am not sure where mine has wandered off to otherwise I was going look up the number. on the other hand even without a nice database through a handy reference book is amazing what happens if you just search online. when looking for Seiko case parts you need to express the case number in the proper form like this 6319–8120. The other number is the serial number which if you do a search somebody will explain online what those numbers mean. Once you get the case number express properly can do a search online and then at some point time grasp that you can just search on eBay and find this. this just happened to be the first one I found conceivably there is other sellers and other sources but you do get a crystal number that you can now search for that. https://www.ebay.com/itm/2948252572861 point

.thumb.jpg.b5812ca51ddb2001a5804aa092824f67.jpg)