Leaderboard

Popular Content

Showing content with the highest reputation on 06/05/22 in all areas

-

The yellow screw/eccentric does not adjust the hammer. Its task is to move the coupling wheel away from the chr runner on stop and reset. Frank2 points

-

I got it!!!!! After hours of futzing, I now have a functional keyless works. The yoke spring and yoke were in their proper orientation. The watch stem was true and nothing was worn. Thanks to all who contributed! I tweaked the setting lever spring a tiny bit, maybe not even noticeable, but who knows? But the real trick was to use pegwood to hold down the yoke while and after positioning it in the sliding clutch. Before proceeding, I screwed down the set lever screw. Then I tightened the setting lever spring screw, the pegwood pressed down so the yoke wouldn't move. The more I do this the more I see shortcomings in watch designs. Now on to the pallet fork and balance wheel and I'll be done with my first ever service of a watch.1 point

-

As a beginner myself who has asked his fair share of questions what this forum needs is a dedicated beginners section, where any question can be asked and where the standard answer of "Have you used the search function" is not allowed. Too much to ask I know1 point

-

I tried a handful of things to avoid the cost of the AmScope. Two different Optivisor knockoffs as the real McCoy. The lenses on the knockoffs both pointed straight ahead rather than converging at the focal point, so you had to close one eye to be able to focus on anything. Full refund, but they wouldn't take either back, and they're both still sitting in a stack on my office table... Then I think I got the name brand one, and while giving me binocular magnification (good), it still resulted in tool obstructions very close to the workpiece. Certain operations had me tapping the plastic to the right of the thing and making it difficult to get good angles with the tool and my vision simultaneously. That was my primary complaint with my clip-on loupe (not having experienced stereoscopic magnification, I couldn't complain about not having it). I also managed to snag a high end dentist's magnifying stereoscopic loupe from a pediatric dental surgeon neighbor. It was permanently attached to some prescription lenses that were lighter than my own, but still off. I could actually get decent magnification from them. Still not better overall than the clip-on loupe. Then the AmScope arrived. Game changed. It's worth the cost of entry. I've actually probably used it for more non-watchmaking things than watchmaking at this point; though that says more about my schedule at the moment than anything. Had I been thinking, I probably could have written it off on my taxes since one of those uses has been soldering for work.1 point

-

Thanks, got it all working nicely now (and a nice steady trace with 305° amplitude DU/DD - The Russian movement is working well, despite having spacers under the balance cock)1 point

-

Is the stem loose in it's hole ? If there's too much play, the yoke can slip out.1 point

-

AFK is a term PC gamers use a lot OH I’m pretty ancient as well and only know this ‘cos I hang out online with some almost as ancient gamers1 point

-

1 point

-

1 point

-

The only thing that does that is the tractors and we have some bloody big ones here getting in the harvest.1 point

-

Hi NEW, very pleased, at lowest magnification the whole of a 6497 movement is in view easily. Full magnification allows for good inspection of jewels etc. cheers Tom1 point

-

This may seem crazy ??? But have you tried turning the yoke over ? Just the way the curve of it looks on the side opposite how you have it placed against the spring in your 1st photo....makes me wonder if when you move the stem, to engage the crown wheel..it's causing the spring to "pinch" hard against the pip it rides against, causing enough pressure against the yoke to jump out. Just a thought....1 point

-

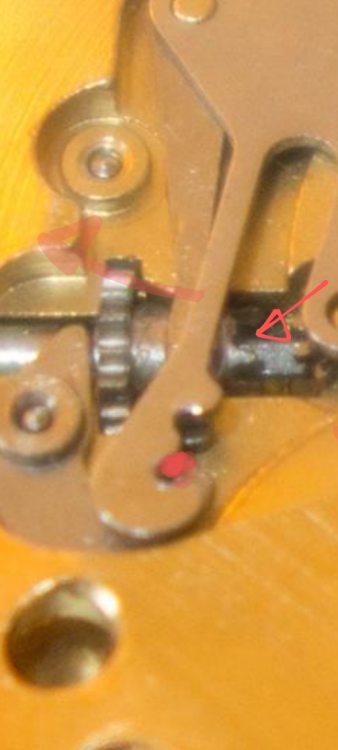

The setting lever spring is resting on top of the small pip of the lever underneath it. You need to move the setting lever spring to the left so that the pip fits in the indent of the setting lever spring (shown in red on my image). You also have a broken tooth on the winding crown wheel. Good luck, Steve. I meant the crown wheel for setting the time.1 point

-

Forgot to upload went out of town will put a reminder in my phone for Monday!1 point

-

Those rolling dies are great, but the initial diameter is crucial as they form rather than cut the thread. Made by Habegger, available from www.schurch-asco.com, surprisingly affordable.1 point

-

I could not open a watch case using my two different types of case openers so I decided to try out this Chinese 5700 type. While it took quite a bit of force to open the case, the tool was easy to use. Quite worth it to save the aggravation and possible marking of the case. As I am not a professional, the tool should be very satisfactory for my use.1 point

-

My personal experience with a Rolex 3135 and a JLC 889 (both modern calibers and been serviced professionally in the 90th) is that over a time period of 10 to 20 years the light synthetic oil in the balance bearings evaporates completely and the watches start loosing time. The oiling state of the upper cap jewel can be evaluated with a microscope or loupe easily.1 point

-

Notice the quote above rubbed in jewels or burnished in jewels? Plus look at the color of them those are natural stones they always have flaws in them or can always have. You need to look very carefully at the hole itself is it nice and shiny does the crack extended in such a way that you can see it. Look at the pivots do they have score marks where the crack scored cut into the pivot? What unlikely the answer is the jewels look fine at least from a bearing point of view and the pivots are fine. Then notice the color the jewels which by the way can be any color but these are clear? Modern jewels are a nice pretty intense red color which means you're going to change the look of the watch. Probably nobody cares here if you are restoring something nice it would look really bad. Then I'm attaching an image jewel on the last is a burnished in jewel. Instead have a straight sides like the modern jewel the sides are tapered. You can actually modify relatively easy modern jewels to that shape. But you require additional tools to do the burnishing and sometimes it breaks off no matter how careful you are. Or you can replace it with the modern jewel which is what the picture showing.. But you have to open up the whole large enough so it's nice and smooth for the modern jewel. Which means usually there physically bigger than what was there before. Then in addition to all of that the watch is old enough that the whole sizes might not correspond to standard jewel slices of today perhaps. Then have you looked up the cost of those tools is this watch worth it. Then the tool at your link I have the Swiss version is an outstanding tool. Personally I think it's almost a must have for doing jewels as it makes it really easy to push them get them exactly where they have to be. But you still have a problem? The problem is modern jewels require a very specific hole size. That's usually made by a tool from the same company that makes the jewels and that means basically you have to have both. Normally what most people do is buy a tool like at this link. Notice the price looks quite reasonable right now check back when the auctions completed it's going to be quite a bit higher as a guess https://www.ebay.co.uk/itm/Seitz-Jeweling-Set-for-Watchmaker-Swiss/373424385098 To understand the tool above which looks in a really outstanding condition normally log a little bits and pieces go missing with time or whenever there. The most important aspect of this tool is the reamers which I circled in the image. Then to understand the tool I've also attached the PDF manual for it. Basically wouldn't need the tool above if you have this one. I just think the tool above is much nicer for adjusting jewels. seitz BOOK.pdf1 point