Leaderboard

Popular Content

Showing content with the highest reputation on 06/03/22 in all areas

-

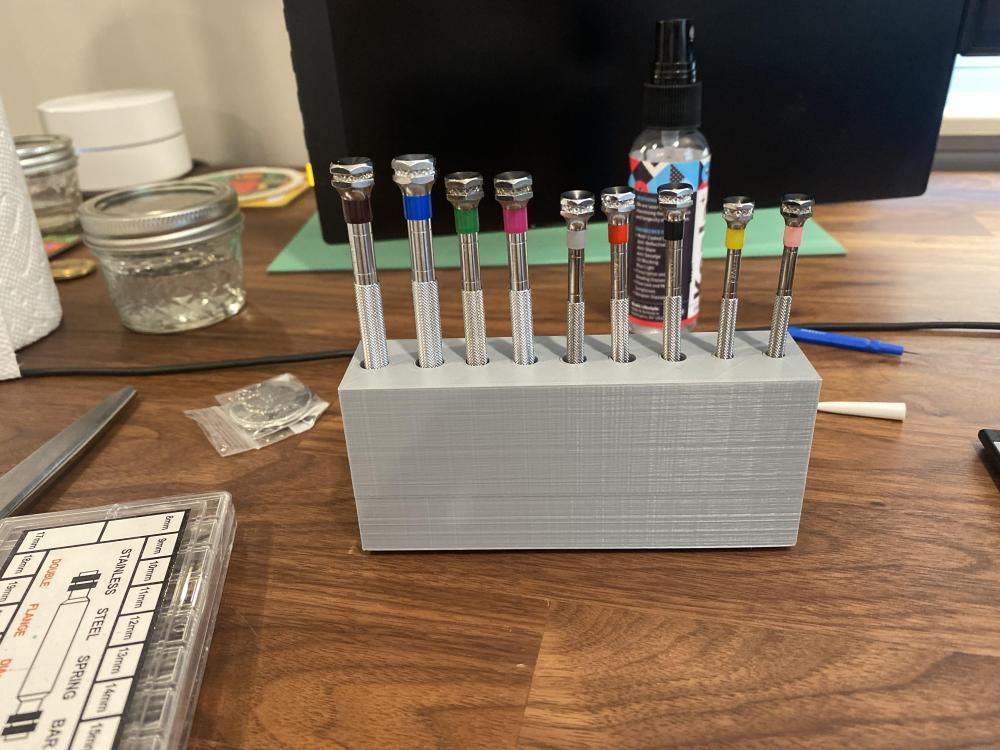

You would use balance screw holders, which are small sliding pin vices with precise diameter openings. Grip the head and unscrew. They are honestly an essential tool for slotted screws as well; get the screw loose with a screwdriver, then unscrew with the holder, now it's held and easy to add a washer to and get it back on the rim, final tighten with screwdriver. The standard set is 3 pieces, 0.30, 0.40, 0.50mm. That covers things pretty well, unless you're working on a tiny 5 ligne LeCoultre or a big pocket watch. Do try to eliminate any other cause of the increased rate before going to adding washers though.5 points

-

3 points

-

3 points

-

3 points

-

3 points

-

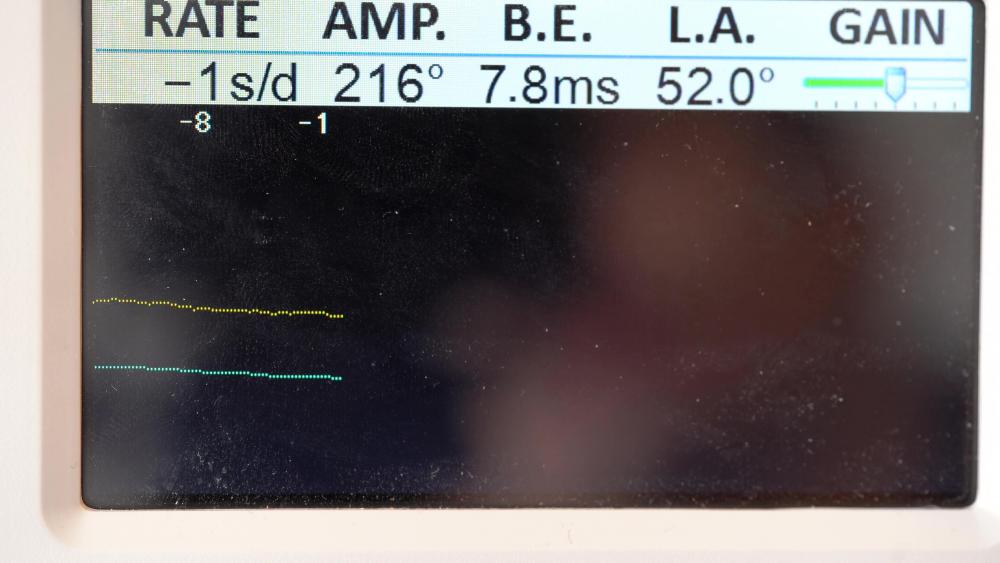

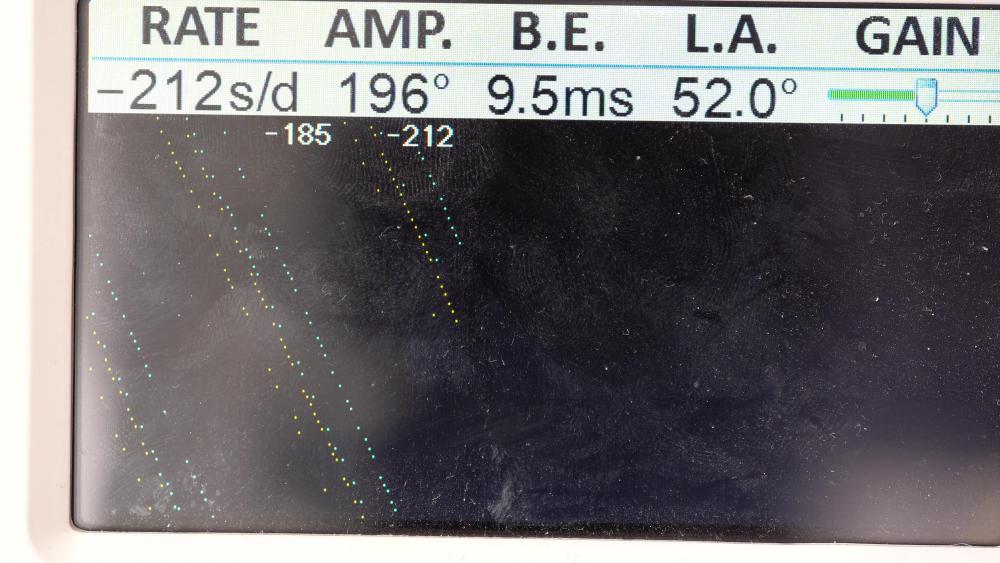

Hi everyone! This time I'm back again with a little something which turned out to be something of a hybrid project. I had repaired and planned a video on a Junghans watch with the 93 movement caliber to give to my younger brother ( which young adult doesn't need a nice looking watch) and had it all set out, planned and executed. The only downside was that the dial was slightly discolored on the right side due to bad cleaning on my part. Here you can see what I mean by that: But I happened to be at a local fleamarket on the day when I wanted to finalize the video and surprisingly found the exact same model! Even though the crystal was pretty scratched up, I was confident that the dial was in a good condition so I bought it for 10 Euros. And yeah, it looks like I hit the jackpot: So.. I got lucky and changed the dials in the end. But enough rambling around and here is the actual process of working on the watch movement: 1. Removing the movement from the case. This movement was from the “trilastic” model line of junghans and it got its name from the tri-legged support beams which held the movement inside the case. Just pop those up and remove the movement. Fun fact: While checking the inside of the caseback for marking I found one from 1981, thats so coooool! : 2. Remove the hands and and then the dial by unscrewing the dial feet clamps ( Forgot to take Pictures sorryyy) 3. Strap the movement into the holder and unwind the watch if needed. Then I removed the broken watch stem. 4. Remove the blued ratchet and the click spring 5. Remove the hour wheel, minute wheel, canon pinion and the very interesting looking yoke and its spring. 6. Then remove the clutch and flip the movement. The leftover lever will be released from the backside later on. 7. Remove the balance wheel and the pallet fork system. 8. Then remove the two screws holding down the mainplate and lift that. You can go ahead and unscrew the screw in between as well since that will release the left over lever on the front side. Do the same for the mainspring cover. 9. Remove the gear train and the mainspring And that's about it with the disassembly! Now moving on to the whole cleaning, lubrication and servicing part! Mainspring service: This Mainspring was something new to me since it had a very interesting arbor! Instead of the traditional small arbor inside the barrel, it extended outwards and acted as a lid and a wheel at the same time. While this is definitely cool, it also brings some negatives such as faster exposure to dirt and etc with it im sure. It looked fine so I just recleaned, lubricated and reinserted the whole thing: Lubrication: Here is a list of lubrications I used Moebius 9010 - All jewels Moebius 8200 - Mainspring and barrel lubrication Moebius HP 1300 slower moving parts such as canon pinion Moebius 9415 - Pallet Fork hooking jewels Molykote DX - Gearless works and high contact/friction zones (Front side only really) Oh and of course don't forget to clean and lubricate the balance shock jewels! Reassembly: Just reverse the disassembly steps or watch (no pun intended) the video for a step by step walkthrough. Timegrapher Test: Before Regulation After Regulation: Now i'm very happy that the rate is so much better. The amplitude can definitely be better however I would blame the old mainspring for that. The one thing that puzzles me really is the Bear Error. I've tried virtually every combination on the balance but the beat error does not improve. Maybe something is wrong with the hairspring? Final Result: After attaching the more aesthetic dial and recasing the watch and adding the straps, these are the final result pics: I must say I'm very happy with the whole process! Of course there were some up and down moments like when I destroyed the balance ( don't even ask) and had to get a replacement and such things but it all worked out in the end did it not? I was not sure how the beat error and the lower amplitude were going to show themselves while wearing the watch so I did a test wear for a week and the time only deviated by a second or two so I'm relieved! Now I apologize for the lack of pictures for a smooth documentation, I forgot and yeah, the rest is history. However, I have uploaded another fully commentated video so If you want explanations, more information or just a smoother experience go check it out: https://youtu.be/ZDXKiNnrmMk Any criticism, questions, comments and tips are always welcome and i'm happy to talk to you all! Hope you enjoyed it and until next time! Stay Healthy!2 points

-

Don‘t put yourself under time pressure. This movement is small for a beginner. Sleep one night before you continue. Otherwise you will most likely damage something (don’t ask me how i know…).2 points

-

How do you keep warm at altitude? I found spandex to be a little thin above 1000ft. I seldom go above that now that I'm a little older2 points

-

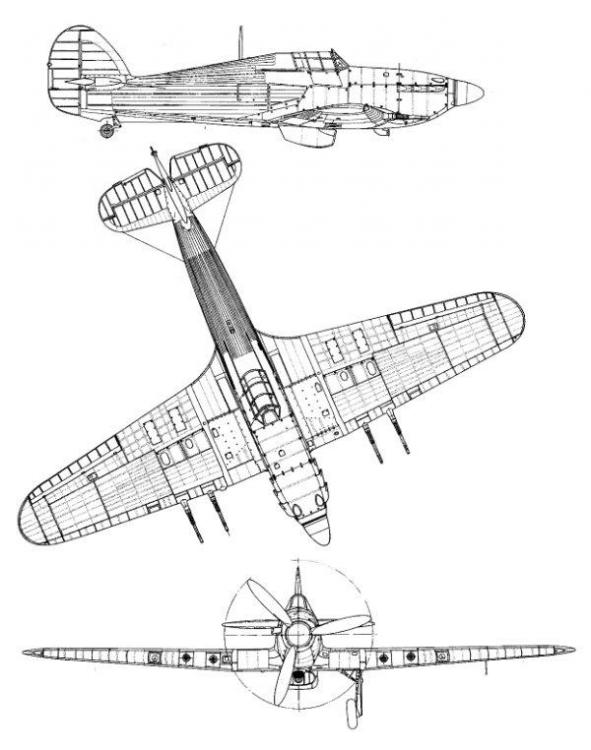

Actually Rich yes you were correct a spitfire and a hurricane, for some reason a change was made to the aircraft choice. 22,000 spitfires manufactured only 54 left in existence. Around 2-4 million depending on its condition if you fancy one. 50,000 a year to maintain it and 30,000 for your insurance to fly it. I managed to get a better photo while i was flying alongside wearing my cape,spandex outfit and boots2 points

-

yes the faceted crystal I've seen one sometime in the past I might've even replaced one I just can't remember anymore. Crystals did not just come in flat glass sometimes they had interesting features.2 points

-

yes twitching seems nice but stepping would be better. the problem is the stepping motors go bad and then they no longer step. it's hiding on the bottom side of the circuit board its there is just hiding. yes that's one of the standard tests to verify the stepping motor remove the wheel that it drives put a felt pen Mark works on the gear and see if it rotates. Then ideally on a quartz watch you should have a variable voltage power supply and a meter capable of measuring microamps. Then the lubrication on these watch is really critical. Originally they felt that no lubrication was required because it's just step paying and there's no load and that didn't work. Then they went the lubrication but that can have issues I would go with quartz watch oil which is really really liked.2 points

-

2 points

-

Apparently there were more than 22,000 Spitfires produced v. approx. 14,400 Hurricanes. In the YT that I watched last night it said that they chopped the wingtips off some of the mk.V versions to make the Spitfire able to roll easier and be more maneuverable. They started out with 1030 hp Rolls-Royce Merlin III engines in the mk.1 (1938) and finished up with 2120 hp Rolls-Royce Griffon 85 engines in the mk.24 (1947).2 points

-

1 point

-

1 point

-

Hi John, Welcome to the forum! When you get a chance, give this video a look. It is very interesting and will give you a lot of insight into how a watch works. The folks here are very helpful -even to an idiot like me.1 point

-

For this watch and similar don't bother buying new parts, all you need is one or two cheap broken mov.ts from Ebay and the like. Or fit a new NH36 which is not expensive and will give a new life. This kind of compatibility information, including details on what exactly changes, can be found in the document that I maintain: https://docs.google.com/spreadsheets/d/e/2PACX-1vRN2UULQKTfKmhRStZhDdIOIQrqd6sPB-g6x2SKyQQjOvTBjG_7TQXQhAT4f1WqAX5QAPkIimi-3jqd/pubhtml1 point

-

Those were among the survivors flown by brave guys who were a lot younger than us. That's a beautiful case back on that IWC. My IWC Mark XV Spitfire doesn't have that on the case back. I believe they increment the Mark designation each time they do a release and the watch is popular (likely since it is relatively affordable). The movement is surrounded by an iron ring which (they say) will prevent the movement from becoming magnetized due to the high RPM's of the engine that the pilot was sitting behind.1 point

-

Supposing the staff was punched or pushed out, and you have a lathe and are skilled, and manage to remove the extra diameter of the enlarged rivet, there might be a small chance of it working- but the rivet height (the metal that gets deformed out and down to secure to the balance) is now much lower, and the metal has been work hardened in addition to its heat treatment, so it's a toss up. I've never done it, and I even had a Major Manufacurer (did their overflow vintage work) send me a watch with a broken staff and a used staff to put in the watch; I made a new staff, didn't even try the used one, and they were happy. I just didn't feel like wasting time.1 point

-

Yes matey you are correct, it looks like you are down to the cone of the pivot unfortunately . These small pins at each end of the train wheels are known as pivots. Some pivots are repairable by someone with good knowledge and skill but ive not heard of an escape wheel pivot being repaired. You will need to replace this to carry on. Sorry for the bad news.1 point

-

I Think we are looking at a NO answer. As most staffs are rivited on the the balance wheel hub means to remove it without damaging the hub the rivit has to be cut off using a lathe or the likes of a Platax tool (Bergeon), or the K&D staff removal tools. doing this renders the staff useless. Any attempt to recut the seat results in the removal of metal and if you could re fit it will result in weight issues and poise issues. So therfore not reccomended.1 point

-

These parts are all identical across versions. There are plenty of pictures and videos that show and analyze this kob.t dow to the most minute detail. The rotor post is pressed and can be easily be replaced.1 point

-

How about a slo mo vid of the hairspring coil when running? Intermitant sticking does sometime go unspotted with naked eye.1 point

-

Are you sure it has the correct mainspring? if so make sure everything to do with the balance is correct. Look at the hairspring to see if you can let it out.1 point

-

1 point

-

Hi the following is a seiko bulletin which describes the function of the "magic Lever " winding system https://r.search.yahoo.com/_ylt=AwrJKiD05pli9wcAPAB3Bwx.;_ylu=Y29sbwMEcG9zAzgEdnRpZAMEc2VjA3Ny/RV=2/RE=1654282101/RO=10/RU=https%3a%2f%2fseikoforum.com%2fthreads%2fthe-cornerstone-of-seiko-automatic-winding-technology-the-bi-directional-magic-lever-system.656%2f/RK=2/RS=ihwMttHbC3El1rUrwDyoznj.RQY- 7S26 parts /service sheet attached should you require the part numbers. Seiko 7S26A, 7S36A.pdf1 point

-

Or, use a scrap arbor. You could put a threaded rod in the hole, to give the pin vice something to clamp.1 point

-

Is your pin vice teeth too sharp for smaller barrel arbors, causing damage? Maybe it is possible to purchase a specific "blunt" pin vice that will work for this instead of the Chinese winder handle?1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. No gasket required for that case and movement.1 point

-

1 point

-

1 point

-

I met an ex-Spitfire pilot in Darwin many years ago. If I remember correctly, he said that the Hurricane was far more manouverable, but could not match the Spitfire for outright speed. Was fascinating to talk to him.1 point

-

To me it's Rolex vs Smiths or countless others. The Hurricanes were superb but didn't have the sex appeal of the Spitfire or the marketing. Spitfire brilliant but not the best.1 point

-

Top one is a Spitfire. I just watched a YT video on those last night. I didn't realize that they went from the mk1 all the way up to the mk24 (although every variation wasn't built or flown). Most had the same airframe. One variation had the wingtips chopped off. The later variations had much higher HP Rolls engines. I think the lower one is a Hurricane.1 point

-

1 point

-

No I haven’t. I’ve never done it before but if you want the file I’ll upload here when I get home!1 point

-

I think this is a two piece back , there is the back plate and the slipring that screws on holding the back. The last one like this I saw had a regulatr slotted slip ring for the Jaxa tool.1 point

-

1 point

-

Great idea, well done. I might give that a go for "odd" sized barrels. I only have a small winder set, so I've made a couple of extra parts : I use the 10.8mm size most but often the arbor is too big for the spring. So using a bit of brass tube in the winder hole allows the next smaller arbor to be used. To allow left hand springs to be wound, I made a couple of new winders. It's not hard, I only have a Dremel type drill and hand file. It's all brass apart from the pin - where I drilled a hole, knocked a bit of steel in, and filed to shape.1 point

-

Even if I invested in a priceworthy 10 sizes Chinese winder set I wouldn‘t be able to use one of these winders for this specific Citizen mainspring/barrel New main springs for this caliber are not available anymore.1 point

-

Good advice here and it is much appreciated. Thanks to @Graziano's PDF file I have ordered the proper tool to remove the 5 spoke drive wheel so I can check to see how the stepper motor works on it's own, according to @Kalanag. Thanks also to @HectorLooiand @ChrisRobinsonfor their suggestions. I will continue testing along those lines and report back.1 point

-

Nice! And thank you! Man, I couldn't find a new stem for this watch (it had broken stem and missing crown). I did see some on Ebay but guys wanted like $80 for it and shipping to me would've made it waaay more expensive than I paid for the watch (or what it's really worth). So I found a used stem (which, of course, was too short) and used a stem extension which worked brilliantly. Maybe something you can try for cheap?1 point

-

I would just dab the dial gently with Rodico. Those "red dots" will be radium - take the recommended care should-i-be-worried-about-radium Basically it's flaking radium you want to avoid, so I would keep the dial in a sealed plastic bag. Once you get a glass fitted it will be OK.1 point

-

These watches often come up on ebay, measure the size of the fitting for the bezel and check out the bay or try welwynwatches.co.uk who are second user parts suppliers, speedtimerkollection.com in europe being another. If you get stuck for parts I may have a couple of tis type in the box.1 point

-

Personly I would leave it alone as rubbing will destroy the surface glaze and expose the souft under structure. Fit a new glass and accept it as is.1 point

-

A one dip in lighter fluid to get rid of any grease, give it couple of hours to dry then a rubber pencil eraser.1 point

-

1 point