Leaderboard

Popular Content

Showing content with the highest reputation on 05/25/22 in all areas

-

That's a Schaublin 102, it has twice the center height of a standard watchmaker lathe. Considered huge by most watchmakers, but tiny to most machinists, haha. If setting a jewel in a bushing, you have to consider the wall thickness of the bushing. To fit a 0.70mm jewel, you'd want a wall thickness of at least 0.25mm, so the bushing would need to be like 1.20mm. To answer a previous question- if making a bushing to fit a rub-in setting, I shape the bushing to suit the setting, and rub it in, if possible. Making a jewel from scratch is a big job- I will always modify a jewel if needed and a jewel that will work is available. The setup above was from a marine chronometer jewel I had to make, which was 3.30mm, with a huge dome and oil sink, and relatively tiny hole of 0.18mm. No chance of finding one, or one that could be modified. On modern (mostly ETA) where they have that tiny jewel held by almost nothing, there's not much you can do. Those are very oddball jewels, and are so small for a reason, so fitting anything else would be very difficult. Some similar movements use a bushing there, that is sort of hourglass shaped, and the whole thing is pressed in to a correspondingly shaped cutout in the plate. When I see a worn one of those (often), I make a new whole bushing, in beryllium copper, which will wear much longer than the original brass. But I do that with a CNC milling machine.3 points

-

I don't mind taking off just a little from a pivot bit if really needed. 10% would be the most I would be comfortable with. Like Hector says, you can adjust jewels if needed. It's a bit hairy going at them with a diamond file, it does work, but sometimes the jewel ends up with the outside eccentric or out of round, even using a lathe. Best is using the lathe, and then a diamond grinding wheel in a live head (milling attachment). If taking of just a few hundredths the file is probably ok. When I need to make an entire jewel from scratch I get out the really cool stuff, haha. That's a magnetic chuck in a larger bench lathe, with a sub chuck on it that takes 8mm collets, microscope to check centering. With this setup I can shellac the jewel on pretty centered, then center up perfectly with the magnet at low force, then turn on magnet, and can grind the outside and drill (grind) the hole, make the dome and sink. A lot of work though, from scratch.3 points

-

Well as I venture into the land of Horology, it can take a while until one really appreciates the tools of the trade. As I had read/watched Mark respond to a post once “the collection of tools never ends”. I can see that now. I have always been a tool guy, no matter what I am doing, from oil & gas drilling to scores of workshop projects. Everything is done better with the right tool, and there’s a tool for everything. Personally, I am generally a LOT buyer, but that’s a story for another post. This post is about a tool I hear Mark reference and recommend quite often. What I found is that they are like Hens Teeth, and hard to come by, unless of course you want to pay a fortune. Well, perseverance paid off a couple days back and I finally picked up the elusive vintage Cannon Pinion Puller for the descent price of $34. Whereas I have had the good luck of pulling Cannon Pinions using various methods, it was only a matter of time. Well my best to all and your tool collecting, Will1 point

-

I'm chuckling as I type this and thought I'd share what just happened to me in the hope that, amongst like minded folk, you might get some amusement form it. I've loved watches for as long as I can remember. I can't actually believe it's taken me this long to get into the hobby, and then I reflect on how busy my life has been and I get it. However, after being fascinated by watch repair videos on YouTube and finding Mark's courses (like many others I'd imagine) I immersed myself in getting ready to enjoy this incredible hobby. I jumped onto CousinsUK and formed my wish list of tools. I pressed the button on my order a week or so ago and it was like Christmas when everything arrived. So there I was earlier on today, sat surrounded by gleaming screwdrivers, cannon pinion remover, magnification, tweezers and finger cots as I looked down at my Unitas 6497 and started to disassemble it. I had some lovely soothing music on in the background and felt very zen indeed. The disassembly want surprisingly well and after what felt like a very short period of time I had all of the parts laid out in front of me. Being a new movement I was surprised that the oil was a bit sticky on some of the pinions and Jewells and decided I might as well clean the Jewells and re-oil the movement as I reassembled it. I successfully cleaned all the set stones with a brush and some one dip and then turned my attention to the shock setting. Leaning in very closely I gently turned the shock spring with my tweezers and yep... you guessed it.... the tiny little blighter took flight and seems to have disappeared into the watchmaker ether. Completely vanished and gone forever. Watching all the videos I never really thought it would be that hard to find a spring that decided to jettison away, and now I have my first lesson. I've jumped back onto the cousinsUK website and the I can see a part code for spare shock springs - packs of 25 (which did make me feel a bit better to be fair). https://www.cousinsuk.com/product/shockproof-springs-wristwatch?code=A20271 Is this the best strategy for having a few spares of these to hand or does anyone have any other advice? Be good to hear from others who have experienced similar learning pains Cheers all and have a great weekend! Rich1 point

-

Folks in my neck of the woods have a saying, " if there isn't a watchmaking factory in the vilage you visit , you are not in Switzerland" Adolf schields made good movements and many variants of 1180 were made with many shapes of bridge layout and they powered watches of many brands. So if you watch looks good, you got a good watch, the brand doesn't mean much in this case. Regs1 point

-

Many Swiss "brands" were so small that one can't find history about them. Just made up names for watches assembled at some generalist factory. If you search AS1180 (brevet means patent, not a maker name) on the Ranfft database, or even the Internet, you will get an wealth of information.1 point

-

Can you show us a picture of the watch on whatever you using for timing machine so we can see what it looks like? Then with no power on the watch in the balance wheel stopped look at one of the balance arms and moved the stud holder does the arm move?1 point

-

This excellent vid by Mark show fitting a jewel (balance) and he also covers that the jewel available is not exact so reams out to fit the new jewel.1 point

-

Personally, if it needs more than 0.1mm I will open it in a faceplate in the lathe, as I know that I won't lose the position- in fact, if I'm not pressed for time I will often do that even if just 0.1mm, especially on ultra thin watches where the slightest error not only changes the depthing of the gearing but will have wheel rubbing on other parts. I know other watchmakers who don't mind doing more- and it depends one for which component- if for a barrel in a 13"' watch that's a lot different than for an escape wheel in a 7 "' watch if things drift. I have some raw synthetic red ruby, and some red ruby jewel blanks. That's about it. For this one since the original was clear, I used a sapphire crystal as my stock. I don't know why they decided to use clear sapphire instead of red or pink ruby; the piece was made right around the time Verneuil established commercial level synthetic ruby production, so probably not quite available (even if it was a chronometer maker would probably be too cautious to use something so new). I am guessing that red ruby large enough for these jewels was more valuable as a gem, so they went with clear, but really just a guess.1 point

-

I got into watchmaking accidentally while working (putting off university) while my wife went to school, just met a jeweler my age (early 20s) who was really into watches, especially independent watchmakers, and a year later I was in school. Then straight into a Swiss school, WOSTEP, then taught for a few years, then moved to Switzerland and that was more than 2 decades ago! It always depends on the piece. But in general I'd rather modify something like a pivot than a bridge or mainplate, as, even if there are parts restrictions like crazy, it's more likely down the road someone could put an original jewel and wheel in, but not necessarily replace the mainplate or bridge (to get it fully original). But in the end, if the work is done cleanly and carefully, I bet even a factory watchmaker would miss that a larger jewel had been implemented in a past repair. Yes, fully handmade jewels are expensive. I figure about a day for something like the above marine chronometer jewel. Pictured below with the original, which was cracked.1 point

-

Good news and bad news. So I took the balance wheel out over the weekend and I could not really not tell if the hairspring was coned, I assumed that it was. I fiddled with the hair spring for about 45 mins and put it back into the balance cock. It lives! But bad news I am back to square one. No matter what I do with the hairspring stud, the beat error stays the same. It is almost as if adjusting the stud has no effect on the roller jewel at all. I am waiting on a couple of new balance complete with stud wheels from ebay to see if that will help. At least the watch is not dead, it is fast 4-5 mins a day, but not dead.1 point

-

1 point

-

As there are no indentations on the back cover showing like you normally get with screw on backs, I would say it is not a screw on. Look very carefully to see if a case knife could open it up, if you could take very clear close ups of the edge of the back we might be able to spot something. It might have a two piece stem in which case it will come out from the front, you would need to try and pull the button out with a little force to see if the stem parts, do not pull as if you are trying to break the thing, with some Omegas manly older types with a two piece stem, when the glass is remove and stem there is a clip built into the case that you move which will release the whole movement.1 point

-

Wow, you have access to tools, and have skills most of us can never hope to achieve in our lifetime. Would you be ok sharing how you managed to make this your career path? You can ignore this if it’s too personal. Anyway, in the Bergeon catalogue I saw, I noticed there’s a large missing space for ID 0.15mm, with no jewels available for OD 1.20mm, 1.30mm, 1.40mm. If the hole for the jewel in a mainplate was for jewel OD 1.20mm, and the watch was considered high grade, what would the appropriate response be? Would it be better to ream the hole out to the next available jewel OD size 1.50mm, or shaping the pivot size down, so that a jewel with OD 1.20mm, and ID 0.14mm can be used? Is reaming the hole in the mainplate from 1.19mm to 1.49mm, or reshaping the pivot considered more intrusive? Technically, making a new jewel is considered best practice, but the next available jewel size would be too large to grind down, and I wouldn’t think many customers would be willing to pay for the work to make a custom jewel outside of museum grade watches.1 point

-

Thank you Nicklesilver. That is some pretty cool stuff and the level of skill involved i would imagine way beyond what most of us here would ever achieve. Fascinating nevertheless and possibly gives us a different approach to what we could manage. I'm Interested to hear how you go about bushing and what equipment is most suited for the job mostly. This sounds like an easier solution that a lot of us might be capable of.1 point

-

As watchweasol has said. This is a poor quality movement, not what I would expect with a ships clock. Certainly not military standard more like from a privately owned boat. I have never seen this type of ships clock over here in the UK.1 point

-

1 point

-

Yes, you'll need a lathe. I use shellac to stick the jewel to a brass rod and centre it. Then use a diamond file to rough out the OD. And finish with diamond paste of diminishing grits. I think @jdrichard has several videos on adjusting jewels.1 point

-

Ok, that's not a cannon pinion. That's a centre second pinion drive wheel. There are several options for dealing with this. You can leave it alone and clean the bridge with the freewheel as a whole. Or you can get a Presto No. 3, 5 spoke wheel puller, or wedge 2 sewing needles under the wheel as close to the centre hub as possible and pop it off. Or my favorite method as taught by my mentor, just remove the bridge with the freewheel intact, then using your fingers to grip the wheels on both sides and gently twist them off.1 point

-

1 point

-

usually with Popoff backs the watch companies will make something or in indent or something to give you a clue that that's with a knife goes. But not always and you have to be careful of prior high marks in other words somebody might've tried before you and did not succeed and you don't want to try in that spot. I once saw a story of someone trying to open up a really nice railroad grade pocket watch the screw off back and observed Primark's and attempted to pry and made the marks much worse before grasping that screwed off. then I'm in agreement we need much better pictures of the case. Like for instance is there anything written on the back is a picture of the back of the case would be nice and much better side views because often times with omega they go out through the front but your pictures just can't tell.1 point

-

1 point

-

Can‘t answer the question, but the broken spring issue on this calibre is well known. As many people had watches with that damage Rolex modified the design of the spring and the wheel to solve the problem. Left old version, right new version. Be sure to get the new version. Afaik there were no further complaints with this.1 point

-

In a watch of this quality I would think its a screw back, so try the sticky ball. But checkout inbetween and at the root of the lugs for signs of previous entry. Last chance saloon is the nut superglued on the back and a spanner to screw it off, super glue removed using acetone.. Also consider it may be a monobloc case using a split stem. In which case it comes out the front after removing the bezel and glass, and pulling out the split stem. Need close ups of the bezel and case sides before being a little more exact.1 point

-

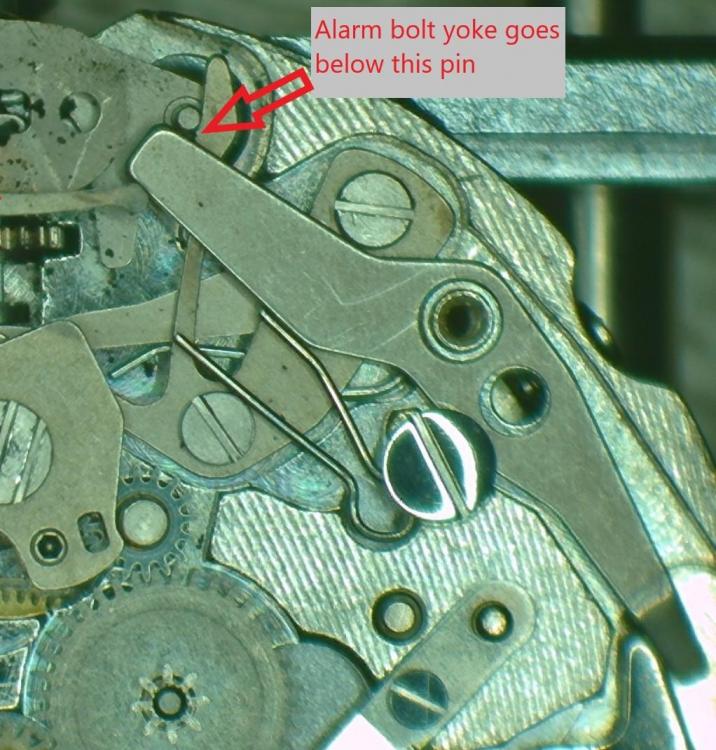

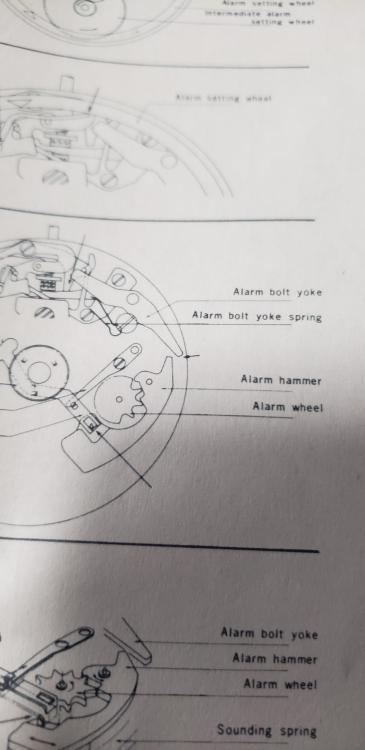

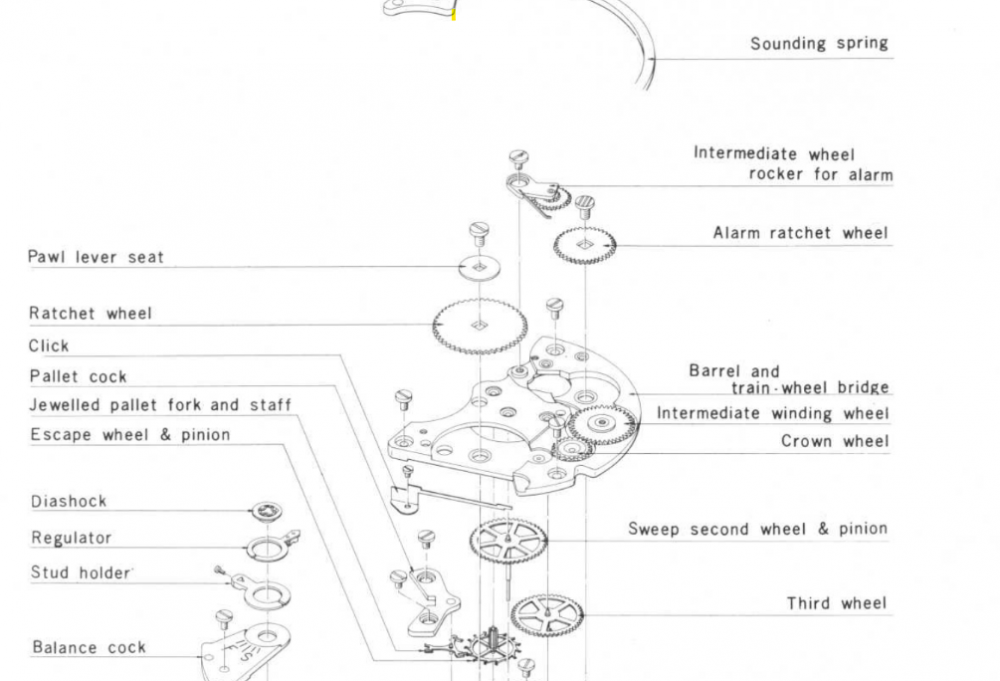

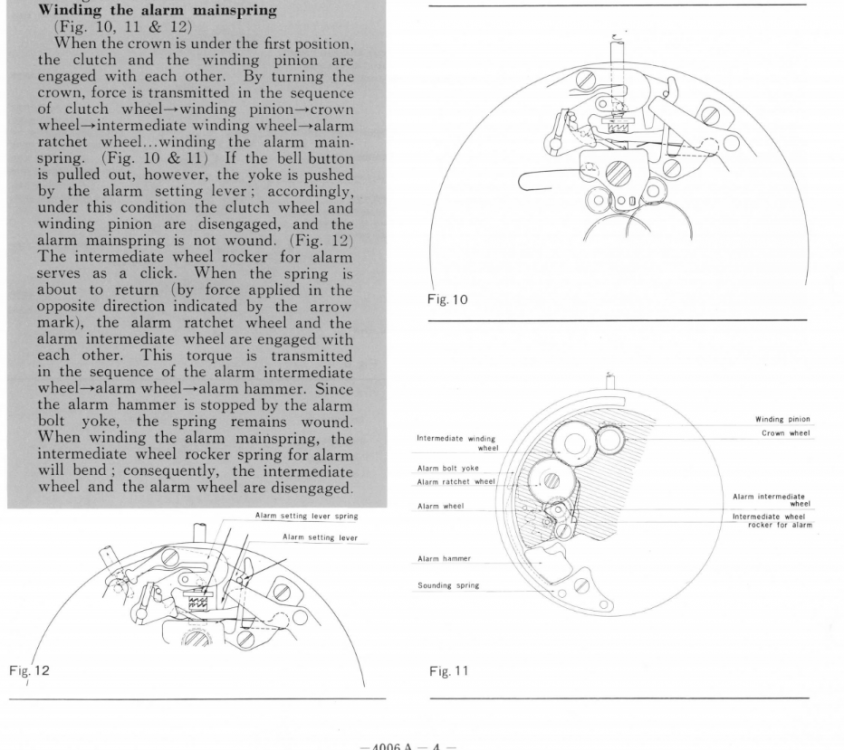

In the section of service guide I posted above, it notes that the alarm spring will not wind if the alarm button is pulled out.1 point

-

Does the spring gain any tension when you try to wind it? Do you see the complete spring spinning with the arbor or does just the arbor spin freely.1 point

-

1 point

-

What did they use to make the moldings? Did they just get another clock and press it into Plasticine and then pour plaster of Paris in that and paint it gold? I've never seen such hideous brass casting on a clock before. 'Superb Antique Enamel Mantle Clock With Key Working' I'm assuming the Enamel he is referring to is Humbrol.1 point

-

Sometimes videos are helpful. Try these: https://youtu.be/SVSV8M-HMtU https://youtu.be/hmBPx47Q5X41 point