Leaderboard

Popular Content

Showing content with the highest reputation on 05/15/22 in all areas

-

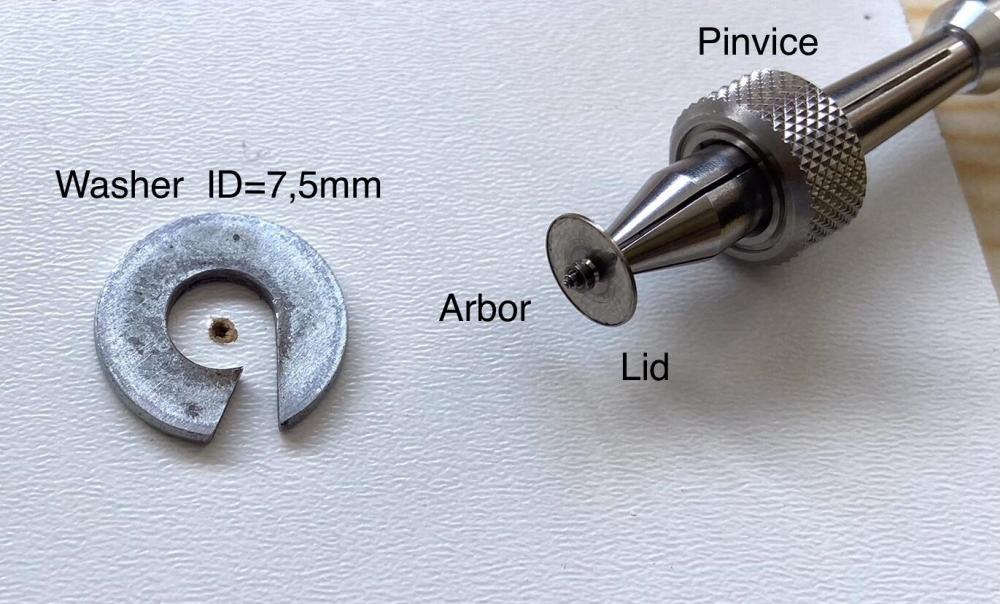

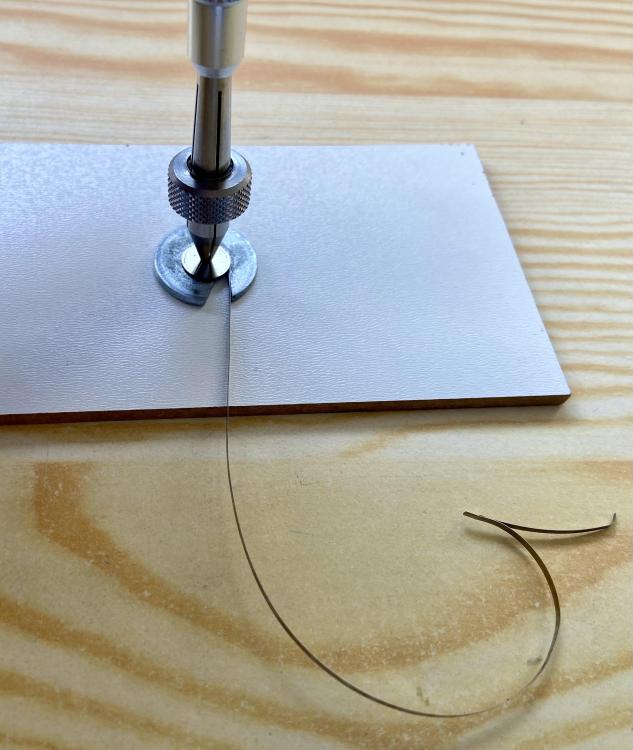

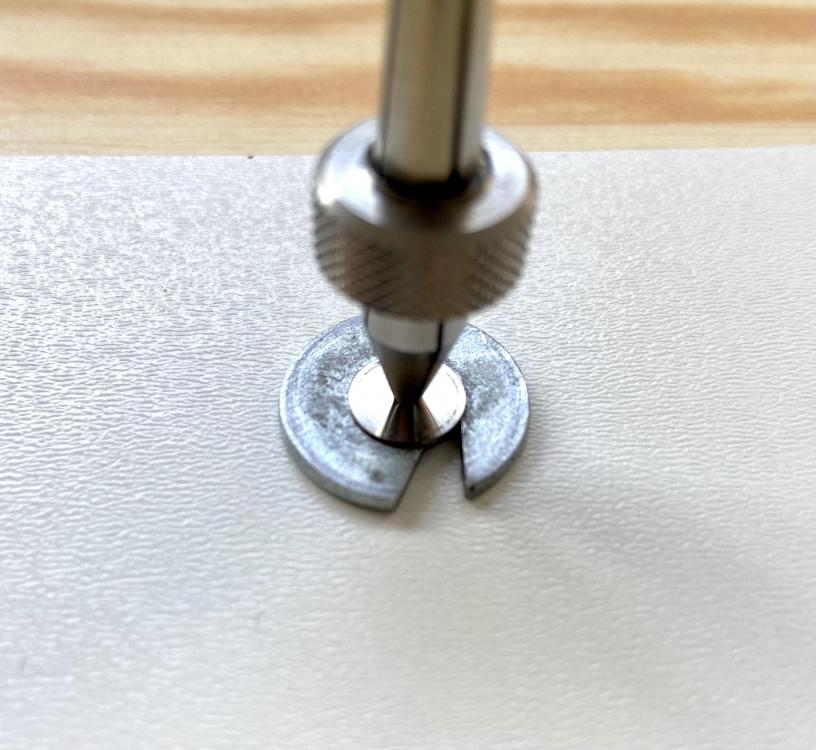

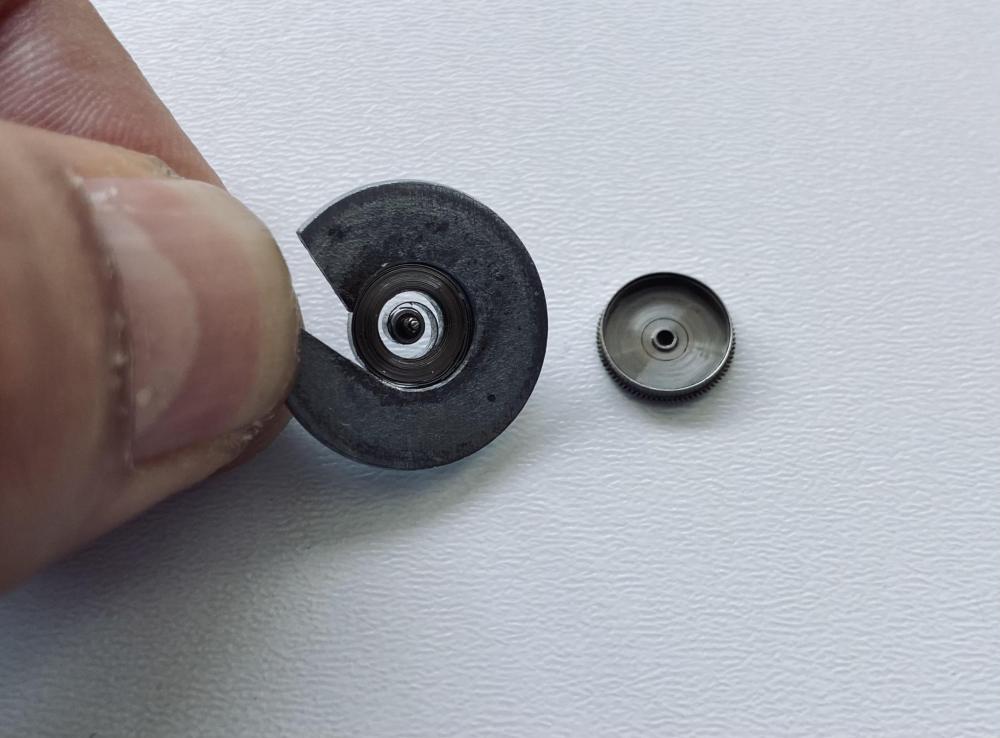

Inspired by the Mastercraft winder I tried to use its principle for a „quick and dirty“ mainspring winder. The spring I used for testing has an arbor diameter of 2,2mm (left wound) and the barrel has an ID of 8mm. The mainspring has a hight of 1,2mm. So I found a washer with the right thickness of 1,2mm, drilled it to 7,5mm ID and cut a slot in with my dremel. Then the washer was fixed to a board with three tiny drops of super glue. I used the original lid and arbor and my pin vice to complete the tool. The rest is selfexplaining looking at the pics. Any thoughts?5 points

-

3 points

-

3 points

-

It be rather nice if you had a timing machine? Even though you may have just purchased the watch there is no guarantee that the watch hasn't been sitting around for the last 10 years and is in desperate need of servicing. Then there is the other problem with automatic watches if the mainspring slips prematurely or slips too much. To keep automatic watches from breaking the mainspring the end of the spring is been designed to slip when the watches getting near to wound up. It's only supposed to slip a little bit if it slips too much you're not going to have enough running time. If the lubrication goes bad you could have premature slipping or it just might not hold at all. Then the power reserve is supposedly because I just now that up around 41 hours. But it also assumes that it's fully wound up because one of the problems of the automatic is it really takes a lot of the automatic to actually wind the main spring up. To understand that put a Mark on your ratchet wheel and then turn the rotor how many times does rotor have to spin for one revolution of your ratchet wheel? Then a fully wound up ratchet wheel as a guess what I'm looking at is about eight full turns which would be equivalent of how many turns of the rotor? Then while I was looking at the Internet notice that somebody else was having the exact same problem and the answer I gave was the same answer they gave the watch might need to be serviced. It's the unfortunate problem of new watches they look new but how long have they been sitting in the store. Then yes the person who asked the question claim that other people are having the same problem so it may be a common problem.3 points

-

3 points

-

Not necessarily, springs can last a surprising time. It depends on how it looks, and if it has lost it's elasticity. Do you have a pic of the spring out of the barrel ?2 points

-

2 points

-

Brilliant. If the arbor is to be re-used you want to make sure no damage comes to it during the process.2 points

-

Caution on the bamboo, it's not a wood but a grass. High in silica, which is very hard and abrasive. It'll leave scratch marks where true woods won't. From a woodworking perspective, working wood will eventually dull blades exactly as you'd expect. Working bamboo either takes special blades, or you'll eat edges in a hurry. Incorporating silica into their cell structure was grasses' killer evolutionary app. Nothing could eat them because it would erode their teeth PDQ. Also part of what makes it difficult to digest. Eventually, the evolutionary arms race caught up, and critters figured out how to eat the stuff, but not before it transformed landscapes worldwide.2 points

-

1- Hairspring's coil has coned and its highly likely to be rubbing on balance spoke, The coil should be flat ,concentric, level and stand at the same height as its collet. 2- Loosen the cock screw, if the oscilator then runs !! then the issue is lack of end shake. Pivots and setting appear OK? Fork snapping , barrel power , power transfer through the gear train are all unrelated to the issue here.2 points

-

I never throw away anything. I'm a hoarder. I'll probably grind off the tips and reshape them. If the tips are too soft, I'll try hardening them. If that doesn't work, I'll still keep the metal in my scrap drawer. You never know when it may come in handy.2 points

-

2 points

-

1 point

-

In parallel with fiddling with actual old watch movements, I've been working through Mark's online watch repair course. To date I've worked through 21 lessons covering 97 topics. Although I "technically" passed my Level 3 course with a 76% score on the assessment (where the average is only a 78%) I didn't do well enough to receive a certificate as I did with Levels 1 and 2. Luckily there's no time limit on access to the courseware so I plan to work through the 5 movements I have on hand and re-do the Level 3 FAULT FINDING course again. Truth be told, I knew once I got started that fault finding was going to be more difficult than either Level 1 or 2 and I was actually surprised that I got 76% on the assessment. I was also encouraged that the average grade was only a 78% which means that while I didn't do great - nobody else did either. So, I guess the "achievement" here is that I'm only just beginning this journey and (possibly) that you can teach an old dog new tricks?1 point

-

grsnovi Well done! Like you I'm doing Marks course. As a complete novice I tried the Youtube watch and learn. However Mark's Course gives direction. Level 1 achievement was 90%. I'm mid-way though level 2. Never realised how much I did not know, and did wrong with regard to cleaning. The forum is great help. Really enjoying the training. Regards to all. Ross1 point

-

It depends upon what you're doing. I used various flapping films for polishing steel watch components. But those are flat components. Conceivably something on a watch case could be polished with a lapping of film where you want a straight edge otherwise I would go for buffing wheel of various sizes. Then of course if you're working in a Swiss service center with infinite deep pockets they do have special lapping machines for their street surfaces but none of us are ever going to get those and I doubt they use lapping film the probably using a diamond lapping wheel1 point

-

As a reminder to everyone this is a full plate English watch and it was made of a very very long time ago. Like any vintage pocket watch we don't know it's repair history and there could be just about anything wrong with this one. Plus as a bonus it looks like it's new enough that they put movable banking pins on. Even if the mainspring is set which it probably is if it's wound up tight it should still run the watch for a little while you just won't get hours and hours of running time. So the mainspring should be good enough to do an evaluation to see what's going on. Then it looks like a seven jewel watch which means all the rest of the holes can wear out or become no longer round. Then of course it's a full plate which has one minor good advantage but for the most part everything else is negative. You want to be extremely careful when you take this apart put it back together because getting the pallet fork where it's supposed to be and not breaking the pivots off or knocking the jewels out of alignment is definitely an issue. As your balance wheel is how could you get a picture of each side of the balance wheel so we can see the pivots and I want to see what the roller table looks like. Also it's hard to see the end of the pallet fork in your picture looking down on the movement so it be nice to see what the end of the pallet fork looks like. Plus while you're there gently push on the pallet fork doesn't jump back and forth when the mainspring is wound up or is it having a problem?1 point

-

I was going to suggest "Eclipse" pin vices as I have a number of them and they are very good indeed. However I have just had a look at them on Amazon and I don't think that they are what they used to be. Mine are all vintage, I would say 1950's to 1970's, and made in England. They are very well made and look almost identical to the Starrett set. The new ones on Amazon look a little different and not so well finished. I'm wondering if they are now a cheaper product altogether that is just trading on a previously quality name. If you can track down the vintage Starrett styles ones on eBay though then provided they haven't been abused they are a good buy.1 point

-

I've tried that, but the square part of the arbor is was never long enough to get a grip on with the pin vice. Maybe I just need better pin vices.1 point

-

1 point

-

I clamped the arbor on the pinion square not touching the bearing surface! So even transfering the torque required to draw the end of the automatic spring in is no problem (with a little help of tweezers).1 point

-

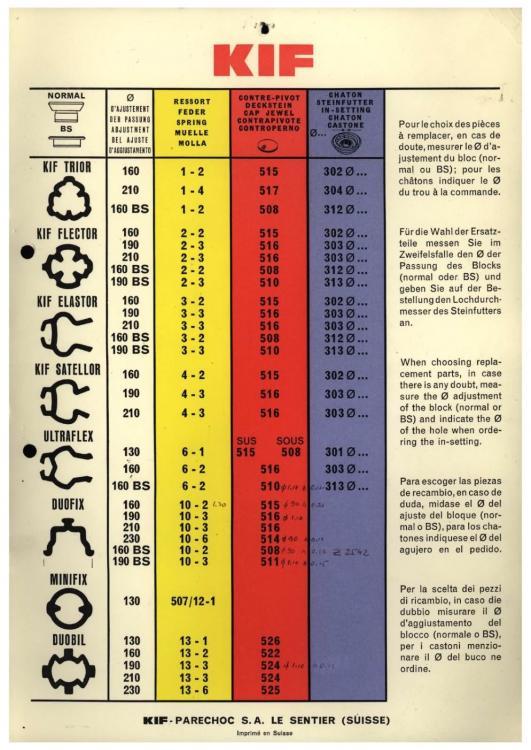

Hi Gary the AS 1361 can be either automatic or non automatic, the movement you have is automatic and yes the bridle is seperate. My answer to this is to use a battery welder to weld the bridle to the mainspring I use single pulse at 15A to perform the weld Firstly tightly wrap the bridle to the mainspring with fine copper wire in order to keep them together and well aligned then turn the electrodes of the battery welding machine inwards (file the tips down to about 0.5mm) Place the mainspring and bridle ensemble between the electrodes at the place where the attachment is needed with light pressure and pulse the welder this should result in a fine spot weld. Hope this helps1 point

-

Hi The main thing is did it work and no damage if yess then smart thinking. As xyzzy said might be better to fabricate a false arbour to avoid damage to the original surface. with a little inginuity you could improvise and make a set as an when required a clever alternative to the expensive winders. I like the idea.1 point

-

I've never been able to get enough of a grip on the arbor to turn it. Even if just to turn it a half turn to get it to engage the notch in the spring properly. I think i'd be worried about clamping a pin vice on the bearing surface that tight. I did manage to make an arbor out of same brass rod. All the arbors from the K&D adjustable winders I have were too large for a Seiko 2539A mainspring. So some 1/16" brass rod with a notch made in it with a dremel worked great. Probably won't last long, but it actually worked better than the real arbors. Easier to disengage by turning backward.1 point

-

1 point

-

Next time use a hammer and chisel to remove the hands. That way you wont bugger up your screwdriver blades.1 point

-

It begs the question when a new movement can be had for the princely sum of £2.30 plus vat and shipping....1 point

-

1 point

-

I‘d like to add that instead of the pin vice the original ratchet wheel can possibly be used to turn the arbor and wind the spring. It‘s fiddly but…1 point

-

Am I looking at an imitation of the old "whip spring" variant of a micrometric regulator? I have to agree with Chris here, in that this appears to be a decorative tack-on, by which the maker can presumably hope to charge more money. On old railroad grade pocket watches, a regulator like this would have that spring pressing against the regulator arm throughout its entire range, with the screw pressing against the other side, and thus no sudden jerk or impact could throw the regulator out of adjustment. If this regulator isn't doing that, then its either for looks, or needs adjustment itself.1 point

-

1 point

-

1 point

-

1 point

-

I think this a common fault with the 7s26 mvt. I have an SKX013 the power reserve is terrible, it barely makes it through the night. Yet i have 2 other seikos with this mvt they seem fine. Also heard others say the same. Yes mate. I was just commenting for Kalanag as to why you didnt crown wind.1 point

-

This does sound like a lack of endshake but it could also be the hairspring touching something and could also be a lot of other things as well. I personally like to check the barrel and mainspring, the free running of the train , the escapement lock and unlock, and the balance performance all separately. If all seem fine then as a whole working in synergy with each other. You wouldnt drive a car if the engine wasn't producing enough power to move the car or if the gears didnt mesh and turn together or if the tranfer of power didn’t reach the kerb wheels or if you couldnt steer the car. You wouldnt look for a fault in the steering column or front axle or check the tyres if the engine lacked performance or ran lumpy. Same principle. If you suspect the balance assembly then dissconnect everything up to that point and test it separately1 point

-

Welcome! I took a stab at your power question over there: You might want to consider Mark's online courses. I assume that you have already watched this video?1 point

-

1 point

-

Most of what I quoted above is true except? Typically on modern watches The fine adjustment which is what this is if it was working is just a fine adjustment. I'm attaching an image you can see that the stud is held by a separate piece regulator pins are separate peace and whatever you have on the other end like this is a separate piece. This means the watch can be regulated without even moving the regulator arm because they're all separate independent of each other. So basically for your watch you can just keep it the way it is as a visual decoration if it bothers you take it off if you really want to try to make it functional I would remove it before you try to bend the spring. Remove it run the regulating screw all the way out so it's not in the way and then try to bend the spring without breaking. But it really isn't necessary as to regulate just fine the way it is.1 point

-

The spring needs to be pushing the regulator, and the screw needs to be pushing back. Regulation is done by adjusting the screw to move the regulator in very fine increments. Much finer than you can do by pushing the regulator around with a piece of pegwood. As it's been done here, it's just a bit of silly bling with no actual use, and in fact only serves to limit how much the regulator can be moved. It wouldn't have been too hard to make it actually functional, but it's like it's been done by someone who doesn't know what it's supposed to do.1 point

-

Melamine can be quite abrasive. If you've tried drilling melamine, you'll know that it can dull your drill bits pretty fast. But I use melamine chopsticks handles for homemade instruments. Carbon fibre is extremely hard and abrasive. But good for scratching off rust stains. So is composite glass fibre I've used disposable bamboo chopsticks for hold-down tools. I really hate sharpening pegwood, so I use a tabletop pencil sharpener, the type with a cranking handle. I just stick my bamboo chopsticks into the pencil sharpener and it does a great job a getting a sharp point. I've also used plastic dental instruments. These used to be given free with every box of cement, so after 30 years I've got a bunch of them. I think the plastic used for these is Delrin. It's a pretty tough material but not easy to get a nice surface after grinding. I also use brass wire. These are great for things like probing train wheels without leaving scratches.1 point

-

anything to stop them cracking. It was called peg poly ethylene glycol if memory serves. It displaced the water content for the peg solution. I used to turn custom newel posts for stair cases and large bowls. Have a go at banksia nuts theyre great fun. The skew chisel was a real beeatch when it bit and threw. Im trying to remember tha name of the brilliant multichuck i had for my lathe. I always wanted a myford lathe but didnt have the room or the money at the time. Might revisit the hobby one day. Really nice work on the pens T1 point

-

Nice Tiny . I used to turn about 20 years ago. I still have my old coronet elf lathe. And a load of tools. I may return to it one day. I used a solution called pegg to seal the stabilise the timber and candle wax to seal the end of blanks.1 point

-

1 point

-

As anyone knows on this discussion group I regard each watch is an individual problem and I don't like generalizations which is the way this discussion is going. So for generalized nations before attempting to time will watch not that you can't the timing machine is still good for diagnostic purposes but before you try to regulate a watch you need to have proper amplitude. As the amplitude drops problems magnify. Positional errors become much much worse and a stamp to do is low enough to beat error will increase and it's not the beat error is because you got to get your amplitude up. As were discussing American pocket watches? Typically bimetallic balance wheels this means if they're squeezed and we all loved the squeeze our bimetallic balance wheels don't we? But they don't like to be squeezed and then there out of round. This creates positional timekeeping issues. Usually when you look at your balance wheel it should be running flat not wobbling all over the place. They hairspring should be flat and where it's supposed to be. Then your beat it be nice to be closer to zero but it can be off a little bit depends on the watch as long as you have proper amplitude. Then you can look at the timekeeping and make some decisions? Like can it be regulated at all? Often times people in the past like the play with their watches they don't have a timing machine they don't necessarily see the consequences of what they're doing. In the past most watchmakers never looked at the watch beyond one position so positional errors are discovering noticed. Or those nifty movable banking pins I get moved along with just about anything else so all of this at some point time may have to be fixed testing at the amplitude of. If you're seeing huge differences in poising error I find it's usually best to statically poise. If you reasonably properly static poise you can get a Delta within 15 seconds. Ideally when you're timing a watch you should develop a procedure. Timing procedures would be for instance you wind your watch up tight in you let it run at least 15 minutes to an hour. That's the modern recommendation if it's wound up the very tightest it 10 step too much amplitude and timing can be unstable so it needs to settle down a little bit. It also notice typically with pocket watches when you changed positions it takes a little bit for the Balance wheel and or timing machine to synchronize and be stable again. So maybe a minimum of 30 seconds between changing positions and measuring for about 30 seconds. Then while most these watches were really timed and six positions always good to evaluate your watches and six positions. But not necessarily get obsessed with well are typically not a Rolex watch so you shouldn't expect chronometer timekeeping.1 point

-

one of the problems we have on this discussion group is people using apps with microphones for audio processing but not designed for picking up watch sounds which are not actually sounds at all. Yes we can hear them as sounds with the timing machine picks up the vibration not the sound. The simplistic of all of this is on multiple occasions we've been led astray because the apps are barely adequate. Which becomes frustrating if we can't help somebody who relies on an app when a timing machine is a relatively inexpensive thing that's actually quite necessary. why would the screws slip? The screw holding the study and should be relatively tight if it slipped thing where you taking it out or doing something with it? than paying the balance wheel the bridge like that isn't really recommended as you can distort the hairspring. As nice as the pictures are of the balance wheel and the bottom side of the balance bridge why don't you give us a view of the balance wheel in the watch. It almost looks like from your pictures of the movement is still in the case? It be really nice to get a sideways view of the balance in the watch which you can't do if it's in the case. That also a view looking straight down on the hairspring once again with the balance and bridge in the watch. Because the ultimate problem is in the watch not out of the watch it's hard to see when it's out of the watch because it's usually better if we can see it in the watch the coding system won't let me quote what I want to quote sledges snipping out an image. The text that somebody wrote is correct for a whole variety of reasons. The text in the photograph is not right at all. If you listen the stud screw all you can do is have the stud go up and down. If you want to push really hard on the hairspring you will destroy it. You will note that they hairspring is held in with a pin in order to shove it it have to pull the pin out. If you pull the pin out and shove the hairspring is not totally screw up regulation and you might as well get a balance completes. This is where we come back to balance wheel goes in the watch and you probably have to make the correction of bending the hairspring there although ideally be nice if you practice on some scrap hairsprings first and we really need to see what it looks like in the watch.1 point

-

1 point