Leaderboard

Popular Content

Showing content with the highest reputation on 05/14/22 in Posts

-

My dad gave me this pocket watch, it was a gift to ware at my sisters wedding, I was 12 years old, I'm now 60. At some point I dropped it too many times and it stopped working, so it got stuffed into a drawer and forgotten...until now. I took it apart and found the escarpment wheel had a broken pivot. I was able to source a new escapement wheel and proceeded to clean and rebuild the watch. At one point I thought I had failed as the balance wheel would not rotate correctly, but I then found that I had installed the wrong screw into the pallet cock bridge and the balance was just barley rubbing on it, but enough to mess it up. Once I figured that out it started to run...and too my absolute joy, it works great now!!! Really a great and fun rebuild / fix, especially because it was a gift from my late dad.3 points

-

For some reason, I suddenly had a desire to learn how to repair watches! I am a designer and engineer by profession, who has not done any real engineering or design in the physical sense, after I sold my old motercycle, And I think that somehting has been welling up inside of me over the years. And then, when I see the watches for sale in shops or stalls, I have a strong design to buy them. Anyway, for the past 6 months or so, I have bought a set of tools, and I am teaching myself to clearn and lubricate watches. And I want to continue doing it... I am on my fourth, and I think I am at the stage where I can lubricate in the corrent way, and I can pick up springs without them vanishing into the fourth dimension. Do I need treatment?2 points

-

2 points

-

Was the spring original (blued or black steel)? That would definitely need replacing. Let down the power and remove the click. Rotate the barrel forward and back a fraction while watching the train. Look for any wheels that wobble around or back/forth which would indicate worn or broken pivots or worn bearing holes. That could cause the stop/start problem as wobbly pivots can allow other things rub and cause friction. I wouldn't suspect a balance problem unless the pivots are broken or something (which is all too common). Disclaimer: I'm just learning myself, but thinking and writing about stuff is how I Iearn.2 points

-

try sanding the wood instead of using a knife (fine sand paper) just make sure you wipe off the dust Here you go from Cousins https://www.cousinsuk.com/product/component-probe-cousins?code=S533972 points

-

I've been pegging some small jewel holes this afternoon. Despite using Bergeon Beech wood, I find it hard to get a really fine point. So for the smallest holes I use bamboo skewers. It's much easier to get a fine point.2 points

-

As anyone knows on this discussion group I regard each watch is an individual problem and I don't like generalizations which is the way this discussion is going. So for generalized nations before attempting to time will watch not that you can't the timing machine is still good for diagnostic purposes but before you try to regulate a watch you need to have proper amplitude. As the amplitude drops problems magnify. Positional errors become much much worse and a stamp to do is low enough to beat error will increase and it's not the beat error is because you got to get your amplitude up. As were discussing American pocket watches? Typically bimetallic balance wheels this means if they're squeezed and we all loved the squeeze our bimetallic balance wheels don't we? But they don't like to be squeezed and then there out of round. This creates positional timekeeping issues. Usually when you look at your balance wheel it should be running flat not wobbling all over the place. They hairspring should be flat and where it's supposed to be. Then your beat it be nice to be closer to zero but it can be off a little bit depends on the watch as long as you have proper amplitude. Then you can look at the timekeeping and make some decisions? Like can it be regulated at all? Often times people in the past like the play with their watches they don't have a timing machine they don't necessarily see the consequences of what they're doing. In the past most watchmakers never looked at the watch beyond one position so positional errors are discovering noticed. Or those nifty movable banking pins I get moved along with just about anything else so all of this at some point time may have to be fixed testing at the amplitude of. If you're seeing huge differences in poising error I find it's usually best to statically poise. If you reasonably properly static poise you can get a Delta within 15 seconds. Ideally when you're timing a watch you should develop a procedure. Timing procedures would be for instance you wind your watch up tight in you let it run at least 15 minutes to an hour. That's the modern recommendation if it's wound up the very tightest it 10 step too much amplitude and timing can be unstable so it needs to settle down a little bit. It also notice typically with pocket watches when you changed positions it takes a little bit for the Balance wheel and or timing machine to synchronize and be stable again. So maybe a minimum of 30 seconds between changing positions and measuring for about 30 seconds. Then while most these watches were really timed and six positions always good to evaluate your watches and six positions. But not necessarily get obsessed with well are typically not a Rolex watch so you shouldn't expect chronometer timekeeping.2 points

-

2 points

-

Good doesn't necessarily need to be expensive and cheap doesn't mean it's bad. I have $2 tweezers and $20 screwdriver sets. And they work fine. The important thing is knowing how to care and maintain your tools. Tweezers and screwdrivers need to be dressed to perform properly. The only thing important to me is the quality of the metal. Anything else can be reworked and refinished to suit preferences. If the metal is weak and breaks or bends easily, then that is useless. I buy a lot of cheap screwdriver sets from $2 stores to make custom tools. That hurts a lot less than grinding down a $10 Swiss screwdriver. So, get a set of grinding stones to reshape and dress your tools. And always use the right tool for the job. I don't know how your tweezers ended up looking like that but I'm sure it was used for something creative.2 points

-

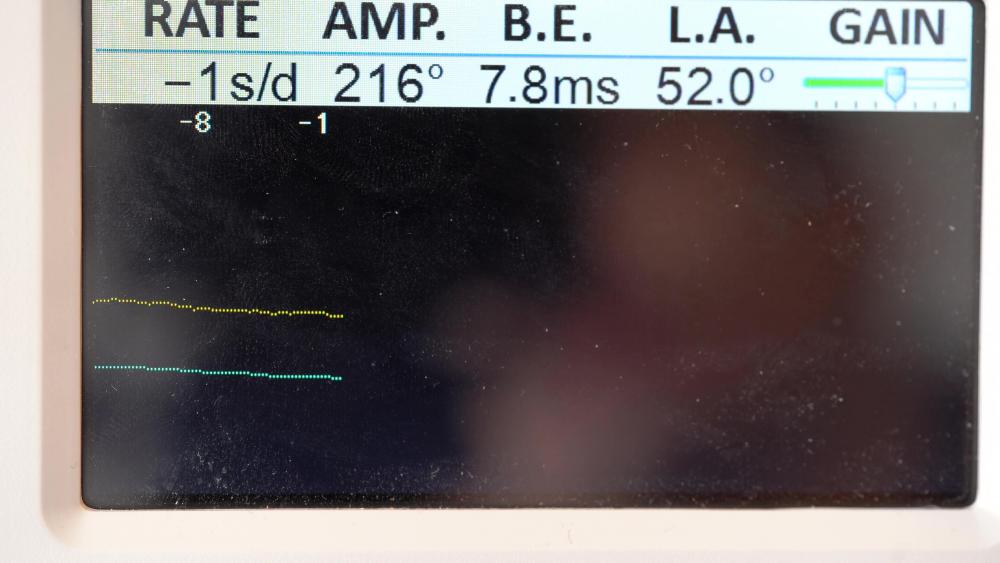

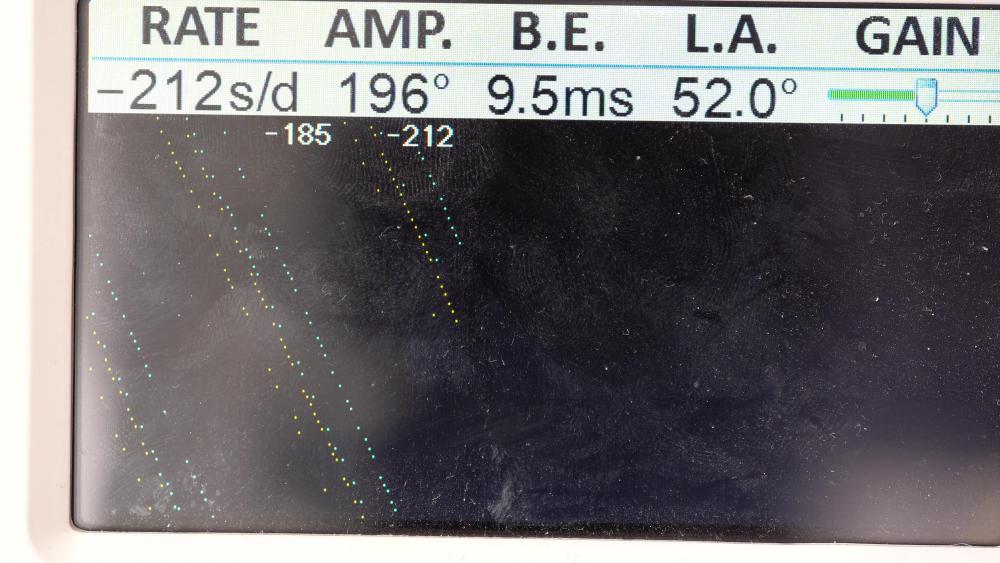

Hi everyone! This time I'm back again with a little something which turned out to be something of a hybrid project. I had repaired and planned a video on a Junghans watch with the 93 movement caliber to give to my younger brother ( which young adult doesn't need a nice looking watch) and had it all set out, planned and executed. The only downside was that the dial was slightly discolored on the right side due to bad cleaning on my part. Here you can see what I mean by that: But I happened to be at a local fleamarket on the day when I wanted to finalize the video and surprisingly found the exact same model! Even though the crystal was pretty scratched up, I was confident that the dial was in a good condition so I bought it for 10 Euros. And yeah, it looks like I hit the jackpot: So.. I got lucky and changed the dials in the end. But enough rambling around and here is the actual process of working on the watch movement: 1. Removing the movement from the case. This movement was from the “trilastic” model line of junghans and it got its name from the tri-legged support beams which held the movement inside the case. Just pop those up and remove the movement. Fun fact: While checking the inside of the caseback for marking I found one from 1981, thats so coooool! : 2. Remove the hands and and then the dial by unscrewing the dial feet clamps ( Forgot to take Pictures sorryyy) 3. Strap the movement into the holder and unwind the watch if needed. Then I removed the broken watch stem. 4. Remove the blued ratchet and the click spring 5. Remove the hour wheel, minute wheel, canon pinion and the very interesting looking yoke and its spring. 6. Then remove the clutch and flip the movement. The leftover lever will be released from the backside later on. 7. Remove the balance wheel and the pallet fork system. 8. Then remove the two screws holding down the mainplate and lift that. You can go ahead and unscrew the screw in between as well since that will release the left over lever on the front side. Do the same for the mainspring cover. 9. Remove the gear train and the mainspring And that's about it with the disassembly! Now moving on to the whole cleaning, lubrication and servicing part! Mainspring service: This Mainspring was something new to me since it had a very interesting arbor! Instead of the traditional small arbor inside the barrel, it extended outwards and acted as a lid and a wheel at the same time. While this is definitely cool, it also brings some negatives such as faster exposure to dirt and etc with it im sure. It looked fine so I just recleaned, lubricated and reinserted the whole thing: Lubrication: Here is a list of lubrications I used Moebius 9010 - All jewels Moebius 8200 - Mainspring and barrel lubrication Moebius HP 1300 slower moving parts such as canon pinion Moebius 9415 - Pallet Fork hooking jewels Molykote DX - Gearless works and high contact/friction zones (Front side only really) Oh and of course don't forget to clean and lubricate the balance shock jewels! Reassembly: Just reverse the disassembly steps or watch (no pun intended) the video for a step by step walkthrough. Timegrapher Test: Before Regulation After Regulation: Now i'm very happy that the rate is so much better. The amplitude can definitely be better however I would blame the old mainspring for that. The one thing that puzzles me really is the Bear Error. I've tried virtually every combination on the balance but the beat error does not improve. Maybe something is wrong with the hairspring? Final Result: After attaching the more aesthetic dial and recasing the watch and adding the straps, these are the final result pics: I must say I'm very happy with the whole process! Of course there were some up and down moments like when I destroyed the balance ( don't even ask) and had to get a replacement and such things but it all worked out in the end did it not? I was not sure how the beat error and the lower amplitude were going to show themselves while wearing the watch so I did a test wear for a week and the time only deviated by a second or two so I'm relieved! Now I apologize for the lack of pictures for a smooth documentation, I forgot and yeah, the rest is history. However, I have uploaded another fully commentated video so If you want explanations, more information or just a smoother experience go check it out: https://youtu.be/ZDXKiNnrmMk Any criticism, questions, comments and tips are always welcome and i'm happy to talk to you all! Hope you enjoyed it and until next time! Stay Healthy!1 point

-

I never throw away anything. I'm a hoarder. I'll probably grind off the tips and reshape them. If the tips are too soft, I'll try hardening them. If that doesn't work, I'll still keep the metal in my scrap drawer. You never know when it may come in handy.1 point

-

Check the oscilator, is it in beat? Does ot swing freely? Check the end shake? Loosen the cock screw a turn or two , see if it runs then. Check if the balance wheel rubs on the fork cock. or hairspring rubs on the balance or its spokes and underside of the cock. Check the jewels including cap jewels in the setting. Check if balance pivots are intact. Regs Gary you beat me to it.1 point

-

1 point

-

1 point

-

1 point

-

Thanks guys, sure feels good, and a great boost in confidence! Not including the wait for the replacement escape wheel, I think it took me about 4 -5 hours or so. I worked on it for an hour or less in the evenings after work, so I didn’t really keep track of the time. I saved the broken escape wheel, I never through stuff like that away, in fact I hardly throw anything away, just ask my wife! Haha!1 point

-

It's the really small screws that disappear here It's possible but you haven't supplied enough info to make a determination It sounds like you're doing better than I am. Hopefully I'll make it to my 4th project without destroying the balance. Welcome to the forum! Looking forward to seeing some photos.1 point

-

Nylon would be ideal. It's soft enough to not damage anything, but stiff enough to be useful. Try searching for "spudger stick" etc. For example this one on Amazon looks close to what you are looking for and is cheap: https://www.amazon.com/Plastic-Spudger-Opening-Repair-Laptops/dp/B00MXHWSV21 point

-

Welcome Andy! I can sympathize also. Granted, I have always been deeply fascinated with timepieces, so becoming involved with repairing them was likely inevitable, but I also learned this trade simply because I came from a humble enough background that paying to have my earlier watches repaired would have been expensive for me back then. And now, these days, I own a handful of high-end watches, not because I bought them brand new, but because I was able to buy them as non-runners for a paltry sum and repair them and regulate them. And I also "flip" pocket watches. I rescue them before the scrappers get them, and I restore them to running order and sell them. Not much of a profit margin, but I feel good about saving them.1 point

-

1 point

-

Try knitting needles or large sewing needles both available in pvc. Im out at mo but ill post a picky when i get in . Mught be tomorrow though. You can also by 2mm carbon rod to go in a pen for cleaning, but i found that it can scratch if not careful. Tbh mate. I tried a few things but always end up going back to a shaped pegwood or bamboo skewer. Get a cheap craft knife for sharpening it takes little more than a few seconds1 point

-

Outstanding work on those pens Tiny. I don't know anything about pens, but I know a left handed #6 winder is the right choice for a Seiko 7019 MS1 point

-

I have stopped using my Weishi-1000 as I don't yet really understand the readings I'm getting also same watch will display one set of figures and then something completely different say three or four hours later I am talking about automatic winding watches. We can all get hung up on trying to get it perfect. I'm quite happy if a self winding watch runs two or three minuets fast/slow a week. lets face it I'm not timing a F1 race or bolt Sorry to gate crash1 point

-

1 point

-

You should go back to your thread https://www.watchrepairtalk.com/topic/22456-doing-it-wrong-makes-you-remember-to-do-it-right/#comment-1898781 point

-

I have a theory about transient micro worm holes. They pop in and out of existence, items disappear, items reappear. I'll win a Nobel prize when proved correct.1 point

-

Shock springs either lost or broken are a regular topic on the forum. I used to clean watch parts in a ultrasonic cleaner and never lost a spring so as a guess it must have been loose or not under tension. Rule of thumb when fitting absolutely make sure the spring and the tweezers are de magnetised. If attempting for the first time put some cling film over it while manipulating. It’s awkward but trust me the springs have life of their own. The easiest style of spring to deal will is the trior. I shaped a piece of pegwood to work with them.1 point

-

Speaking to the tweezers, I've found an awesome budget option is getting some precision ESD tweezers which are normally for electronics repair. They seem to be of higher quality than cheap dumont clones.1 point

-

I find if you really want to know the amplitude with the modern timing machine you have to follow the procedure at the video below. That's because lift angle for American pocket watches can very think the lowest I've recorded has been about 38 to 62° and this is independent of the size of the verse watches. In other words is because the watch is a 16 size you can't say it's going to be a low lift angle because it might actually be a higher lift angle.1 point

-

That's a full 360 rotation, but only 180 degrees amplitude, which is not that good at all. Balance wheel amplitude is the angle of rotation from the neutral point (where the wheel would be sitting if the balance was at rest with no power on) and either one of its extremes of rotation (the point where it reverses direction), so half the total rotation from one extreme to the other. If the amplitude was 360 then the balance would rotate a full 720 degrees from its extreme clockwise position to its extreme anticlockwise position, which as @nickelsilverpoints out, is impossible as the pallet fork would be in the way and hard up against the banking. You would get re-banking, with the impulse jewel crashing into the outside of the fork horns causing the balance wheel to rebound. Sounds like a galloping horse.1 point

-

Good practice for a couple of days will develop your natural ability, keep at it.1 point

-

Good attitude to have mate. A lot of folk underestimate right from the beginning what is involved and then get sorely disappointed and eventually give it up as a bad job. Some you tube vids dont help either as they make it look far too easy. Some days will be great others you will be tearing your hair out over. This just doesn't apply to beginners either, guys that have been doing it for years still have problems. Take the rough with the smooth, the good with the bad. Enjoy the challenges rather than fear them and just work through them as you would anything in life. A calm logical approach is your best friend, if frustration starts to ensue be sure you know when you need a cuppa break or else it can end up a watch break. But most of all enjoy this fascinating rewarding hobby whatever each encounter brings. Good to have you here my mate1 point

-

I've said it elsewhere on this forum before, but I recently spent a good long while spring hunting, only to give up. Then I immediately found it stuck to the inside of the lens of my glasses.1 point