Leaderboard

Popular Content

Showing content with the highest reputation on 05/13/22 in Posts

-

4 points

-

That's a full 360 rotation, but only 180 degrees amplitude, which is not that good at all. Balance wheel amplitude is the angle of rotation from the neutral point (where the wheel would be sitting if the balance was at rest with no power on) and either one of its extremes of rotation (the point where it reverses direction), so half the total rotation from one extreme to the other. If the amplitude was 360 then the balance would rotate a full 720 degrees from its extreme clockwise position to its extreme anticlockwise position, which as @nickelsilverpoints out, is impossible as the pallet fork would be in the way and hard up against the banking. You would get re-banking, with the impulse jewel crashing into the outside of the fork horns causing the balance wheel to rebound. Sounds like a galloping horse.3 points

-

I find if you really want to know the amplitude with the modern timing machine you have to follow the procedure at the video below. That's because lift angle for American pocket watches can very think the lowest I've recorded has been about 38 to 62° and this is independent of the size of the verse watches. In other words is because the watch is a 16 size you can't say it's going to be a low lift angle because it might actually be a higher lift angle.2 points

-

as others have stated 360° is a very undesirable amplitude. I think usually about 320 is the maximum because anything over he you will have bad things happen. yyes the problem of vintage watches they don't give us a lift angle.. Then yes from the ones that I've measured they can vary by quite a bit and it's really independent of their size.. The ones I've figured out range from anywhere from 38 to 62°.. tthen in addition to lift angle problem if you amplitude is super low often times the timing machine will look at the middle part of the waveform and give you an abnormally high number. Which means visually your amplitude has to agree with the machine or the machine is having a problem.. then as others have pointed out that appears to be a mean time screw it's not supposed to ever come out. They're not supposed to be screwed in tight either but sometimes you find him that way. Another way to tell is usually the threaded part is longer. Then of course the thread dimensions are entirely different the usually much finer and are designed to stay in place hopefully. The word hopeful is because of they get played with too much they get loose. https://pocketwatchdatabase.com/search/result/waltham/15644188 obviously not your serial number but close enough. Being as it's a seven jewel watch of that size I'm suspicious as to whether it has a mean time screw or not? because usually mean time screws are associated with better grade balance wheels which would never be found on a seven jewel watch especially of this size. It's possible that somebody is mixing and matching components before you and shoving and whatever they had.2 points

-

Buy a working movement, if it still works when you have reassembled it, then you have done nothing wrong. Fault finding is more difficult than a service, I've learnt the hard way.2 points

-

Hello and welcome to the forum. I have attached a little reading to introduce you to complexities of the watch. Hope you find it usefull 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf2 points

-

Tweezers and screwdrivers are worth putting a little money into. Anything you use constantly. If you were to now go buy a pair of Dumont #2 or #5, they're just $6 more expensive than they would have been had you bought them the first time. My kneejerk on the detritus is that it looks like a shock spring that went through the wash. Flatten it out, and it looks like it's missing the the end of one tine, and the hook that fits into the setting. If you have all of yours, then it's probably Sea Gull QC failings.2 points

-

Using the Rodico means you don't have to hold the spring in (wobbling) tweezers. You can just push it down with pegwood. Good luck2 points

-

That looks like a meantime screw, should be a light friction fit on the threads, and is used to adjust the rate in addition to the regulator. Usually isn't screwed all the way in, should stay with the balance. Check other screws for timing washers and remove those, see how it does. If you need to remove weight still you can trim other screws as needed. 360 degrees isn't possible, were you looking at the timing machine's amplitude or the watch itself? The lift angle on some of these is quite low, even below 40; if you're set to 52 you'll get an artificially high reading.2 points

-

2 points

-

Is it an Inclabloc 'lyre' type spring where you have to get "T" end back in place ? They seem nearly impossible when you are a beginner - but you will look back in a few years and wonder why you struggled ! One way to make it easier is to put some Rodico at the edge of the block where you are trying slide to spring in. Stick the spring to the Rodico vertically - you may need to adjust the angle to get it to slide in. Then using pegwood and tweezers, slide the spring down in to place. The Rodico should stop it pinging off. It's much easier if you are lucky enough to have a microscope to work under2 points

-

If it's 19L, then 42.86 mm I had a look in Best Fit to try to identify the keyless work, but nothing close.2 points

-

Generic seagull factory swarf? Some of those Chinese clones are actually pretty nice -- some are terrible. It also looks like your tweezers need some TLC2 points

-

I bought selections of 100 each of screws, springs and click springs from cousinsuk, cost about £6.00. I have been taking them from their boxes onto the mat, turning them over, picking up and putting them in another dish then reversing the process after doing all 100 of a type. Advantage of doing this is if you ping one off to the Swiss space program it doesn’t really matter as it is not part of the movement and is really cheap to get lots of practice. Tom Oh, and you have potential spares for the future Tom2 points

-

Don't know if anyone else noticed this but Moebious are now doing a slightly cheaper route into using their Fixodrop, Moebius 8981 Fixodrop (Ready to Use), 10ml Supplied in a small application bottle with mesh filter built into the bottle, only 10ml but also under £30, should do a few pallets and end stones and a cheaper route into seeing if an Epelame works as claimed, at that price even I may get some. I wonder what the evaporation time is for 10ml in a none pinched neck bottle.2 points

-

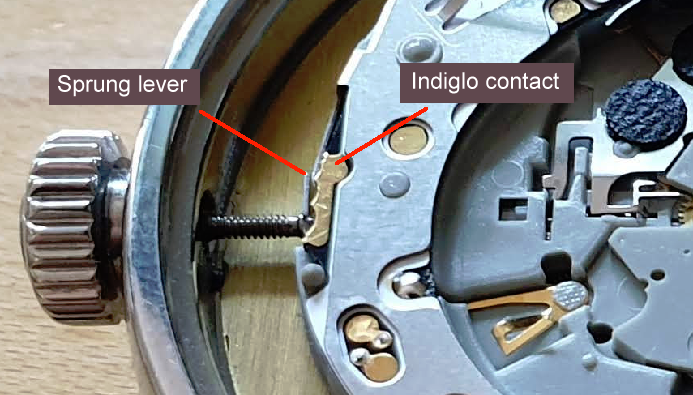

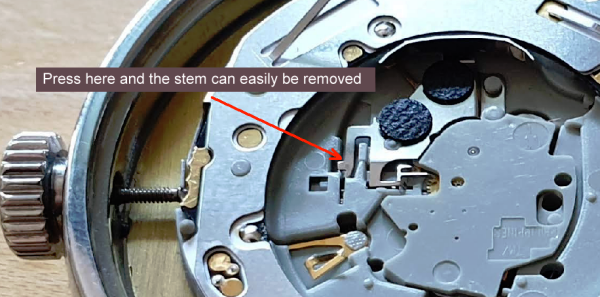

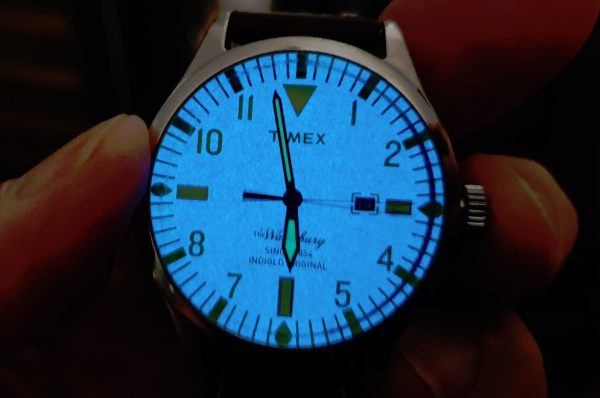

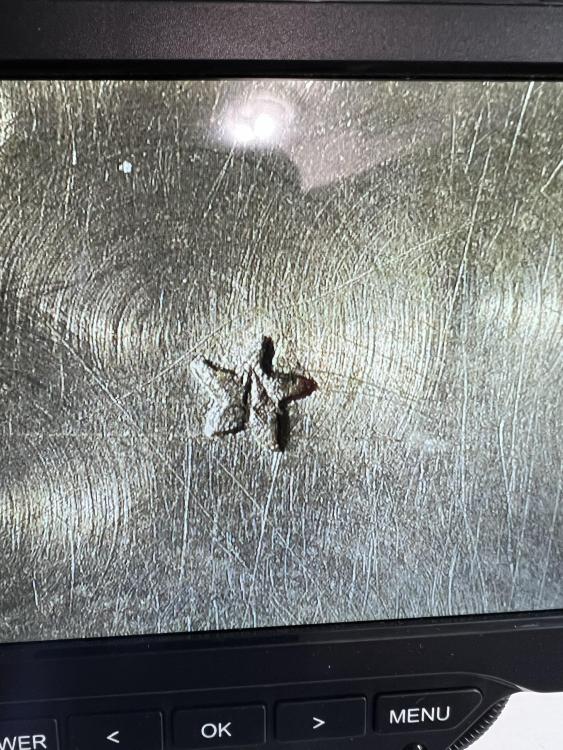

My Timex Waterbury 2018 backlight was intermittent from new. This was a 60th birthday present which I really appreciated so I didn't want to try and return it in the heat of the Pandemic. After about a month the Idiglo stopped working altogether even though the watch keeps excellent time. The illumination itself was working fine when it worked at all. The problem was that pushing the watch crown inwards to activate the light seemed at fault. Towards the end I found I had to pull the crown out slightly and then press to get the light to come on. This ran the risk of accidentally changing the position of the hands which meant I couldn't trust the time afterwards. It was getting annoying! Following advice in the forums I used a stout bladed knife and popped the back off by lifting the tabbed part against the nearest lug. Replacing the back was going to be very tough but more on that later. The scratches on the crystal look terrible in this picture but it's hardly noticeable in reality. The fault did appear to be with the on/off switch mechanism so that's what I went looking for. When you press on the crown the sprung lever should be pressed against the gold plated electrical contact and complete the circuit for the light. The spring then returns the crown, the circuit is broken and the light goes off again. Ok so cool. I know how it is supposed to work now but it's so simple, how can it not be working? To make matters worse it did work absolutely perfectly with the back off! So I figured that I had mended it and put the back cover back on. This was VERY HARD. I couldn't press the thing hard enough to make it snap back and all that happened was that the cover 'see-sawed' around and I started to worry that I would damage it. So in the end I pushed the cover as far into position as I could and then clamped it between two pieces of wood in a table vice. Protecting it with layers of paper towel I gradually increased the pressure - fully expecting to crush the crystal - until it popped back on. I'd been very careful to clean the surfaces around the seal and replace the rubber gasket without any twists that might compromise the water resistance. But the backlight was still faulty. Exactly the same. I guess the stem was touching the lever while the back and retaining parts were removed. I took the back off again and decided to go a bit further this time. The stem was removed very easily by pressing the little locking tab. I don't have a picture of it happening but when I was handling the case to get the stem out a tiny, tiny circlip fell out as well. About 1.75mm diameter. I'd never seen one of these things so small! Here's a picture of it close to the groove it should be clipped into. I know that holding it with a magnetic pick could risk magnetising it but I tried tweezers and immediately realised that the tiny thing would go flying into orbit and be lost forever. How am I supposed to get the circlip into the groove without it disappearing across the room? The answer was Blu-Tack. I pressed the circlip into it with the open part upwards and then pressed the watch stem down on to it until it clicked in. Result!! And that was it. I replaced the stem and did the scary vice thing again to replace the back and it was done. Good result! Considering how many Indiglos have been sold around the world I was surprised that there was just nothing like this on the internet so I'm posting to help others in the future. It was pretty easy to do once I knew what was needed. But it was also VERY fiddly and you really should be aware that losing the circlip or crushing a watch in a vice are likely to void your warranty! See you out there, Moo1 point

-

I've just done my fist attempt at a full disassemble and rebuild. Watched the Mark Lovick video tutorial a number of times. Good to go. Ready for the first clean in Lighter fluid. Check everything. Balance secured to base plate. Balance jewels removed from balance cock and plate. Kept separate. Good to go. Jewel spring on cock secured. Good to go. Place everything in Ultrasonic cleaner. Off we go. Done it. Feels good to achieve everything. The rebuild will be a doddle. Put everything out of the tray into a receptacle to dry. What's this extra bit of gold glitter? I did not have anything golden in the tray. Pantomime. OH yes you did. I had not secured the balance bottom jewel spring on the base. There it was!!!!! Easy to put back isn't it? OH no it's not. I've been at it 3 days now. Not skilled enough. Even sent off a set of ss tweezers. I will get there. Doing it wrong means you do it right next time. Will I secure both springs before a clean? You betcha. Ross1 point

-

@Levine98 You may not have entered a reasonable LIFT ANGLE for your old Elgins. While 52° is usually correct for new watches it may not be correct for older movements.1 point

-

I went that route. I even got two that were "the same" - except they weren't really (same grade but 16 years apart). Richard's advice is sound, if you get one and you think all you need to do is clean it, oil it and put it back together you may find all sorts of other problems that you're not really ready to tackle. Like Richard, I too have learned the hard way1 point

-

Don't worry, you'll need more! Do you have a movement that you're planning to start working on? Welcome to the forum!1 point

-

Actually…no thank you. I have returned back. It is hard to inspect a watch if the online images are not good quality. I had my doubts about this watch but I was hoping I’m wrong.After all It is a beautiful looking watch ; but not for me.1 point

-

Good practice for a couple of days will develop your natural ability, keep at it.1 point

-

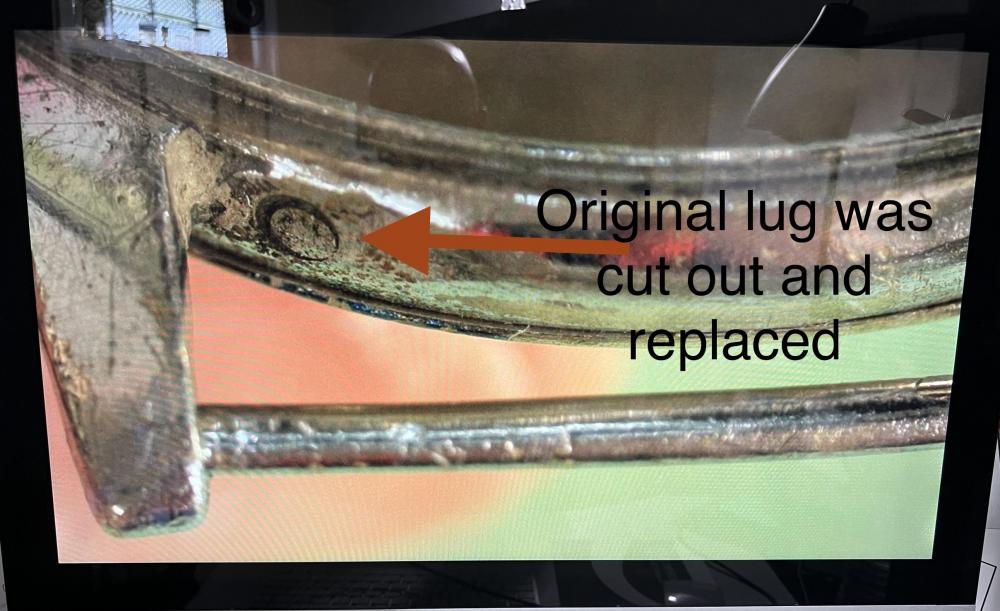

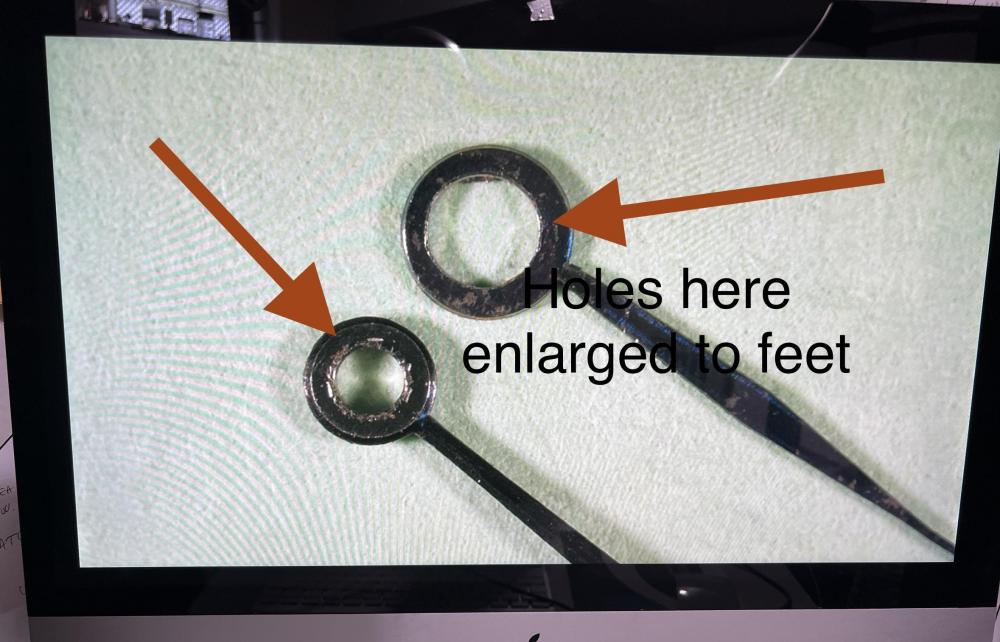

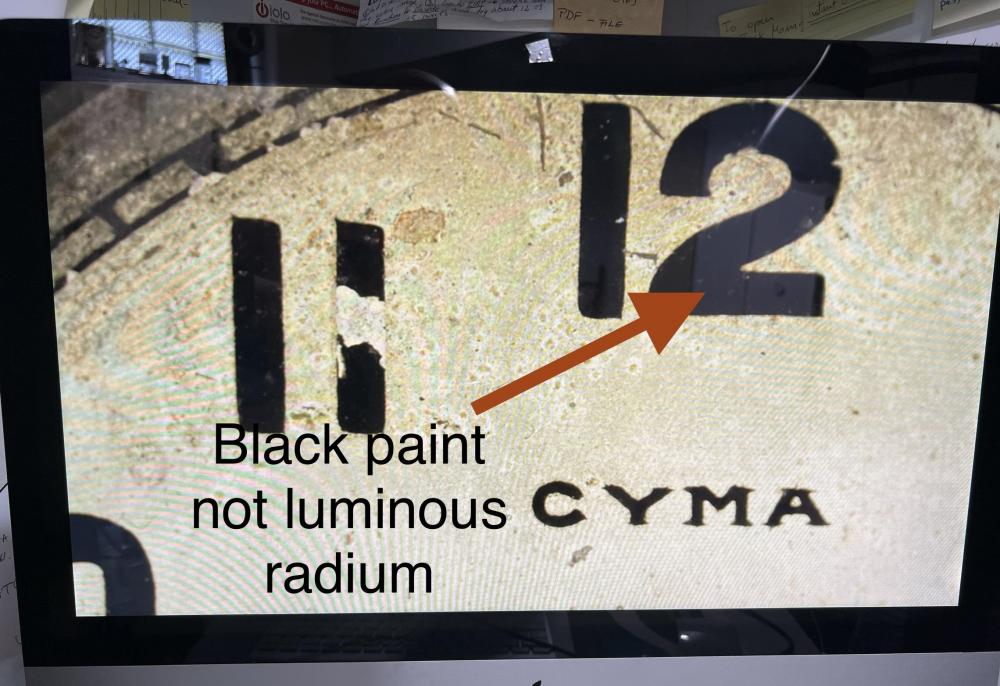

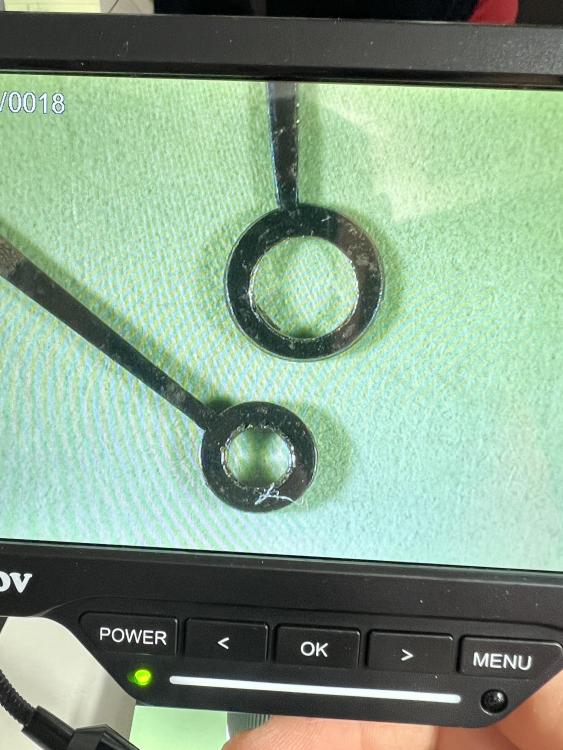

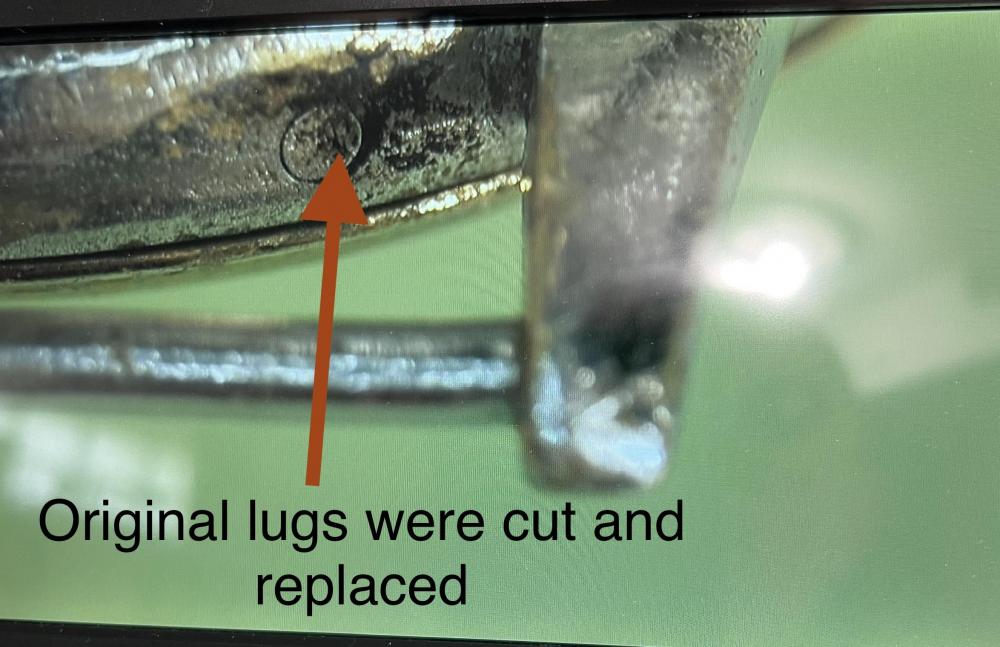

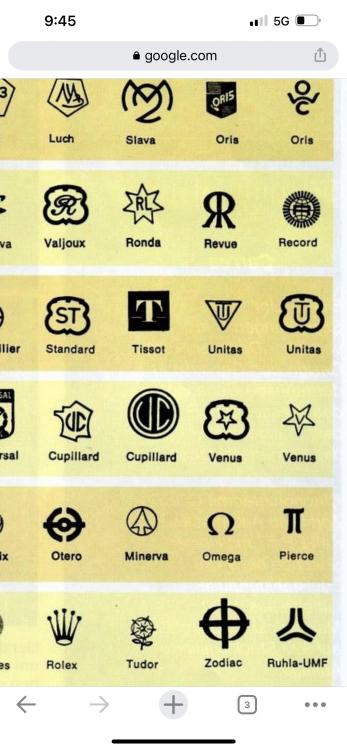

I believe I have solved the mystery here. Finally got the watch in my hands to take a closer look. The watch movement along with case and hands were heavily modified. Hands are not original to this watch, they been modified. The hands holes were enlarged so they can feet this caliber. Case also was modified and is not original to this watch. The original lugs were cut and replaced with a larger ones.The numbers on dial, they don’t have the radium lumens like all military watches have, they have black paint. The dial seems to be original but far away to by military. Also I believe the case was borrowed from another watch , perhaps Venus. Looking at the star stamp and I’m comparing with the logo of the Venus watch. They look very similar to my eyes. Not to mention the balance wheel does not have the Breguet hairsping. According to my research the caliber 570 supposed to have Breguet hairspring and not flat like this one. Also this particular movement has only 5 jewels. At least this is my conclusion with this watch. That’s way I have posted my conclusions here, perhaps I can help somebody else in the future not to purchase this watch. This is definitely a Franken watch.1 point

-

So had wire lugs that makes sense. I have a venus at home to repair so i will check that. Zenith also has a star. Great find matey. Remind me never to ask you to help me buy a watch.1 point

-

Lesson of the day Tea strainer for finding lost parts in toxic sonic cleaner. Yes I had a bit of a day so now I've mastered the tweezers on small screw. the trials & tribulations of a watch maker or even small part handler, today throw me a curve ball. After finding or the lack of finding a very small date spring on my Seiko 7019a I had to replace it from my extra movement. After striping the movement date side, I needed to clean it. So off to the sonic cleaner with the part in a small press fit basket (1mm mesh) I continued to procced to go through the three stages of cleaning fluid all was going really well until the last jar at the end of the cleaning cycle the press fit basket had opened (I do have to say it's the first one) with the very small date spring no longer in the jar I looked and looked for the spring but no spring. so cutting a long story short the spring was found in the first jar, the real problem was picking it out of the glass jar finding the spring was easier if you are looking from the outside of the glass jar because every time I placed the jar on the bench too open the glass jar it had moved that cleaner Elma WP Pro cleaning fluid is not to good for you. so lesson of today is really small parts I'm going to put in a screw mesh container I have but the spring being found in the first jar means the 1mm mesh is not holding the really small items so I will have to see if I can find something with a smaller mesh and strain all cleaning jars is a tea strainer and filter paper.1 point

-

Doesn‘t look like e technical item. Perhaps belonging to the (any other?) dial.1 point

-

1 point

-

I was referring to the name you have chosen. It doesn't really fit in with the watch repair theme. Lol. Great that youve started your journey its a very enjoyable hobby. Good tool selection will definitely help you from the start .1 point

-

TG is quite correct i often find the stuff in cheap swiss. Your tweezers do need a bit of alignment fella. Make some investment into learning tweezer and screwdriver dressing. It will greatly improve your handling of parts which will add up to less losses.1 point

-

i'll be honest ..... the whole process so far has been just as hard as i thought it would be! i suspect (and thoroughly hope) that it gets easier with practice. Nevertheless, i've loved the experience so far!1 point

-

That will be a completely different experience ws. We look forward to hearing about and helping you with that one. There are some very knowledgable pros here that I'm sure will give you their time with that one.1 point

-

1 point

-

Many more painful lessons to go Super-small springs are not worth washing in mesh baskets anyway. I just use rodico if they are dirty at all. With cheap mesh baskets you still have to be careful with tiny parts finding a way into the rims of the basket. I've had to take a jeweler's saw to them to free items. Now I only put slightly larger items in the cheap baskets, and tiny parts go in a Bergeon ($$) basket. Even larger parts can go directly in the cleaning machine's partitioned baskets.1 point

-

I've attached a PDF you'll notice that it converts metric inches whatever into ligne which is how we measure watch movements it's measured on the dial side. It's because if were looking at a book trying to identify your watch that's the size we need then the measurements are nice but present a problem in that in watches usually the size the watch is referred to with this measurement ligne. I've attached a PDF that will cross reference to that. a little research indicates that well it existed https://mb.nawcc.org/threads/rode-watch-co.23189/ then casually in a the site sort of books I have on not seeing any staffs that resemble yours at all. Maybe if you could drop picture and label where the dimensions came from. The problem is all the reference books label things a little bit differently even one of my references uses Roman numbers but casually I'm just not seeing anything that looks like your staff at all. Maybe a picture would be nice so we can see with the staff looks like. watch-ligne-size-chart.pdf1 point

-

Tweezer acrobatics. First make sure your tweezers are dressed. Then practice picking up small items such as very small screws etc then try and turn the item 180 degrees without dropping the item. Trust me it’s not easy.1 point

-

Not all military issued watches were field or pilot's watches. I was told by the watchmaker that restored mine many years ago that it was an officer's watch. The scratched up back (it's REALLY messed up) was to get rid of the number etched into the back by the German gov't for tracking. The battlefield repair is a series of small tangs knocked into the periphery around the crystal by the tip of a knife or bayonet to hold the crystal in lacking access to a new crystal or proper tools or what have you. It was likely either picked off a corpse or traded for cigarettes or something in a POW camp. Eastern front based on having come to me from Ukraine. If yours is military, the case back will tell you.1 point

-

Brief update. I went out and bought some guitar wire and made a few springs. Pinged about 3 of them into the void again but finally got the keyless works back into place. I will try over the weekend to put the rest of the movement back together and see if the whole cleaning and oiling will help1 point

-

Never forget yesterday, but always live for today... Because you never know what tomorrow can bring, or what it can take away...1 point

-

if someone is getting their arse kicked over it then call me Dumbo Were you driving it too hard ?1 point

-

Hi @Edifred, I mistakenly thought I could interchange parts on an old Elgin and created various headaches along the way. I have some other movements that I'm working on. Welcome to the forum!1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

When and where will the sale be. I could spend days looking at all that lot. Just looking at those few photos this is the star of the show. It's a French alarm in a nice case you don't see them in that type of case they are normally just in a round drum case that is why they are known as a French drum clock.1 point

-

1 point

-

ign30, I just scored an incredible deal on those types of winders myself although they came with a handle. In messing around with some scrappers and installing and removing mainsprings, I found you don't really need a handle for them to work as it only makes it easier to hold onto while winding. You have access to the plunger to eject the mainspring into the barrel once its wound into the winding drum. So in a pinch or until you get a handle for the RH or LH winders, you still can wind mainsprings with just the crank arbor and winder drum.1 point

-

I adapted a tool to allow me to repivot a balance staff on a watchmakers lathe…and it all worked. Here is the video.1 point

-

After 1 year my Timex expedition Scout 43 Indiglo illumination has failed. Upon pressing the stem a small light appears below the 6 but the face doesn't light up. The watch used to be very accurate never gaining or losing 1 second over several months. It was really impressive and I thought Timex really does make accurate, high quality watches now unlike when I was a kid (the 60's) when Timex watches never lasted more than a year. Now, it loses about 2 seconds per day since the Indiglo failed. (I have to assume they're somewhat related). The battery, CR2016, has been replaced 2 times just to make sure it wasn't a battery problem. It's out of warranty (as you'd expect) Is there any practical repair that can be done to get the Indiglo working again? Thanks, Peter Dutton1 point

-

0 points

-

Letter from International Dial: I am writing this letter to inform our customers that International Dial is closing till further notice. This is a tough decision and I am aware this will cause issues with our customers and their customers as well... Health isssues and staffing difficulties are the reason for this decision. I have had a heart attack and I am currently recovering from that and the related issues that have arisen. David has found employment in a different career direction and has left International Dial. This has caused production to come to a halt and these issues combined have resulted in the decision that I have made. I am not currently able to focus on the long training cycle for any new hires that would be required to establish the skill sets needed to produce quality dial refinishes. My recovery is the priority now. The other refinisher that exist and should be able to assist in your future needs are listed below: L & S Dial in Los Angeles web site info is lsdialsca.etsy.com ph- 213-627-3455 Kirk Dial in Kent Washington no web site found ph- 253-852-5125 M & G Jewelers of Rancho Cucamonga, CA info@ mandgjewelers.com ph-909-989-2929 This company recently purchased Kirk Rich Dial and is now refinishing dials in its own production facilities. Kirk Rich Dial .... Ph 909 481 1949 or 760 843 3999 info@ krdial.com I am working to return all dials that I currently have to their owners... This is to be completed in the next couple weeks. I again am sorry for the problems this has and will cause for you, This has been a tough couple years and I wish you all the best moving forward . Sincerely, Timothy G McMullen0 points

.thumb.jpg.0dcf48cf505ca9adea0b5fc300df16cb.jpg)