Leaderboard

Popular Content

Showing content with the highest reputation on 05/10/22 in Posts

-

Two old gents are sitting down to breakfast in the local cafe one morning. Bob looks over at his pal and sees something strange sticking out of his ear. "Hey Jim, did you know you have a suppository sticking out of your lug" he asks. Jim reaches up and removes the offending item. "Bob, I'm sure glad you spotted that, now I think I know where I must have put my hearing aid."4 points

-

2 points

-

The way the tool is made the headstock runner is aligned to the center of the opposing notch, yes. Horia (Steiner), usually, marks the notches so that a pivot made in that notch will match the nominal same jewel, i.e. have just enough freedom: a 10 notch will produce a pivot a bit less than 10, 0.950-0.975 or so. The idea is you continue to burnish until it won't anymore, so now the pivot is level with the top of the runner. At any rate just a few microns difference even if you don't go that far. So you're right, that anywhere outside of that will be off, and should make a taper, but in practice the taper is so slight it's unmeasurable with any normal equipment. A few microns height difference over say 3mm, measured over a length of perhaps 0.3mm, is invisible. If you are getting visible taper there is an issue with your tool. It is definitely more pronounced on center wheels, true. Especially as the sizes between notches tend to skip by 3 or 4 hundredths. For larger work like that it's really nice to have one of the supplemental tools that works with the jacot tool using a carbide wheel, or a Pivofix or similar. All very expensive of course- but nice. Edit- just sketched it up, with a 0.01mm height difference from center, the total taper over 0.3mm is one micron. But- if using the tool "properly" where the burnisher sort of bottoms-out on the top of the runner, even that gets evened out.2 points

-

Hey y'all! After spending many an hour tinkering, reading FB group threads and of course taking Mark's online course I realized it was probably a really good idea to dive in here too. I've tinkered with mechanical things all my life but never seriously. It all started at age 5 with trying to figure out how a door handle works. With access to Dad's tools I just dove it. Of course I couldn't get it back together, just like the TV I got into not long after. We won't talk about the consequences of both. Like many I suspect, the pandemic led me to find Mark's videos on You Tube. So, here I am now with about a dozen or so new watch builds under my belt and now diving into tinkering with old watches.1 point

-

I often drive my the beautiful Lititz Watch Technicum campus and always find it fascinating that students there are getting a free education from Rolex on watch making. But I was even more amazed to (eventually) realize that I could learn rudimentary watch repair online. So here I am, having fun with teeny tiny parts that somehow fit together.1 point

-

1 point

-

Yes, it makes sense. The capacitor is a very high value...perhaps 1uF. It is a short circuit at the oscillating frequency. The resistor is there to bias the transistor. Maybe the coil resistance is 5K which without the 2.5M resistor (RGG is 2500000), that would bias the base current at 200u which is probably too high.1 point

-

the first thing I would do is take the dial off. If you're lucky you will see the click on the other side. Then and it be nice if you give us pictures before you do this but I'll explain. With a key on the square although universal key would be better because it's around a no spin in your fingers carefully you might build two of the pin vice may be. Vacation one a hold on the square really nice and tight don't lose control the release they click carefully and you let the power off slowly. Removing the balance bridge is also a good idea in that because the balance out of the way so you don't break anything. You do not want to remove the barrel bridge until the powers off the spring because when the power releases suddenly it tends to break things.1 point

-

you didn't say whether this was a manual wind or an automatic? Basically make sure the spring is nice and clean depending upon whose philosophy of mainspring lubrication you look at. If it's an automatic you put breaking grease on the outer barrel wall of suitable type. Then if you're falling Seiko's recommendation they have a lubrication that they put all over everything if you could find it. Or you can put no lubrication on the mainspring because are supposed to be self lubricating otherwise you could put some 8200 grease. Remember to lubricate the barrel arbor also1 point

-

Any jeweler will tell you. I would subtract 5 to 10g (max.) for movement and crystal and calculate with $20 per gram gold 375.1 point

-

Ah excellent, that's a nice Steiner there. The little jack screws you see set the height, but different than first impression. By tightening them down, they force the V block in the head upwards, raising the spindle. To lower, you loosen, then tighten down tight with the normal knurled screw on the runner, this forces it down. To make adjustment side to side, you can tilt the whole block, using a tool in the two holes. I have several of these and some don't have the holes; there you need a tool that fits the slot where the jack screw is, but it needs a little recess for the screw. You can see I made a decent tool for the holes, and a quick-and-dirty one for ones without holes- but it works! The Steiners with adjustable height headstocks don't have the jackscrews, as they aren't needed. To see what adjustment is needed, it's nice to have a wheel fairly large in diameter, not too long of an arbor. Set it up in the tool (in the correct sized runner), and check if it's nice and square to the runner, looking down and from the side. That's about as scientific as it gets. If this was a larger machine tool you'd check stuff with dial test indicators and such, but simply no room here. If you get it so that your test wheel (make sure it's running true to itself first, haha) can be taken out an put back and it's always lined up, you're all set. The only thing to really pay attention to is "nod" of the spindle; if you make adjustments to the jackscrews unevenly you can tilt the spindle, so that it hits correctly at one distance but not at others. Easy enough to check, pull the spindle in so that the tail runner is as far forward as it goes, check, do the reverse, check, adjust. In practice I automatically try to use the head spindle in more or less the same position if I can.1 point

-

1 point

-

I haven't seen a balance complete that was intended to have the overcoil formed by the watchmaker, but it could exist. One thing to check- pretty much all Breguet springs have a collet with the hole for the spring significantly lower than a normal collet (normal would be hole right in the middle of the collet height). If your spring is in the middle, it was to be a flat spring.1 point

-

Yeah the teeny tiny chinese quartz movements surrounded by a 48mm case and with hands the size of a 6 ft 4in lumberjack. The day it stops it sees the back of a wheely bin. Aw swatch's moonwatch. Pretty to look at but cheap tacky and money grabbing on the inside. I went through a few of those before i met my missus. And also fashion watches. You see men and women looking at them in jewellery shops. You know the ones Armani, Gabo kors and such. I cant help but stand next to them while my wife is looking at braclet charms and say out loud, "hmm i wonder why some people dont buy real watches anymore" . She ends up pulling me away and telling me to behave myself. Do I ? Nah why change the habit of a lifetime.1 point

-

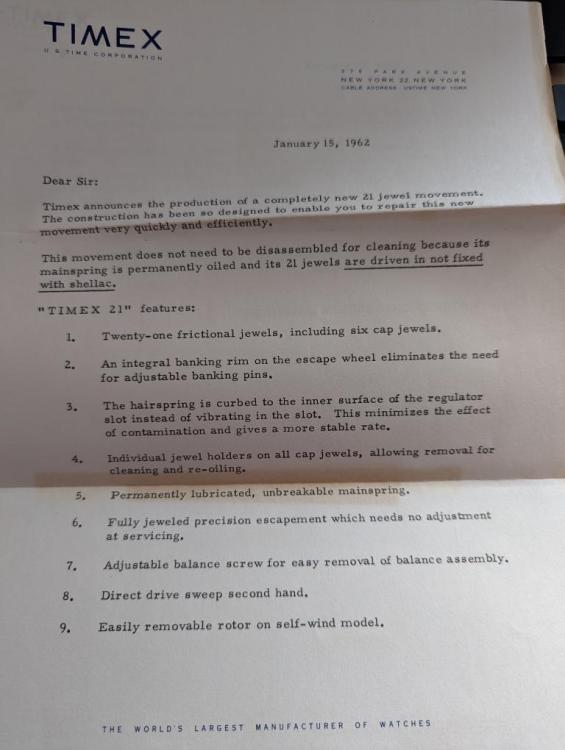

I think the problem I have with Swatch is the fact that they are designed to be disposable. The Timex 21 was at least designed that it *could* be serviced, but the Swatch designs are such that in almost all cases it is almost impossible to even open the watch without damaging it. You *can* fix them (and I have fixed a couple of Swatch Ironys) but the "designed to be disposable" nature just annoys me. I would rather wear something that doesn't have a factory fitted, pre-paid ticket to the land fill.1 point

-

I still think for "worst ever", some of those cheap Chinese movements that turn up in "replica" watches have Timex beat every day of the week. Gad I hate seeing those. The pivots break off if you just look at them wrong. Some are worse than others, but man they're awful as a whole. I'd rather work on a Timex.1 point

-

Oh just go for it Andy, i seem to get away with alsorts of things. Its all down to your delivery. Lol Oh Andy i think youve just sealed the fate of me buying one of their moonwatches. They are so pretty as well. Not that i would have ever opened the back, but having cheap tat on my wrist would bring out the sadist in me and my 2 lb lump hammer.1 point

-

I've had pretty limited success with those too. They may not be *THE* worst movements, but they are certainly in the running for the title. Even they are fixable if you have a slightly masochistic streak, and maybe a donor movement. Modern quartz movements are worse in the sense that pretty much everything is plastic, often glued together and you have zero chance of getting spare parts. Add to that the fact that you have a fifty fifty chance of a leaky battery having dissolved some vital part, and I would say they are probably worse. EDIT: Swatch... need I say more?1 point

-

A few days ago was pretty tough going. But i am on a keto phase at the moment.1 point

-

From what I remember, the TG trace was still dismal. The balance was still using conical pivots and a pin pallet escapement. The pins however were made of rubies. Soo.... draw your own conclusions.1 point

-

Many thanks to all of you. Apologies for the wrong terminology JohnR725. I did acquire the same document you sent me (Thank you very much) before I read your reply and I did learn, the yoke is indeed what I should have referred it to. You were both correct as this piece is held only by a post and not a screw. In my defense I think someone before me was making the same error as the top of the post is quite messed up, but admittedly, my photography does not show this very well, and my magnification probably did me no favors. I appreciate everyone's patience here in helping me on this learning journey. The yoke does move freely but because the head of the post is somewhat mushroomed, I will not be removing it. Cheers1 point

-

Hi @shaigh Do you have any watch movements that you are planning to work on? Where are you located in the world - there are members here from all around the globe. Welcome to the forum.1 point

-

He means that is not "fully swiss made". That aside, your watch market value is not much. perhaps 10 GBP if you can find someone wanting this style. The crystal could be replaced for say 5 GBP by an honest repairer, again, if you can find one.1 point

-

1 point

-

1 point

-

I may have mentioned before that 'you can't have too many multimeters' and others here have hinted that there is no such thing as too many watches, so why not combine both. A volt meter in a metal pocket watch case, with what looks suspiciously like possibly an asbestos infused flying lead. I'm pretty sure this would fail petty much every part of every electrical safety standard the world over. Time to don the hazmat suit and the rubber gloves perhaps.1 point

-

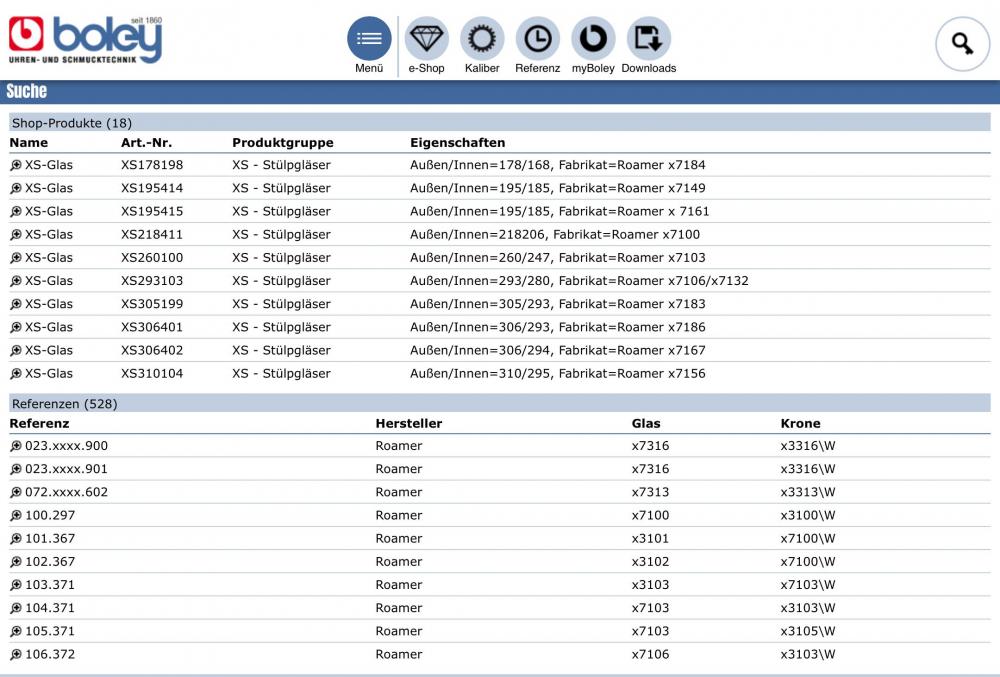

I had one of those on a 40s Certina a while back. Major PITA to find a replacement... I took very careful measurements of all the critical dimensions, then looked through the crystal manufacturers' catalogs. All of the required measurements aren't always published, and I ended up calling the company that had the closest match across a small number of the specs that were published, and told them the third critical dimension. She did some digging, and came back with a couple that were close on either side. I got both, and ended up needing to carefully reduce the outer dimension until it fit snug, but not so snug I couldn't get the case open/closed again. Not my favorite means crystal replacement, but doable.1 point

-

I forgot to mention: Medana = Roamer = MST = Meyer & Stüdeli1 point

-

1 point

-

Hahaha. I think I've just found my long lost brother. Mike where have you been all this time, mum has been worried sick1 point

-

A helpful tip for anyone looking at this discussion? I snipped out an image found up above a typical newbie mistake? People usually reassemble the watch in the opposite order they took apart. Usually what I'll notice is they put the pallet fork in right at the very beginning and that's a big mistake. Yes you can put it in but you don't have to. If you don't have the pallet fork in you can verify that the gear train spins. It makes it a lot easier to put the wheels back in if the pallet fork is not there. So typically you put it in just before you put the balance wheel in makes things a lot easier.1 point

.thumb.jpg.993a040a70c4935677eb6a31de70e29b.jpg)