Leaderboard

Popular Content

Showing content with the highest reputation on 05/05/21 in all areas

-

3 points

-

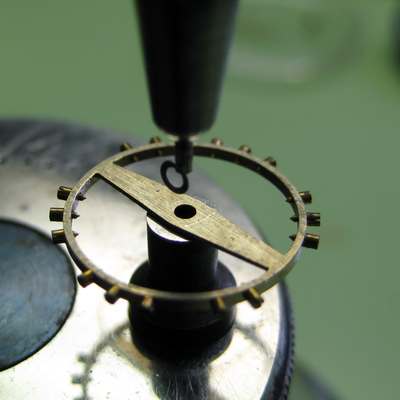

Instal balance& cock as you do, leave the cock screw loose by couple of turns so the cock can be raised like 2mm, grab the balance rim with tweezers, raise the balance wheel by 2mm so impulse jewel is lifted high enough to go over the fork, drop the impulse jewel inside the fork horn, slide the lower pivot into jewel hole, tighten cock screw a bit, then slide the upper jewel into cock jewel, gently push down on cock with peg wood, lower the cock gently , oscilator should start running, make sure all is correct then drive the cock screw all the home,tighten.2 points

-

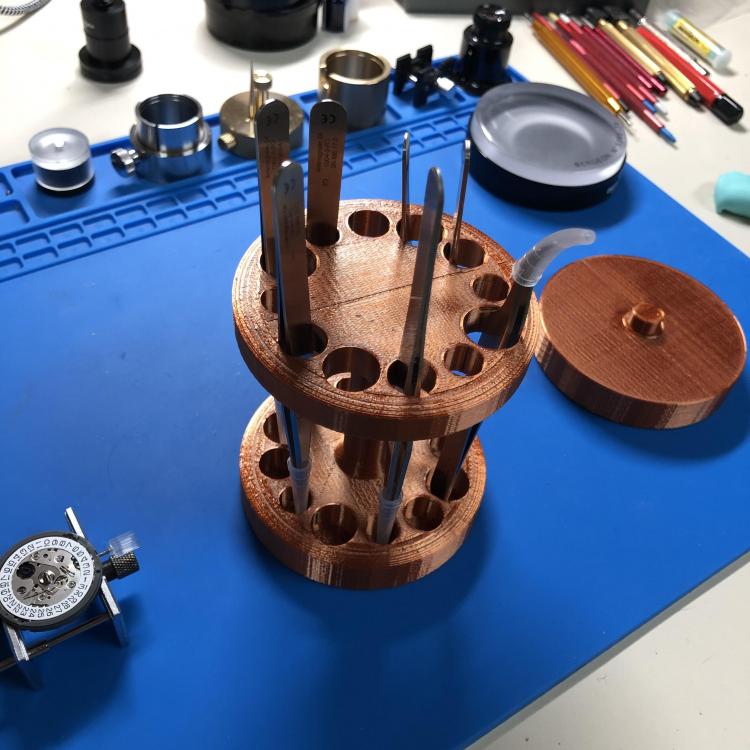

ETA 2836-2 Disassembly walkthrough here ETA 2836-2 Assembly walkthrough here When I started out servicing watches (Vostok cal. 2414) I was desperately looking for easy to follow walkthroughs and tutorials. That was several years ago. I did find a walkthrough on WUS, and I did find the YT-videos of former car mechanic Dan, the “Ratfaced Git”, and although his approach was much that of a car mechanic, rather than that of a skilled watch repairer (he hardly knew the names of parts, didn’t care much, and was proud of it), it inspired me endlessly and gave me - at that time a complete mechanical idiot - the courage to try it myself. Without those videos I’m not sure my interest would have taken off. I know Dan struggled with many difficulties in his life including cancer, and it has been close to three years since he published anything on his YT-channel. Anyway, I hope you’re still with us “Ratfaced git” and I say thank you for the inspiration and dedicate this walkthrough to you. In ETA’s technical communication for calibre 2836-2 the assembly is made in seven steps in the following order: 1. Keyless works 2. Train of wheels 3. Mainspring barrel and bridge 4. Balance assembly 5. Self-winding mechanism 6. Dial train (/motion works) and the calendar works part 1 7. Dial train (/motion works) and the calendar works part 2 However, if you follow my assembly procedure, I put it together in a different order as I find it more convenient and wish to test the running of the watch as soon possible, that is, as soon as the train of wheels, barrel, and balance have been replaced. If at that point it’s not running well, I can more easily deal with it before continuing on with the assembly. Also, should problems arise at a later stage I’ll know it’s (very likely) not related to the train, barrel or balance. The downside, of course, is that the balance is exposed to potential damage for a longer period, although it can of course be removed. So, here are the steps of my assembly procedure: 1. Train of wheels 2. Mainspring barrel and bridge 3. Balance assembly 4. Keyless works 5. Dial train (/motion works) and the calendar works part 1 6. Dial train (/motion works) and the calendar works part 2 7. Self-winding mechanism Apart from the click spring and the pallet stones, the oiling suggestions follow ETA’s technical communication. Finally, I make walkthroughs for my personal use and enjoyment. They are not meant to be tutorials (for that I wholeheartedly recommend watchrepairlessons.com), but I like to share them in case there’s someone who would find them useful. So, without further ado…1 point

-

1 point

-

1 point

-

Thank you, VWatchie, for the reply. I also thought mixing parts is not a good idea, but it was a great practice!!! I´ve been following your post on Russian movements and they are great. So, thanks very much for that. I just got some Vostok 2409 and your post on disassembly of this movement will be of great help. One question, do you know where to get balance assembly parts for the 2602? I checked Cousin and Ebay, with not too much luck. Thanks1 point

-

personally I still like the witschi test device but it probably cost an arm and a leg and six fingers and your firstborn. so I'm intrigued and enthusiastic about your idea but were still stuck with what I'm trying to get at is we need a reference device. It should simulate a pocket watch and a little tiny ladies watch with set parameters of all of us in the entire group put it on our what ever we all would get the exact same results which is hard to do if everyone has everything different. The problem I've seen when answering questions on the discussion group at least watch repair questions is my watch is doing this well is it really? Are we basing answers on faulty diagnostics. This actually happened in a rather lengthy discussion with a little tiny ladies watch where we just weren't sure where we stood with us faulty diagnostics or faulty watch. We needed a tiny reference to verify that the timing whatever was working. Or here when people put their circuits together how do they know it's actually working out of they know it's sensitive enough. I was just thinking of you all have the same watch at least we would all have the same results but you indicate that's not necessary so I'm looking forward to your ideas of solving this problem. then probably too many variables but I wonder if we could take your wave file for instance play it on a computer perhaps a small speaker because it has a moving coil I wonder if that could simulate a watch? But were still stuck with a standard if your computer is outputting the volume at twice the level of mine were measurement results may look different.1 point

-

1 point

-

@Nucejoeis telling you straight. I am still an amateur, but what I do is take note of the position of the pallet fork. Then I turn the balance so that at is biased to engage the horn once it drops in. That means rotating it by 30-40 degrees biased away from the horn--one way or the other. Then when it drops in, I rotate the cock into position and about half of the time, the balance takes off. When it does not, I do exactly with @Nucejoesays. If after a nudge, the balance seems to hit a hard stop, then you know that you are on one side or the other of the horn. You can tell...it is a hard stop.1 point

-

Hi VWatchie, this is a minimum requirement but cannot avoid the danger of deforming the balance with your procedure - even with special tools: Generally punching out is a warranty to widen the hole and earn all kinds of wobbling and poise issues. Today serious repair people use to remove the staff from the other side. Frank1 point

-

Did you know that at the time radium was the most valuable substance on Earth, selling for $120,000 for a single gram—$2.2 million at today's value ,just a bit of trivia.1 point

-

1 point

-

I have a link to an interesting video below he's making a pen for bluing. Notice that it's not exactly a lightweight pen it's super heavy and he has a lot of brass and he's basically using the same torch. The only real differences are his is going to hold a heck of a lot a heat it looks like he pre-heat set before putting the hand and. In the above example it doesn't look like enough brass and with the brass pan projecting outward almost like a heat sink it may be waking the heat away? https://youtu.be/uST7iJgC_gs then there is the other problem with those hands if those are not steel hands find a magnet make sure and if there plated in other words you cannot blue typically other metals to pretend their steel it has to be steel on the surface. Then looking at the color spectrum yellow is at the bottom of the scale. Is it a lot a hands to practice just hold onto a hand with something disposable and gently pass it near the flame and see if you can turn up blue don't put it in the flame the probably turn a pretty red color that won't last. So don't worry this could be splotchy just hold the high above the flame is slowly bring it down and see if it will blue it should turn blue at least for a little bit it should go through all the colors before it washes out just make sure you can't blue them.1 point

-

1 point

-

My interest in watches was sparked when I bought a birth year (and month) watch off ebay only to find it didn't work. I rang a few watch repairers and they quoted me about £300. No way was I spending £300, the robbing ********. So, one year later and £4,000 worth of tools I finally fixed my watch. Who's laughing now eh?1 point

-

1 point

-

1 point

-

Just lift slightly the tip of the holding lever at the top. BTW we have a section here where it's considered polite to introduce oneself even before asking questions.1 point

-

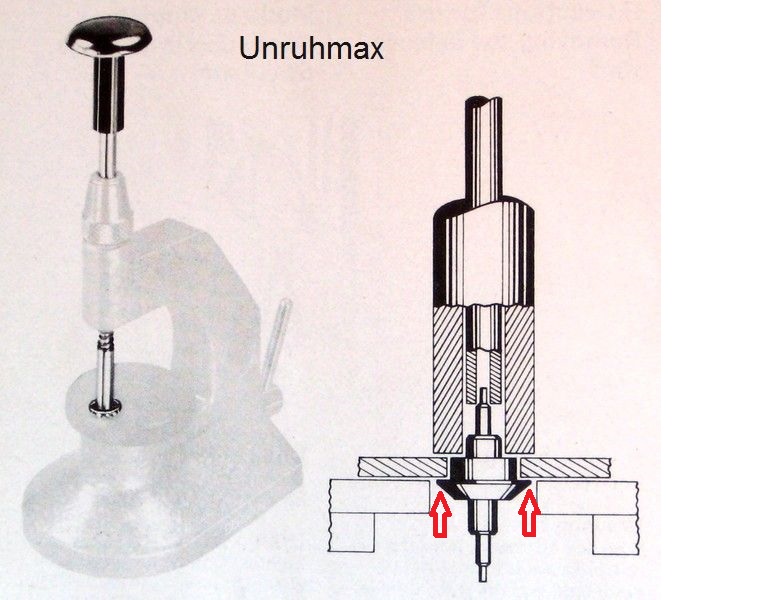

A while ago I was asked about my Unruh-Max balance staff remover. It works great with pocket watch balance staffs in combination with a staking set. This has just been posted & is worth a punt at the right price that is. Unruh-Max balance staff remover ebay listing no. 2013855089051 point